Professional Documents

Culture Documents

6004551b en FCal Calc Uncert Thermocouple W

Uploaded by

FajarAdiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6004551b en FCal Calc Uncert Thermocouple W

Uploaded by

FajarAdiCopyright:

Available Formats

Calculating

uncertainties in

a thermocouple

calibration system Application Note

Thermocouple application

note series

This is the third of four application notes

on thermocouples:

1. Thermocouple fundamentals

2. How to select thermocouple

calibration equipment

3. Calculating uncertainties in a

thermocouple calibration system

1586A Super-

4. How to calibrate a thermocouple DAQ Precision

Temperature

Scanner with

DAQ-STAQ

Multiplexer

Sample uncertainty budget

There are several calibration uncertainties to be The following uncertainty analysis lists each

evaluated in determining the total uncertainty uncertainty in both standard and expanded

of a thermocouple calibration system. This form. The difference between standard and

section gives an example of how to prepare an expanded is that the standard uncertainty

uncertainty budget for a system comprised of has been multiplied by some coverage factor,

the following equipment when calibrating a typically stated in the form of a value of k,

thermocouple at 1000° C: to become an expanded uncertainty. Or, an

•• Reference probe: 5650 Type S Thermocouple uncertainty is divided by a conversion divi-

with reference junction sor to estimate its standard uncertainty (k=1)

value. The k value corresponds to a confidence

•• Readout: 1586A Super-DAQ Precision

Temperature Scanner with DAQ-STAQ

Multiplexer

•• Temperature source: 9118A Thermocouple

Calibration Furnace

•• Unit under test (UUT): Type S thermocouple

without reference junction

Figure 1 presents a sample uncertainty

budget. It offers one method for aggregating

some of the most important contributors to the

system uncertainty. Each uncertainty has been

given a code and a corresponding discussion is

provided. This uncertainty analysis is compre-

hensive but is simplified for a general technical

9118A

audience so it may be important to consult with Thermocouple

your local NMI (National Metrology Institute) for Calibration

further details or with your accreditation body Furnace

(for accredited calibration labs).

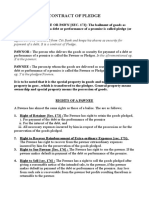

Figure 1. Thermocouple calibration system uncertainty evaluation at 1000 °C

Type B standard uncertainties Code Standard uncertainty (°C) Coverage factor Expanded uncertainty (°C)

Measurement noise/stability of reference (n≥30) A1 0.01 2 0.02

Measurement noise/stability of UUT (n≥30) A2 0.01 2 0.02

Check standard statistic A3 0.01 2 0.02

1586A readout accuracy (for reference probe) B1 0.19 2 0.38

Reference junction accuracy (for reference probe) B2 0.01 √3 0.01

1586A readout accuracy (for UUT – Type S) B3 0.28 2 0.56

Reference junction accuracy (for UUT – Type S) B4 0.07 2 0.13

Reference probe calibration uncertainty B5 0.13 2 0.26

Reference probe long-term drift limit B6 0.06 √3 0.10

9118A furnace axial uniformity B7 0.10 2 0.20

9118A furnace radial uniformity B8 0.12 2 0.23

Total standard uncertainty (k=1) 0.52

Total expanded uncertainty (k=2) 1.04

Note: Each uncertainty is rounded to two decimal places after calculations are applied.

interval. For example, in most cases, k = 2 The following equation demonstrates how to

corresponds to a 2-sigma or 95 % confidence make this calculation:

interval. More will be explained in the "Com- s ± 0.050 °C

bining uncertainties" section of this document. UA1 = = = ± 0.009 °C

√n √30

A1 and A2. Measurement noise •• UA1: uncertainty due to measurement noise

Measurement noise is the uncertainty caused (°C)

by the noise or instability of the measurement •• s: measurement standard deviation (°C)

readings. Each measurement point is based •• n: number of samples (30 or more)

on the average or mean of 30 or more read- Tip: If readings are in units of voltage (mV),

ings or samples. The uncertainty of the noise divide UA1 by the sensitivity of the thermocouple

or instability of the 30 readings is calculated to convert to temperature (°C).

by dividing the standard deviation of the 30

samples by the square-root of n (n = 30). This A3. Check standard statistic

calculation is often referred to as Standard Error

of the Mean. The check standard statistic is an indication of

Typically, measurement noise covers both the stability of the calibration process. It is a

readout noise and heat source instability. The good idea to measure a check standard probe

manufacturer’s specification for heat source along with the UUTs. The check standard mea-

stability may be similar, but it is best to make surement results are plotted in a control chart

measurements and monitor actual standard and analyzed to make sure no unexpected

deviation to ensure that the uncertainty analy- errors occur.

