Professional Documents

Culture Documents

Fiberstrong Wavistrong: Flange Guide

Uploaded by

siva8000Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fiberstrong Wavistrong: Flange Guide

Uploaded by

siva8000Copyright:

Available Formats

FIBERSTRONG

WAVISTRONG

Flange Guide

8. Bolt torques

The bolts of flange joints shall be tightened using the prescribed bolt torques, which are given in tables 1 and 2.

These torque values are applicable for ASA 150, ASA 300 and PN 10 to PN 63 drilling patterns in combination with the

recommended sealing material as specified in chapter 4.

Bolt torques for other drilling patterns (API/JIS/ASA 600/etc) or for gaskets, other than recommended by FPI, including

special gaskets on valves, pumps, etc, might differ from the values given in tables 1 and 2. Recommended bolt torque

values for these applications shall be reviewed on a case-by-case basis by the FPI Technical Support team.

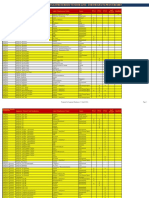

Table 1. Bolt torques for gaskets

Torque (Nm)

Rubber gaskets with steel inlay

Kroll & Ziller G-ST-P/K(N) & G-ST-P/S and Kempchen WG2

ID PN ≤ 12.5 PN 16 - 20 PN 25 - 32 PN 40 - 50

(mm) (bar) (bar) (bar) (bar)

25 10 10

40 - 65 15 15

80 - 125 25 25

150 - 200 35 50 50

250 - 300 50 50 75 100

350 - 500 75 90 125 150

600 - 700 100 200 300 300

750 - 800 200 300 300 400

900 - 1400 300 400 550

Table 2. Bolt torques for “O-ring” seal

Torque (Nm)

ID PN ≤ 12.5 PN 16 - 25 PN 25 - 32

(mm) (bar) (bar) (bar)

1500 - 1800 100 200 300

1900 - 4000 100

10 Fiberstrong & Wavistrong Flange Guide

You might also like

- Contractor Performance Evaluation FORMDocument4 pagesContractor Performance Evaluation FORMAnonymous ziKTLimNo ratings yet

- CV - Edson C Ayuste - Senior Instrument Engineer - March2018Document8 pagesCV - Edson C Ayuste - Senior Instrument Engineer - March2018Edson AyusteNo ratings yet

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFDocument53 pagesA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFMOST PASONNo ratings yet

- Construction Logbook SheetDocument1 pageConstruction Logbook SheetFrederick Atienza Reyes100% (1)

- Volvo Xc70 (08-) - 2011 Supplement Volvo v70 (08-), Xc70 (08-) & s80 (07-) Wiring DiagramDocument21 pagesVolvo Xc70 (08-) - 2011 Supplement Volvo v70 (08-), Xc70 (08-) & s80 (07-) Wiring Diagramsen tilNo ratings yet

- Dimensions of Bolts and Nuts BS3692Document6 pagesDimensions of Bolts and Nuts BS3692azam RazzaqNo ratings yet

- 07 DiagnosticsDocument132 pages07 DiagnosticsJosué Soldera100% (2)

- 1670 4-2004Document45 pages1670 4-2004Quyet Thang Tran100% (3)

- QAP For Ducting V1 R0Document1 pageQAP For Ducting V1 R0Hema NandhNo ratings yet

- K-FLEX HVAC Applications Installation ManualDocument63 pagesK-FLEX HVAC Applications Installation ManualMohammad TaheriNo ratings yet

- Earthing and Electrical Grounding InstallationDocument19 pagesEarthing and Electrical Grounding InstallationAdythia100% (3)

- Piping - Mapress Installation GuidelinesDocument144 pagesPiping - Mapress Installation GuidelinesPetru VladeanuNo ratings yet

- Basic valve datasheets for inquiryDocument21 pagesBasic valve datasheets for inquirymainur mechanical engineerNo ratings yet

- Consolidated Contractors Welding Procedure SpecificationDocument3 pagesConsolidated Contractors Welding Procedure Specificationsiva8000100% (1)

- Consolidated Contractors Welding Procedure SpecificationDocument3 pagesConsolidated Contractors Welding Procedure Specificationsiva8000100% (1)

- Ga Drawing of Gate, Ball, Check, Butterfly Valve & T Type Stainer P.O. No. - Pl17100130 W.O. No. - 100181 r1Document7 pagesGa Drawing of Gate, Ball, Check, Butterfly Valve & T Type Stainer P.O. No. - Pl17100130 W.O. No. - 100181 r1siva8000No ratings yet

- Slope Brochure Tecco Spider en CH 72dpi 160617Document12 pagesSlope Brochure Tecco Spider en CH 72dpi 160617Mehmet Ilker GurhaniNo ratings yet

