Professional Documents

Culture Documents

VEFV1100 - Flange Face Alignment

Uploaded by

khsaeed0 ratings0% found this document useful (0 votes)

81 views1 pageflange Face Alignment

Original Title

VEFV1100_flange Face Alignment

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentflange Face Alignment

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

81 views1 pageVEFV1100 - Flange Face Alignment

Uploaded by

khsaeedflange Face Alignment

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

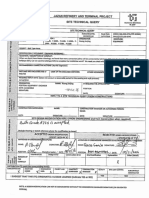

PROCESS INDUSTRY PRACTICES

FABRICATION/INSTALLATION DETAILS

VESSEL; TOLERANCES

VEFV1102

JDRAWING DATE: 05/01/08

REAFFIRMED

PAGE 1 OF 2

(ELEVATION)

PRACT REF VEFIION

1. HEIGHT FROM BASE LINE TO FACE

OF TOP Nore

B]be

@

3

*

5

4

"7" ALIGNMENT OF FLANGE FACE OF NOZZLE” SHALL BE

MESELID "CLASS A+ GAS &

® ay tye ae

seo cra She Ye

sie

26

27

28

+ CLASS A AND CLASS 8 TOLERANCES WLL BE GOVERNED

BY THE TYPE OF TRAY SPECIFIED. THIS INFORMATION

WLL BE PER THE TRAY SPECICATION’ SHEET /HYDRAULECS,

20,

THESE TOLERANCES APPLY TO VERTICAL & HORZONTAL

VESSELS EXCEPT AS OTHERWISE NOTED ON VESSEL

DRAWNG/DATA SHEET RELATING TO SPECIFIC. VESSELS,

0

NOZZLES FOR” AGITATOR MOUNTING SHALL. HAVE.

FLANGE FACE ALIGNED WITHIN 1/4 DEG. OF SPECIED

DISTANGE FROM BOTTOM TO TOP OF TRAY SUPPORTS 4 1/6"

WEIR HEIGHT 4. 1/16" MEASURED AT HIGH POINT OF WEIR

VERTICAL CLEARANCE UNDER DOWNFLOW PLATE. FOR

INSTALLED TRAYS 41/16"

FACE OF NOZZIF To. CENTERUNE OF VESSEL & 1/8"

‘will 1/2_DEG_OF SPECIFIED PLANE.

LOCATION OF SHELL NOZZLES FROM BASE UNE SHALL

‘BC = 1/4" FOR SHOP FABRICATED VESSELS OR SUD

ASSEMBLES AND & 1/2" FOR FIELD ASSEMBLED

VESSELS, WHEN LOCATON IS SPECIFIED FROM OTHER

REFERENCE POINTS, TOLERANCE SHALL BE 1/5"

“ALIGNMENT OF FLANGE FACE OF MANWAY SHALL GE

WITHIN DEO, OF SPECIFIED PLANE,

FACE OF MANWAY 10. CENTERLINE OF VESSEL =172"

LOCATION ‘OF MANWAYS FROM BASE UNE SHALL BE

41/2" FOR SHOP FABRICATED VESSELS AND SUB~

ASSEMBLIES AND £1" FOR FIELD ASSEMBLED VESSELS.

BOTTOM OF VESSEL SUPPORT TO BASE LINE. +0" 1/32"

BER FOOT OF VESSEL DIAMETER, 1/2" MAX

FOR SUPPORTS LOCATED ABOVE GASEUNE, TOLERANCES

SHALL BE 10",-1/32" PER FOOT OF VESSEL IA,4/2" MAX.

ALIGNMENT OF” CHLINORICAL SHELL SECTIONS SHALL. BE

TRUE AND STRAIGHT WITHIN 0.01" PER FOOT OF HEIGHT

FROM BASE LNE BUT SHALL NOT EXCEED 3/4"

MIGHPONT TO LOW-PONT OF INSTALLED TRAY LEVEL,

AND PLANE WITHIN THE FOLLOWING:

> 120" s

FAR SDE OF TOWER TO WEIR PLAY & 1/8"

IWEIRS SHALL BE LEVEL WITHIN’ 1/16" FROW A LEVEL

PLANE AT THE MIDPONT OF THE WER,

TRAY SPACNG 1/8"

LOCATION OF TRAY PLATES FROM BASE LINE 21/8"

DEVIATION FROM AVERAGE 1.0. (AS DETERMINED BY

STRAPPING) FROM NOMINAL 1D. 1/4" ASME. CODE

SECTION Wil TO APPLY TO OUT~OF-ROUNONESS EXCEP

WHEN NOTED OTHERWISE.