sis requirements are met. A check standard should be similar to the

Either the actual measurement standard UUT so that changes in the process will affect

deviation or corresponding Standard Error of the check standard and UUT in the same way.

the Mean can be entered into the uncertainty A check standard made of non-noble metal

analysis each time a measurement is made, or material may not be sufficiently repeatable

a measurement noise limit can be assigned to to indicate the long term stability of the cali-

each measurement point. In the case of a limit, bration process. It is recommended to use a

the measurements are monitored to verify that high-quality Type S or Type R thermocouple as

the stability (standard deviation) meets the a check standard.

limit stated in the uncertainty analysis. In this The value entered into the uncertainty

example, we will use a standard deviation limit. analysis is the standard deviation of the check

2 Fluke Calibration Calculating uncertainties in a thermocouple calibration system

standard measurements over time. For example, specifications into values that can be entered

the Figure 2 table shows readings taken from into the uncertainty analysis.

multiple runs in a calibration process. Standard Since most thermocouple readouts are

deviation of the seven check standard readings specified in terms of voltage accuracy, the fol-

is calculated to be 0.011 °C. This can be entered lowing equation converts voltage uncertainty to

into the uncertainty analysis, but it is best to temperature:

continue to add more readings and update the U

Check Standard Statistic component until the UT(°C) = v

SMJ

count reaches 30 or greater. This number is

also used to establish control lines on the check •• UT(°C): equivalent temperature uncertainty

standard control chart. The standard devia- •• UV : voltage measurement uncertainty

tion (σ) value is multiplied by two or three to

•• SMJ: thermocouple sensitivity at the measur-

establish 2-σ or 3-σ control lines, depending

ing junction temperature

on what your requirements are. The Figure 3

sample control chart shown has 3-σ control Tip: Calculate SMJ by using a thermocouple

lines. voltage table. It is the change in voltage (mV)

per 1 °C change (ΔV/ΔT).

Figure 2: Sample control readings

The 1586A readout accuracy for the reference

Check standard reading (°C) probe is:

Run 1 1000.025 •• 1586A voltage accuracy specification is

0.004 % + 4 μV (% of reading, k=2), Note:

Run 2 1000.014

add additional 2 μV for UUT being measured

Run 3 1000.042 on a DAQ-STAQ scanner channel.

Run 4 1000.022 •• The thermocouple is Type S

Run 5 1000.008 •• The temperature is 1000 °C

Run 6 1000.031 •• The Type S thermocouple voltage at 1000 °C

Run 7 1000.021

is 9.6 mV

Standard Deviation = ± 0.011 °C

•• The specified voltage accuracy in this range

is ± 0.0022 mV (k=1) see following equation:

9.6mV

Figure 3: Sample control chart 0.004 × 100 + 0.004mV

UV(k=1) = = ± 0.0022mV

2

Check standard control chart - 1000 °C

•• The Type S thermocouple has a sensitivity of

± 0.0115 mV/°C at 1000 °C

1000.060

•• The readout accuracy is converted to units of

1000.050

temperature with the following:

1000.040

± 0.0022 mV

Check std. reading (°C)

UT(°C) = = ± 0.191 °C

1000.030

± 0.0115 mV/°C

1000.020

B2. Reference junction accuracy (for

1000.010

reference probe)

999.990

The reference junction may be external or

999.980 internal. In this example, an external reference

junction is being used. The uncertainty of the

5/31/2014 6/10/2014 6/20/2014 6/30/2014 7/10/2014 7/20/2014 7/30/2014

external reference junction is dependent on

Date

the type of equipment being used. Most labo-

ratories use a 0 ºC temperature source such as

B1 and B3. 1586A readout accuracy an ice bath or a dry-well like the Fluke 9101

calculation (for reference probe and Zero-Point Dry-Well. Uncertainties associated

