Professional Documents

Culture Documents

ASME 31.3 - 2016 VT, Ut

Uploaded by

sanketOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASME 31.3 - 2016 VT, Ut

Uploaded by

sanketCopyright:

Available Formats

ASME B31.

3-2016

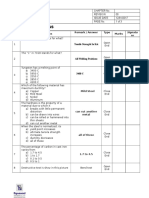

Table K341.3.2 Acceptance Criteria for Welds (16)

Criteria (A–F) for Types of Welds, and for Required Examination Methods [Note (1)]

Type of Weld

Methods

Longitudinal Branch

Type of Ultrasonics or Girth Groove Fillet Connection

Imperfection Visual Radiography Groove [Note (2)] [Note (3)] [Note (4)]

Crack ⻫ ⻫ A A A A

Lack of fusion ⻫ ⻫ A A A A

Incomplete penetration ⻫ ⻫ A A A A

Internal porosity ... ⻫ B B N/A B

Internal slag inclusion, tungsten inclusion, ... ⻫ C C N/A C

or elongated indication

Undercutting ⻫ ⻫ A A A A

Surface porosity or exposed slag inclusion ⻫ ... A A A A

Concave root surface (suck-up) ⻫ ⻫ D D N/A D

Surface finish ⻫ ... E E E E

Reinforcement or internal protrusion ⻫ ... F F F F

GENERAL NOTES:

(a) Weld imperfections are evaluated by one or more of the types of examination methods given, as specified in paras. K341.4.1 and

K341.4.2.

(b) “N/A” indicates this Chapter does not establish acceptance criteria or does not require evaluation of this kind of imperfection for this

type of weld.

(c) Check (⻫) indicates examination method generally used for evaluating this kind of weld imperfection.

(d) Ellipsis (. . .) indicates examination method not generally used for evaluating this kind of weld imperfection.

Criterion Value Notes for Table K341.3.2

Criterion

Symbol Measure Acceptable Value Limits [Note (5)]

A Extent of imperfection Zero (no evident imperfection)

B Size and distribution of internal porosity See BPV Code, Section VIII, Division 1, Appendix 4

C Internal slag inclusion, tungsten inclusion, or elon-

gated indication. Indications are unacceptable if the

amplitude exceeds the reference level, or indications

have lengths that exceed

Individual length [Note (6)] 6 mm (1⁄4 in.) for T w ≤ 19 mm (3⁄4 in.)

T w /3 for 19 mm (3⁄4 in.) < T w ≤ 57 mm (21⁄4 in.)

19 mm (3⁄4 in.) for T w > 57 mm (21⁄4 in.)

Cumulative length ≤T w in any 12 T w weld length

D Depth of root surface concavity Wall Thickness, Depth of Surface Concavity,

T w , mm (in.) mm (in.)

≤13 ( 1⁄2 ) ≤1.5 ( 1⁄16 )

>13 ( ⁄2 ) and ≤51 (2)

1

≤3 ( 1⁄8 )

>51 (2) ≤4 ( 5⁄32 )

and total joint thickness including weld reinforcement

≥T w

E Surface roughness ≤12.5 m (500 in.) Ra (see ASME B46.1 for definition of

roughness average, Ra )

F Height of reinforcement or internal protrusion [Note (7)] External Weld Reinforcement

in any plane through the weld shall be within the Wall Thickness, or Internal Weld Protrusion,

limits of the applicable height value in the tabula- T w , mm (in.) mm (in.)

tion at the right. Weld metal shall be fused with and

≤13 ( 1⁄2 ) ≤1.5 ( 1⁄16)

merge smoothly into the component surfaces.

>13 ( 1⁄2 ) and ≤51 (2) ≤3 (1⁄8 )

>51 (2) ≤4 ( 5⁄32 )

ASME B31.3-2016

(16) Table K341.3.2 Acceptance Criteria for Welds (Cont’d)

NOTES:

(1) Criteria given are for required examination. More stringent criteria may be specified in the engineering design.

(2) Longitudinal welds include only those permitted in paras. K302.3.4 and K305. The criteria shall be met by all welds, including those

made in accordance with a standard listed in Table K326.1 or in Appendix K.

(3) Fillet welds include only those permitted in para. K311.2.2.

