Professional Documents

Culture Documents

Ultrafilter Ultradepthii Pbe PDF

Uploaded by

AllanBorgesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultrafilter Ultradepthii Pbe PDF

Uploaded by

AllanBorgesCopyright:

Available Formats

For calls outside the UK

Telephone +44 1777 701141

ULTRAFILTER or Fax +44 1777 869983

FREEPHONE:

0800 666397

ultradepth II® P-BE The ultradepth II® P-PB

– sterile ventilation of

storage tanks

The sterile depth filter for the sterile ventilation of storage tanks under atmospheric

conditions

Product description: Sterilisation:

The ultradepth II® filter is a wrapped depth • In-line sterilisation with slow speed

filter with an inner and an outer guard as saturated steam

well as end caps made from stainless steel. max. 121°C (250°F) for 30 minutes

The retention rate is 0.01 µm up to

max. 131°C (270°F) for 20 minutes

99.999%. The ultradepth II® binder-free,

three-dimensional borosilicate depth max. 141°C (290°F) for 10 minutes

media has a hollow volume of more than • Autoclave

95%. This ensures a high dirt hold capacity 125°C (260°F) for 30 minutes

and a low differential pressure at high flow ultratedepth II® filter elements are

rates. The filter media is inherently guaranteed for 100 sterilisation cycles –

hydrophobic. without loss of integrity

Features: Materials: Absolute retention rates:

All components meet the FDA Filter medium: Borosilicate 99.999% related to 0,01 µm

requirements for the contact with food

according to the CFR (Code of Federal Outer core: SS 1.4301 (304)

Regulations) Titel 21. ultradepth II® filter Inner core: SS 1.4301 (304) Bacterial retention:

elements have passed the toxicological Supporting fabric: Polyester LRV > 7/cm2 for T1 Coliphagen

tests according to USP XX Class VI for

plastics. Endcaps: SS 1.4301 (304)

The filter element corresponds to the cGMP Bonding material: Silicone Temperature range:

requirements (current Good Manufacturer O-Rings: Silicone (standard), –20°C (–4°F) to 200°C (400°F)*

Practice) and is manufactured in Buna N, EPDM or * > 150°C (300°F) only for dry compressed air

accordance with DIN EN ISO 9001. The Viton

filter media is non-fibre releasing, is

asbestos free and manufactured without

the use of binders or other chemical

additives. FEATURES BENEFITS

High quality stainless steel construction High mechanical and thermal stability, good durability range against

chemicals and against numerous aggressive gases

Applications: Absolute retention rate of 99,999% related to 0,01 µm Validated retention rate, integrity testable with DOP test according to HIMA

The ultradepth II® sterile filters are, among Manufactured in accordance with cGMP and DIN EN ISO 9001 Constant product quality, high operational and process safety

others, designed and developed for sterile Three dimensional borosilicate depth filter medium High dirt hold capacity, low differential pressure, high flow rate

tank storage applications such as: Biologically and chemically inert No breeding ground for separated micro-organisms

• Chemical industry 100 sterilisation cycles guaranteed Highly economical and low filtration costs

100% integrity tested by factory Guaranteed quality

• Aseptic packaging

Available in 6 element sizes Optimum filter size for the individual application

• Pharmaceutical industry Stainless steel cores and end caps Temperature range from –20°C (–4°F) to 200°C (400°F), sterilisable at a

• Biotechnology steam temperature of up to 141°C (290°F)

