Professional Documents

Culture Documents

A. Z-Purlin (ASD) Design Example B. C - Girt (ASD) Design Example

Uploaded by

michel92748Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A. Z-Purlin (ASD) Design Example B. C - Girt (ASD) Design Example

Uploaded by

michel92748Copyright:

Available Formats

STANDARDS SECONDARY PURLINS

and STRUCTURAL and

PRACTICES DESIGN GIRTS

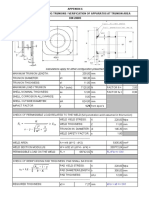

APPENDIX EX1 1

a. Z- Purlin (ASD) Design Example

b. C- Girt (ASD) Design Example

The following design example is intended to illustrate the design of continuous Z-

purlins and simple C-girts and in accordance with the 2001/04 AISI Specification using

U.S.A. ASD design provisions.

1 Entire section 4.1.EX1 has been fully re-written

VP DESIGN MANUAL Section: 4.1.EX1

BUILDINGS 03/01/06 Rev. 1 Page 1 of 20

STANDARDS SECONDARY PURLINS

and STRUCTURAL and

PRACTICES DESIGN GIRTS

a. 8 ½" Continuous Z-Purlin Design Example – Gravity Load

Given:

1. Four span continuous 8½" Z-purlin system as shown below:

W (LC 1 = 1.0 LL + 1.0 DL )

1’-6” 3’-0” 1’-6”1’-6” 3’-0” 1’-6”

Lap

8.5 Z - 0.082” 8.5 Z - 0.073” 8.5 Z - 0.073” 8.5 Z - 0.082”

1’-0” 24’-0” 25’-0” 25’-0” 24’-0” 1’-0”

2. VP SSR Standing Seam Roof covering attached to purlins.

3. Building geometry: 60' wide x 100' long, eave height 20' and roof slope 1:12.

4. 2003 IBC Code. Wind 90 mph, Ground Snow = 10 psf, LL = 30 psf non-reducible.

5. VP Command Design printout for the endbay purlin, Load Case1:

Secondary Designs for Shape 2a1 on Side A

Design Id 2, Segment 1 is Continuous with a 0.082 Thickness, Detail Lap = 48, Design Lap = 36, Configuration II

Secondary Unfactored Loads

Shape Units Type Description Mag1 Loc1 Mag2 Loc2 Supp. Dir. Coef. Add Loc.

Web

LN plf D Covering Weight - 24 SSR : Roof: A -5.65 0/0/0 -5.65 25/0/0 N IN 1.000 N CL

LN plf L Live - Not Reducible : Roof: A -150.00 0/0/0 -150.00 25/0/0 N IN 1.000 N CL

LN plf S Snow : Roof: A -31.50 0/0/0 -31.50 25/0/0 N IN 1.000 N CL

LN plf *US1 Snow : Roof: A -63.00 0/0/0 -63.00 25/0/0 N IN 2.000 N CL

LN plf PF1 Snow : Roof: A - Partial, Full, Span 1 -31.50 0/0/0 -31.50 25/0/0 N IN 1.000 N CL

LN plf PF1 Snow : Roof: A - Partial, Full, Span 4 -15.75 0/0/0 -15.75 25/0/0 N IN 0.500 N CL

LN plf PH1 Snow : Roof: A - Partial, Half, Span 1 -15.75 0/0/0 -15.75 25/0/0 N IN 0.500 N CL

LN plf PH1 Snow : Roof: A - Partial, Half, Span 4 -31.50 0/0/0 -31.50 25/0/0 N IN 1.000 N CL

LN plf PF2 Snow : Roof: A - Partial, Full, Span 1 and 2 -31.50 0/0/0 -31.50 25/0/0 N IN 1.000 N CL

LN plf PF2 Snow : Roof: A - Partial, Full, Span 2 and 3 -15.75 0/0/0 -15.75 25/0/0 N IN 0.500 N CL

LN plf PF2 Snow : Roof: A - Partial, Full, Span 3 and 4 -15.75 0/0/0 -15.75 25/0/0 N IN 0.500 N CL

LN plf W1> Wind - Parts:Side Zone 1 : Roof: A 101.74 0/0/0 101.74 8/0/0 N OUT -1.280 N CL

LN plf <W2 Wind - Parts:Side Zone 1 : Roof: A -50.00 0/0/0 -50.00 8/0/0 N IN 0.629 N CL

LN plf W1> Wind - Parts:Interior Area : Roof: A 85.84 8/0/0 85.84 25/0/0 N OUT -1.080 N CL

LN plf <W2 Wind - Parts:Interior Area : Roof: A -50.00 8/0/0 -50.00 25/0/0 N IN 0.629 N CL

Secondary Design

Actual Forces Allowable Forces Stress Condition

Seg Loc. Load Axial Shear Moment Axial Shear Moment % % % % % %

No. (ft) Case (k) (k) (in-k) (k) (k) (in-k) Bnd Shear Bnd+Ax Bnd+Shr Bnd+Wcp Wcp

1 0.00 1 0.00 -0.00 0.00 9.79 6.36 99.69 0.00 0.00 0.00 0.00 0.00 0.00

1 1.00 1 0.00 -0.16 -0.96 9.79 6.36 71.78 0.01 0.03 0.01 0.03 0.48 0.71

1 1.00 1 0.00 1.46 -0.96 9.79 6.36 71.78 0.01 0.23 0.01 0.23 0.48 0.71

1 23.50 1 0.00 -2.14 -93.20 9.79 6.36 99.69 0.93 0.34 0.93 0.99 0.00 0.00

1 10.17 1 0.00 -0.01 78.62 9.79 6.36 81.28 0.97 0.00 0.97 0.79 0.00 0.00

1 23.50 1 0.00 -2.14 -93.20 18.42 10.84 184.04 0.51 0.20 0.51 0.54 0.00 0.00

1 25.00 1 0.00 -2.38 -133.91 18.42 10.84 184.04 0.73 0.22 0.73 0.76 0.90 0.84

Secondary Design Member Section Properties

Seg Loc. Depth Thick. Shp Len Area Rx Ry Lx Ly-1 Ly-2 Klx Kly1 Kly2 Sx Lb1 Lb2 Cb1 Cb2 R-f1 R-f2

No. (ft) (in.) (in.) (ft) (in.2) (in.) (in.) (in.) (in.) (in.) Rx Ry Ry in.3 (in.) (in.)

1 0.00 8.50 0.082 Z 25.00 1.21 3.26 1.25 300.00 12.0 0.0 82.82 9.6 0.0 3.03 12.0 0.0 2.30 0.00 1.00 1.00

1 1.00 8.50 0.082 Z 25.00 1.21 3.26 1.25 300.00 12.0 1.0 82.82 9.6 0.8 3.03 12.0 1.0 2.30 2.18 0.72 0.82

1 1.00 8.50 0.082 Z 25.00 1.21 3.26 1.25 300.00 12.0 1.0 82.82 9.6 0.8 3.03 12.0 1.0 2.30 2.18 0.72 0.82

1 23.50 8.50 0.082 Z 25.00 1.21 3.26 1.25 300.00 18.0 6.0 82.82 14.4 4.8 3.03 52.0 18.0 1.76 1.14 1.00 1.00

1 10.17 8.50 0.082 Z 25.00 1.21 3.26 1.25 300.00 48.0 0.0 82.82 38.4 0.0 3.03 48.0 0.0 1.01 0.00 1.00 1.00

1 23.50 8.50 0.082 Z 25.00 2.29 3.27 1.25 300.00 18.0 6.0 82.64 14.4 4.8 5.59 52.0 18.0 1.76 1.14 1.00 1.00

1 25.00 8.50 0.082 Z 25.00 2.29 3.27 1.25 300.00 12.0 12.0 82.64 9.6 9.6 5.59 18.0 36.0 1.14 1.28 1.00 1.00

VP DESIGN MANUAL Section: 4.1.EX1

BUILDINGS 03/01/06 Rev. 1 Page 2 of 20

STANDARDS SECONDARY PURLINS

and STRUCTURAL and

PRACTICES DESIGN GIRTS

Load Case 1: Gravity 1.0 LL + 1.0 DL

Live Load = 30 psf non-reducible @ 5’

-0”space = 150.00 plf

Span Element LL 1.0 LL Load Distribution Total Purlin Load

All Live Load 150 plf 150 plf 0’– 100’= (100’

) 15,000 lbs.