(4) Branch connection welds include only those permitted in para. K328.5.4.

(5) Where two limiting values are given, the lesser measured value governs acceptance. T w is the nominal wall thickness of the thinner of

two components joined by a butt weld.

(6) For ultrasonic examination, refer to para. K344.6.3 for acceptable value limits.

(7) For groove welds, height is the lesser of the measurements made from the surfaces of the adjacent components. For fillet welds,

height is measured from the theoretical throat; internal protrusion does not apply. Required thickness tm shall not include

reinforcement or internal protrusion.

Examination shall be as follows: (b) When specified in the engineering design and with

(a) When the defective item or work is repaired, the the owner’s approval, ultrasonic examination of welds

repaired portion of the item or work shall be examined. may be substituted for radiographic examination where

The examination shall use the same methods and accept- T w ≥ 13 mm (1⁄2 in.).

ance criteria employed for the original examination. See (c) In-process examination (see para. 344.7) shall not

also para. K341.3.1(a). be substituted for radiographic or ultrasonic examina-

(b) When the defective item or work is replaced, the tion of welds.

new item or work used to replace the defective item or

K341.4.3 Certifications and Records. Paragraph

work shall be examined. The examination shall use any

341.4.1(c) applies.

method and applicable acceptance criteria that meet the

requirements for the original examination. See also K341.5 Supplementary Examination

para. K341.3.1(a).

Any of the examination methods described in para.

K341.4 Extent of Required Examination K344 may be specified by the engineering design to

Piping shall be examined to the extent specified herein supplement the examination required by para. K341.4.

or to any greater extent specified in the engineering The extent of supplementary examination to be per-

design. formed and any acceptance criteria that differ from those

specified in para. K341.3.2 shall be specified in the engi-

K341.4.1 Visual Examination neering design.

(a) The requirements of para. 341.4.1(a) apply with the

following exceptions in regard to extent of examination: K341.5.1 Hardness Tests. Paragraph 341.5.2

(1) Materials and Components. 100%. applies.

(2) Fabrication. 100%. K341.5.2 Examinations to Resolve Uncertainty.

(3) Threaded, Bolted, and Other Joints. 100%. Paragraph 341.5.3 applies.

(4) Piping Erection. All piping erection shall be

examined to verify dimensions and alignment. Supports,

guides, and points of cold spring shall be checked to K342 EXAMINATION PERSONNEL (16)

ensure that movement of the piping under all conditions Paragraph 342 applies in its entirety.

of startup, operation, and shutdown will be accom-

modated without undue binding or unanticipated

constraint. K343 EXAMINATION PROCEDURES (16)

(b) Pressure-Containing Threads. 100% examination for Paragraph 343 applies, except that the examination

finish and fit is required. Items with visible imperfec- methods shall comply with para. K344.

tions in thread finish and/or the following defects shall

be rejected:

(1) Tapered Threads. Failure to meet gaging require- K344 TYPES OF EXAMINATION

ments in API Spec 5B or ASME B1.20.1, as applicable. K344.1 General

(2) Straight Threads. Excessively loose or tight fit Paragraphs 344.1.1 and 344.1.2 apply. In para. 344.1.3,

when gaged for light interference fit. terms other than “100% examination” apply only to

K341.4.2 Radiographic and Ultrasonic Examination supplementary examinations.

(a) All girth, longitudinal, and branch connection

welds shall be 100% radiographically examined, except K344.2 Visual Examination

as permitted in (b) below. Paragraph 344.2 applies in its entirety.

You might also like

- Early Signs of AutismDocument27 pagesEarly Signs of AutismErica Alejandra Schumacher100% (1)

- NDT Acceptance Criteria PDFDocument2 pagesNDT Acceptance Criteria PDFamit84indNo ratings yet

- ASME B31 3 Acceptance Criteria Tab 341-3-2ADocument2 pagesASME B31 3 Acceptance Criteria Tab 341-3-2Aadel100% (1)

- Welding Rod Selection 2 PDFDocument1 pageWelding Rod Selection 2 PDFPrior Drake89% (9)

- Welding Rod Selection 2 PDFDocument1 pageWelding Rod Selection 2 PDFPrior Drake89% (9)