UUT) with an ice bath can be as low as a few mK

but this requires careful technique and can

Readout accuracy applies to both the reference

be complicated. The Fluke Primary Tempera-

probe and UUT. The following calculations dem-

ture Calibration Laboratory uses a simplified

onstrate how to convert typical thermocouple

3 Fluke Calibration Calculating uncertainties in a thermocouple calibration system

approach by building an ice bath with shaved URJ_Effective =

URJ × SRJ

ice and tap water but monitoring the tempera- SMJ

ture with a thermistor probe and readout. The

uncertainty in this approach is based on the •• URJ_Effective: effective reference junction tempera-

acceptable temperature range of the ice bath, ture uncertainty

which is 0 ºC ± 0.025 ºC. To build an ice bath •• URJ: reference junction uncertainty

with lower uncertainty, refer to ASTM document

•• SMJ: thermocouple sensitivity at the measur-

E563-11 “Standard Practice for Preparation

ing junction temperature

and Use of an Ice-Point Bath as a Reference

Temperature.” •• SRJ: thermocouple sensitivity at the reference

The following equation is used to calculate junction temperature

the effective reference junction temperature The temperature uncertainty of the internal

uncertainty. When measuring a thermocouple, reference junction in this example would be:

both junctions contribute to the measurement. •• The thermocouple is type S

Therefore, the reference junction uncertainty

is multiplied by the ratio of the thermocouple •• The temperature is 1000 ºC

sensitivity values (Seebeck) at the temperature •• The 1586A internal reference junction accu-

of the reference junction and measuring junc- racy is 0.25 (k=2) or 0.13 (k=1) ºC

tion to calculate the effective reference junction •• The thermocouple has a sensitivity of 0.0115

uncertainty. mV/ºC at 1000 ºC

U ×S

RJ RJ •• The thermocouple has a sensitivity of 0.006

U =

mV/ºC at 25 ºC

RJ_Effective

S MJ

•• URJ_Effective: effective reference junction tempera- •• The equivalent temperature uncertainty is

ture uncertainty calculated with the following:

•• URJ: reference junction uncertainty U =

0.25 °C × 0.006 mV/°C

RJ_Effective = 0.13 °C

•• SMJ: thermocouple sensitivity at the measur- 0.0115 mV/°C

ing junction temperature

•• The following converts the uncertainty to a

•• SRJ: thermocouple sensitivity at the reference standard uncertainty:

junction temperature

0.13 °C

The temperature uncertainty of the reference U = B4 (k=1) = 0.07 °C

2

junction in this example would be:

•• The thermocouple is type S B5. Reference probe calibration

•• The temperature is 1000 °C uncertainty

•• The reference junction accuracy is 0.025 °C This uncertainty is transferred directly from the

•• The thermocouple has a sensitivity of 0.0115 calibration certificate of the reference probe.

mV/ºC at 1000 °C If the uncertainty at a particular temperature

point is not listed on the certificate, it will have

•• The thermocouple has a sensitivity of 0.006 to be calculated. Consult with the provider of

mV/°C at 25 °C the calibration for advice in how to perform

•• The equivalent temperature uncertainty is this calculation. A safe, but typically over-esti-

0.013 °C mated, approximation is to choose the higher

0.025 °C × 0.006 /°C

mV uncertainty of the two surrounding reported

U = = 0.013 °C

RJ_Effective

0.0115 /°C

mV

temperature points.

If the reference probe is a thermocouple,

•• The following converts the uncertainty to a be sure to account for inhomogeneity. If the

standard uncertainty: calibration uncertainty does not address inho-

0.013 °C mogeneity, it will be important to include an

U B2 (k=1) = = 0.007 °C

additional uncertainty component to account for

√3

it. Consult with a reputable calibration labora-

B4. Reference junction accuracy tory or NMI for more information on this topic.

(for UUT) B6. Reference probe long-term drift

In this example, the corresponding uncertainty Reference probe long-term drift can be difficult

for the internal reference junction is calculated to determine. Manufacturers may specify

using the following equation.

4 Fluke Calibration Calculating uncertainties in a thermocouple calibration system

long-term drift using a value based on a certain Temperature stability

number of hours of use at maximum tempera- Specification 9118A 9118A-ITB

ture. This really only addresses material aging Stability ± 0.2 °C ± 0.1 °C

and doesn’t cover other sources of drift such as Stabilization 2 hours, full range 3 hours at or below

handling, mechanical shock, and temperature Time 700 °C, 2 hours above

700 °C

cycling. It is suitable to start with the manu-

Note: Temperature stability measured as 2-sigma over 30

facturer’s long-term drift specification, but it is minutes

important to monitor the probe for drift.