• Cosmetic industry

• Breweries DIMENSIONS

ELEMENT A B ØC ØD CF

• Dairies nominal

SIZE o.d. width

• Food and beverage 03/10 76 12 31.0 ( 3/4'' ) 42 0.12

• Water treatment systems 04/10 104 12 31.0 ( 3/4'' ) 42 0.17

• Fermentation processes 04/20 104 14 38.5 ( 1'' ) 52 0.19

05/20 128 14 38.5 ( 1'' ) 52 0.25

05/25 128 14 38.5 ( 1'' ) 62 0.32

07/25 180 14 38.5 ( 1'' ) 62 0.47

05/30 128 16 63.0 ( 2'' ) 86 0.46

07/30 180 16 63.0 ( 2'' ) 86 0.68

10/30 254 16 63.0 ( 2'' ) 86 1.00

15/30 381 16 63.0 ( 2'' ) 86 1.55

20/30 508 16 63.0 ( 2'' ) 86 2.10

20/30 762 16 63.0 ( 2'' ) 86 3.28

30/50 762 16 91.0 ( 3'' ) 140 5.89

14

You might also like

- Sterilfilter P SRFDocument3 pagesSterilfilter P SRFPapaleguas gamesNo ratings yet

- P SRF Depth Filter ElementsDocument5 pagesP SRF Depth Filter Elementsesmail aliNo ratings yet

- (P) - SRF E: Process Filtration From Pure To SterileDocument4 pages(P) - SRF E: Process Filtration From Pure To SterileRei_budNo ratings yet

- ID250 - Silirub Cleanroom - Belgium - EnglishDocument2 pagesID250 - Silirub Cleanroom - Belgium - Englishsamira bashirvandNo ratings yet

- P-SRF N: Process Sterile Air Filter ElementsDocument6 pagesP-SRF N: Process Sterile Air Filter ElementsParis AnabelNo ratings yet

- Pall Emflon PFRW LDocument2 pagesPall Emflon PFRW Lhamoon.jabbari.94No ratings yet

- Emflon PFRW Filter Cartridges: For Sterile Filtration of GasesDocument3 pagesEmflon PFRW Filter Cartridges: For Sterile Filtration of GasesMarcelo García FacalNo ratings yet

- (P) SRFDocument6 pages(P) SRFYing Kei ChanNo ratings yet

- 014.070 EN - Donaldson P-GS FilterDocument2 pages014.070 EN - Donaldson P-GS FilterNg MeriedNo ratings yet

- Dental AutoclaveDocument5 pagesDental Autoclavehasanosamah12No ratings yet

- Process Filter P-BE Sterile Depth Filter For Storage TanksDocument4 pagesProcess Filter P-BE Sterile Depth Filter For Storage Tanksprabal rayNo ratings yet

- Thermaline 450 EP PDSDocument3 pagesThermaline 450 EP PDSdgambhavaNo ratings yet

- Interchar 1190 (2 Hour) DatasheetDocument4 pagesInterchar 1190 (2 Hour) DatasheetCongson JeffNo ratings yet

- GPD Cartridge Service DSDocument2 pagesGPD Cartridge Service DSJoseNo ratings yet

- Esdti Spray Dryer: The Cost Effective SolutionDocument4 pagesEsdti Spray Dryer: The Cost Effective SolutionpressNo ratings yet

- P GS VE Steam Filter ElementsDocument6 pagesP GS VE Steam Filter ElementsmarianraulNo ratings yet

- Thermaline 450 EP PDSDocument3 pagesThermaline 450 EP PDSNguyễn Duy BiênNo ratings yet

- P-SRF N: Process Sterile Air Filter ElementsDocument8 pagesP-SRF N: Process Sterile Air Filter ElementsDavid MartinNo ratings yet

- Steripleat Vent: Sterile Tank Vent FiltrationDocument3 pagesSteripleat Vent: Sterile Tank Vent FiltrationPraful IngleNo ratings yet

- BR-STI-EN-0623Document6 pagesBR-STI-EN-0623santirat.phoNo ratings yet

- Thermaguard TIC 400 TDSDocument4 pagesThermaguard TIC 400 TDSJIMMY JAMESNo ratings yet

