Professional Documents

Culture Documents

Field Qulity Plan: 1. Chemical Test

Uploaded by

Vinoth Kumar RavindranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Field Qulity Plan: 1. Chemical Test

Uploaded by

Vinoth Kumar RavindranCopyright:

Available Formats

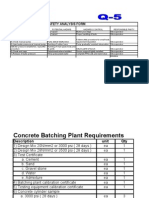

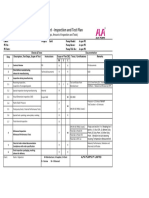

FIELD QULITY PLAN

INSPECTION TEST PLAN Not for circulation

INSPECTION & TEST PLAN FOR CIVIL WORK

H= hold point W=witness point C= Monitoring & verification P=Performance Test

CLIENT NAME: Doc No URC/

STRUCTURAL CONSULTANT : Rev No 1

SI.NO Component / Nature of check/ Test Method of Frequency Reference Form of level of inspection

process activity Check Documents Record

Third URC Client

party

1 Survey Calibration of survey Equipment third party test once a year Test P C C

Report

2 Earth work Filling Soil test External lab once in each source IS 2720, BS lab test P C C

e) Maximum dry density Test 1375, BS reports

b) Liquid limit 1377, Tech

c) Plastic limit specs

d) Plasticity index

e) Maximum dry density

f) optimum Moisture content

g) Field density test Every 500 Cum ( min Six - P W

samples)

3 Cement 1. Chemical test MTC 100% MTC

a) chlorides (as Cl) External lab Every Change of Source lab test

b) Ratio of alumina to that of iron oxide Test reports

c) Magnesia (MgO)

d) Sulphuric Anhydride (% by mass)

e) Loss of ignition

f) Insoluble residue

2. Physical test MTC 100% IS 8112, IS MTC - C C

12269, IS

1489 (Part-I)

Tech specs

a) Standard consistency Internal / every 2000 MT and lab test P P C

b) Initial setting time External lab change of source reports

c) Final setting time Test

d) Fineness

e) compressive strength (3/7/28 days)

f) Soundness Every Change of Source

g) Specific Gravity

4 Water 1. Chemical test External lab Once in 6 months / IS 456, IS lab test P C C

a) PH Value Test Change in source 3025 reports

b) Sulphates (as SO3)

c) Chlorides (as Cl)

d) NaOH Neutralised using mixed indicator

2. Physical test

a) Suspended matter

b) Organic matter

c) In-Organic matter

5 Fine aggregate 1.Silt Content Test Site Lab Daily/ every supply IS 383 , Report - P C

IS2386

2. Sieve Analysis Test Daily

3. Moisture Correction Daily

4. Specific gravity External lab once in each source Test P C C

Test Report

5. Deleterious Material Visual Inspection for

every supply

6. Organic Matter Visual Inspection for

every supply

FIELD QULITY PLAN

INSPECTION TEST PLAN Not for circulation

INSPECTION & TEST PLAN FOR CIVIL WORK

H= hold point W=witness point C= Monitoring & verification P=Performance Test

CLIENT NAME: Doc No URC/

STRUCTURAL CONSULTANT : Rev No 1

SI.NO Component / Nature of check/ Test Method of Frequency Reference Form of level of inspection

process activity Check Documents Record

Third URC Client

party

6 Coarse aggregate 1. Crushing Value External lab once in each source IS 383, IS Report P C C

Test/ Periodic 2386

Inspection)

2. Deleterious Materials Visual Inspection for

every supply

3.Alkaline aggregate reactivity test once in each source

4. Specific gravity Site Lab once in each source

5. Sieve analysis weekly Test - o C

Report

6. Impact Value

7. Flakiness Elongation test

8. Moisture Correction Daily

7 Mix Design Mix design as per IS 456: ACI 211.1 Conducting One for Change in IS 456, IS Report P C H

Mix design as per IS 10262 Trial mix in lab Component 10262, SP

Mix design as per SP 23 for atleast 3 23, ACI 211.1

a) Cement grade/ brand / Type different mixes Tech. spec.

