Professional Documents

Culture Documents

KIRK KSEP Liquid Coalescers - 2 PDF

Uploaded by

สิทธิไชย อรุณวํฒนชัยOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KIRK KSEP Liquid Coalescers - 2 PDF

Uploaded by

สิทธิไชย อรุณวํฒนชัยCopyright:

Available Formats

K-SEP™ Separator Internals

Highspeed™ Gas Cyclones

SEP-Calc™ Separator Design Software

Achieving Separation

K-SEP™ Liquid/Liquid Coalescers

Compact and efficient gas/liquid/solid separation

solutions using cyclone and conventional

internals for a range of applications

KFP Flat Plate Pack KMP Matrix Coalescer KDM Dual Media Mesh

Mixtures of immiscible liquids can generally be separated by a process of settling as a result of the

density difference between the two phases. However gravitational settling becomes increasingly

difficult as the droplet size of the dispersed phase decreases. The settling process can be enhanced

considerably by passing the dispersion through a suitable coalescer pack.

www.kirkprocess.com London Pune Houston info@kirkprocess.com

K-SEP™ Separator Internals

Highspeed™ Gas Cyclones

SEP-Calc™ Separator Design Software

KIRK’s K-SEP™ Coalescer Packs are effective coalescers in both liquid-liquid and vapour-liquid

service. Coalescer type, face velocity and configuration will depend on the specific application.

Light Phase

Dispersion

Inlet

COALESCER

Heavy Phase

TYPICAL ARRANGEMENT OF SEPARATOR VESSEL

Dispersions of droplets sized over 1000 microns tend to be very unstable and separate rapidly under

gravity. Dispersions of droplets sized below 10 microns tend to be very stable and do not easily

separate. To enhance the separation of mid-range droplet sizes several alternate technologies are

employed in our coalescers.

KFP Flat Plate Packs Offer moderate performance in fouling applications, these use

Stokes Law between plates 10-50mm spacing to remove

droplets down to 100 microns.

KMP Matrix Coalescer Packs For mildly fouling applications, corrugations in the plates

promote gentle agitation to enhance the separation

performance, removing droplets down to around 50 microns.

KDM Dual Media Knitted Mesh Pads Used in clean service, the separation is achieved by impact of

droplets on a fine wire mesh, further enhanced by the

introduction of co-knitted oleophilic/oleophobic materials.

Effective separation can be down to 20 microns or less.

Axial flow velocities are normally below 1 m/min for optimum performance, but can be up to 2-3 m/min

for high capacity applications. For performance predictions please refer to KIRK.

www.kirkprocess.com London Pune Houston info@kirkprocess.com

You might also like

- 6004550b How To Cal Thermocouple An WDocument8 pages6004550b How To Cal Thermocouple An WAgung Podo MoroNo ratings yet

- 6 Malaysia PetronasDocument37 pages6 Malaysia Petronasel hadiNo ratings yet

- Theoretical Basis For Slurry Computation and Compounding in Highly Deviated Wells CementingDocument5 pagesTheoretical Basis For Slurry Computation and Compounding in Highly Deviated Wells CementingArlette Ramirez ValdesNo ratings yet

- 30 Cementing Cont'd PDFDocument20 pages30 Cementing Cont'd PDFJosé TimanáNo ratings yet

- IWCF ExerciseDocument94 pagesIWCF ExerciseAKWFT94% (17)

- 3 - Well Control ExercisesDocument98 pages3 - Well Control ExercisesJoão MayrinkNo ratings yet

- 1 Primary Cementing 1 PDFDocument45 pages1 Primary Cementing 1 PDFสิทธิไชย อรุณวํฒนชัยNo ratings yet

- Activated CarbonDocument6 pagesActivated CarbonSholekhah ArviyantiNo ratings yet

- Objectives For: Artificial Lift SystemsDocument39 pagesObjectives For: Artificial Lift Systemsสิทธิไชย อรุณวํฒนชัยNo ratings yet