- Sikagard 403 W PdsDocument3 pagesSikagard 403 W PdsPRERAKNo ratings yet

- Sikafloor 304 W PDSDocument4 pagesSikafloor 304 W PDST SNo ratings yet

- Shelco MPX Filter CartridgesDocument2 pagesShelco MPX Filter CartridgesArturo Camacho SalazarNo ratings yet

- Borstar HE3460 BlackDocument2 pagesBorstar HE3460 Blacklamia.elgammalNo ratings yet

- Sterility Test IsolatorDocument6 pagesSterility Test IsolatorFiza SanoNo ratings yet

- Purocept ADocument2 pagesPurocept ARonaldo JanglinNo ratings yet

- Process Filters EngDocument12 pagesProcess Filters Engmaurozuri100% (1)

- FBDSFDSWENDocument2 pagesFBDSFDSWENmisuakechiNo ratings yet

- Industrial Filters PDFDocument14 pagesIndustrial Filters PDFSameera LakmalNo ratings yet

- Product Data: Hempel'S Silicone Zinc 16900Document2 pagesProduct Data: Hempel'S Silicone Zinc 16900Anuar SalehNo ratings yet

- Instruction Ultra DB EN15 (Magnaplast)Document62 pagesInstruction Ultra DB EN15 (Magnaplast)Nanda IszharNo ratings yet

- Spray Dryer SD Basic Brochure 2013Document2 pagesSpray Dryer SD Basic Brochure 2013Augusto MatiasNo ratings yet

- 014.070 EN - Donaldson (P) - GSL N Brochure Gas and SteamDocument6 pages014.070 EN - Donaldson (P) - GSL N Brochure Gas and SteamNg MeriedNo ratings yet

- Sikagard®-405 W: Product Data SheetDocument4 pagesSikagard®-405 W: Product Data SheetIulian BobocNo ratings yet

- CLAROX-Membranes 04 2018 E PDFDocument3 pagesCLAROX-Membranes 04 2018 E PDFjpsingh75No ratings yet

- TDS Penguard Tie Coat 100 Euk GBDocument6 pagesTDS Penguard Tie Coat 100 Euk GBIliyan PetrovNo ratings yet

- TechDS Elm - FF - MF - SMFDocument2 pagesTechDS Elm - FF - MF - SMFHendri KurniawanNo ratings yet

- Pulsation Dampener - Tech - SheetDocument2 pagesPulsation Dampener - Tech - SheetJuan Dela CruzNo ratings yet

- Hsro 4040 FFDocument3 pagesHsro 4040 FFAlejandro OdioNo ratings yet

- Proguard CN 100 Iso TDSDocument3 pagesProguard CN 100 Iso TDSm_f_deathNo ratings yet

- ERIKSORINGSDocument14 pagesERIKSORINGStuannhocutNo ratings yet

- TDS-PDF-Interchar 1290 Eng A4 20170228Document4 pagesTDS-PDF-Interchar 1290 Eng A4 20170228shameelNo ratings yet

- Endress-Hauser Dosimag 5BH ENDocument4 pagesEndress-Hauser Dosimag 5BH ENDiki DikiNo ratings yet

- Endo Angl v2011Document58 pagesEndo Angl v2011Yousab CreatorNo ratings yet

- Arde Respira Ç ÃoDocument8 pagesArde Respira Ç ÃoSuprimentos IndaloNo ratings yet

- Everything You Need to Know About Sterilization and Disinfection in DentistryDocument50 pagesEverything You Need to Know About Sterilization and Disinfection in DentistryAFEEDANo ratings yet

- PEPLYN AIR Filter Cartridges: Performance CharacteristicsDocument2 pagesPEPLYN AIR Filter Cartridges: Performance CharacteristicsDucVikingNo ratings yet

- AB Emflon PFRDocument2 pagesAB Emflon PFRsaulookNo ratings yet

- Think Top 101Document8 pagesThink Top 101Đivềphía Mặt TrờiNo ratings yet

- HO160 Specification SheetDocument6 pagesHO160 Specification SheetSteven BrownNo ratings yet

