Professional Documents

Culture Documents

Polygomma EPDM Roofing Membrane Catalogue

Uploaded by

polygomma Industries Pvt. LtdCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polygomma EPDM Roofing Membrane Catalogue

Uploaded by

polygomma Industries Pvt. LtdCopyright:

Available Formats

EPDM ROOFING MEMBRANE

EPDM membrane is the most preferred choice when it comes to choosing long lasting, hassle free

roofing solutions. The PolygommaTM Roofing Membranes are manufactured using high grade synthetic

rubber (EPDM) compounds.

Our waterproofing membranes can be applied on the roofs to protect them from water leakages and

attack of chemicals and vapors. The PolygommaTM Roofing Membranes are single-ply waterproofing

membranes which make the surface watertight and are resistant to ozone and UV light. The

PolygommaTM Roofing Membranes are easy to install and serves as best choice for a long lasting, fit and

forget, waterproofing solution for Roofing as well as Terrace Gardens and Podiums.

The PolygommaTM Advantage

Quality : Our products confirm to international product standards and the manufacturing process is

certified as per ISO 9001.

Technology : We use the intermesh mixing technology and cold feed roller head technology that

ensures that our membranes are compact and have a higher density compared to the ones

manufactured using calendar technology.

Vulcanizing Technology : Our products are cured using an ‘Online Vulcanizing Mechanism’, which

ensures that every square inch of our membrane is evenly cured. Since we do not use steam boilers to

cure the membranes, our manufacturing process is non-polluting.

Economical Price : The easy availability of manufacturing resources, and fewer overheads, helps us

provide a better price to our customers.

Higher Widths : Our products are manufactured up to a width of 15 meters with factory seam. This

ensures quick installations and fewer field overlaps.

Chemical Resistance$ : Our products are formulated to withstand chemical and toxic service

conditions.

Experience : Our group has been manufacturing various rubber products from polymers such as

Hypalon*, Butyl, EPDM, etc since the early 1960’s. This rich experience and expertise is our biggest

asset, and helps to provide the world with excellent, durable and cost effective products.

* Hypalon is a registered trademark of E.I. DuPont de Nemours and Co. Inc.

$ Prior check is required.

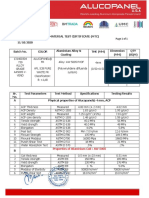

Technical Specifications of PolygommaTM EPDM Roofing Membranes - Grade RM

Requirement of

Physical Property Test Method RMA / Roofing ASTM PolygommaTM

Council Standard Result

(USA) (Type I)

Colour - Black - Black

Thickness ASTM D-412 1.016 1.016 1.0 to 1.5

Tensile Strength (MPa) ASTM D-412 9-Min 9-Min 9.90

Elongation Ultimate (%) ASTM D-412 300-Min 300-Min 450

Angular Tear (kN/m) ASTM D-624 26.27 Min 26.27 Min 37

Temperature Resistance - - - -40°C to +160°C

Tensile Set (%) ASTM D-412 - 10 Max 2

Brittleness Point Max °F (°C) ASTM D-2137 -49 (-45) -49 (-45) No Crack

Ozone Resistance/166 hrs/ ASTM D-1149 No Cracks No Cracks No Cracks

50 PPHM/40°C 50% extension (Pass)

Heat Aging ASTM D-573 - - -

(670h @ 116°C)

• Tensile Strength (MPa) ASTM D-412 6.0 8.30 min 11.2

• Elongation Ultimate (%) ASTM D-412 200 Min 200 Min 295

• Angular Tear (kN/m) ASTM D-624 21.9-Min 21.9-Min 23

Linear Dimensional Change (%) ASTM D-1204 ±2 ±1 +0.3

Water Absorption at ASTM D-471 +8, -2 +8, -2 +1.7

70° for 166 hours (%)

Factory Seam Strength (kN/m) ASTM D-816 Sheet failure or 8.8 Sheet failure

50 lb/inch Min

Puncture Resistance (Kg) ASTM E-154 - 32 37

Flex Cracking BS 903 Part A10 - - 200000 Cycles

Hardness ASTM 2240 - - 62 ±5°A

Specific Gravity ASTM D-297 - - 1.3

Visual Inspection G 26 - Pass Pass

PRFSE Min (%) D 518 - 30 <35

• Ref D 4637/D 6134 & tolerance as per UEATC: MOAT No 46.

