Professional Documents

Culture Documents

Rhino

Uploaded by

Valeria Rendon NoyolaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rhino

Uploaded by

Valeria Rendon NoyolaCopyright:

Available Formats

SPEC 47321

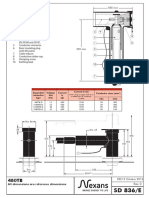

3/C CU 5KV Type SHD-GC RHINOSHIELD™ CPE Mining Cable 90°C

Flexible Copper conductors, EPR 100% Insulation Level, Cu/Nylon Braid Shield, Extra Heavy

Duty Two Layer Chlorinated Polyethylene (CPE) Jacket with Optional Reflective Stripes

13

1 5

13 12 11 10 9 8 76 5 4 3 2 1

Images not to scale. See Table 1 for Dimensions. Reflective Stripe is optional.

CONSTRUCTION:

1. Conductor: Tin coated, soft drawn, annealed, flexible, rope-lay stranded copper per ASTM B33/B172.

2. Separator Tape: Semi-conducting tape applied between the conductor and insulation to facilitate stripping.

3. Conductor Shield: Semi-conducting cross-linked copolymer.

4. Insulation: Ethylene Propylene Rubber (EPR) 100% Insulation Level.

5. Shield Separator: Semi-conducting SBR tape applied to the phase insulation with a 50% overlap, adhesive side up.

6. Braid Shield: Tin coated, soft drawn, annealed, copper braid shield (60% minimum coverage), combined with color coded nylon

(black, white, red) with a 40% maximum coverage.

7. Ground Check Conductor: Tin coated, soft drawn, annealed, rope stranded, flexible lay copper per ASTM B33/B172 with high

strength yellow polypropylene insulation.

8. Ground Conductors: Two uninsulated, tin coated, soft drawn, annealed, rope stranded, flexible lay copper per ASTM B33/B172.

9. Tape: SBR tape applied over the cabled core for improved mechanical integrity and ease of stripping.

10. Inner Jacket: Black, mold cured, extra heavy-duty modified integral fill, flame resistant, thermosetting Chlorinated Polyethylene

(CPE).

11. Reinforcement: Reinforcing twine applied between the two jacket layers.

12. Outer Jacket: Black, mold cured, extra heavy-duty, flame resistant, thermosetting Chlorinated Polyethylene (CPE). Alternate jacket

colors available.

13. Reflective Stripe: Highly visible reflective stripe embedded into the outer jacket to increase safety and help prevent cable runover

(optional, contact your sales representative for part number).

APPLICATIONS AND FEATURES:

RHINOSHIELD™ Type SHD-GC is a heavy-duty trailing cable where flexibility and maximum protection is required. For use with mobile,

reeling, or stationary mining equipment, continuous mining machines, longwall mining systems, and blast hole drillers. It is also an ex-

cellent choice for shovels, draglines, dredges, cranes and marine shore-to-ship power supplies, and anytime extra-durable, flexible cable

is required. Suitable for continuous submersion in water. Ground check conductor provides fail-safe ground monitoring. Embossed print

legend for easy cable identification.

SPECIFICATIONS:

• MSHA Approved, Cold Bend and Impact Tested to -50°C

• ICEA S-75-381/NEMA WC 58 Portable and Power Feeder Cables for use in Mines and Similar Applications

• ASTM B33 Tinned Soft or Annealed Copper Wire for Electrical Purpose

• ASTM B172 Rope-Lay-Stranded Copper Conductors Having Bunch-Stranded Members, for Electrical Conductors

•

SAMPLE PRINT LEGEND:

SOUTHWIRE (R) RHINO™ BRAND CABLE # AWG CU 3/C EPR TYPE SHD-GC 5000V -50°C 90°C P-07-KA140005 MSHA

Southwire Company, LLC | One Southwire Drive, Carrollton, GA 30119 | www.southwire.com

Copyright © 2017 Southwire Company, LLC. All Rights Reserved SPEC 47321_PSS DIVISION DATE: 07/12/2017 Rev:1.0.00M

SPEC 47321

Table 1 – Weights & Measurements

Phase Conductors Insulation Ground Conductors Ground Check Conductor

Stock Diameter Diameter Insul. Jacket Nominal

Code Size Strands (1) Thickness (3) Size Strands Size Strands Thickness Thickness OD (11) Weight