Σ (1.0 LL) = 15,000 lbs.

Dead Loads = Panel and Purlin Self Weight

Span Element DL 1.00 DL Load Distribution Total Purlin Load

1 0.082”Z 4.12 plf 4.12 plf 0 – 28’= (28’

) 115.36 lbs.

2 0.073”Z 3.66 plf 3.66 plf 23.5’– 51.5’= (28’

) 102.48 lbs.

3 0.073”Z 3.66 plf 3.66 plf 48.5’– 76.5’= (28’

) 102.48 lbs

4 0.082”Z 4.12 plf 4.12 plf 72’– 100’= (28’

) 115.36 lbs.

All 24 Ga. SSR 5.65 plf 5.65 plf 0’– 100’= (100’

) 565.00 lbs.

Σ (1.0 DL) = 1,001 lbs.

Σ (1.0 LL+ 1.0 DL) = 16.00 kips

Compare total loads applied to purlin reactions. Purlin reactions are not readily

available in vp command, however, may be obtained by summing the shear forces.

Σ (Reactions) = Σ (Shears) = ( 0.16 + 1.46 )FL1 + ( 2.38 + 2.15 ) FL2 + ( 1.85 + 1.85 ) FL3 +

( 2.38 + 2.15 ) FL4 + ( 0.16 + 1.46 ) FL5

Σ (Reactions) = 15.96 kips --- OK

VP DESIGN MANUAL Section: 4.1.EX1

BUILDINGS 03/01/06 Rev. 1 Page 3 of 20

STANDARDS SECONDARY PURLINS

and STRUCTURAL and

PRACTICES DESIGN GIRTS

Applied Loads, Moments, Shears and Reactions for Case 1

Unfactored Loads: 150 plf

Live

4.12 plf 7.78 plf 7.32 plf

3.66 plf

Purlin Dead

Symmetrical

5.65 plf

Panel Dead

1’-6” Lap 3’-0” 1’-6” Lap 1’-6”

8.5 Z-0.082” 8.5 Z-0.073”

1’-0” 24’-0” 25’-0”

Reaction 1.62 k 4.53 k 3.70 k

`

Inflection

78.62 k-in. 5.83’ 5.87’ 4.29’

0.06’ 38.31 k-in.

Moment

-0.96 k-in. -93.20 k-in. -65.36 k-in.

-90.03 k-in.

-133.91 k-in.

2.38 k

1.61 k 1.85 k

2.14 k

Shear 0.16 k

-1.46 k -2.15 k -1.66 k

VP DESIGN MANUAL Section: 4.1.EX1

BUILDINGS 03/01/06 Rev. 1 Page 4 of 20

STANDARDS SECONDARY PURLINS

and STRUCTURAL and

PRACTICES DESIGN GIRTS

Design Verification – Gravity Load Case

Location • : End Support

Bending, Shear, Web Crippling, Combined Bending and Shear and Combined Bending

and Web Crippling design checks are required at the exterior supports. The

compression flange (inside) either side of the support is assumed to be fully braced

due to short unbraced lengths (Ly < 12”).

M= - 0.96 k-in.

Bending Strength ref. AISI C3.1.1 •

Mn 8.5”Z - 0.082”

( 8.5Z − 0.082" ) = 99.69 kip − in. ref. DM 4.2.S, Table S1

b

R =1.62 k

Stress Ratio = M = 0.96 = 0.01 < 1.0 OK VR = 1.46 k

( Mn b) 99.69

Note: VP Command incorrectly utilizes the positive moment-uplift R-Factor = 0.72 (SSR System II, 1:12)

which is being applied to the nominal moment capacity resulting in an allowable moment of (0.73)x 99.69

= 71.78 k-in. . This is conservative and does not impact results.

Web Crippling Strength ref. AISI C3.4.1

Pn

( 8.5Z − 0.082" ) = 1.85 kip ref. DM 4.2.S, Table S7, End Loading

w

= 1.23 ref. DM 4.2.S, Table S9, Overhang Coefficient

Pn

= 1.23 (1.85 kip) = 2.28 kip

w

Stress Ratio = P = 1.62 = 0.71 < 1.0 OK

Pn 2.28

( )

w

Combined Bending and Web Crippling Strength ref. 2004 AISI C3.5.1, Eq. C3.5.1- 1

Pn (8.5Z − 0.082" ) = 3.235 kip ref. DM 4.2S, Table S6

Mn (8.5Z − 0.082" ) = 166.485 kip - in. ref. DM 4.2S, Table S1

P = 1.62 kip, M = 0.96 kip - in.

0.91 P

P

+ M

n n

(

M = 0.91 1.62 1.23[3.235 ] + 0.96 166.485 = 0.376 < [

1.33

= 1.7

)

= 0.782 ] OK

Stress Ratio = 0.376 = 0.48

0.782

Shear Strength ref. AISI C3.2.1

Vn

(8.5Z - 0.082" ) = 6.36 kips ref. DM 4.3.S, Table S5

v

Stress Ratio = V = 1.46 = 0.23 < 1.0 OK

( Vn v) 6.36

VP DESIGN MANUAL Section: 4.1.EX1

BUILDINGS 03/01/06 Rev. 1 Page 5 of 20

STANDARDS SECONDARY PURLINS

and STRUCTURAL and

PRACTICES DESIGN GIRTS

Combined Bending and Shear ref. 2004 AISI C3.3.1, Eq. C3.3.2 - 1

2 2

b M v V

2 2

=

0.96 1.46

+ + = 0.23 < 1.0 OK

M

nxo Vn 99.69 6.36

Location ‚ : End Span @ Maximum Positive Moment

Bending design checks are required at this location. The compression flange (outside)

is partially braced by the SSR Standing Seam roof requiring the use of tested R-factors

per AISI C3.1.4.

M = 78.62 k-in.

‚

Bending Strength ref. AISI C3.1.4

8.5”Z - 0.082”

8.5Z - 0.082" , SSR Configuration II required

R = 0.425 Tanθ + 0.78 = 0.425 (1/12) + 0.78 = 0.8154 ref. DM 4.2

Mn = R S eFy = 0.8154 (3.027 in.3 ) (55 ksi) = 135.75 kip − in. ref. AISI Eq. C3.1.3 - 1

Mn

= 135.75 = 81.29 kip − in.

b 1.67

Stress Ratio = M = 78.62 = 0.97 < 1.0 OK

(Mn b) 81.29

Note: SSR Configuration II is required per design. (2)- “X”braced sags are required 6’

-0”apart, centered

on the purlin, every other purlin space.

Location ƒ : End Span @ End of Lap

Bending, Shear and Combined Bending and Shear Design checks are required at the

end of the lap. The compression flange (inside) is unbraced between the end of the

purlin lap and the inflection point. Reference AISI Section C3.1.2.1 Lateral-Torsional

Buckling Strength.

5.83’

18”

8.5”Z - 0.082” 8.5”Z - 0.073

ƒ

M = -93.20 k-in.

V = 2.14 k

VP DESIGN MANUAL Section: 4.1.EX1

BUILDINGS 03/01/06 Rev. 1 Page 6 of 20

STANDARDS SECONDARY PURLINS

and STRUCTURAL and

PRACTICES DESIGN GIRTS

Bending Strength ref. AISI C3.1.2.1

L y = distance between end of lap and inflection

L y = 5.82' (12) − 18" = 51.84"

2

Cb E d I yc

Fe = ref. AISI Eq. C3.1.2.1 − 15

(

2S f K y L y )2

I yc = 0.952 in.4 , S f = 3.034 in.3 , S e = 3.027 in.3 ref. DM 20.1.1

Cb = 1.77 from design printout

VP DESIGN MANUAL Section: 4.1.EX1

BUILDINGS 03/01/06 Rev. 1 Page 7 of 20

STANDARDS SECONDARY PURLINS

and STRUCTURAL and

PRACTICES DESIGN GIRTS

2

(1.76) (29500) (8.5) (0.952)

Fe = = 255.12 ksi

2 (3.034) (51.84 )

2

Fe = 255.12 > (2.78 Fy = 152.90)

∴ Fc = Fy = 55 ksi ref. AISI Eq. C3.1.2.1 − 1

VPC conservatively assumes : S c = S e = 3.027 in.3

Mn = S cFc = (3.027)(55 ) = 166.485 kip − in.