• The above values are taken from specimens made under reproducible conditions. However they may differ somewhat on actual production/supply

due to vulcanization conditions at the factory.

• As the ASTM Standards continue to revise, please refer to the latest applicable code for any update on the properties.

PolygommaTM EPDM Roofing Membrane Product Range

Thickness Width Length

0.80 mm (31.5 mil) 1.2 meters, 3 meters, 6 meters 30 meters

1.00 mm (40 mil) 1.2 meters, 3 meters, 6 meters 30 meters

1.14 mm (45 mil) 1.2 meters, 3 meters, 6 meters 30 meters

1.20 mm (47 mil) 1.2 meters, 3 meters, 6 meters 30 meters

1.50 mm (60 mil) 1.2 meters, 3 meters, 6 meters 30 meters

2.00 mm (80 mil) 1.2 meters, 3 meters, 6 meters 30 meters

Special sizes can be manufactured upon request.

FEATURES

APPLICATIONS

The information indicated here is true to the best of our knowledge. However no warranty/guaranty is implied on our products as the conditions of use and the skill and quality of

manpower used for installation is beyond our control.

Manufactured by -

POLYGOMMA INDUSTRIES PVT. LTD.

Office : A-229, Antophill Warehousing Complex,

Vidyalankar College Road, Wadala(E),

Mumbai- 400037, India.

Tel : +91 22 66059800, Fax :+91 22 24162885.

E-mail : polygomma@polygomma.com

Web : www.polygomma.com

You might also like

- Tle - H.E.-Cookery: Quarter 2 - Module 2: Prepare Salad DressingDocument26 pagesTle - H.E.-Cookery: Quarter 2 - Module 2: Prepare Salad DressingRodel Camposo88% (25)

- Ficha Tecnica Um180821 Tds Tough Pla RB v11Document3 pagesFicha Tecnica Um180821 Tds Tough Pla RB v11Servirol CiaNo ratings yet

- Tds BR Macline SDH Rev01 Sep16 SPDocument1 pageTds BR Macline SDH Rev01 Sep16 SPEdier Alexander Atilua BelloNo ratings yet

- Laminated CompressDocument42 pagesLaminated CompressMACHINE-30 ISTENNo ratings yet

- O&M Manual For Vms PumpDocument11 pagesO&M Manual For Vms PumpKaushik ChakrabortyNo ratings yet

- Polygomma EPDM Pond Liner BrochureDocument4 pagesPolygomma EPDM Pond Liner Brochurepolygomma Industries Pvt. LtdNo ratings yet

- TDS 140N - TipicosDocument2 pagesTDS 140N - TipicosCris AranzNo ratings yet

- Corys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsDocument1 pageCorys Geosynthetics Data Sheet HDPE Smooth Geomembrane: Metric UnitsVenkadesh PeriathambiNo ratings yet

- JUNE2020 Transparent Noise Barrier Technical Datasheet Final ReducedDocument2 pagesJUNE2020 Transparent Noise Barrier Technical Datasheet Final Reducedionut cerneaNo ratings yet

- Um180821 TDS Tpu 95a RB V11Document3 pagesUm180821 TDS Tpu 95a RB V11Steven DonosoNo ratings yet

- Microstructure Evolution in Metal Forming Processes (2012)Document2 pagesMicrostructure Evolution in Metal Forming Processes (2012)MedSparkNo ratings yet

- MIRATAKDocument1 pageMIRATAKmiroslava mondragonNo ratings yet

- TDS ASIA MACLINE TMH Rev7 Mar 2015Document1 pageTDS ASIA MACLINE TMH Rev7 Mar 2015Andrew Zapanta Jr.No ratings yet

- Cold Shrink 8420Document3 pagesCold Shrink 8420PringetteNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrintersDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsvassaNo ratings yet

- ABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersDocument2 pagesABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersSINo ratings yet

- Spec Sheet - ABS-M30 ENDocument2 pagesSpec Sheet - ABS-M30 ENTUSHAR BANGERANo ratings yet