- API 1169 - Prep Test #3: Written by Dale Honn, P.E., P.L.SDocument45 pagesAPI 1169 - Prep Test #3: Written by Dale Honn, P.E., P.L.SHeartyscorpionNo ratings yet

- WPS for Urea Reclaimer Butt Joint WeldingDocument1 pageWPS for Urea Reclaimer Butt Joint Weldingasirul_meNo ratings yet

- API 510 Study GuideDocument3 pagesAPI 510 Study GuidedanikakaNo ratings yet

- 32 Samss 007Document38 pages32 Samss 007sanketNo ratings yet

- CALCULATIONS SUMMARY SHEET GUIDEDocument2 pagesCALCULATIONS SUMMARY SHEET GUIDEcrackrojoNo ratings yet

- Acceptance Criteria for Welds Visual and Radiographic ExaminationDocument3 pagesAcceptance Criteria for Welds Visual and Radiographic ExaminationerboalNo ratings yet

- Api 510 QuizletDocument6 pagesApi 510 QuizletMahmoud Alwasif100% (1)

- Fuel System D28Document4 pagesFuel System D28Ian MuhammadNo ratings yet

- 12) Api 510 Day 4Document67 pages12) Api 510 Day 4hamedNo ratings yet

- API-570 - Data Sheets (2018 Test)Document6 pagesAPI-570 - Data Sheets (2018 Test)mahmoud alwasif100% (1)

- CBT Questions-1Document2 pagesCBT Questions-1kumarNo ratings yet

- In Servicepressurevesselinspectionaccordingtoapi 51010theditionoverview 180328042225 PDFDocument33 pagesIn Servicepressurevesselinspectionaccordingtoapi 51010theditionoverview 180328042225 PDFKrishna Vacha100% (2)

- API 510 Course Puspatri Apr 09Document185 pagesAPI 510 Course Puspatri Apr 09ahmedelhajNo ratings yet

- ASME B16.5 practice questions and answersDocument66 pagesASME B16.5 practice questions and answersAbdul Qhadeer AnsariNo ratings yet

- ASME IX Welding Qualification RequirementsDocument33 pagesASME IX Welding Qualification RequirementsBabel THIAMNo ratings yet

- API570Document4 pagesAPI570Rajesh ManoharanNo ratings yet

- Ultrasonic Inspection Velocity TableDocument2 pagesUltrasonic Inspection Velocity TableCesar Tochukwu NwokoNo ratings yet

- API 510 - Day 1: G T Technical & Management Institute PVT - LTD.Document109 pagesAPI 510 - Day 1: G T Technical & Management Institute PVT - LTD.fathiNo ratings yet

- 1 API 653 Memories Sept 2012Document20 pages1 API 653 Memories Sept 2012majid100% (1)

- 1 6Document58 pages1 6Emiliano.Armando Aguilera.Vázquez100% (1)

- API 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationDocument8 pagesAPI 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationmelvinNo ratings yet

- API 570 Exame Questions Dated 5 July 2018Document10 pagesAPI 570 Exame Questions Dated 5 July 2018Ahmed ShakirNo ratings yet

- AWS D1.1-D1.1M-2015 (WeldingWorld) 250Document1 pageAWS D1.1-D1.1M-2015 (WeldingWorld) 250Ali Clubist100% (1)

- Asme B31.3 Open & Closed Book (165 Q&A) (For Api 570 & Si Examinations)Document28 pagesAsme B31.3 Open & Closed Book (165 Q&A) (For Api 570 & Si Examinations)nani356No ratings yet

- 17 Multiple Choice Questions: No Answer GivenDocument5 pages17 Multiple Choice Questions: No Answer GivenAnonymous Q4YUvRNo ratings yet

- Plumbing Refresher CourseDocument44 pagesPlumbing Refresher CourseRomyr0% (1)

- Preguntas Practicas ASME B31.3Document25 pagesPreguntas Practicas ASME B31.3Andres BermudezNo ratings yet

- Wa0000.Document207 pagesWa0000.Ahmed Shakir100% (1)

- Api 570 - 02 Asme B 31.3Document12 pagesApi 570 - 02 Asme B 31.3Mohammad RawoofNo ratings yet

- All You Need To Know About API 571 Corrosion and MaterialsDocument13 pagesAll You Need To Know About API 571 Corrosion and MaterialsMasood KhanNo ratings yet