•• The allowed long-term drift is ± 0.10 °C Combining uncertainties

(divide by square root of 3 to convert to In order to combine all of the uncertainty

± 0.06 °C, k=1) components, they first must be converted to

standard uncertainties. To do this, it is impor-

B7 and B8. Furnace axial uniformity tant to understand the type (distribution) of

and radial uniformity each uncertainty so the correct conversion

calculation can be done. In this uncertainty

The main contributors to the uncertainty analysis, there are two kinds of uncertainties in

analysis from the furnace are stability and the table—normal distribution and rectangular

uniformity. Stability is already accounted for distribution.

in A1 and A2 measurement noise, as this A normal distribution uncertainty is an

uncertainty describes the general noise of the uncertainty that tends to have most results in

calibration system, including furnace stabil- the center, so the distribution is shaped like a

ity. Uniformity is specified in two parts; radial bell curve. A rectangular distribution has equal

(hole-to-hole) and axial (the gradient over probability that the result will reside anywhere

different depths into the equilibration block). inside the limit, so the distribution is shaped

These are specified by the manufacturer and as a rectangle. Quite often process limits, such

are listed in Figure 4. You can rely on these as long-term allowed drift, are assigned a

numbers for a preliminary uncertainty budget, rectangular distribution. If it is unknown what

but best practice dictates that they must be the distribution is, it is safe to assume that is a

verified. In some cases, the uncertainty may be rectangular distribution.

lowered because the unit is performing better To convert an expanded (k=2 or k=3) normal

than manufacturer specification. To estimate distribution to standard uncertainty (k=1) form,

the uniformity values at 1000 °C, use the values you simply divide it by the k value. To convert

stated for 700 °C and 1200 °C and interpolate a rectangular uncertainty to its standard form,

linearly. divide it by the square root of 3. For convert-

•• Manufacturer specified uniformity at 1000 °C ing other types of uncertainty distributions,

is: Axial ± 0.20 °C (k=2) or ± 0.10 °C (k=1) refer to the GUM (Guide to the Uncertainty in

and Radial 0.23 °C (k=2) or ± 0.12 °C (k=1) Measurement) or some other reliable source of

information on how to calculate uncertainties.

Figure 4: 9118A manufacturer Finally, to combine the standard uncertain-

specifications ties in order to calculate total uncertainty, it

is important to know if each uncertainty is

Radial uniformity independent or correlated. An independent

Temperature 9118A (14 mm (0.6 in) from 9118A-ITB uncertainty is one that has nothing in common

geometry central point) hole-to-hole with the other uncertainties. All indepen-

300 °C ± 0.5 °C ± 0.1 °C dent uncertainties can be combined or added

700 °C ± 0.5 °C ± 0.20 °C together using Root Sum Squares (RSS). An

1200 °C ± 0.5 °C ± 0.25 °C example of RSS is shown below. A correlated

Axial uniformity uncertainty means that it has some type of cor-

Temperature 9118A (± 30 mm (1.2 9118A-ITB (at 60 mm relation or relationship with one or more other

in) axial length from (2.4 in) from full uncertainties. Correlated uncertainties can often

geometry central point) immersion)

be added together with simple addition and

Full range ± 0.25 °C ± 0.2 °C

then the sum is added by RSS with the other

uncertainties. Sometimes more sophisticated

5 Fluke Calibration Calculating uncertainties in a thermocouple calibration system

techniques of calculating correlations are used

but this uncertainty analysis doesn’t require

that.

In this uncertainty analysis the 1586A

readout accuracy uncertainties are correlated

since the same instrument is used to measure

both the reference probe and the UUT. There-

fore they are added by simple addition first,

then combined with the others using RSS. After

the total standard uncertainty is calculated, it

is multiplied by the desired coverage factor, in

this case 2, for k=2 (95 %), to arrive at the total

expanded uncertainty.

Root sum squares

U= √B1 2

+ B22 + B32 + B42 + B52 + B62...

Fluke Calibration. Precision, performance, confidence.™

Fluke Calibration Fluke Europe B.V.

PO Box 9090, PO Box 1186, 5602 BD

Everett, WA 98206 U.S.A. Eindhoven, The Netherlands

For more information call:

In the U.S.A. (877) 355-3225 or Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or Fax +31 (0) 40 2675 222

In Canada (800)-36-Fluke or Fax (905) 890-6866

From other countries +1 (425) 446-5500 or Fax +1 (425) 446-5116

Web access: http://www.flukecal.com

©2015 Fluke Calibration. Specifications subject to change without notice.

Printed in U.S.A. 6/2015 6004551b-en

Pub-ID 13348-eng

Modification of this document is not permitted without written permission

from Fluke Calibration.