PIPE-OR WALKWAY SUPPORTS AND STRUCTURAL

ATTACHMENTS. TO, VESSEL CENTERUNE 1/8";

BASE UNE 1/4"

LOCATION OF HORIZONTAL, VESSEL SUPPORT FROM

VESSEL CENTERLNES 40". 1/8"

LOeATION OF HORIZONTAL VeSSéL” SUPPORTS FROM

BASE UNE # 1/4"; SUPPORTS LOCATED FROM

OTHER REFERENCE FONTS 41/8"

BASE UNE SHALL BE 1/4"

UGHT CENTER PUNCH WARK (WITH A ROUND NOSE

STAMP) THE PRINCIPAL CENTER LINES SHOWN ON

ORIENTATION PLAN. CRCLE PUNCH MARKS WH

PAINT TO. DESIGNATE LOCATION,

SUPPORTS. OUT OF LEVEL OVER ANY DIAMETER THE

GREATER OF 1/8" Of 4 0.02" PER FOOT OF

VESSEL DIAMETER, 5/8" MAX,

BOLT HOLES WITHIN 1/8” OF SPECIFIED LOCATION

IF BOTTOM FLANGE IS USED AS FOOT BEARING

MOUNT AND WITH AGITATOR MOUNTING FLANGE

HORIZONTAL, CENTER OF TOP FLANGE SHALL FALL

WTHIN 0.025" PER FOOT (OF DISTANCE BETWEEN

FLANGE FACES) OF CENTER OF BOTTOM FLANGE” AND

OTTOM FLANGE SHALL BE NOT MORE” THAN 1/4 DEC,

OFF HORIZONTAL.

HORIZONTAL CLEARANCE BETWEEN OOWNFLOW PLATE

AND TOP OF INLET WEIR 1/16"

FOR POST SUPPORTED TRAYS, CLEARANCE. BETWEEN

TRAY COLLAR AND SHELL OOS" MAX. OVER. 90% OF

CIRCUMFERENCE, + 1/16" MAX. OVER REMANNG. 10%

se

Fie

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Khaled Saeed PMP Udemy Certificate 5Document1 pageKhaled Saeed PMP Udemy Certificate 5khsaeedNo ratings yet

- 1509111888361Document2 pages1509111888361khsaeedNo ratings yet

- Ch01-Introduction - ExamDocument7 pagesCh01-Introduction - Examkhsaeed100% (1)

- ITP CommentsDocument1 pageITP CommentskhsaeedNo ratings yet

- Hidada Safety OrientationDocument1 pageHidada Safety OrientationkhsaeedNo ratings yet

- V D43 K 1801A 0002 - P&I Diagram LegendDocument2 pagesV D43 K 1801A 0002 - P&I Diagram LegendkhsaeedNo ratings yet

- J20-F-1500-047 - R1 ModelDocument1 pageJ20-F-1500-047 - R1 ModelkhsaeedNo ratings yet

- SER STR No Mark No FLOW TYPE ITEMS NO. Qty. Unit Wt Tot Wt COMMENTS MATING STRUCTURE R F PaintDocument2 pagesSER STR No Mark No FLOW TYPE ITEMS NO. Qty. Unit Wt Tot Wt COMMENTS MATING STRUCTURE R F PaintkhsaeedNo ratings yet

- Cases Weights Item Number NO Net KG Gross KG Item Number Pieces Description Internal Paint Last Status (16 AprilDocument1 pageCases Weights Item Number NO Net KG Gross KG Item Number Pieces Description Internal Paint Last Status (16 AprilkhsaeedNo ratings yet

- Trfg-Aoc-l-72204 Intergen VPR 1004012290 July 2017Document5 pagesTrfg-Aoc-l-72204 Intergen VPR 1004012290 July 2017khsaeedNo ratings yet

- V D43 K 1801A 0002 - P&I Diagram LegendDocument2 pagesV D43 K 1801A 0002 - P&I Diagram LegendkhsaeedNo ratings yet

- Check My TripDocument2 pagesCheck My TripkhsaeedNo ratings yet

- 32 SAMSS 004 - Flange Face AlignmentDocument1 page32 SAMSS 004 - Flange Face AlignmentkhsaeedNo ratings yet

- V D43 K 1801A 0050 Gear DrawingsDocument2 pagesV D43 K 1801A 0050 Gear DrawingskhsaeedNo ratings yet

- Customer PoDocument1 pageCustomer PokhsaeedNo ratings yet

- Two Commonly Asked Soft Foot QuestionsDocument2 pagesTwo Commonly Asked Soft Foot QuestionskhsaeedNo ratings yet

- My Old IqamaDocument1 pageMy Old IqamakhsaeedNo ratings yet

- Tile CastingDocument1 pageTile CastingkhsaeedNo ratings yet

- Meeting Agenda August 22Document1 pageMeeting Agenda August 22khsaeedNo ratings yet

- EPC10-11 Contact ListDocument11 pagesEPC10-11 Contact Listkhsaeed50% (2)

- Aramco Weekly MeetingDocument1 pageAramco Weekly MeetingkhsaeedNo ratings yet

- Breeching Rotation PDFDocument1 pageBreeching Rotation PDFkhsaeedNo ratings yet

- Breeching Rotation PDFDocument1 pageBreeching Rotation PDFkhsaeedNo ratings yet

- Release Note: Date 26-06-2015 Project P02220 Jazan Refinery and Terminal ProjectDocument3 pagesRelease Note: Date 26-06-2015 Project P02220 Jazan Refinery and Terminal ProjectkhsaeedNo ratings yet

- Sin Eqt STQ 00 0640Document1 pageSin Eqt STQ 00 0640khsaeedNo ratings yet

- 3D - View: Seal Weld With BreachingDocument1 page3D - View: Seal Weld With BreachingkhsaeedNo ratings yet

- Packing List Burners (101-102)Document1 pagePacking List Burners (101-102)khsaeedNo ratings yet

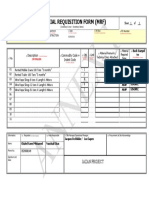

- Construction Material Requisition FormDocument1 pageConstruction Material Requisition FormkhsaeedNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)