Mn

= 166.485 = 99.69 kip − in.

b 1.67

Stress Ratio = M = 93.20 = 0.93 < 1.0 OK

(Mn b) 99.69

Note: By referencing Table S3 of DM 4.2S an unbraced length up to

L y = (4'−2" ) Cb = (4'−2" ) 1.76 = 5.53' will provide full bending moment capacity.

Shear Strength ref. AISI C3.2.1

Vn

(8.5Z - 0.082" ) = 6.36 kips ref. DM 4.3.S, Table S5

v

Stress Ratio = V = 2.14 = 0.34 < 1.0 OK

( Vn v) 6.36

Combined Bending and Shear ref. 2004 AISI C3.3.1, Eq. C3.3.2 - 1

2 2

b M v V

2 2

=

93.20 2.14

+ + = 0.99 < 1.0 OK

M

nxo Vn 99.69 6.36

Location „ : First Interior Support

Bending, Shear, Web Crippling, Combined Bending and Shear and Combined Bending

and Web Crippling Design checks are required at the interior support. The

compression flange (inside) within the lapped area is assumed fully supported.

Bending Strength ref. AISI C3.1.1 5.83’

18”

Mn

( 8.5Z - 0.082" ) = 99.69 kip − in. ref. DM 4.2.S, Table S1

b

8.5”Z - 0.082” 8.5”Z - 0.073”

Mn

( 8.5Z - 0.073" ) = 84.34 kip − in. ref. DM 4.2.S, Table S1

b M = -133.91 k-in.

@ Lapped Purlin : Mn b = 184.03 kip − in. VL = 2.38 k „

R = 4.53 k

Stress Ratio = M = 133.91 = 0.73 < 1.0 OK

Mn b 184.03

VP DESIGN MANUAL Section: 4.1.EX1

BUILDINGS 03/01/06 Rev. 1 Page 8 of 20

STANDARDS SECONDARY PURLINS

and STRUCTURAL and

PRACTICES DESIGN GIRTS

Web Crippling Strength AISI C3.4.1

Pn

( 8.5Z - 0.082" ) = 3.03 kip ref. DM 4.2.S, Table S7, Int. Loading

w

Pn

( 8.5Z - 0.073" ) = 2.34 kip ref. DM 4.2.S, Table S7, Int. Loading

w

@ Lapped Purlun : Pn w = 5.37 kip

Stress Ratio = P = 4.53 = 0.84 < 1.0 OK

Pn w 5.37

Shear Strength AISI C3.2.1

Vn

( 8.5Z - 0.082" ) = 6.36 kip ref. DM 4.2.S, Table S5

v

Vn

( 8.5Z - 0.073" ) = 4.48 kip ref. DM 4.2.S, Table S5

v

@ Lapped Purlins : Vn v = 10.84 kip

Stress Ratio = P = 2.38 = 0.22 < 1.0 OK

Vn v 10.84

Combined Bending and Web Crippling Strength ref. 2004 AISI C3.5.1, Eq. C3.5.1- 3

Pn (8.5Z − 0.082" ) = 5.007 kip ref. DM 4.2S, Table S7, Interior

Pn (8.5Z − 0.073" ) = 3.867 kip ref. DM 4.2S, Table S7, Interior

@ Lapped Purlins : ∑ Pn = 8.874 kip

Mn (8.5Z − 0.082" ) = 166.485 kip - in. ref. DM 4.2S, Table S1

Mn (8.5Z − 0.073" ) = 140.855 kip - in. ref. DM 4.2S, Table S1

@ Lapped Purlins : ∑ Mn = 307.34 kip note : Mn = Mnxo

P = 4.53 kip, M = 133.91 kip - in.

0.86 P

∑

+ M

Pn ∑

Mn

(

= 0.86 4.53

8.874

) (

+ 133.91

307.34

)

= 0.87 < [

1.65

= 1.7

= 0.97 ] OK

Stress Ratio = 0.87 = 0.90

0.97

Combined Bending and Shear ref. 2004 AISI C3.3.1, Eq. C3.3.2 - 1

2 2

bM V 2 2

=

133.91 2.38

+ v

+ = 0.76 < 1.0 OK

M Vn

nxo 184.03 10.84

VP DESIGN MANUAL Section: 4.1.EX1

BUILDINGS 03/01/06 Rev. 1 Page 9 of 20

STANDARDS SECONDARY PURLINS

and STRUCTURAL and

PRACTICES DESIGN GIRTS

8 ½" Continuous Z-Purlin Design Example – Wind Load

Given:

1. Four span continuous 8½" Z-purlin system as shown below:

W (LC 12 = 1.0 W>1 + 1.0 DL )

1’-6” 3’-0” 1’-6”1’-6” 3’-0” 1’-6”

Lap

8.5 Z - 0.082” 8.5 Z - 0.073” 8.5 Z - 0.073” 8.5 Z - 0.082”

1’-0” 24’-0” 25’-0” 25’-0” 24’-0” 1’-0”

2. VP SSR Standing Seam Roof covering attached to purlins.

3. Building geometry: 60' wide x 100' long, eave height 20' and roof slope 1:12.

4. 2003 IBC Code. Wind 90 mph, Ground Snow = 10 psf, LL = 30 psf non-reducible.

5. VP Command Design printout for the endbay purlin, Load Case12:

Secondary Designs for Shape 2a1 on Side A

Design Id 2, Segment 1 is Continuous with a 0.082 Thickness, Detail Lap = 48, Design Lap = 36

Secondary Unfactored Loads

Shape Units Type Description Mag1 Loc1 Mag2 Loc2 Supp. Dir. Coef. Add Loc.

Web

LN plf D Covering Weight - 24 SSR : Roof: A -5.65 0/0/0 -5.65 25/0/0 N IN 1.000 N CL

LN plf L Live - Not Reducible : Roof: A -150.00 0/0/0 -150.00 25/0/0 N IN 1.000 N CL

LN plf S Snow : Roof: A -31.50 0/0/0 -31.50 25/0/0 N IN 1.000 N CL

LN plf *US1 Snow : Roof: A -63.00 0/0/0 -63.00 25/0/0 N IN 2.000 N CL

LN plf PF1 Snow : Roof: A - Partial, Full, Span 1 -31.50 0/0/0 -31.50 25/0/0 N IN 1.000 N CL

LN plf PF1 Snow : Roof: A - Partial, Full, Span 4 -15.75 0/0/0 -15.75 25/0/0 N IN 0.500 N CL

LN plf PH1 Snow : Roof: A - Partial, Half, Span 1 -15.75 0/0/0 -15.75 25/0/0 N IN 0.500 N CL

LN plf PH1 Snow : Roof: A - Partial, Half, Span 4 -31.50 0/0/0 -31.50 25/0/0 N IN 1.000 N CL

LN plf PF2 Snow : Roof: A - Partial, Full, Span 1 and 2 -31.50 0/0/0 -31.50 25/0/0 N IN 1.000 N CL

LN plf PF2 Snow : Roof: A - Partial, Full, Span 2 and 3 -15.75 0/0/0 -15.75 25/0/0 N IN 0.500 N CL

LN plf PF2 Snow : Roof: A - Partial, Full, Span 3 and 4 -15.75 0/0/0 -15.75 25/0/0 N IN 0.500 N CL

LN plf W1> Wind - Parts:Side Zone 1 : Roof: A 101.74 0/0/0 101.74 8/0/0 N OUT -1.280 N CL