AWG No. inches mils inches AWG No. AWG No. mils. mils. inches. lbs./MFT

TBD 6 133 0.210 110 0.496 10 104 8 168 45 185 1.56 1,480

TBD 4 259 0.256 110 0.542 8 168 8 168 45 185 1.68 1,830

TBD 3 259 0.285 110 0.571 7 49 8 168 45 205 1.78 2,100

TBD 2 308 0.320 110 0.606 6 133 8 168 45 205 1.87 2,400

TBD 1 385 0.355 110 0.641 5 133 8 168 45 205 1.95 2,730

TBD 1/0 273 0.385 110 0.671 4 259 8 168 45 220 2.08 3,230

TBD 2/0 324 0.420 110 0.706 3 259 8 168 45 220 2.20 3,780

TBD 3/0 418 0.506 110 0.792 2 308 8 168 45 235 2.36 4,460

TBD 4/0 532 0.577 110 0.863 1 385 8 168 45 235 2.50 5,230

TBD 250 608 0.610 120 0.916 1/0 273 6 133 60 250 2.69 6,190

TBD 300 735 0.737 120 1.043 1/0 273 6 133 60 250 2.81 6,790

TBD 350 855 0.720 120 1.026 2/0 324 6 133 60 265 2.95 7,900

TBD 500 1221 0.900 120 1.206 4/0 532 6 133 60 280 3.31 10,530

All dimensions are nominal and subject to normal manufacturing tolerances

Table 2 – Electrical and Engineering Data

Resistance Reactance Minimum

Conductor DC AC XC XL Working Bending Allowable

Stock Code Size @ 250C @ 900C @ 60Hz @ 60Hz Tension Radius Ampacities †

AWG Ω/MFT Ω/MFT MΩ*MFT Ω/MFT lbs. inches Amps

TBD 6 0.421 0.526 0.041 0.046 179 9.4 93

TBD 4 0.267 0.334 0.039 0.040 285 10.1 122

TBD 3 0.212 0.265 0.038 0.038 360 10.7 140

TBD 2 0.168 0.210 0.036 0.034 454 11.2 159

TBD 1 0.133 0.166 0.035 0.032 572 11.7 184

TBD 1/0 0.111 0.139 0.034 0.030 722 12.5 211

TBD 2/0 0.085 0.106 0.034 0.028 910 13.2 243

TBD 3/0 0.067 0.084 0.032 0.024 1147 14.2 279

TBD 4/0 0.053 0.066 0.031 0.022 1446 15.0 321

TBD 250 0.045 0.056 0.031 0.022 1709 16.1 355

TBD 300 0.037 0.046 0.030 0.019 2051 16.9 398

TBD 350 0.032 0.040 0.030 0.019 2393 17.7 435

TBD 500 0.023 0.029 0.028 0.016 3418 19.9 536

† Ampacity based on ICEA S-75-381 Table H-1 and is for a single isolated cable in air operated with an open-circuited shield at an ambient temperature of 40°C

and a conductor temperature of 90°C

Southwire Company, LLC | One Southwire Drive, Carrollton, GA 30119 | www.southwire.com

Copyright © 2017 Southwire Company, LLC. All Rights Reserved SPEC 47321_PSS DIVISION DATE: 07/12/2017 Rev:1.0.00M

You might also like

- 1-C CU 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105 2x5 Mils Tape Shield - SpecDocument2 pages1-C CU 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105 2x5 Mils Tape Shield - SpecpurushothamnareNo ratings yet

- 3-C CU 5kV 115 NLEPR 133 Percent CPE MV-105.specDocument2 pages3-C CU 5kV 115 NLEPR 133 Percent CPE MV-105.specFrancisco Zanin FernandesNo ratings yet

- Data Sheet Southwire 3c#500kcmilDocument2 pagesData Sheet Southwire 3c#500kcmilNestor-leoNo ratings yet

- 1C Cu Epr-Pvc 35KV@133% 2017Document2 pages1C Cu Epr-Pvc 35KV@133% 2017CarlosNo ratings yet

- 3/C CU 15kV 220 NLEPR 133% CPE MV-105: SPEC 46403Document2 pages3/C CU 15kV 220 NLEPR 133% CPE MV-105: SPEC 46403Yesith AlmanzaNo ratings yet

- 1-C CU 35kV 420 NLEPR 133 Percent CPE MV-105.specDocument2 pages1-C CU 35kV 420 NLEPR 133 Percent CPE MV-105.specEdgar Sierra RodriguezNo ratings yet

- SPEC83013 600 Volt UndergroundDocument3 pagesSPEC83013 600 Volt Undergroundakib javedNo ratings yet

- Ficha Técnica CABLE ERP SOUTHWIREDocument3 pagesFicha Técnica CABLE ERP SOUTHWIREGhislaine SousaNo ratings yet