- Calibration uncertainty guide for non-expertsDocument7 pagesCalibration uncertainty guide for non-expertsmagtrolNo ratings yet

- Kirloskar Valves Technical Specification CatalogueDocument24 pagesKirloskar Valves Technical Specification CatalogueAbhinay SuratkarNo ratings yet

- FIT UP ReportDocument2 pagesFIT UP Reportsiva8000No ratings yet

- DataTraffic Monitoring and AnalysisDocument370 pagesDataTraffic Monitoring and Analysisdinhtc159100% (1)

- CTSDG 06513 XDMDocument5 pagesCTSDG 06513 XDMArchnotNo ratings yet

- Cargo Net l3 Ast Le Adma 314Document6 pagesCargo Net l3 Ast Le Adma 314Anwar DeenNo ratings yet

- Qatargas South - Pvl-Rev-6 - March 2019Document166 pagesQatargas South - Pvl-Rev-6 - March 2019siva8000No ratings yet

- Standard Dimension Ratio (SDR) : HDPE Pressure Pipes According To EN 12201, EN 13244 and DIN 8074/75Document1 pageStandard Dimension Ratio (SDR) : HDPE Pressure Pipes According To EN 12201, EN 13244 and DIN 8074/75Arunprasad MurugesanNo ratings yet

- Buried Pipes and Fittings Painting SpecDocument5 pagesBuried Pipes and Fittings Painting SpecRohan Sharma50% (2)

- Valve Inspection ChecklistDocument2 pagesValve Inspection Checklistsiva80000% (1)

- SBC (Safety Break-Away Couplings) v140630Document16 pagesSBC (Safety Break-Away Couplings) v140630Robert Villavicencio0% (1)

- Hermle Machining Centres OverviewDocument78 pagesHermle Machining Centres OverviewNguyen GiangNo ratings yet

- Piping Design InfoDocument273 pagesPiping Design InfoFerry SiswantoNo ratings yet

- KL UHP Catalog 2011-02 PDFDocument30 pagesKL UHP Catalog 2011-02 PDFaconibet9040No ratings yet

- Ptfe Torque Chart Aps KitsDocument2 pagesPtfe Torque Chart Aps KitsJo KingsNo ratings yet

- Conbextra EP Data SheetDocument4 pagesConbextra EP Data Sheetprabhu81No ratings yet

- Iso 15552 2004 en PDFDocument8 pagesIso 15552 2004 en PDFashokkumarNo ratings yet

- Grounding - 1501479512Document74 pagesGrounding - 1501479512zaheer2931No ratings yet

- Storage and HandlingDocument6 pagesStorage and HandlingalagurmNo ratings yet

- WPMP NDT Request FormDocument7 pagesWPMP NDT Request FormVimin PrakashNo ratings yet

- Knife Gate Valve - For Reference OnlyDocument16 pagesKnife Gate Valve - For Reference Onlysj_scribdNo ratings yet

- Bill 06 CivilDocument128 pagesBill 06 CivilSaeed AhmedNo ratings yet

- Short List of Applied Piping Standard PDFDocument3 pagesShort List of Applied Piping Standard PDFmohamad3010No ratings yet

- Sec 05100 - Structural SteelDocument10 pagesSec 05100 - Structural Steeltiju2005hereNo ratings yet

- Nabakem Metal Surface Coating AgentDocument6 pagesNabakem Metal Surface Coating Agentsutrisno00No ratings yet

- ST - 13.02 Stainless Steel PipingDocument45 pagesST - 13.02 Stainless Steel PipingMaksim.em001No ratings yet

- Fittings, Grooved and Plain End - Ul Product IqDocument4 pagesFittings, Grooved and Plain End - Ul Product IqJorge Inostroza0% (1)

- Virgo Welded Valve BrochureDocument8 pagesVirgo Welded Valve BrochureHerrera Jorge AgustínNo ratings yet

- KITZ Bronze Brass Valves E-101-11Document0 pagesKITZ Bronze Brass Valves E-101-11uyab1989No ratings yet

- JFD 100Document1 pageJFD 100ecsuperalNo ratings yet

- Shell Joint SpecificationsDocument37 pagesShell Joint SpecificationsKiran NikateNo ratings yet

- Foster Adhesive: Technical Data SheetDocument2 pagesFoster Adhesive: Technical Data SheetMounir BoutaghaneNo ratings yet

- Hyundai Pipe CatalogueDocument36 pagesHyundai Pipe Cataloguefelram100% (2)

- Syed Usamn Shah - AY5581 Proposal PDFDocument13 pagesSyed Usamn Shah - AY5581 Proposal PDFusmanNo ratings yet

- Tank Installation Daily ReportDocument1 pageTank Installation Daily ReportSaddem HadfiNo ratings yet