- Interview QuestionsDocument5 pagesInterview Questionsavinash1987100% (1)

- 1 Engg DBD PP 010Document19 pages1 Engg DBD PP 010sanketNo ratings yet

- API 510 Preparatory Training Key PointsDocument3 pagesAPI 510 Preparatory Training Key PointsshakeelahmadjsrNo ratings yet

- API-570 SAMPLE Closed Book ExamDocument12 pagesAPI-570 SAMPLE Closed Book ExamuttamNo ratings yet

- API 510 Case Study - 7Document2 pagesAPI 510 Case Study - 7Khaled FatnassiNo ratings yet

- Api 570 272-395Document56 pagesApi 570 272-395nancyNo ratings yet

- API 510 Pressure Vessel Inspector: Training Description Training ObjectivesDocument6 pagesAPI 510 Pressure Vessel Inspector: Training Description Training ObjectivesPrashant KumarNo ratings yet

- Submerged Arc Welding (Saw)Document5 pagesSubmerged Arc Welding (Saw)Nnaji Chukwuma SlamNo ratings yet

- Acceptable Std. For NDTDocument4 pagesAcceptable Std. For NDTHarshaVeeragandhamNo ratings yet

- ASME Plant Inspector Level 1 BoK: Inspection KnowledgeDocument5 pagesASME Plant Inspector Level 1 BoK: Inspection KnowledgeNnamdi Celestine NnamdiNo ratings yet

- Case Study - 7: Numerical in API 510 CodeDocument4 pagesCase Study - 7: Numerical in API 510 CodeVishal BailurNo ratings yet

- Cswip Div 9 03 General Inspector 4th Edition Jan 2008Document12 pagesCswip Div 9 03 General Inspector 4th Edition Jan 2008obinnaNo ratings yet

- Sis Book1Document99 pagesSis Book1Hamza AlamNo ratings yet

- Sis Book Asme IxDocument107 pagesSis Book Asme IxHamza AlamNo ratings yet

- (PDF) PRACTICE QUESTIONS FOR API RP 577 Quizlet - Gustavo HC - Academia - EduDocument4 pages(PDF) PRACTICE QUESTIONS FOR API RP 577 Quizlet - Gustavo HC - Academia - EduKumar R100% (1)

- API 510 vessel inspection standardsDocument2 pagesAPI 510 vessel inspection standardsHemaNo ratings yet

- Decibel Nde Training Institute Offers NDT CoursesDocument1 pageDecibel Nde Training Institute Offers NDT CoursesSangeeth.KpNo ratings yet

- 3.4 Arc Length: The Distance From The Tip of The WeldingDocument7 pages3.4 Arc Length: The Distance From The Tip of The WeldingMohammed IlliasuddinNo ratings yet

- API577 IDC Weld Inspect Aug15 PDFDocument7 pagesAPI577 IDC Weld Inspect Aug15 PDFMohamad AzuwanNo ratings yet

- Answer Key For The Inspector's Calc's ExercisesDocument4 pagesAnswer Key For The Inspector's Calc's ExercisesHeartyscorpionNo ratings yet

- API RP 577 Welding InspectionDocument7 pagesAPI RP 577 Welding InspectionLuthfi ArdiansyahNo ratings yet

- 17 Multiple Choice QuestionsDocument3 pages17 Multiple Choice QuestionsAnonymous Q4YUvR100% (1)

- Corrosion and Cathodic Protection in PipelinesDocument3 pagesCorrosion and Cathodic Protection in PipelinesPavan_yoyoNo ratings yet

- ASME P-NumbersDocument9 pagesASME P-NumbersAamer MohammedNo ratings yet

- API 653 - 577 Flash Cards - 62 QuestionsDocument8 pagesAPI 653 - 577 Flash Cards - 62 QuestionsSERFORTEC CIA. LTDA.No ratings yet

- Introduction To API 571Document13 pagesIntroduction To API 571M. Nasikhun WahidinNo ratings yet

- QM 05. Line PipesDocument2 pagesQM 05. Line Pipesmohamed elmasryNo ratings yet

- Section 6 B31.3 330 Preheating: Haward Technology Middle East 1 Section 6Document37 pagesSection 6 B31.3 330 Preheating: Haward Technology Middle East 1 Section 6Mohamed ElsayedNo ratings yet