LN plf <W2 Wind - Parts:Side Zone 1 : Roof: A -50.00 0/0/0 -50.00 8/0/0 N IN 0.629 N CL

LN plf W1> Wind - Parts:Interior Area : Roof: A 85.84 8/0/0 85.84 25/0/0 N OUT -1.080 N CL

LN plf <W2 Wind - Parts:Interior Area : Roof: A -50.00 8/0/0 -50.00 25/0/0 N IN 0.629 N CL

Secondary Design

Actual Forces Allowable Forces Stress Condition

Seg Loc. Load Axial Shear Moment Axial Shear Moment % % % % % %

No. (ft) Case (k) (k) (in-k) (k) (k) (in-k) Bnd Shear Bnd+Ax Bnd+Shr Bnd+Wcp Wcp

1 0.00 12 0.00 0.00 -0.00 9.79 6.36 99.69 0.00 0.00 0.00 0.00 0.00 0.00

1 1.00 12 0.00 0.09 0.55 9.79 6.36 67.03 0.01 0.01 0.01 0.02 0.00 0.00

1 1.00 12 0.00 -0.78 0.55 9.79 6.36 67.03 0.01 0.12 0.01 0.12 0.00 0.00

1 23.50 12 0.00 1.04 45.65 9.79 6.36 67.03 0.68 0.16 0.68 0.49 0.00 0.00

1 9.83 12 0.00 0.00 -39.68 9.79 6.36 51.84 0.77 0.00 0.77 0.00 0.00 0.00

1 23.50 12 0.00 1.04 45.65 18.42 10.84 123.74 0.37 0.10 0.37 0.27 0.00 0.00

1 25.00 12 0.00 1.15 65.35 18.42 10.84 123.74 0.53 0.11 0.53 0.37 0.00 0.00

Secondary Design Member Section Properties

Seg Loc. Depth Thick. Shp Len Area Rx Ry Lx Ly-1 Ly-2 Klx Kly1 Kly2 Sx Lb1 Lb2 Cb1 Cb2 R-f1 R-f2

No. (ft) (in.) (in.) (ft) (in.2) (in.) (in.) (in.) (in.) (in.) Rx Ry Ry in.3 (in.) (in.)

1 0.00 8.50 0.082 Z 25.00 1.21 3.26 1.25 300.00 12.0 0.0 82.82 9.6 0.0 3.03 12.0 0.0 2.30 0.00 1.00 1.00

1 1.00 8.50 0.082 Z 25.00 1.21 3.26 1.25 300.00 12.0 1.0 82.82 9.6 0.8 3.03 12.0 1.0 2.30 2.16 1.00 1.00

1 1.00 8.50 0.082 Z 25.00 1.21 3.26 1.25 300.00 12.0 1.0 82.82 9.6 0.8 3.03 12.0 1.0 2.30 2.16 1.00 1.00

1 23.50 8.50 0.082 Z 25.00 1.21 3.26 1.25 300.00 18.0 6.0 82.82 14.4 4.8 3.03 18.0 6.0 1.19 1.05 1.00 1.00

1 9.83 8.50 0.082 Z 25.00 1.21 3.26 1.25 300.00 48.0 0.0 82.82 38.4 0.0 3.03 217.0 0.0 1.13 0.00 0.52 0.67

1 23.50 8.50 0.082 Z 25.00 2.29 3.27 1.25 300.00 18.0 6.0 82.64 14.4 4.8 5.59 18.0 6.0 1.19 1.05 1.00 1.00

1 25.00 8.50 0.082 Z 25.00 2.29 3.27 1.25 300.00 12.0 12.0 82.64 9.6 9.6 5.59 12.0 12.0 1.09 1.08 1.00 1.00

VP DESIGN MANUAL Section: 4.1.EX1

BUILDINGS 03/01/06 Rev. 1 Page 10 of 20

STANDARDS SECONDARY PURLINS

and STRUCTURAL and

PRACTICES DESIGN GIRTS

Load Case 12: Wind Uplift 1.0 W1> + 1.0 DL

Basic Wind Load = 8.13 psf

Zone 1 (0 to 8’

): -15.90 psf * 1.28 = -20.352 psf @ 5’ -0”space = -101.76 plf

Zone 2 (8’to 92’ ): - 15.90 psf * 1.08 = -17.172 psf @ 5’

-0”space = -85.86 plf

Span Element WL 1.0 WL Load Distribution Total Purlin Load

Zone I Purlins -101.74 plf -101.74 plf 0’– 8’& 92’

-100’ -1,628 lbs.

Zone II Purlins -85.84 plf -85.84 plf 8’– 92’ -7,211 lbs.

Σ (1.0 WL) = -8,839 lbs.

Dead Loads = Panel and Purlin Self-Weight

Span Element DL 1.00 DL Load Distribution Total Purlin Load

1 0.082”Z 4.12 plf 4.12 plf 0 – 28’= (28’

) 115.36 lbs.

2 0.073”Z 3.66 plf 3.66 plf 23.5’– 51.5’= (28’

) 102.48 lbs.

3 0.073”Z 3.66 plf 3.66 plf 48.5’– 76.5’= (28’

) 102.48 lbs

4 0.082”Z 4.12 plf 4.12 plf 72’– 100’= (28’

) 115.36 lbs.

All 24 Ga. SSR 5.65 plf 5.65 plf 0’– 100’= (100’

) 565.00 lbs.

Σ (1.0 DL) = 1,001 lbs.

Σ (1.0 DL + 1.0W ) = 7.84 kips

Compare total loads applied to purlin reactions. Purlin reactions are not readily

available in vp command, however, may be obtained by summing the shear forces.

Σ (Reactions) = Σ (Shears) = ( 0.09 + 0.78 )FL1 + ( 1.15 + 1.02 ) FL2 + ( 0.87 + 0.87 ) FL3 +

( 1.15 + 1.02 ) FL4 + ( 0.09 + 0.78 ) FL5

Σ (Reactions) = - 7.82 kips --- OK

VP DESIGN MANUAL Section: 4.1.EX1

BUILDINGS 03/01/06 Rev. 1 Page 11 of 20

STANDARDS SECONDARY PURLINS

and STRUCTURAL and

PRACTICES DESIGN GIRTS

Applied Loads, Moments, Shears and Reactions for Case 12

Unfactored Loads:

-101.74 plf`

-85.84 plf

Wind

8’-0”

4.12 plf 7.78 plf 7.32 plf

3.66 plf

Purlin Dead

Symmetrical

5.65 plf

Panel Dead

1’-6” Lap 3’-0” 1’-6” Lap 1’-6”

8.5 Z-0.082” 8.5 Z-0.073”

1’-0” 24’-0” 25’-0”

Reaction - 0.87 k - 2.17 k - 1.74 k

`

Inflection

-39.68 k-in. 5.92’ 7.02’

0.07’ - 18.17 k-in.

Moment

+ 0.55 k-in. + 45.65 k-in. + 32.50 k-in.

+ 42.45 k-in.

+ 65.35 k-in.

- 1.15 k

- 0.76 k - 0.87 k

- 1.04 k

- 0.09 k

Shear

+ 0.78 k + 1.02 k + 0.80 k

VP DESIGN MANUAL Section: 4.1.EX1

BUILDINGS 03/01/06 Rev. 1 Page 12 of 20

STANDARDS SECONDARY PURLINS

and STRUCTURAL and

PRACTICES DESIGN GIRTS

Design Verification -- Wind Load Case

Location • : End Support

Bending, Shear and Combined Bending and Shear design checks are required at the

exterior supports. The compression flange (outside) either side of the support is

assumed to be fully braced due to short unbraced lengths (Ly < 12”).

M= + 0.55 k-in.