- Bond Strand 5000 eDocument8 pagesBond Strand 5000 eUmar KidaNo ratings yet

- SP3D Piping Isometrics Practice Labs PDFDocument97 pagesSP3D Piping Isometrics Practice Labs PDFKukuh KurniadiNo ratings yet

- ERW Steel Tubes Guide (IS 1239 & 1161 StandardsDocument1 pageERW Steel Tubes Guide (IS 1239 & 1161 Standardsdyke_enggNo ratings yet

- 2 Months Lookahead Plan & Major Material RequirmentsDocument110 pages2 Months Lookahead Plan & Major Material RequirmentsshankarswaminathanNo ratings yet

- L&T Aquaseal Butterfly Check Valves PDFDocument28 pagesL&T Aquaseal Butterfly Check Valves PDFSanjay SahulNo ratings yet

- HVAC Works for Intermediate School Type 2000Document54 pagesHVAC Works for Intermediate School Type 2000oth369No ratings yet

- MIV Product Overview Valves and FittingsDocument13 pagesMIV Product Overview Valves and FittingsugljevikNo ratings yet

- Copper Fittings For HVACR Applications 082820Document7 pagesCopper Fittings For HVACR Applications 082820Md Saddam HossainNo ratings yet

- 0901b80380959cc7 PDFDocument2 pages0901b80380959cc7 PDFZaheedManooNo ratings yet

- Pipe Fittings Equivalent LengthDocument3 pagesPipe Fittings Equivalent LengthRashel Hasan100% (1)

- ISCO Product Catalog - 2011Document252 pagesISCO Product Catalog - 2011Cristhian Solano BazalarNo ratings yet

- S o P-PipingDocument17 pagesS o P-PipingPrakash TiwariNo ratings yet

- Spring Terminology and DefinitionsDocument3 pagesSpring Terminology and DefinitionsltflcjNo ratings yet

- Victaulic 2D BlocksDocument8 pagesVictaulic 2D BlocksdemdiinNo ratings yet

- Piping Spec C ClassDocument1 pagePiping Spec C Classnestor ferrel floresNo ratings yet

- Installation of Underground Drainage Piping: ChecklistDocument1 pageInstallation of Underground Drainage Piping: Checklistakash nairNo ratings yet

- 5 Units Separator BOQ Pipe, Flange and Fitting 25-8-15Document24 pages5 Units Separator BOQ Pipe, Flange and Fitting 25-8-15Engr Khurram Jaan RamayNo ratings yet

- Wiik Catalogue 2007Document16 pagesWiik Catalogue 2007suosvannakNo ratings yet

- Fire Piping Astm A795Document3 pagesFire Piping Astm A795sinahimsNo ratings yet

- U-PVC pipes and fittings dimensionsDocument12 pagesU-PVC pipes and fittings dimensionsGeorge SobhyNo ratings yet

- ASME Piping Standards and Material Selection GuideDocument36 pagesASME Piping Standards and Material Selection Guideتدریس زبان ESLNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Cable ScunDocument8 pagesCable ScunPoppy IrawanNo ratings yet

- Ute Print PDFDocument1 pageUte Print PDFVishal MandlikNo ratings yet

- Model: TT: FeaturesDocument1 pageModel: TT: FeaturespoongodiskNo ratings yet

- Appendix 2-7.ep11482 - g-16Document17 pagesAppendix 2-7.ep11482 - g-16bsnegi111No ratings yet

- Gre Bolt Length-2000m 2432Document20 pagesGre Bolt Length-2000m 2432ABDUL KADHARNo ratings yet

- Technical Confirmation List Pipe & PlatesDocument2 pagesTechnical Confirmation List Pipe & Platessiva8000No ratings yet

- Technical Confirmation List FlangesDocument2 pagesTechnical Confirmation List Flangessiva8000No ratings yet

- Experienced Professional ResumeDocument2 pagesExperienced Professional Resumesiva8000No ratings yet

- OUR Coupling Max. Angular Misalignment Is 0.5 Deg. Coupling DiaDocument1 pageOUR Coupling Max. Angular Misalignment Is 0.5 Deg. Coupling Diasiva8000No ratings yet

- Material Receiving Inspection Report ChecklistDocument96 pagesMaterial Receiving Inspection Report Checklistsiva8000No ratings yet

- CPR BY KGS - Top 12 stocks with price, volume and % change analysisDocument2 pagesCPR BY KGS - Top 12 stocks with price, volume and % change analysissiva8000No ratings yet

- Wkm-Dynacentric-High-Performance-Butterfly-Valves-BrochureDocument28 pagesWkm-Dynacentric-High-Performance-Butterfly-Valves-Brochuresiva8000No ratings yet