- CatalogueDocument6 pagesCatalogueRakesh RanjanNo ratings yet

- Filmtec™ Bw30Xfrle-400/34 Element: Product Data SheetDocument3 pagesFilmtec™ Bw30Xfrle-400/34 Element: Product Data SheetElajmi RostomNo ratings yet

- TDS Tankguard 412 English (Uk) Issued.22.05.2009Document4 pagesTDS Tankguard 412 English (Uk) Issued.22.05.2009Ahmed NabilNo ratings yet

- MOLYKOTE Longterm 00 Fluid Grease 2019Document2 pagesMOLYKOTE Longterm 00 Fluid Grease 2019ANo ratings yet

- Unrivalled VOC Detection in Just 2 SecondsDocument2 pagesUnrivalled VOC Detection in Just 2 SecondsPalashNo ratings yet

- Thermaline 450 EP: Selection & Specification DataDocument3 pagesThermaline 450 EP: Selection & Specification DataGMSNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- MARS 1.0 License - EnglishDocument1 pageMARS 1.0 License - EnglishSydney D. BajentingNo ratings yet

- CryptoppDocument2 pagesCryptoppfreddie123No ratings yet

- Apache LicenseDocument5 pagesApache Licenseapi-286574869No ratings yet

- SM0010371-R00-022 TraduzidoDocument7 pagesSM0010371-R00-022 TraduzidoAllanBorgesNo ratings yet

- PEG8 - Final-160812 Siemens PDFDocument569 pagesPEG8 - Final-160812 Siemens PDFDanielDuránNo ratings yet

- SM0010371-R00-022 TraduzidoDocument7 pagesSM0010371-R00-022 TraduzidoAllanBorgesNo ratings yet

- Europass CV Instructions enDocument5 pagesEuropass CV Instructions enSaverio GrisorioNo ratings yet

- Ultrafilter Ultradepthii Pbe PDFDocument1 pageUltrafilter Ultradepthii Pbe PDFAllanBorgesNo ratings yet

- Datasheet - IM08-02BPS-ZT1 - 7900005 - enDocument6 pagesDatasheet - IM08-02BPS-ZT1 - 7900005 - enAllanBorgesNo ratings yet

- 30 Plugs PDFDocument29 pages30 Plugs PDFAries TsaiNo ratings yet

- AC S M: C: Offee HOP ENU OnversationDocument2 pagesAC S M: C: Offee HOP ENU OnversationAllanBorgesNo ratings yet

- Alpha LP Gears Technical CatalogueDocument22 pagesAlpha LP Gears Technical CatalogueAllanBorgesNo ratings yet

- 5 Project StructureDocument22 pages5 Project StructureAries TsaiNo ratings yet

- IFFM-08P17A3-O1S35L-web-ENDocument1 pageIFFM-08P17A3-O1S35L-web-ENAllanBorgesNo ratings yet

- Momentum Heat Mass Transfer For Chemical and Food EngineeringDocument37 pagesMomentum Heat Mass Transfer For Chemical and Food EngineeringTigrigna TenagariNo ratings yet

- Forming Processes (MP Module 3)Document77 pagesForming Processes (MP Module 3)Kailas Sree ChandranNo ratings yet

- Waste Water Treatment PlantDocument10 pagesWaste Water Treatment PlantBoiler ScrubberNo ratings yet

- Hough - The Crystallography, Metallography and Composition of Gold PDFDocument6 pagesHough - The Crystallography, Metallography and Composition of Gold PDFSantiaGoAlejandRoNo ratings yet

- Iso 13438 2018Document9 pagesIso 13438 2018Phạm Hùng CườngNo ratings yet

- Rry'S Chemical Engineers' Handbook: Seventh EditionDocument2 pagesRry'S Chemical Engineers' Handbook: Seventh EditionRamaNo ratings yet