- Api 577Document1 pageApi 577HIIOJGFNo ratings yet

- ASME Sec VIII d1 Ma App 8Document2 pagesASME Sec VIII d1 Ma App 8fuihiufhNo ratings yet

- MCE Welder Performance Qualification ReportDocument2 pagesMCE Welder Performance Qualification ReporthamidjoyiaNo ratings yet

- API 653 PC 15may04 Exam 2 ClosedDocument8 pagesAPI 653 PC 15may04 Exam 2 ClosedShaalan AliNo ratings yet

- TABLA ASME - B31.3 - Ed.2018 (001-269) (114-117)Document4 pagesTABLA ASME - B31.3 - Ed.2018 (001-269) (114-117)ANDRES LOPEZNo ratings yet

- AR NED - Offer List - 18.11.201500138Document1 pageAR NED - Offer List - 18.11.201500138sanketNo ratings yet

- Sorry: Please Downloa DDocument1 pageSorry: Please Downloa DsanketNo ratings yet

- 575 ReviewDocument4 pages575 ReviewjasminneeNo ratings yet

- 1 SS PP 005Document18 pages1 SS PP 005sanketNo ratings yet

- Document Inspection and Test PlanDocument5 pagesDocument Inspection and Test PlansanketNo ratings yet

- 1 SS MT 006Document44 pages1 SS MT 006sanketNo ratings yet

- Calibration Certi DFT Gauge - Paint Report Lot 02Document6 pagesCalibration Certi DFT Gauge - Paint Report Lot 02sanketNo ratings yet

- BTC Welding Cons JSWDocument6 pagesBTC Welding Cons JSWsanketNo ratings yet

- 1 Engg DBD ST 010Document11 pages1 Engg DBD ST 010sanketNo ratings yet

- API 650 Tank Design ReviewDocument1 pageAPI 650 Tank Design ReviewjasminneeNo ratings yet

- Api-1169 Pipeline Construction Inspector: Body of KnowledgeDocument9 pagesApi-1169 Pipeline Construction Inspector: Body of KnowledgeKhalilahmad KhatriNo ratings yet

- Asmesection Viii-Div-1& 2Document7 pagesAsmesection Viii-Div-1& 2sanketNo ratings yet

- Witness Inspection and Test PlanDocument5 pagesWitness Inspection and Test PlansanketNo ratings yet

- DFGDGGHFGHJJJ: Excellent Satisfactory Below Satisfactory NODocument2 pagesDFGDGGHFGHJJJ: Excellent Satisfactory Below Satisfactory NOsanketNo ratings yet

- DFGDGGHFGHJJJDGDGDG: Excellent Satisfactory Below Satisfactory NODocument2 pagesDFGDGGHFGHJJJDGDGDG: Excellent Satisfactory Below Satisfactory NOsanketNo ratings yet

- Pipe Fitting Dimantion and ScheduleDocument1 pagePipe Fitting Dimantion and SchedulesanketNo ratings yet

- Muscles Anatomy: Singleg GlutebridgDocument1 pageMuscles Anatomy: Singleg GlutebridgsanketNo ratings yet

- Aws D1.1-D1.1M (R) - 2015 2Document1 pageAws D1.1-D1.1M (R) - 2015 2sanketNo ratings yet

- 350 Master CanDocument113 pages350 Master CanSangeeth.KpNo ratings yet

- Ultrasound VelocityDocument1 pageUltrasound VelocitymmNo ratings yet

- AWS D1.1-D1.1M (R) - 2015 RT PDFDocument5 pagesAWS D1.1-D1.1M (R) - 2015 RT PDFsanketNo ratings yet

- New Microsoft Office Word DocumentDocument1 pageNew Microsoft Office Word DocumentsanketNo ratings yet

- Oxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupsDocument6 pagesOxygen Level in Purging Gas During Welding of Duplex Stainless Steel - Google GroupssanketNo ratings yet

- New Microsoft Office Word DocumentDocument1 pageNew Microsoft Office Word DocumentsanketNo ratings yet

- Atlas Tool Specs SummaryDocument3 pagesAtlas Tool Specs SummaryWaleed Barakat MariaNo ratings yet