Bending Strength ref. AISI C3.1.1

•

Mn

( 8.5Z − 0.082" ) = 99.69 kip − in. ref. DM 4.2.S, Table S1 8.5”Z - 0.082”

b

Stress Ratio = M = 0.55 = 0.006 < 1.0 OK R =- 0.87 k

( Mn b) 99.69

VR = - 0.78 k

Note: VP Command incorrectly utilizes the negative moment R-Factor = 0.673 (SSR System I, 1:12)

which is being applied to the nominal moment capacity resulting in an allowable moment of (0.673)x

99.69 = 67.09 . This is conservative and does not impact results.

Shear Strength ref. AISI C3.2.1

Vn

(8.5Z - 0.082" ) = 6.36 kips ref. DM 4.3.S, Table S5

v

Stress Ratio = V = 0.78 = 0.12 < 1.0 OK

( Vn v) 6.36

Combined Bending and Shear ref. 2004 AISI C3.3.1, Eq. C3.3.2 - 1

2 2

b M v V

2 2

=

0.55 0.78

+ + = 0.12 < 1.0 OK

M

nxo Vn 99.69 6.36

Location ‚ : End Span @ Maximum Negative Moment

Bending design checks are required at this location. The compression flange (inside) is

partially braced by the SSR Standing Seam roof requiring the use of tested R-factors

per AISI C3.1.4.

M = - 39.68 k-in.

Bending Strength ref. AISI C3.1.4 ‚

8.5Z - 0.082" , SSR Configuration I (uplift) required 8.5”Z - 0.082”

R = 0.52 ref. DM 4.1

Mn = R S eFy = 0.52 (3.027 in.3 ) (55 ksi) = 86.57 kip − in. ref. AISI Eq. C3.1.3 - 1

Mn

= 86.57 = 51.84 kip − in.

b 1.67

Stress Ratio = M = 39.68 = 0.77 < 1.0 OK

(Mn b) 51.84

VP DESIGN MANUAL Section: 4.1.EX1

BUILDINGS 03/01/06 Rev. 1 Page 13 of 20

STANDARDS SECONDARY PURLINS

and STRUCTURAL and

PRACTICES DESIGN GIRTS

Note: SSR Configuration II was required for gravity load design.

Location ƒ : End Span @ End of Lap

Bending, Shear and Combined Bending and Shear Design checks are required at the

end of the lap. The compression flange (outside) is unbraced between the end of the

purlin lap and the inflection point. Reference AISI Section C3.1.2.1 Lateral-Torsional

Buckling Strength.

5.92’

18”

Bending Strength ref. AISI C3.1.2.1

L y = distance between end of lap and inflection 8.5”Z - 0.082” 8.5”Z - 0.073

ƒ

L y = 5.92' (12) − 18" = 53.04"

M = +45.65 k-in.

2

Cb E d I yc V = - 1.04 k

Fe = ref. AISI Eq. C3.1.2.1 − 15

(

2S f K y L y )2

I yc = 0.952 in.4 , S f = 3.034 in.3 , S e = 3.027 in.3 ref. DM 20.1.1

Cb = 1.19 from design printout

2

(1.19) (29500) (8.5) (0.952)

Fe = = 164.24 ksi

2 (3.034) (53.04 )

2

Fe = 164.24 > (2.78 Fy = 152.90)

∴ Fc = Fy = 55 ksi ref. AISI Eq. C3.1.2.1 − 2

VPC conservatively assumes : Sc = S e = 3.027 in.3

Mn = ScFc = (3.027)(55 ) = 166.485 kip − in.

Mn

= 166.485 = 99.69 kip − in.

b 1.67

Stress Ratio = M = 45.65 = 0.46 < 1.0 OK

(Mn b) 99.69

Note: VP Command incorrectly utilizes the negative moment R-Factor = 0.673 (SSR System I, 1:12)

which is being applied to the nominal moment capacity resulting in an allowable moment of (0.673)x

99.69 = 67.09 . This is conservative.

Shear Strength ref. AISI C3.2.1

Vn

(8.5Z - 0.082" ) = 6.36 kips ref. DM 4.3.S, Table S5

v

Stress Ratio = V = 1.04 = 0.16 < 1.0 OK

( Vn v) 6.36

VP DESIGN MANUAL Section: 4.1.EX1

BUILDINGS 03/01/06 Rev. 1 Page 14 of 20

STANDARDS SECONDARY PURLINS

and STRUCTURAL and

PRACTICES DESIGN GIRTS

Combined Bending and Shear ref. 2004 AISI C3.3.1, Eq. C3.3.2 - 1

2 2

b M v V

2 2

=

45.65 1.04

+ + = 0.49 < 1.0 OK

M

nxo Vn 99.69 6.36

Location „ : First Interior Support

Bending, Shear, and Combined Bending and Shear design checks are required at the

interior support. The compression flange (outside) within the lapped area is assumed

fully supported.

Bending Strength ref. AISI C3.1.1 5.92’

Mn 18”

( 8.5Z - 0.082" ) = 99.69 kip − in. ref. DM 4.2.S, Table S1

b

Mn 8.5”Z - 0.082” 8.5”Z - 0.073”

( 8.5Z - 0.073" ) = 84.34 kip − in. ref. DM 4.2.S, Table S1

b

M = + 65.35 k-in.

@ Lapped Purlin : Mn b = 184.03 kip − in. VL = 1.15 k „

R = 2.17 k

Stress Ratio = M = 65.35 = 0.36 < 1.0 OK

Mn b 184.03

Note: VP Command incorrectly utilizes the negative moment R-Factor = 0.673 (SSR System I, 1:12)

which is being applied to the nominal moment capacity resulting in an allowable moment of (0.673)x

184.03 = 123.85 . This is conservative.

Shear Strength AISI C3.2.1

Vn

( 8.5Z - 0.082" ) = 6.36 kip ref. DM 4.2.S, Table S5

v

Vn

( 8.5Z - 0.073" ) = 4.48 kip ref. DM 4.2.S, Table S5

v

@ Lapped Purlins : Vn v = 10.84 kip

Stress Ratio = P = 1.15 = 0.11 < 1.0 OK

Vn v 10.84

Combined Bending and Shear ref. 2004 AISI C3.3.1, Eq. C3.3.2 - 1

2 2

bM V 2 2

=

65.35 1.15

+ v

+ = 0.37 < 1.0 OK

M Vn

nxo 184.03 10.84

VP DESIGN MANUAL Section: 4.1.EX1

BUILDINGS 03/01/06 Rev. 1 Page 15 of 20

STANDARDS SECONDARY PURLINS

and STRUCTURAL and

PRACTICES DESIGN GIRTS

b. 8 ½" Simple C-Girt Design Example – Wind Suction Load

Given:

1. Four simple span 8½" C- girt system as shown below:

W ( LC 1 = 1.0 W1> )

8.5 C - 0.092” 8.5 C - 0.105” 8.5 C - 0.105” 8.5 C - 0.092”

1’-0” 24’-0” 25’-0” 25’-0” 24’-0” 1’-0”

2. VP Panel Rib Wall covering attached to girts.

3. Building geometry: 175' wide x 100' long, eave height 20' and roof slope 1:12.

4. 2003 IBC. Wind = 90 mph, Ground Snow = 10 psf, LL = 30 psf non-reducible.

5. VP Command Design printout for the sidewall, interior bay girt, Load Case1:

Design Id 2, Segment 2 is Simple with a 0.082 Thickness

Secondary Unfactored Loads

Shape Units Type Description Mag1 Loc1 Mag2 Loc2 Supp. Dir. Coef. Add Loc.