b) Min. cement content/ Cum and submission

c) Max water cement ratio for approval to

d) Aggregate cement ratio PM consultant

e) Degree of workability

f) Degree of quality control

g)Grade of concrete

h) Density of concrete

i) Admixture if required

j) Trial mix sample for testing Test - P W

k) Compressive strength after 3 days/ 7 Report

days / 28 days

8 Reinforcement MTC Review of MTC 100 % every MTC - C C

steel consignment of steel

1.Chemical test External lab Three samples for each Tech specs, Test P C C

a) Carbon Test 100 MT for each IS 1786 Report

b) Sulphur diameter eachbrand/

c) Phosphorous According to heat

d) Sulphur and Phosphorus number, Every supply

2. Physical test rolling margin to be

a) Ultimate tensile strength checked

b) 0.2% Proof stress/ yield stress

c) Bend test

d) Rebend test

e)Rolling Margin

f) Elongation

Storage on raised platform periodic 100% IS 4082 Report / - P C

inspection Picture

9 Formwork Form material condition Tech. spec 100% IS 4990, Report - P C

External lab if necessary IS14687, Test P C W/C

Test ( optional) Tech spec Report

10 Concrete in Situ check for following: area to be concreted visual 100% Tech specs, Pour card - C W

shall be clean and free from extraneous inspection IS 456 and check

matter/ saw dust, wooden pieces etc, list

pour card cleareness visual 100% - C W

inspection

Post concrete deshuttering visual 100% - C W

inspection

workability test Slump cone Every load Cube - P H

Compressive strength Lab Test 7 & 28 days sampling as Register - P W

per IS 456

FIELD QULITY PLAN

INSPECTION TEST PLAN Not for circulation

INSPECTION & TEST PLAN FOR CIVIL WORK

H= hold point W=witness point C= Monitoring & verification P=Performance Test

CLIENT NAME: Doc No URC/

STRUCTURAL CONSULTANT : Rev No 1

SI.NO Component / Nature of check/ Test Method of Frequency Reference Form of level of inspection

process activity Check Documents Record

Third URC Client

party

11 Concrete -RMC a) Cement Reports As directed by client in- IS 8112, IS reports P C W/C

b) Aggregate charge 12269, IS

c) Water 383, IS456,

d) Admixture IS 516, IS

e) Cube compressive strength 9103

f) Calibration report for all instrument / plant

12 Chemical a) Dry material content for liquid and solid Review of MTC 100% every Tech specs, MTC - C C

Admixture- admixture consignment of IS 9103-

Uniformity test admixture 1999, IS

b) Ash Content 6925-1973

c) Relative density

d) Chloride content

e) PH Value

13 NDT Test a) Hammer Test third party test 2 times during Tech specs, Test P C C/W

construction work- IS 13311- Report

b) Cover meter Test third party test initial test can be done 1992

when progress of 25% -

c) UPV Test third party test 30% RCC work done and

final test can be done

when progress of 70-

75% RCC work

completed

14 Bricks/Blocks a) Dimensional tolerance External Lab & Random sampling from Tech specs IS Test - C W

b) Density and compressive strength site lab test 5000 nos of blocks 2185-1987 Report

c) Water absorption

15 Tiles MTC Review of MTC 100 % every Tech specs /ISMTC - C W

consignment

Physical and chemical test External lab For each source 15266:2006 (Reaffirmation

Report yr) P C C

test

16 Calibration Report a) Batching plant Lab Test Every 6 months Tech specs Report P C C/W

b) Compressive strength testing machine External lab

test

c) All Lab Equipments

17 PT Works a) HT Strands

b) Anchorages

c) Wedges

Review of MTC For each source Tech specs MTC - C C

d) Trumplate

e) GI Flat Ducts

18 PT Works - a) 25t*200 mm stroke double acting plain

Calibration Report ram center hole Mono Strand Jack External lab

For each year Tech specs Report P C C/W

test

b) Power Pack unit 7.50hp

19 PT Works - Cube compressive strength Site Lab As directed by client in-

Tech specs Report P C C/W

Grouting charge

You might also like

- Cone Penetration Testing: Methods and InterpretationFrom EverandCone Penetration Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (3)

- Name of The Work:: Quality Assurance PlanDocument21 pagesName of The Work:: Quality Assurance PlanSharat SahaNo ratings yet

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Civil SOR QAP MasterDocument12 pagesCivil SOR QAP MasterKgnconstcorediffmail.com 557786No ratings yet

- Automated Stream Analysis for Process Control V1From EverandAutomated Stream Analysis for Process Control V1Dan MankaNo ratings yet