- HT Cables - Leading China Cable ManufacturerDocument18 pagesHT Cables - Leading China Cable ManufacturerSIMON S. FLORES G.100% (1)

- 3-c Cu 5kv 115 Nlepr 133 Percent Aia PVC Mv-105.SpecDocument2 pages3-c Cu 5kv 115 Nlepr 133 Percent Aia PVC Mv-105.SpecRodrigo Chambilla VernazaNo ratings yet

- Standard Power Cables: XLPE Insulated, PVC Sheathed, Single Core Unarmoured Cables To BS7889Document7 pagesStandard Power Cables: XLPE Insulated, PVC Sheathed, Single Core Unarmoured Cables To BS7889Bhagoo HatheyNo ratings yet

- Spec44140 CablesDocument2 pagesSpec44140 CablesCarlos LozanoNo ratings yet

- 3-C AL 5kV 115 NLEPR 133 Percent PVC MV-105.specDocument2 pages3-C AL 5kV 115 NLEPR 133 Percent PVC MV-105.specFrancisco Zanin FernandesNo ratings yet

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionDocument2 pagesFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionAngga SenjayaNo ratings yet

- 1-C AL 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105.specDocument2 pages1-C AL 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105.specFrancisco Zanin FernandesNo ratings yet

- Interlocked Armor Power Cable, 5000 VOLTSDocument1 pageInterlocked Armor Power Cable, 5000 VOLTSpedro perezNo ratings yet

- T2XDocument3 pagesT2XMarius CANJANo ratings yet

- Simpull XHHW/CT: SpecificationsDocument2 pagesSimpull XHHW/CT: SpecificationsrlaureanoNo ratings yet

- Firetuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionDocument25 pagesFiretuf FTP 120 - Fire Resistant Armoured Power Cable: ConstructionBhagoo HatheyNo ratings yet

- Origin 350 MCM o Kcmil o MamalonDocument2 pagesOrigin 350 MCM o Kcmil o MamalonJuan Andres AguileraNo ratings yet

- BS5308 Part 1 Type 2Document4 pagesBS5308 Part 1 Type 2Anil ChakkadathNo ratings yet

- Control and Signal CableDocument3 pagesControl and Signal CableLuis Carlos ValdezNo ratings yet

- Zero Halogen EP Welding Cable 105ºC Industrial Grade: Specifications & Standards ConstructionDocument1 pageZero Halogen EP Welding Cable 105ºC Industrial Grade: Specifications & Standards ConstructionAndri YunafrisonNo ratings yet

- N2XCY 1 X (1.5-800) MM 0.6/1 KVDocument5 pagesN2XCY 1 X (1.5-800) MM 0.6/1 KVCombox BlackNo ratings yet

- Dlo RHH RHW-2 RW90-2000VDocument1 pageDlo RHH RHW-2 RW90-2000VSalvatierra Rojas MoisesNo ratings yet

- Hoja de Datos Cable Xtu 1C (Xlpe)Document2 pagesHoja de Datos Cable Xtu 1C (Xlpe)Daniel CordovaNo ratings yet

- Ptfe BS3G210 Type B PtfeDocument1 pagePtfe BS3G210 Type B Ptfemichele muccioliNo ratings yet

- Type TC Power Cable-THHN: ApplicationsDocument2 pagesType TC Power Cable-THHN: ApplicationsHenry MontenegroNo ratings yet

- Triplex Service DropDocument3 pagesTriplex Service DropEvan MerkelNo ratings yet

- Binder - Mvolt - Aluminum Conductor.13 14 1Document2 pagesBinder - Mvolt - Aluminum Conductor.13 14 1FdWorkNo ratings yet

- Soow H07RN-F Aj 24.02.2022Document4 pagesSoow H07RN-F Aj 24.02.2022Tamara TrejosNo ratings yet

- Spec 45440Document2 pagesSpec 45440ger80No ratings yet

- NNDDocument9 pagesNNDdardakNo ratings yet

- Datasheet 770 PDFDocument3 pagesDatasheet 770 PDFMiGuel RodasNo ratings yet

- Technical: Single In-Line Conformal Series 770Document3 pagesTechnical: Single In-Line Conformal Series 770MiGuel RodasNo ratings yet

- GB011 Underground HV Cable and Accessories 22kV CablesDocument14 pagesGB011 Underground HV Cable and Accessories 22kV CablesMauricio SaulNo ratings yet

- Pages From PowerPlusLowres2Document50 pagesPages From PowerPlusLowres2veljal6317No ratings yet