Web

LN plf W1> Wind - Parts:Interior Area : Wall: 2 64.40 0/0/0 64.40 25/0/0 N OUT -0.960 N CL

LN plf <W2 Wind - Parts:Interior Area : Wall: 2 -58.37 0/0/0 -58.37 25/0/0 N IN 0.870 N CL

Secondary Design

Actual Forces Allowable Forces Stress Condition

Seg Loc. Load Axial Shear Moment Axial Shear Moment % % % % % %

No. (ft) Case (k) (k) (in-k) (k) (k) (in-k) Bnd Shear Bnd+Ax Bnd+Shr Bnd+Wcp Wcp

2 25.00 1 0.00 -0.81 0.00 1.90 6.36 63.37 0.00 0.13 0.00 0.00 0.00 0.00

2 50.00 1 0.00 0.81 0.00 1.90 6.36 63.37 0.00 0.13 0.00 0.00 0.00 0.00

2 37.50 1 0.00 0.00 -60.38 1.90 6.36 63.37 0.95 0.00 0.95 0.00 0.00 0.00

Secondary Design Member Section Properties

Seg Loc. Depth Thick. Shp Len Area Rx Ry Lx Ly-1 Ly-2 Klx Kly1 Kly2 Sx Lb1 Lb2 Cb1 Cb2 R-f1 R-f2

No. (ft) (in.) (in.) (ft) (in.2) (in.) (in.) (in.) (in.) (in.) Rx Ry Ry in.3 (in.) (in.)

2 25.00 8.50 0.082 C 25.00 1.21 3.22 0.94 300.00 12.0 12.0 93.17 12.8 12.8 2.96 287.0 300.0 1.13 1.14 0.65 1.00

2 50.00 8.50 0.082 C 25.00 1.21 3.22 0.94 300.00 24.0 24.0 93.17 25.5 25.5 2.96 300.0 300.0 1.14 1.14 0.65 1.00

2 37.50 8.50 0.082 C 25.00 1.21 3.22 0.94 300.00 24.0 0.0 93.17 25.5 0.0 2.96 300.0 0.0 1.14 0.00 0.65 1.00

Load Case 1: Wind Uplift 1.0 W1> (wind suction)

Basic Wind Load = -15.90 psf

Zone 2: -15.90 psf * 0.960 = -15.264 psf

7’

-5 ¼”Girt Load Trib. = (3’-5 ¼”+ 5’ -0”) / 2 = 4.2188’(note – 4’

-0”wind girt added)

W = 4.2188’(-15.264 psf) = - 64.40 plf

Span Element WL 1.5 WL Load Distribution Total Purlin Load

Zone II Girts -64.40 plf -64.40 plf 25’– 50’ Σ (1.0 WL) = -1610 lbs.

Σ (Reactions) = Σ (Shears) = (0.81 + 0.81) = 1.62 kips --- OK

VP DESIGN MANUAL Section: 4.1.EX1

BUILDINGS 03/01/06 Rev. 1 Page 16 of 20

STANDARDS SECONDARY PURLINS

and STRUCTURAL and

PRACTICES DESIGN GIRTS

Design Verification – Wind Suction Load Case

Location • : End Support

Shear is the only design check required at the exterior supports.

Shear Strength ref. AISI C3.2.1

Vn

(8.5C - 0.082" ) = 6.36 kips ref. DM 4.3.S, Table S5

v

Stress Ratio = V = 0.81 = 0.13 < 1.0 OK

Vn v 6.36

Location ‚ : Mid-Span Maximum Negative Moment

Bending design checks are required at this location. The compression flange (inside) is

partially braced by the Panel Rib wall panel requiring the use of tested R-factors per

AISI C3.1.3.

Bending Strength ref. AISI C3.1.3

8.5C - 0.082"

R = 0.65 (no insulation) ref. AISI Table C3.1.3 - 1

Mn = R S eFy = 0.65 (2.963 in. ) (55 ksi) = 105.93 kip − in.

3

ref. AISI Eq. C3.1.3 - 1

Mn

= 105.93 = 63.43 kip − in.

Ωb 1.67

Stress Ratio = M = 60.38 = 0.95 < 1.0 OK

Mn Ω b 63.43

VP DESIGN MANUAL Section: 4.1.EX1

BUILDINGS 03/01/06 Rev. 1 Page 17 of 20

STANDARDS SECONDARY PURLINS

and STRUCTURAL and

PRACTICES DESIGN GIRTS

8 ½" Simple C-Girt Design Example – Wind Pressure Load

Given:

1. Four simple span 8½" C- girt system as shown below:

W ( LC 2 = 1.0 W1< )

8.5 C - 0.092” 8.5 C - 0.105” 8.5 C - 0.105” 8.5 C - 0.092”

1’-0” 24’-0” 25’-0” 25’-0” 24’-0” 1’-0”

2. VP Panel Rib Wall covering attached to girts.

3. Building geometry: 175' wide x 100' long, eave height 20' and roof slope 1:12.

4. 2003 IBC. Wind = 90 mph, Ground Snow = 10 psf, LL = 30 psf non-reducible.

5. VP Command Design printout for the sidewall, interior bay girt, Load Case1:

Design Id 2, Segment 2 is Simple with a 0.082 Thickness

Secondary Unfactored Loads

Shape Units Type Description Mag1 Loc1 Mag2 Loc2 Supp. Dir. Coef. Add Loc.

Web

LN plf W1> Wind - Parts:Interior Area : Wall: 2 64.40 0/0/0 64.40 25/0/0 N OUT -0.960 N CL

LN plf <W2 Wind - Parts:Interior Area : Wall: 2 -58.37 0/0/0 -58.37 25/0/0 N IN 0.870 N CL

Secondary Design

Actual Forces Allowable Forces Stress Condition

Seg Loc. Load Axial Shear Moment Axial Shear Moment % % % % % %

No. (ft) Case (k) (k) (in-k) (k) (k) (in-k) Bnd Shear Bnd+Ax Bnd+Shr Bnd+Wcp Wcp

2 25.00 2 0.00 0.73 0.00 9.79 6.36 97.49 0.00 0.11 0.00 0.00 0.00 0.00

2 50.00 2 0.00 -0.73 0.00 9.79 6.36 97.49 0.00 0.11 0.00 0.00 0.00 0.00

2 37.50 2 0.00 0.00 54.72 9.79 6.36 97.49 0.56 0.00 0.56 0.00 0.00 0.00

Secondary Design Member Section Properties

Seg Loc. Depth Thick. Shp Len Area Rx Ry Lx Ly-1 Ly-2 Klx Kly1 Kly2 Sx Lb1 Lb2 Cb1 Cb2 R-f1 R-f2

No. (ft) (in.) (in.) (ft) (in.2) (in.) (in.) (in.) (in.) (in.) Rx Ry Ry in.3 (in.) (in.)

2 25.00 8.50 0.082 C 25.00 1.21 3.22 0.94 300.00 12.0 12.0 93.17 12.8 12.8 2.96 12.0 12.0 1.65 1.65 1.00 1.00

2 50.00 8.50 0.082 C 25.00 1.21 3.22 0.94 300.00 24.0 24.0 93.17 25.5 25.5 2.96 24.0 24.0 1.63 1.63 1.00 1.00

2 37.50 8.50 0.082 C 25.00 1.21 3.22 0.94 300.00 24.0 0.0 93.17 25.5 0.0 2.96 24.0 0.0 1.00 0.00 1.00 1.00

Load Case 1: Wind Uplift 1.0 W2> (wind pressure)

Basic Wind Load = -15.90 psf

Zone 2: -15.90 psf * 0.870 = 13.833 psf

7’

-5 ¼”Girt Load Trib. = (3’-5 ¼”+ 5’ -0”) / 2 = 4.2188’(note – 4’

-0”wind girt added)

W = 4.2188’(13.833 psf) = 58.36 plf

Span Element WL 1.5 WL Load Distribution Total Purlin Load

Zone II Girts 58.36 plf 58.36 plf 25’– 50’ Σ (1.0 WL) = 1,459 lbs.

VP DESIGN MANUAL Section: 4.1.EX1

BUILDINGS 03/01/06 Rev. 1 Page 18 of 20

STANDARDS SECONDARY PURLINS

and STRUCTURAL and

PRACTICES DESIGN GIRTS

Σ (Reactions) = Σ (Shears) = (0.73 + 0.73) = 1.46 kips --- OK

VP DESIGN MANUAL Section: 4.1.EX1

BUILDINGS 03/01/06 Rev. 1 Page 19 of 20

STANDARDS SECONDARY PURLINS

and STRUCTURAL and

PRACTICES DESIGN GIRTS

Design Verification – Wind Suction Load Case

Location • : End Support

Shear is the only design check required at the exterior supports.