- Lot Inspection Report For LPG New CylindersDocument3 pagesLot Inspection Report For LPG New CylindersJagannath MajhiNo ratings yet

- Qualitative Analysis of Flavor and Fragrance Volatiles by Glass Capillary Gas ChromatographyFrom EverandQualitative Analysis of Flavor and Fragrance Volatiles by Glass Capillary Gas ChromatographyNo ratings yet

- Attachment No.3-2. QIP - Shunt ReactorDocument2 pagesAttachment No.3-2. QIP - Shunt ReactorEdciel EbuenNo ratings yet

- CE 200L Report 3Document13 pagesCE 200L Report 3Hayden Chappelear-Robbins100% (1)

- Labs - For SolitacDocument3 pagesLabs - For Solitacluis valdezNo ratings yet

- Job Safety Analysis Form HydrotestDocument4 pagesJob Safety Analysis Form HydrotestMarvin BerrensteinNo ratings yet

- Esco Micro Pte. Ltd. - Co. Reg No.: 198400165W - 21 Changi South Street 1, Singapore 486777Document6 pagesEsco Micro Pte. Ltd. - Co. Reg No.: 198400165W - 21 Changi South Street 1, Singapore 486777rajNo ratings yet

- Form QAS TES 07 (Permintaan Pengujian Battery)Document1 pageForm QAS TES 07 (Permintaan Pengujian Battery)Bella FebiolitaNo ratings yet

- Job Safety Analysis Form HydrotestDocument3 pagesJob Safety Analysis Form Hydrotestyayongjcs100% (4)

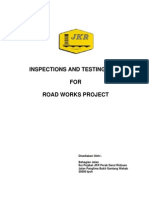

- ITP Projek JalanDocument14 pagesITP Projek Jalanzindha100% (1)

- JLL Quality Test Reports & Checklists - CivilDocument55 pagesJLL Quality Test Reports & Checklists - CivilN.PrabhuNo ratings yet

- Vdocuments - MX Quality Assurance in Peb Pre Engineered Steel BuildingsDocument1 pageVdocuments - MX Quality Assurance in Peb Pre Engineered Steel Buildingsvelmurug_balaNo ratings yet

- Powergrid Corporation of India Limited: Standard Field Quality Plan For Switchyard Civil WorksDocument18 pagesPowergrid Corporation of India Limited: Standard Field Quality Plan For Switchyard Civil WorksPremBhushanNo ratings yet

- QCR RegisteregisterDocument19 pagesQCR Registeregisterchitranjan4kumar-8No ratings yet

- Field Quality PlanDocument8 pagesField Quality PlanJaydip NathNo ratings yet

- 021 Itp For Site Preparation and Earth Works PDFDocument2 pages021 Itp For Site Preparation and Earth Works PDFKhyle Laurenz DuroNo ratings yet

- Quality Assurance Plan: Pre-Engineered Steel BuildingDocument3 pagesQuality Assurance Plan: Pre-Engineered Steel BuildingsivakumarNo ratings yet

- Sample Quality Assurance Plan For Nuts ANNEXURE-1Document2 pagesSample Quality Assurance Plan For Nuts ANNEXURE-1x yNo ratings yet

- Inspection Test Plan For Building Materials Name of Project: Material: Cement - Opc 53 GradeDocument9 pagesInspection Test Plan For Building Materials Name of Project: Material: Cement - Opc 53 GradeMohammed Abdul BaseerNo ratings yet

- GeotechDocument242 pagesGeotechAkhilesh Kumar SinghNo ratings yet

- Quality Assurance Plan For Inert Ceramic Ball (Al2O3:90%)Document3 pagesQuality Assurance Plan For Inert Ceramic Ball (Al2O3:90%)Satyanneshi ERNo ratings yet

- Condition: GatchDocument4 pagesCondition: GatchSampath Kumar KandasamyNo ratings yet

- Quality Control Laboratory ManualDocument77 pagesQuality Control Laboratory Manualparvez100% (1)

- L&T QapDocument2 pagesL&T Qapsriram.5230No ratings yet

- Test ReportDocument1 pageTest Reportq.khalid.mNo ratings yet

- PM IS 1364 Part 1 April 2020Document9 pagesPM IS 1364 Part 1 April 2020jyoti prakash singhNo ratings yet

- Hashemi2020 Article AnInclusiveConsistencyCheckProDocument21 pagesHashemi2020 Article AnInclusiveConsistencyCheckProshakouri1370_8902064No ratings yet