- Prac - 2Document3 pagesPrac - 2nv471646No ratings yet

- ZV Class Links @Medliferesuscitation-CopyDocument31 pagesZV Class Links @Medliferesuscitation-CopyDebajyoti DasNo ratings yet

- 4a. PAE Ch-4a. Project-AnalysisDocument15 pages4a. PAE Ch-4a. Project-AnalysisProf. Dr. Anbalagan ChinniahNo ratings yet

- Drug Study Pre OpDocument6 pagesDrug Study Pre OpgiaNo ratings yet

- We Think About Rotary Valve ReliabilityDocument8 pagesWe Think About Rotary Valve ReliabilityAhmed KhairyNo ratings yet

- Microeconomics 5th Edition Hubbard Solutions Manual 1Document23 pagesMicroeconomics 5th Edition Hubbard Solutions Manual 1christina100% (48)

- Technical Information Bulletins Ajax # 010717Document28 pagesTechnical Information Bulletins Ajax # 010717harley florezNo ratings yet

- EfAD BenchmarkJune2005 UKDocument55 pagesEfAD BenchmarkJune2005 UKCristina Dobrin ClaudiaNo ratings yet

- Penyakit Palpebra Dan AdneksaDocument39 pagesPenyakit Palpebra Dan AdneksaayucicuNo ratings yet

- P1007 PPPS For Raw Milk 1AR SD3 Cheese Risk AssessmentDocument304 pagesP1007 PPPS For Raw Milk 1AR SD3 Cheese Risk AssessmentNicholasNo ratings yet

- Intermediate Alloy Steels Properties and SpecificationsDocument15 pagesIntermediate Alloy Steels Properties and Specificationsanon_558118723100% (1)

- Barangay Ordinance Vaw 2018Document7 pagesBarangay Ordinance Vaw 2018barangay artacho1964 bautista100% (3)

- Smartphone Technician Cum App Tester: Trade PracticalDocument218 pagesSmartphone Technician Cum App Tester: Trade PracticalF ZaidiNo ratings yet

- 2016 Ruptured Pseudoaneurysm of The Middle Meningeal ArteryDocument5 pages2016 Ruptured Pseudoaneurysm of The Middle Meningeal ArteryJulio Cesar Velasco CastroNo ratings yet

- Campus Waste Lab Proposal To Substitute Single-Use Plastic With Paper Products and Plastic Utensils For BambooDocument14 pagesCampus Waste Lab Proposal To Substitute Single-Use Plastic With Paper Products and Plastic Utensils For Bambooapi-529878933No ratings yet

- Oplan Nena (Violation of RA 10364 Expanded Anti-Trafficking in Person Act of 2012)Document3 pagesOplan Nena (Violation of RA 10364 Expanded Anti-Trafficking in Person Act of 2012)Jhunary MunarNo ratings yet

- 6th Class EM All LessonsDocument33 pages6th Class EM All LessonsSathish PurushothamNo ratings yet

- Moot CourtDocument7 pagesMoot CourtsushmaNo ratings yet

- Weekly Home Learning Plan: Grade 8 - Quarter 2. Week 7Document3 pagesWeekly Home Learning Plan: Grade 8 - Quarter 2. Week 7Danmer Jude TorresNo ratings yet

- Q 400 SYSTEM BestDocument9 pagesQ 400 SYSTEM BestTeddy EshteNo ratings yet

- Gimnazjum Exam Practice GuideDocument74 pagesGimnazjum Exam Practice GuideVaserd MoasleNo ratings yet

- Writing About Emotional Experiences As A Therapeutic Process PDFDocument6 pagesWriting About Emotional Experiences As A Therapeutic Process PDFOscarNo ratings yet

- Arthropods: A Guide to the Diverse PhylumDocument10 pagesArthropods: A Guide to the Diverse Phylumpkkalai112No ratings yet

- An Island To Oneself - Suvarov, Cook Islands 2Document8 pagesAn Island To Oneself - Suvarov, Cook Islands 2Sándor TóthNo ratings yet

- Community Medicine DissertationDocument7 pagesCommunity Medicine DissertationCollegePaperGhostWriterSterlingHeights100% (1)

- Computed Tomography (CT) - BodyDocument7 pagesComputed Tomography (CT) - Bodyfery oktoraNo ratings yet