- Chapter5 New (Cementing)Document47 pagesChapter5 New (Cementing)AveFenix473No ratings yet

- GL CC Mix Design 071110Document55 pagesGL CC Mix Design 071110RamkumarNo ratings yet

- Intro To ESPDocument49 pagesIntro To ESPTerminatorX75No ratings yet

- 6351591Document119 pages6351591สิทธิไชย อรุณวํฒนชัยNo ratings yet

- Tech/drilling/Casing Design ExDocument43 pagesTech/drilling/Casing Design ExSohaib RashidNo ratings yet

- API Mixing Energy Proposal: June 24-28, 2013Document11 pagesAPI Mixing Energy Proposal: June 24-28, 2013สิทธิไชย อรุณวํฒนชัยNo ratings yet

- Tech/drilling/Casing Design ExDocument43 pagesTech/drilling/Casing Design ExSohaib RashidNo ratings yet

- 6351591Document119 pages6351591สิทธิไชย อรุณวํฒนชัยNo ratings yet

- Tech/drilling/Casing Design ExDocument43 pagesTech/drilling/Casing Design ExSohaib RashidNo ratings yet

- Pressure Drop Calculations for Well DrillingDocument44 pagesPressure Drop Calculations for Well Drillingสิทธิไชย อรุณวํฒนชัยNo ratings yet

- Lift Cap Drill FluidDocument48 pagesLift Cap Drill Fluiddn1366No ratings yet

- API RP 14E - Design and Installation of Offshore Proeuction Platform Piping SystemsDocument1 pageAPI RP 14E - Design and Installation of Offshore Proeuction Platform Piping Systemsสิทธิไชย อรุณวํฒนชัยNo ratings yet

- 3 Equipments PlacementTechniques EvaluationsDocument47 pages3 Equipments PlacementTechniques Evaluationsaboey sandiNo ratings yet

- 4537273Document37 pages4537273สิทธิไชย อรุณวํฒนชัย100% (1)

- 3 CirculatingSystemDocument19 pages3 CirculatingSystemAoun MuhammadNo ratings yet

- Casing design for well drillingDocument44 pagesCasing design for well drillingChristian Olascoaga Mori50% (2)

- 30 Cementing Cont'd PDFDocument20 pages30 Cementing Cont'd PDFJosé TimanáNo ratings yet

- 31 Plugback CementingDocument42 pages31 Plugback CementingJosé TimanáNo ratings yet

- Cementing Salt So LutDocument29 pagesCementing Salt So Lutสิทธิไชย อรุณวํฒนชัยNo ratings yet

- 2 Classification Additives CalculationsDocument32 pages2 Classification Additives CalculationsSaa D ShamimNo ratings yet

- Chapter5 New (Cementing)Document47 pagesChapter5 New (Cementing)AveFenix473No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Exp # 13 (Study of Theodolite)Document4 pagesExp # 13 (Study of Theodolite)Sudin PradhanNo ratings yet

- PSA Cast-In Plates - Technical Data SheetDocument7 pagesPSA Cast-In Plates - Technical Data SheetGnansabesan JathurschanNo ratings yet

- U.S.M PhysicsDocument6 pagesU.S.M PhysicsPriyanshu GuptaNo ratings yet

- Part - I: Subjective QuestionsDocument11 pagesPart - I: Subjective Questionspankaj agarwalNo ratings yet

- Earth Science Honors, Grade 7 HMH Earth's Water & Atmosphere (Module E)Document21 pagesEarth Science Honors, Grade 7 HMH Earth's Water & Atmosphere (Module E)aveen rasulNo ratings yet

- Updated PPT of Types of Laser and HolographyDocument27 pagesUpdated PPT of Types of Laser and HolographyTejo KanthNo ratings yet

- Carbon Fibre ReportDocument14 pagesCarbon Fibre ReportyoyotoyoNo ratings yet

- Dye Penetrant Lab ReportDocument6 pagesDye Penetrant Lab Reportking kong80% (5)