- Delrin100 NC10Document2 pagesDelrin100 NC10avinashchauhan2695No ratings yet

- Stratasys - MSS FDM ABSplusP430Document2 pagesStratasys - MSS FDM ABSplusP430feltofsnakeNo ratings yet

- ABS-M30: Real Production-Grade ThermoplasticDocument2 pagesABS-M30: Real Production-Grade ThermoplasticqualityfreekNo ratings yet

- 612 en Sureseal Epdm TdsDocument1 page612 en Sureseal Epdm TdsMohamed Ismail ShehabNo ratings yet

- ULTEM 9085: Production-Grade Thermoplastic For Fortus 3D PrintersDocument3 pagesULTEM 9085: Production-Grade Thermoplastic For Fortus 3D PrintersRui MatiasNo ratings yet

- Technical Data Sheet: Property Test Method Unit FrequencyDocument1 pageTechnical Data Sheet: Property Test Method Unit FrequencyJuli JulekNo ratings yet

- Solmax - HDPE REFLECTIVE IMPERIALDocument6 pagesSolmax - HDPE REFLECTIVE IMPERIALchipnowNo ratings yet

- TDS-GEOPROTEC-GS3000S-22-01 Rev.01Document1 pageTDS-GEOPROTEC-GS3000S-22-01 Rev.01AMINNo ratings yet

- Global Synthetics Proliner HDPE Smooth DatasheetDocument1 pageGlobal Synthetics Proliner HDPE Smooth DatasheetMatt GhanaviNo ratings yet

- DRISCOPLEX 6500 Tubería y AccesoriosDocument7 pagesDRISCOPLEX 6500 Tubería y AccesoriosBrayan CJNo ratings yet

- Especificación LLDPEDocument1 pageEspecificación LLDPERainer TerronesNo ratings yet

- Propriedades Das Matrizes PolimericasDocument7 pagesPropriedades Das Matrizes PolimericasllepsterlNo ratings yet

- Aludecor Al 45 Firewall En13501-1 Class A2 Technical SpecificationDocument2 pagesAludecor Al 45 Firewall En13501-1 Class A2 Technical Specificationsoham senNo ratings yet

- DOW™ Butene 1220P: Polyethylene ResinDocument1 pageDOW™ Butene 1220P: Polyethylene Resinvantuan17792No ratings yet

- Infino Pc-Abs Hp1000xa (Natural)Document1 pageInfino Pc-Abs Hp1000xa (Natural)Rhekron PlasticsNo ratings yet

- Ficha Tecnica Cinta de Juntas 930 35 50 PDFDocument3 pagesFicha Tecnica Cinta de Juntas 930 35 50 PDFfernando100% (1)

- CTM Geosynthetics Uniaxial-UnlockedDocument1 pageCTM Geosynthetics Uniaxial-UnlockedGautam RaiNo ratings yet

- PREPRUFE 300R Plus & 160R Plus Membranes Data Sheet (US Version)Document2 pagesPREPRUFE 300R Plus & 160R Plus Membranes Data Sheet (US Version)Joyce Agustine Glory LNo ratings yet

- Rowad HDSDocument1 pageRowad HDSsellami walidNo ratings yet

- Techdrain Gtg27.6: Drainage GeocompositeDocument1 pageTechdrain Gtg27.6: Drainage GeocompositeJORGE LUIS GAMARRA MIRANDANo ratings yet

- Pc-Iso: Mechanical Properties Test Method ValueDocument2 pagesPc-Iso: Mechanical Properties Test Method ValuekaledioskoppNo ratings yet

- Technical Data Sheet PC: Filament SpecificationsDocument3 pagesTechnical Data Sheet PC: Filament SpecificationsVladimir SarmientoNo ratings yet

- Grade: St900 DM311: Polypropylene CompoundDocument1 pageGrade: St900 DM311: Polypropylene Compoundhugo santiago chavez godoyNo ratings yet

- Data Sheet - Polyfelt® Alidrain AD530 (300 604-td-10-18) PDFDocument1 pageData Sheet - Polyfelt® Alidrain AD530 (300 604-td-10-18) PDFErnie ErnieNo ratings yet