- Technical Confirmation List-FittingspdfDocument2 pagesTechnical Confirmation List-Fittingspdfsiva8000No ratings yet

- MTC-17 5MM&25 4MMDocument208 pagesMTC-17 5MM&25 4MMsiva8000No ratings yet

- Temps Trainers Proof 2Document12 pagesTemps Trainers Proof 2siva8000No ratings yet

- Changing Employers in Qatar: Key Information For WorkersDocument5 pagesChanging Employers in Qatar: Key Information For Workerssiva8000No ratings yet

- Virgin CPR, Technical Analysis ScannerDocument2 pagesVirgin CPR, Technical Analysis Scannersiva8000No ratings yet

- RSI Above 70, Technical Analysis ScannerDocument8 pagesRSI Above 70, Technical Analysis Scannersiva8000No ratings yet

- Qgx2000mptsna710 E4 Att-6-1Document3 pagesQgx2000mptsna710 E4 Att-6-1siva8000No ratings yet

- IOM - M SeriesDocument12 pagesIOM - M SeriesIrving Mireles ReyesNo ratings yet

- Maari 2 LyricsDocument3 pagesMaari 2 Lyricssiva8000No ratings yet

- Strong uptrend stocks technical analysis scannerDocument2 pagesStrong uptrend stocks technical analysis scannersiva8000No ratings yet

- Crescent Valve GAD 12 Inch QTN - 1065Document1 pageCrescent Valve GAD 12 Inch QTN - 1065siva8000No ratings yet

- ITP-846-556, Rev.4, Installation of HVAC Systems in BuildingsDocument29 pagesITP-846-556, Rev.4, Installation of HVAC Systems in Buildingssiva8000No ratings yet

- NDT Services Price ComparisonDocument6 pagesNDT Services Price Comparisonsiva8000No ratings yet

- Quality Surveillance ReportDocument1 pageQuality Surveillance Reportsiva8000No ratings yet

- Compressiv Strength of Mortar Cubes C 109 PDFDocument9 pagesCompressiv Strength of Mortar Cubes C 109 PDFAnjali Anju0% (1)

- 1.-Partlow Serie MRC 5000Document4 pages1.-Partlow Serie MRC 5000Angel RamirezNo ratings yet

- Data Assest Management System (DAMS)Document32 pagesData Assest Management System (DAMS)Greg WiedemanNo ratings yet

- Metrology AssignmentDocument24 pagesMetrology AssignmentKailas Sree ChandranNo ratings yet

- CV Said WajdiDocument2 pagesCV Said WajdisaidwajdiNo ratings yet

- Create Your KML File by KML Editor 18517Document40 pagesCreate Your KML File by KML Editor 18517VIKAS DOGRANo ratings yet

- Conversor Mecanico 1808Document8 pagesConversor Mecanico 1808ALBERTONo ratings yet

- New IEC 61850-Based Solutions: Client Functionality On All Device FamiliesDocument8 pagesNew IEC 61850-Based Solutions: Client Functionality On All Device FamiliesHung Cuong PhamNo ratings yet

- Stratix 2000 SwitchesDocument2 pagesStratix 2000 SwitchesMarisurNo ratings yet

- KUBOTA KC250H DUMPER Service Repair Manual PDFDocument13 pagesKUBOTA KC250H DUMPER Service Repair Manual PDFufjjdjfkskemmdNo ratings yet

- SAP HANA Modeller - Tata Consultancy Services, Bglor, F2F Interview On Sun, 23rd Aug'15 (Source: Monster)Document2 pagesSAP HANA Modeller - Tata Consultancy Services, Bglor, F2F Interview On Sun, 23rd Aug'15 (Source: Monster)Mani ShankarNo ratings yet

- Grounding and Bonding: Product GuideDocument12 pagesGrounding and Bonding: Product GuideheinhomeNo ratings yet

- en Operating Instructions VEGABAR 28 Two Wire 4 20 MADocument56 pagesen Operating Instructions VEGABAR 28 Two Wire 4 20 MAVegard SømliøyNo ratings yet

- Rittal 7955211 Instrucciones 3 5902Document68 pagesRittal 7955211 Instrucciones 3 5902Elfy PalmaNo ratings yet

- .AnomDocument2 pages.AnomMC CondéNo ratings yet

- SR30 - Modbus MapDocument9 pagesSR30 - Modbus MapMuathNo ratings yet

- Mismatch Defect in ERW Steel Tubes: September 2014Document5 pagesMismatch Defect in ERW Steel Tubes: September 2014Riza KhanNo ratings yet

- Manual - Aztec THDDocument112 pagesManual - Aztec THDCesar Augusto100% (1)

- Sell Sheet Optal XP en FinalDocument2 pagesSell Sheet Optal XP en Finalalguna54No ratings yet