- Testing Procedure For SHP EquipmentsDocument7 pagesTesting Procedure For SHP EquipmentsKoushik DeyNo ratings yet

- NDT Basics GuideDocument29 pagesNDT Basics Guideravindra_jivaniNo ratings yet

- Tata Consulting Engineers Limited Minimum Inspection Requirements For Butterfly ValvesDocument2 pagesTata Consulting Engineers Limited Minimum Inspection Requirements For Butterfly Valveser_sanjaypatelNo ratings yet

- ComposteadoDocument2 pagesComposteadoMagin Idelfonso TorreblancaNo ratings yet

- Quality Assurance Plan For Inert Ceramic Ball (Al2O3:90%) : Standerd SpecificationDocument1 pageQuality Assurance Plan For Inert Ceramic Ball (Al2O3:90%) : Standerd SpecificationsUPRAKASHNo ratings yet

- Grouding TestDocument8 pagesGrouding TestHân TiênNo ratings yet

- FA - Geosynthetics LaboratoryDocument43 pagesFA - Geosynthetics LaboratoryJufriadi Civil EngineeringNo ratings yet

- Well Test FinalDocument131 pagesWell Test FinalVinit AhlawatNo ratings yet

- WI-QA-02, 13 SOP For SST Operation DT 27th Feb.2019.Document3 pagesWI-QA-02, 13 SOP For SST Operation DT 27th Feb.2019.All in OneNo ratings yet

- CE 200L Report 3 - PCCDocument11 pagesCE 200L Report 3 - PCCravenringsNo ratings yet

- Routine & Acceptance Tests - InsulatorsDocument22 pagesRoutine & Acceptance Tests - InsulatorsavgNo ratings yet

- Inspection Item (Preliminary)Document10 pagesInspection Item (Preliminary)Muhammad FazilNo ratings yet

- Test Data Sheet Determination of Consistency of Standard Cement Paste Ref: IS: 4031 (P-4) - 1988, RA 2009Document8 pagesTest Data Sheet Determination of Consistency of Standard Cement Paste Ref: IS: 4031 (P-4) - 1988, RA 2009Chandan MondalNo ratings yet

- Instructions&Form For Air Jet Sieve Test - PortlandCem203&204Document3 pagesInstructions&Form For Air Jet Sieve Test - PortlandCem203&204Khairil HidayahNo ratings yet

- Concrete Quality Control ResponsibilitiesDocument5 pagesConcrete Quality Control ResponsibilitiesOzy SalatigaNo ratings yet

- Liquid Penetrant Testing (PT) Level - 2 Specific ExamDocument7 pagesLiquid Penetrant Testing (PT) Level - 2 Specific ExamMohammed Aljawhar0% (1)

- List of Aggregates TestsDocument30 pagesList of Aggregates TestsGeorges Abi JaoudeNo ratings yet

- Screenshot 2023-06-19 at 2.29.38 PMDocument76 pagesScreenshot 2023-06-19 at 2.29.38 PMMuhammad OwaisNo ratings yet

- Chapter1 Well TestingDocument51 pagesChapter1 Well TestingSebastiánRodríguezNo ratings yet

- MDR Report Tank PDFDocument11 pagesMDR Report Tank PDFWahyudi MetrizaNo ratings yet

- Standard Quality Assurance Plan For Ac MotorDocument6 pagesStandard Quality Assurance Plan For Ac MotorSonti Mani kumar100% (1)

- Type Tests On Disc Insulator Units & StringsDocument33 pagesType Tests On Disc Insulator Units & Stringssalsa222100% (8)

- Precision Metals: Qa LabDocument1 pagePrecision Metals: Qa Labpm metlabNo ratings yet

- Ee050-4-2-Re1 - Final Exam - Apu2f2008pe - QPDocument8 pagesEe050-4-2-Re1 - Final Exam - Apu2f2008pe - QPabdilrhman sulimanNo ratings yet

- Quality Management - Inspection and Test PlanDocument1 pageQuality Management - Inspection and Test PlanVIKASH RAINo ratings yet

- Dha Medical City at Dha Phase-Viii, Lahore (Main Hospital Building)Document2 pagesDha Medical City at Dha Phase-Viii, Lahore (Main Hospital Building)Hammad GilaniNo ratings yet