6 Fluke Calibration Calculating uncertainties in a thermocouple calibration system

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Invitation 2023Document10 pagesInvitation 2023Joanna Marie Cruz FelipeNo ratings yet

- Discussion #3: The Concept of Culture Learning ObjectivesDocument4 pagesDiscussion #3: The Concept of Culture Learning ObjectivesJohn Lery SurellNo ratings yet

- Biosphere Noo Sphere Infosphere Epistemo PDFDocument18 pagesBiosphere Noo Sphere Infosphere Epistemo PDFGeorge PetreNo ratings yet

- Modern DrmaDocument7 pagesModern DrmaSHOAIBNo ratings yet

- Ergonomics For The BlindDocument8 pagesErgonomics For The BlindShruthi PandulaNo ratings yet

- Ib Physics SL - Unit 4 ReviewDocument46 pagesIb Physics SL - Unit 4 ReviewMax HudgenesNo ratings yet

- Pathfinder CharacterSheet.1.8InterActiveDocument3 pagesPathfinder CharacterSheet.1.8InterActiveJessica AlvisNo ratings yet

- Contract of PledgeDocument4 pagesContract of Pledgeshreya patilNo ratings yet

- Ancestral Healing PrayersDocument4 pagesAncestral Healing Prayerssuperhumannz100% (13)

- August Strindberg's ''A Dream Play'', inDocument11 pagesAugust Strindberg's ''A Dream Play'', inİlker NicholasNo ratings yet

- Risteski Space and Boundaries Between The WorldsDocument9 pagesRisteski Space and Boundaries Between The WorldsakunjinNo ratings yet

- Bersin PredictionsDocument55 pagesBersin PredictionsRahila Ismail Narejo100% (2)

- Introduction To Political ScienceDocument18 pagesIntroduction To Political Sciencecyrene cayananNo ratings yet

- Understanding Ui-Ux-By Harry Muksit - SDocument109 pagesUnderstanding Ui-Ux-By Harry Muksit - Sgodzalli44100% (1)

- Easter in RomaniaDocument5 pagesEaster in RomaniaDragos IonutNo ratings yet

- (Abhijit Champanerkar, Oliver Dasbach, Efstratia K (B-Ok - Xyz)Document273 pages(Abhijit Champanerkar, Oliver Dasbach, Efstratia K (B-Ok - Xyz)gogNo ratings yet

- Level 5 - LFH 6-10 SepDocument14 pagesLevel 5 - LFH 6-10 SepJanna GunioNo ratings yet

- Sop 2Document43 pagesSop 2naveengargnsNo ratings yet

- Capgras SyndromeDocument4 pagesCapgras Syndromeapi-459379591No ratings yet

- Accomplishment Report: For Service Credits (Availment/claim) Election May 2019Document1 pageAccomplishment Report: For Service Credits (Availment/claim) Election May 2019Glazy Kim Seco - JorquiaNo ratings yet

- ASME-Y14.5.1M 1994 Mathematical Definition of Dimensioning and Tolerancing Principles PDFDocument89 pagesASME-Y14.5.1M 1994 Mathematical Definition of Dimensioning and Tolerancing Principles PDFwulfgang66No ratings yet

- Ielts Reading Whale CultureDocument4 pagesIelts Reading Whale CultureTreesa VarugheseNo ratings yet

- Errol PNP Chief AzurinDocument8 pagesErrol PNP Chief AzurinDarren Sean NavaNo ratings yet

- How Is Extra-Musical Meaning Possible - Music As A Place and Space For Work - T. DeNora (1986)Document12 pagesHow Is Extra-Musical Meaning Possible - Music As A Place and Space For Work - T. DeNora (1986)vladvaidean100% (1)

- Saber Toothed CatDocument4 pagesSaber Toothed CatMarie WilkersonNo ratings yet

- Factor Causing Habitual Viewing of Pornographic MaterialDocument64 pagesFactor Causing Habitual Viewing of Pornographic MaterialPretzjay BensigNo ratings yet

- 25 ConstitutionDocument150 pages25 ConstitutionSaddy MehmoodbuttNo ratings yet

- Conversational Maxims and Some Philosophical ProblemsDocument15 pagesConversational Maxims and Some Philosophical ProblemsPedro Alberto SanchezNo ratings yet

- Kami Export - Document PDFDocument2 pagesKami Export - Document PDFapi-296608066No ratings yet

- Hero Cash Cash Lyrics - Google SearchDocument1 pageHero Cash Cash Lyrics - Google Searchalya mazeneeNo ratings yet