- Small Scale SoapmakingDocument82 pagesSmall Scale SoapmakingDemelash GebreNo ratings yet

- SM256Document1 pageSM256Tan Chen TatNo ratings yet

- PHYSICAL PROPERTIES OF MATERIALS Review QuestionsDocument2 pagesPHYSICAL PROPERTIES OF MATERIALS Review Questionsprince stevenNo ratings yet

- Aging of LiFePO4 Upon Exposure To H2O PDFDocument13 pagesAging of LiFePO4 Upon Exposure To H2O PDFadalid contrerasNo ratings yet

- VIESSMANN DHW Calculation VitocellTechnicalGuideDocument52 pagesVIESSMANN DHW Calculation VitocellTechnicalGuideaakoglanisNo ratings yet

- ACOT21 Round 2 - Gold TierDocument7 pagesACOT21 Round 2 - Gold Tierjoe mamaNo ratings yet

- United States: Patent OfficeDocument4 pagesUnited States: Patent OfficesherlybonitaNo ratings yet

- Cutting Tool Tech and Tool Life CalcDocument25 pagesCutting Tool Tech and Tool Life CalcPrashant ChouhanNo ratings yet

- What Are Magic RocksDocument2 pagesWhat Are Magic Rocksdatta sdNo ratings yet

- Tell sth apart = distinguish between sth: phân biệt giữa 2 thứ gìDocument6 pagesTell sth apart = distinguish between sth: phân biệt giữa 2 thứ gìHiền TrầnNo ratings yet

- Brochure - Eu Standard Equipment For Commercial Kitchens v1.0 En-WebDocument4 pagesBrochure - Eu Standard Equipment For Commercial Kitchens v1.0 En-WebalanatoraNo ratings yet

- Comparison of Phytoremediation Process On Tempe Waste Water Using Three Types of Aquatic PlantsDocument9 pagesComparison of Phytoremediation Process On Tempe Waste Water Using Three Types of Aquatic PlantsYhanaNo ratings yet

- CWP Cert PDFDocument4 pagesCWP Cert PDFmurtazagulzar3No ratings yet

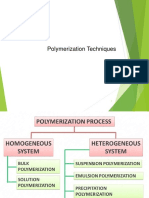

- Polymerisation Practice TEPEDocument39 pagesPolymerisation Practice TEPEDr. Dure Najaf Iqbal100% (3)

- Completing The Puzzle:: 100% Plant-Derived PETDocument4 pagesCompleting The Puzzle:: 100% Plant-Derived PETAtif AzamNo ratings yet

- Coco Yam Bioplastic: A Solution to Plastic PollutionDocument10 pagesCoco Yam Bioplastic: A Solution to Plastic PollutionCharity AmboyNo ratings yet

- Ch11 CastingProcessesDocument102 pagesCh11 CastingProcessesFahmi PrayogiNo ratings yet

- GDocument3 pagesGjeas grejoy andrewsNo ratings yet

- Safety Data Sheet: Product Name: MOBIL SHC RARUS 68Document10 pagesSafety Data Sheet: Product Name: MOBIL SHC RARUS 68Daniel Rodriguez GutierrezNo ratings yet

- Pharmacology Review - A Comprehensive Reference Guide For Medical, Nursing, and Paramedic StudentsDocument276 pagesPharmacology Review - A Comprehensive Reference Guide For Medical, Nursing, and Paramedic StudentsfjletonaNo ratings yet

- Scope and Sequence - ChemistryDocument2 pagesScope and Sequence - Chemistryapi-232424041No ratings yet

- Panduan Troli EmergencyDocument3 pagesPanduan Troli EmergencyTukiyemNo ratings yet

- Nickel CobaltDocument8 pagesNickel CobaltSunnyNo ratings yet

- Soil Pollution: Causes, Effects and Simple SolutionsDocument7 pagesSoil Pollution: Causes, Effects and Simple SolutionsVon MorenNo ratings yet