- 185mm EPDM Insulated Separable Connector GuideDocument1 page185mm EPDM Insulated Separable Connector Guidenalvaro88No ratings yet

- HONG TAI ELECTRIC COPPER FOIL WEIGHTS AND THICKNESSESDocument1 pageHONG TAI ELECTRIC COPPER FOIL WEIGHTS AND THICKNESSESSergio Daniel Cruz PupoNo ratings yet

- HES KABLO POWERCABLE CATALOGUEDocument292 pagesHES KABLO POWERCABLE CATALOGUEحسن علي جاسمNo ratings yet

- According To International Standard IEC 60502 - 1: Single Core and Three Core Medium Voltage CablesDocument10 pagesAccording To International Standard IEC 60502 - 1: Single Core and Three Core Medium Voltage CablesRaj KiranNo ratings yet

- NYFGbY cable specificationsDocument4 pagesNYFGbY cable specificationsSaung KuringNo ratings yet

- Anixter SPEC-44020 DLO-Cable PDFDocument3 pagesAnixter SPEC-44020 DLO-Cable PDFJoon LeeNo ratings yet

- Katalog Bare PDFDocument41 pagesKatalog Bare PDFYuDiNo ratings yet

- Nyy 1CDocument1 pageNyy 1Chenry_gtNo ratings yet

- XLPE-Insulated Cables: 600/1000V Single-Core XLPE Insulated, Unarmoured & Armoured, PVC Sheathed CableDocument3 pagesXLPE-Insulated Cables: 600/1000V Single-Core XLPE Insulated, Unarmoured & Armoured, PVC Sheathed CablewkcNo ratings yet

- Armor X 3C XHHW-2 Power 3GND 600V 2017 - CCDocument2 pagesArmor X 3C XHHW-2 Power 3GND 600V 2017 - CCpglv0210No ratings yet

- PVC Insulated Copper and Aluminum Wire Armored Power CablesDocument5 pagesPVC Insulated Copper and Aluminum Wire Armored Power CablesAhmad Arif SaktiNo ratings yet

- Catalog Low Voltage Armour Cable XLPE CableDocument39 pagesCatalog Low Voltage Armour Cable XLPE Cableteguh prasetyoNo ratings yet

- POTABLE Slab SCAFFOLDING BOQ (CRCC)Document1 pagePOTABLE Slab SCAFFOLDING BOQ (CRCC)Mohamed AdelNo ratings yet

- Tri-Rated Rev005Document2 pagesTri-Rated Rev005Jean Pierre Goossens100% (1)

- Me1.3.6-Me1.3.10 Cable XHHW SouthwireDocument2 pagesMe1.3.6-Me1.3.10 Cable XHHW SouthwireHenry MontenegroNo ratings yet

- NYYDocument5 pagesNYYrioNo ratings yet

- LT PVC Catalogue PDFDocument14 pagesLT PVC Catalogue PDFkapilNo ratings yet

- XHHW-2: 1. DescriptionDocument2 pagesXHHW-2: 1. DescriptionPreditec PeruNo ratings yet

- Cylinder Name Lift Cylinder Bucket Cylinder: Tube FosDocument11 pagesCylinder Name Lift Cylinder Bucket Cylinder: Tube FosSandipTakalikarNo ratings yet

- Na2Xfgby 2 X (10-300) MM 0.6/1 KVDocument4 pagesNa2Xfgby 2 X (10-300) MM 0.6/1 KVHajie OmenNo ratings yet

- (Fa-) Ttys, Ttycs, Ttycys (Fa-) Ttpys, Ttpycs, TtpycysDocument3 pages(Fa-) Ttys, Ttycs, Ttycys (Fa-) Ttpys, Ttpycs, Ttpycystwo travellerNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 2.4 KV 3c STD TC Aia CwaDocument8 pages2.4 KV 3c STD TC Aia CwaValeria Rendon NoyolaNo ratings yet

- Concentric OsDocument3 pagesConcentric OsValeria Rendon NoyolaNo ratings yet

- Inn VoiceDocument3 pagesInn VoiceValeria Rendon NoyolaNo ratings yet

- DRDocument2 pagesDRValeria Rendon NoyolaNo ratings yet

- DRDocument3 pagesDRValeria Rendon NoyolaNo ratings yet

- X Te Interface Serv LetDocument2 pagesX Te Interface Serv LetValeria Rendon NoyolaNo ratings yet

- BellonDocument7 pagesBellonValeria Rendon NoyolaNo ratings yet

- AL Building Wire 1.8.18 Data FinalDocument1 pageAL Building Wire 1.8.18 Data FinalValeria Rendon NoyolaNo ratings yet