Shear Strength ref. AISI C3.2.1

Vn

(8.5C - 0.082" ) = 6.36 kips ref. DM 4.3.S, Table S5

v

Stress Ratio = V = 0.73 = 0.11 < 1.0 OK

Vn v 6.36

Web crippling checks not required due to girt clips.

Location ‚ : Mid-Span Maximum Negative Moment

Bending design checks are required at this location. The compression flange (outside)

is fully braced by the Panel Rib wall panel not requiring the use of R-factors.

Bending Strength ref. AISI C3.1.1

8.5C - 0.082"

Mn

= 97.58 kip − in. ref. DM 4.2.DA, Table S2

b

Stress Ratio = M

ϕb Mn = = 0.56 < 1.0

54.72 OK

97.58

VP DESIGN MANUAL Section: 4.1.EX1

BUILDINGS 03/01/06 Rev. 1 Page 20 of 20

You might also like

- ST 501Document15 pagesST 501amrNo ratings yet

- Design Basic Report for Development BuildingDocument9 pagesDesign Basic Report for Development BuildingMuhammad HasanNo ratings yet

- TRUNIONSDocument3 pagesTRUNIONSakisdassasNo ratings yet

- Underpass Bilal FSDDocument11 pagesUnderpass Bilal FSDAli ShanNo ratings yet

- 10M Steel Pole Design CalculationsDocument26 pages10M Steel Pole Design Calculationsatokku50% (2)

- Pressure Vessel Calculation ReportDocument82 pagesPressure Vessel Calculation ReporteeghbaliNo ratings yet

- Project Sanvira Carbon Stock Shed Column ReactionsDocument4 pagesProject Sanvira Carbon Stock Shed Column ReactionsElancheliyanNo ratings yet

- ST 404Document12 pagesST 404amrNo ratings yet

- Wind Load Computation ResultsDocument22 pagesWind Load Computation ResultsFranklyn Genove100% (1)

- Staad Report - FinalDocument25 pagesStaad Report - FinalparthibanNo ratings yet

- Guide PV analysis resultsDocument4 pagesGuide PV analysis resultsSiri SiriNo ratings yet

- Rev01 - Report - Analysis - JK-JKB-0002 DR MAKALIWEDocument37 pagesRev01 - Report - Analysis - JK-JKB-0002 DR MAKALIWEsalman alfarisyNo ratings yet

- Pargola Connection ReportDocument11 pagesPargola Connection ReportRajesh KumarNo ratings yet

- Results For LegsDocument9 pagesResults For LegsOscar MarinNo ratings yet

- Analysis Report Basket Las MachineDocument17 pagesAnalysis Report Basket Las Machinejumansyahamid1988No ratings yet

- ST 505Document18 pagesST 505amrNo ratings yet

- Midas Gen SEIS LOAD CALCDocument6 pagesMidas Gen SEIS LOAD CALCCSEC Uganda Ltd.No ratings yet

- Building Dimensions:: Wind LoadsDocument5 pagesBuilding Dimensions:: Wind LoadsNikhilVasistaNo ratings yet

- Spreadsheets To BS 8110: Column InternalDocument1 pageSpreadsheets To BS 8110: Column InternalmayphyoNo ratings yet

- Design Condition 41C101Document64 pagesDesign Condition 41C101arifinzaky27No ratings yet

- JBL0435 GRD ZAIN Report - Rev - ADocument77 pagesJBL0435 GRD ZAIN Report - Rev - AEhtesham AliNo ratings yet

- Ametank Model Example 2 API 650 Calculation Report PDFDocument54 pagesAmetank Model Example 2 API 650 Calculation Report PDFChristian D. Orbe100% (1)

- Axial StopDocument4 pagesAxial Stopanurag7878No ratings yet

- Project 42 Joint Design AnalysisDocument8 pagesProject 42 Joint Design AnalysisshoebNo ratings yet

- Nozzle Calculation - Auxiliary Boiler Stack-R0Document13 pagesNozzle Calculation - Auxiliary Boiler Stack-R0Aditya JainNo ratings yet

- Document 1Document13 pagesDocument 1Prince SharmaNo ratings yet

- Spreadsheets To BS 8110: Internal ColumnDocument9 pagesSpreadsheets To BS 8110: Internal ColumnKhac Hoang PhamNo ratings yet

- 00 UBF C 51 001 001 (Rev.X0)Document101 pages00 UBF C 51 001 001 (Rev.X0)Amr AbdeinNo ratings yet

- Shoring Calculation Report 20211118Document37 pagesShoring Calculation Report 20211118Oshin RajapakshaNo ratings yet

- Curtain Wall With HZ & VL Louvers Structural Calculation For Building a-PART (6) at AXIS (34-42) - A'Document59 pagesCurtain Wall With HZ & VL Louvers Structural Calculation For Building a-PART (6) at AXIS (34-42) - A'نصر عبدالسلامNo ratings yet

- Spreadsheets To BS 8110Document10 pagesSpreadsheets To BS 8110Alma M. LaraNo ratings yet

- Hea160 Ebsp 1Document4 pagesHea160 Ebsp 1Bùi Trọng QuỳnhNo ratings yet

- Aerator Tank - Calculation - 1B14Document2 pagesAerator Tank - Calculation - 1B14abd razak haronNo ratings yet

- Nozzle Calculation - Primary Reformer Stack-R0Document22 pagesNozzle Calculation - Primary Reformer Stack-R0Aditya Jain100% (1)

- ST 102Document20 pagesST 102amrNo ratings yet

- Cold-Formed Steel Design CheckDocument2 pagesCold-Formed Steel Design CheckLuís OliveiraNo ratings yet

- Installation calculation report for Model Project 01SLD_1_860_6481Document36 pagesInstallation calculation report for Model Project 01SLD_1_860_6481Rodrigo ChoqueNo ratings yet

- UAA10 Canopy Design Report - MergedDocument11 pagesUAA10 Canopy Design Report - MergedAbilaash VelumaniNo ratings yet

- Plaza Stage NewDocument11 pagesPlaza Stage NewFelix Albit Ogabang IiiNo ratings yet

- ST 506Document14 pagesST 506amrNo ratings yet

- One Way Slab 1Document15 pagesOne Way Slab 1ahmedanyNo ratings yet

- Teres House Calculation ReportDocument51 pagesTeres House Calculation ReportTom YeeNo ratings yet

- Sag Tension Report - 4pm 15th MayDocument12 pagesSag Tension Report - 4pm 15th MayRakshit KumarNo ratings yet

- Galvacoat Tech SubmittalDocument233 pagesGalvacoat Tech SubmittalAkash BogaNo ratings yet

- UW-2 OutDocument48 pagesUW-2 Out966571016208No ratings yet

- WC Sheet R0 (Updated)Document9 pagesWC Sheet R0 (Updated)Sunil RahangdaleNo ratings yet

- AA-SM-004-004 Bolt Group - 1 - 2D Bolt Group - 2 Bolts - Multiple CasesDocument3 pagesAA-SM-004-004 Bolt Group - 1 - 2D Bolt Group - 2 Bolts - Multiple CasesjowarNo ratings yet

- Handout W Wallace 9!13!12 FullPageColorDocument76 pagesHandout W Wallace 9!13!12 FullPageColorYusak Santoso UseNo ratings yet

- Load Combinations and Joint Displacements TableDocument24 pagesLoad Combinations and Joint Displacements TableBilal A BarbhuiyaNo ratings yet

- ST 403Document17 pagesST 403amrNo ratings yet

- KNM Process Systems Sdn. BHD.: Project Name: Ammonia & Urea Plant Revamp ProjectDocument32 pagesKNM Process Systems Sdn. BHD.: Project Name: Ammonia & Urea Plant Revamp ProjectrichardchiamNo ratings yet

- Spreadsheets To BS 8110: Column InternalDocument1 pageSpreadsheets To BS 8110: Column Internalmdelacua2No ratings yet

- Member Reinforced Concrete Column Design Report (Eurocode-2)Document13 pagesMember Reinforced Concrete Column Design Report (Eurocode-2)Lalith RohanaNo ratings yet