- Concrete and Highway MANUAL 2022 23 62Document121 pagesConcrete and Highway MANUAL 2022 23 62siddu 082No ratings yet

- Reference Manufacturing Quality Plan: For NTPC Use Review Ed by Approved byDocument4 pagesReference Manufacturing Quality Plan: For NTPC Use Review Ed by Approved byNaresh RajuNo ratings yet

- Dies & Inserts Catalog 2018 PDFDocument35 pagesDies & Inserts Catalog 2018 PDFJuan David Fuentes100% (1)

- Geo PolymerizationDocument19 pagesGeo PolymerizationAhmed EssamNo ratings yet

- Fiitjee: Talent Reward Exam - 2018Document19 pagesFiitjee: Talent Reward Exam - 2018DSNo ratings yet

- OpticsHW Ch11KeyDocument12 pagesOpticsHW Ch11KeyJane Winner100% (1)

- Broadband Drop CableDocument28 pagesBroadband Drop CableAngel LopezNo ratings yet

- FLS Coal FeederDocument17 pagesFLS Coal Feedertrung2iNo ratings yet

- Dovidovits - Geopolymer Chemistry and Applications PDFDocument33 pagesDovidovits - Geopolymer Chemistry and Applications PDFdimas dibiantara0% (1)

- Lab 3heatengine PhysicDocument3 pagesLab 3heatengine Physicapi-263500375No ratings yet

- Modal Damping Estimates From Static Load-Deflection CurvesDocument8 pagesModal Damping Estimates From Static Load-Deflection CurvesJose ManuelNo ratings yet

- Turflow Heat Exchanger High Efficiency Heat Transfer Solution-Sales BrochureDocument8 pagesTurflow Heat Exchanger High Efficiency Heat Transfer Solution-Sales BrochurePablo Angel ToiaNo ratings yet

- Rasa Rat Nasa Muc ChayaDocument8 pagesRasa Rat Nasa Muc ChayatemmNo ratings yet

- Short Note Modelling of A Crude Distillation Column: LANG', Szalp&S, G. Chikany' Kemi%Ny'Document7 pagesShort Note Modelling of A Crude Distillation Column: LANG', Szalp&S, G. Chikany' Kemi%Ny'Luis Rodriguez GonzalesNo ratings yet

- Makalah KLTDocument9 pagesMakalah KLTretnofarahd5No ratings yet

- C1130Document4 pagesC1130dinhtung2210No ratings yet

- Nov1994 Paper3 ChemistryDocument11 pagesNov1994 Paper3 ChemistrydhsNo ratings yet

- Pile Capacity APIDocument30 pagesPile Capacity APIsitti.a100% (1)

- Free EnergyDocument17 pagesFree EnergyDolih GozaliNo ratings yet

- Optical Based Non Invasive Glucometer With IoTDocument3 pagesOptical Based Non Invasive Glucometer With IoTSuwetha I GNo ratings yet

- Kinetic Aspects in The OxidationDocument5 pagesKinetic Aspects in The OxidationKatiane MesquitaNo ratings yet

- Batang GuroDocument2 pagesBatang GuroMerida BravoNo ratings yet

- Ijftr 34 (2) 137-143Document7 pagesIjftr 34 (2) 137-143Mohammad HussainNo ratings yet

- Historical Steelwork HandbookDocument80 pagesHistorical Steelwork HandbookÉmilie Riverin100% (1)

- Galaxy Surfactants - Product Range BrochureDocument15 pagesGalaxy Surfactants - Product Range BrochureTo Ra100% (4)

- NEET Syllabus 2023Document7 pagesNEET Syllabus 2023Shaik AmjadNo ratings yet

- Mark Scheme (Results) Summer 2010: IGCSE Chemistry (4335) Paper 1FDocument16 pagesMark Scheme (Results) Summer 2010: IGCSE Chemistry (4335) Paper 1FCoolman PoonNo ratings yet

- DNA Structure + Function 12-1Document31 pagesDNA Structure + Function 12-1Jalajarani AridassNo ratings yet

- Clear ShotDocument5 pagesClear ShotPrabhjeet SinghNo ratings yet

- Electromagnetic RadiationDocument5 pagesElectromagnetic Radiationprateek_goyal2091No ratings yet

- Engine Lubrication SystemsDocument8 pagesEngine Lubrication SystemsMentsnot GetuNo ratings yet