- Book 1Document5 pagesBook 1Valeria Rendon NoyolaNo ratings yet

- FCM-75kW-Standalone (ETP-Chennai Location) (ID 793838)Document12 pagesFCM-75kW-Standalone (ETP-Chennai Location) (ID 793838)Gopikrishnan ThangarajNo ratings yet

- Saes T 903Document29 pagesSaes T 903Eagle SpiritNo ratings yet

- Section7 FlexCablesforServos MotorsDocument24 pagesSection7 FlexCablesforServos MotorstotovasiNo ratings yet

- ESG (11) - General Specification For Public Address SystemsDocument23 pagesESG (11) - General Specification For Public Address SystemsjunqiangdongNo ratings yet

- Adas Sonarpur FreshDocument11 pagesAdas Sonarpur Freshorion enterpriseNo ratings yet

- Ducab Flat Cable Catalogue Final HI-ResDocument8 pagesDucab Flat Cable Catalogue Final HI-Resshaik abdullahNo ratings yet

- 007 - Parry Sugars - SOP Scrap Sales V01Document5 pages007 - Parry Sugars - SOP Scrap Sales V01Sushma SelaNo ratings yet

- CM Cs9000-Eng-Int-C-Symm-CatalogueDocument22 pagesCM Cs9000-Eng-Int-C-Symm-CatalogueWillyNo ratings yet

- GUIDES BUSWAY TITLEDocument6 pagesGUIDES BUSWAY TITLEMuhammed Talha QureshiNo ratings yet

- Specification of Cables - Turn Key Sub StationDocument25 pagesSpecification of Cables - Turn Key Sub StationjamilNo ratings yet

- AVT 4235 - Wire and Wireless CommunicationDocument39 pagesAVT 4235 - Wire and Wireless CommunicationLey Martinez FaylognaNo ratings yet

- Telecom OSP and Subscriber Line Installation Copper Cable POTS and DSL NC II CGDocument19 pagesTelecom OSP and Subscriber Line Installation Copper Cable POTS and DSL NC II CGmalditoNo ratings yet

- Wire - Building Al FanarDocument63 pagesWire - Building Al FanarKhaled BellegdyNo ratings yet

- QAW70-B Fiche Produit en PDFDocument0 pagesQAW70-B Fiche Produit en PDFe-genieclimatique.comNo ratings yet

- Earthing PDFDocument49 pagesEarthing PDFmoh100% (1)

- Mempower Busduct - PG - EN - 6 - 2012 PDFDocument38 pagesMempower Busduct - PG - EN - 6 - 2012 PDFAbelRamadhanNo ratings yet

- BS 638-4Document24 pagesBS 638-4Santhosh V RaajendiranNo ratings yet

- HML Estimate Ambakanti ThandaDocument22 pagesHML Estimate Ambakanti ThandanayaninikshilreddyNo ratings yet

- Catalogo Ekabel 2014Document412 pagesCatalogo Ekabel 2014OSCAR THIERRY GARCIANo ratings yet

- Module 2 PDFDocument17 pagesModule 2 PDFSumangala BelurNo ratings yet

- Cable L3Document2 pagesCable L3Riccardo AdamiNo ratings yet

- Prabhat Cables price list for wires and cablesDocument4 pagesPrabhat Cables price list for wires and cablesPower RoboticsNo ratings yet

- Katalog Busbar Bab 3Document8 pagesKatalog Busbar Bab 3Mujtahid Fajri ArdianNo ratings yet

- EP-MS-P4-S3-085 - 11kV Heat Shrinkable Joints - (KM Material Spec)Document8 pagesEP-MS-P4-S3-085 - 11kV Heat Shrinkable Joints - (KM Material Spec)dimaomarNo ratings yet

- Cleveland CatalogueDocument124 pagesCleveland Catalogueapi-3713457No ratings yet

- 15 Step Guide to Build Simple Electric GeneratorDocument13 pages15 Step Guide to Build Simple Electric GeneratorSeindahNyaNo ratings yet

- Instrumentation Cable BSDocument42 pagesInstrumentation Cable BSShivaniNo ratings yet

- X016 Conductor Resistance PDFDocument1 pageX016 Conductor Resistance PDFŽeljko BokanovićNo ratings yet

- Energy LV Insulated Overhead LinesDocument66 pagesEnergy LV Insulated Overhead LinesvhgiaoNo ratings yet

- SD8B 3 Part3Document159 pagesSD8B 3 Part3Daniel PrataNo ratings yet