- FF Punching ShearDocument10 pagesFF Punching Shear98675No ratings yet

- Super Critical AirfoilDocument20 pagesSuper Critical AirfoilGOWTHAMAN.DNo ratings yet

- Sko0061283 R2Document52 pagesSko0061283 R2ciwidop390No ratings yet

- Ss 210a Armco Panel Ul90 StructDocument56 pagesSs 210a Armco Panel Ul90 StructErick Quan LunaNo ratings yet

- LAGOS DORMITORY-BeamDesignDocument147 pagesLAGOS DORMITORY-BeamDesignadetokunbo fapuroNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Material TranslationDocument10 pagesMaterial Translationmichel92748No ratings yet

- A. Z-Purlin (ASD) Design Example B. C - Girt (ASD) Design ExampleDocument20 pagesA. Z-Purlin (ASD) Design Example B. C - Girt (ASD) Design Examplemichel92748No ratings yet

- DM02 11Document14 pagesDM02 11michel92748No ratings yet

- Ansys Workbench OptimizationDocument247 pagesAnsys Workbench Optimizationanmol6237100% (1)

- Aashto LRFD SlabDocument2 pagesAashto LRFD Slabmichel92748No ratings yet

- Building Codes GuideDocument103 pagesBuilding Codes GuideHomer SilvaNo ratings yet

- Building Codes GuideDocument103 pagesBuilding Codes GuideHomer SilvaNo ratings yet

- Ansys Workbench OptimizationDocument247 pagesAnsys Workbench Optimizationanmol6237100% (1)

- Discussion - Bin Supports - A Caution To Designers PDFDocument2 pagesDiscussion - Bin Supports - A Caution To Designers PDFmichel92748No ratings yet

- Fabrication Tools for Economical Corrugated Web I-BeamsDocument3 pagesFabrication Tools for Economical Corrugated Web I-BeamsHafiz AshadiNo ratings yet

- Aashto PCC KH KSDocument13 pagesAashto PCC KH KSAdeRatihIspandiariNo ratings yet

- DM02 11Document14 pagesDM02 11michel92748No ratings yet

- Design Aids For Unreinforced Web Openings in Steel and Composite Beams With W-Shapes PDFDocument10 pagesDesign Aids For Unreinforced Web Openings in Steel and Composite Beams With W-Shapes PDFmichel92748No ratings yet

- Sección WhitmoreDocument5 pagesSección WhitmoreczapatachueNo ratings yet

- AASHTO - LRFD (Design Example For Steel Girder Superstructure Bridge - 2003)Document698 pagesAASHTO - LRFD (Design Example For Steel Girder Superstructure Bridge - 2003)Ridwan Kris50% (2)

- prEN1993 3 1st 02 PDFDocument14 pagesprEN1993 3 1st 02 PDFmichel92748No ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Gusset StressDocument21 pagesGusset StressSameera RaoNo ratings yet

- prEN1993 1 9 2nd Rev PDFDocument27 pagesprEN1993 1 9 2nd Rev PDFmichel92748No ratings yet

- FOOTINGSDocument10 pagesFOOTINGSmichel92748No ratings yet

- prEN1993 1 8 01 PDFDocument40 pagesprEN1993 1 8 01 PDFmichel92748No ratings yet

- Sección WhitmoreDocument5 pagesSección WhitmoreczapatachueNo ratings yet

- prEN1993 1 8 05 PDFDocument30 pagesprEN1993 1 8 05 PDFmichel92748No ratings yet

- Aisi2001c PDFDocument187 pagesAisi2001c PDFmichel92748No ratings yet

- prEN1993 3 1st 01 PDFDocument27 pagesprEN1993 3 1st 01 PDFmichel92748No ratings yet

- Aisi2001c PDFDocument187 pagesAisi2001c PDFmichel92748No ratings yet

- AISI - Notas Tecnicas para Perfis Conformados A Frio PDFDocument6 pagesAISI - Notas Tecnicas para Perfis Conformados A Frio PDFmichel92748No ratings yet

- Technical Paper - Heat Capacity RatioDocument5 pagesTechnical Paper - Heat Capacity RatiodatUPstudentdoeNo ratings yet

- Contact Stress and Fatigue Analysis of Spur GearDocument6 pagesContact Stress and Fatigue Analysis of Spur GearSharath P CNo ratings yet

- Projectile MotionDocument2 pagesProjectile Motionashok pradhanNo ratings yet

- Design and Analysis of Tire Coupling: November 2018Document8 pagesDesign and Analysis of Tire Coupling: November 2018Basu SbNo ratings yet

- WCD P3Document43 pagesWCD P3RupaliNo ratings yet

- Strength of Materials Basics and Equations - Mechanics of Materials PDFDocument6 pagesStrength of Materials Basics and Equations - Mechanics of Materials PDFEmil Lawrence EspirituNo ratings yet

- Beam and Column Design in Reinforced ConcreteDocument21 pagesBeam and Column Design in Reinforced ConcreteSambhav PoddarNo ratings yet

- Physics Problem SetDocument1 pagePhysics Problem Setjhovane episNo ratings yet

- Astm C39Document5 pagesAstm C39Sergio Pascual50% (2)

- Static Web Moment ConnectionsDocument43 pagesStatic Web Moment ConnectionsAlejandro SantiagoNo ratings yet

- Upthrust WorksheetDocument5 pagesUpthrust WorksheetRanjit SinghNo ratings yet

- FATEMI Lecture On Fatigue (Must Read Again and Again)Document94 pagesFATEMI Lecture On Fatigue (Must Read Again and Again)masoodkamal100% (1)

- CURVILINEAR MOTION EQUATIONS AND CONCEPTSDocument21 pagesCURVILINEAR MOTION EQUATIONS AND CONCEPTSPrime Rose CutaonNo ratings yet

- Q 1Document4 pagesQ 1Manu K VasudevanNo ratings yet

- CHAPTER 5 AGITATATION and MIXING PDFDocument42 pagesCHAPTER 5 AGITATATION and MIXING PDFProfessionalNo ratings yet

- Steel Connection Failure ModesDocument22 pagesSteel Connection Failure ModesJoshua CalaNo ratings yet

- Lecture On Limit State Design by Manish BhutaniDocument27 pagesLecture On Limit State Design by Manish BhutaniTarunNo ratings yet

- PPSC Physics Lecturer Test Past Papers SolvedDocument18 pagesPPSC Physics Lecturer Test Past Papers SolvedfatimaNo ratings yet

- Safety Analysis of New Actros CabinDocument14 pagesSafety Analysis of New Actros CabinGirish Raj100% (1)

- 2 Polyflow 12.1 Polyflow A IIDocument95 pages2 Polyflow 12.1 Polyflow A IIwoongs73No ratings yet

- 44flow Through PipesDocument42 pages44flow Through PipesVenkata RamanaNo ratings yet

- Internal Combustion EngineDocument40 pagesInternal Combustion EngineMingNo ratings yet

- Physical Chemistry of InterfacesDocument20 pagesPhysical Chemistry of InterfacesTeka KamNo ratings yet

- CFD Simulation in AbaqusDocument34 pagesCFD Simulation in AbaqusGraham RobertsNo ratings yet

- Griffith TheoryDocument8 pagesGriffith TheoryKarthick RamNo ratings yet

- Velocity-Time Graphs ExplainedDocument10 pagesVelocity-Time Graphs ExplainedAisha ShamimNo ratings yet

- The Working SubstanceDocument10 pagesThe Working SubstanceBryan YuNo ratings yet

- New Developments and Applications of Skin-Friction Measuring TechniquesDocument14 pagesNew Developments and Applications of Skin-Friction Measuring TechniquesVyssionNo ratings yet

- Mechanics (Dynamics) Question TuteDocument2 pagesMechanics (Dynamics) Question TuteGevindu SamarakoonNo ratings yet

- Elemen Mesin Rem PDFDocument46 pagesElemen Mesin Rem PDFM Fathin NaufalNo ratings yet