- Earth's Internal Geologic Processes ExplainedDocument2 pagesEarth's Internal Geologic Processes ExplainedAj AsaNo ratings yet

- 1 - Quiz - 1D - KinematicsDocument2 pages1 - Quiz - 1D - KinematicsMiya GomezNo ratings yet

- Effect of Crystallinity On Electrical Properties of ElectronDocument4 pagesEffect of Crystallinity On Electrical Properties of Electronapi-3837841No ratings yet

- Vibration Analysis Iso Cat III DLPDFDocument8 pagesVibration Analysis Iso Cat III DLPDFWisnuNo ratings yet

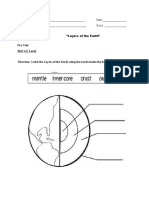

- Worksheets LS2 Layers of The EarthDocument7 pagesWorksheets LS2 Layers of The EarthAngeline Panaligan Ansela100% (1)

- Optical Leak Testing of Hermetic DevicesDocument9 pagesOptical Leak Testing of Hermetic DevicesTueNo ratings yet

- 20367e04-Weld Code For Welding Procedure and ExaminationDocument9 pages20367e04-Weld Code For Welding Procedure and ExaminationPhilip OjugohNo ratings yet

- Electromagnetic Wave Propagation in Sea WaterDocument12 pagesElectromagnetic Wave Propagation in Sea WaterKaren Gordillo RamosNo ratings yet

- Seismic Performance of Buckling Restrained Braced Frames in A Chilean BuildingDocument12 pagesSeismic Performance of Buckling Restrained Braced Frames in A Chilean BuildingSebastian Contreras ContrerasNo ratings yet

- Desiccant Dehumidifier MDC 18000: Forget Humidity For Ever!Document4 pagesDesiccant Dehumidifier MDC 18000: Forget Humidity For Ever!Mourad AhmadNo ratings yet

- 5054 s16 QP 21Document20 pages5054 s16 QP 21pixelhoboNo ratings yet

- Heat Exchanger Thermal Calculation by Rey FiedacanDocument5 pagesHeat Exchanger Thermal Calculation by Rey FiedacanRajdeepsinhNo ratings yet

- Brochure Ftir Cary 630 5990-8570en Us AgilentDocument12 pagesBrochure Ftir Cary 630 5990-8570en Us AgilentMarcela RobayoNo ratings yet

- 8P2A.3 & 4 Newton's Laws of Motion PPT 2017Document52 pages8P2A.3 & 4 Newton's Laws of Motion PPT 2017Jerome Nicolas Jr. MoraNo ratings yet

- N-G-HE - 200 - EN Pressure Safety ReliefDocument77 pagesN-G-HE - 200 - EN Pressure Safety ReliefMEGAN ASBROCK100% (1)

- Assignment # 2 ME - 615 Last Date of Submission: 01-03-2013 Rotor Dynamics Marks: 20Document1 pageAssignment # 2 ME - 615 Last Date of Submission: 01-03-2013 Rotor Dynamics Marks: 20Nishant PatilNo ratings yet

- Damped Free VibrationDocument9 pagesDamped Free VibrationAdeoti OladapoNo ratings yet

- Welding TMCP SteelsDocument7 pagesWelding TMCP SteelsElias Kapa100% (1)

- Siemens Air Cooled Generators Sgen 2000h Brochure Ensiemens-Air-Cooled-Generators-Sgen-2000hDocument4 pagesSiemens Air Cooled Generators Sgen 2000h Brochure Ensiemens-Air-Cooled-Generators-Sgen-2000hronaldosallesNo ratings yet

- 2 - Presentation - Echometer - PIP From Dyno CardsDocument27 pages2 - Presentation - Echometer - PIP From Dyno CardsJairo DoradoNo ratings yet

- Tire Terminology Explained: 40+ Key TermsDocument6 pagesTire Terminology Explained: 40+ Key Termsgovindarun5No ratings yet

- 12 PLAXISBulletinDocument24 pages12 PLAXISBulletinMark ChanNo ratings yet