- ABS-M30i: Production-Grade Thermoplastic For Fortus 3D PrintersDocument2 pagesABS-M30i: Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNo ratings yet

- Miratech GT500: Technical Data SheetDocument3 pagesMiratech GT500: Technical Data SheetNicolás CanoNo ratings yet

- GP100ORXP enUS ASTMDocument1 pageGP100ORXP enUS ASTMRaul ArmendarizNo ratings yet

- 3M Heavy Wall Heat Shrink Tubing ITCSNDocument4 pages3M Heavy Wall Heat Shrink Tubing ITCSNmuahdibNo ratings yet

- Material Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Document4 pagesMaterial Test Certificate (MTC) : Properties of Aluminium Coil: AW 5005Waleed Obieden100% (1)

- HDPE Espec. Tec. FM SeriesDocument1 pageHDPE Espec. Tec. FM SeriesYhonny ValenzuelaNo ratings yet

- Inflon Ptfe Gasket Sheet: Inmarco Type 600Document1 pageInflon Ptfe Gasket Sheet: Inmarco Type 600ArunNo ratings yet

- InsufineMineral TDSDocument2 pagesInsufineMineral TDSEgyp XsNo ratings yet

- For Solid Concrete Interlocking Paving UnitsDocument7 pagesFor Solid Concrete Interlocking Paving UnitsomerNo ratings yet

- PORON 4701-50 Firm - Supported MaterialsDocument2 pagesPORON 4701-50 Firm - Supported MaterialsLayeeq AhmedNo ratings yet

- Tairilac ABS Resin: Properties (1/3)Document3 pagesTairilac ABS Resin: Properties (1/3)DiegoTierradentroNo ratings yet

- Resin - ABS Tairalac PDFDocument3 pagesResin - ABS Tairalac PDFDiegoTierradentroNo ratings yet

- Tds Ecozen t110gDocument1 pageTds Ecozen t110galfred quinNo ratings yet

- S1005 TairiproDocument1 pageS1005 TairiproJacquelin DelgadoNo ratings yet

- POM Delrin 900 HFDocument2 pagesPOM Delrin 900 HFcountzeroaslNo ratings yet

- ELITE™ AT 6111: Enhanced Polyethylene ResinDocument3 pagesELITE™ AT 6111: Enhanced Polyethylene ResinRoberto De Mesa PNo ratings yet

- Viton Cord DatasheetDocument1 pageViton Cord DatasheetGokul royalveritasNo ratings yet

- Absplus-P430: Production-Grade Thermoplastic For 3D PrintersDocument2 pagesAbsplus-P430: Production-Grade Thermoplastic For 3D PrinterscontrolorNo ratings yet

- TPU Estane 2103-55DDocument1 pageTPU Estane 2103-55DcountzeroaslNo ratings yet

- 10 Effective Ayurvedic Treatment For Hair LossDocument9 pages10 Effective Ayurvedic Treatment For Hair Lossrpav77No ratings yet

- Pin ContentDocument20 pagesPin ContentSwetha100% (2)

- EO MNC 10 June 2022Document4 pagesEO MNC 10 June 2022LeulaDianneCantosNo ratings yet

- Trump ReportDocument237 pagesTrump ReportAaron Nobel100% (1)

- Valerie Tillard Murder: Probable CauseDocument11 pagesValerie Tillard Murder: Probable CauseLeigh EganNo ratings yet

- DT-M Datasheet Vertex Ne19r en 2022 Pa1 Web Ne19r 2022pa1 en 20220916Document2 pagesDT-M Datasheet Vertex Ne19r en 2022 Pa1 Web Ne19r 2022pa1 en 20220916Producto ITICCOLNo ratings yet

- Experiment-3: Study of Microstructure and Hardness Profile of Mild Steel Bar During Hot Rolling (Interrupted) 1. AIMDocument5 pagesExperiment-3: Study of Microstructure and Hardness Profile of Mild Steel Bar During Hot Rolling (Interrupted) 1. AIMSudhakar LavuriNo ratings yet

- 1896 - Pearson - Mathematical Contributions To The Theory of Evolution. III. Regression, Heredity, and PanmixiaDocument67 pages1896 - Pearson - Mathematical Contributions To The Theory of Evolution. III. Regression, Heredity, and PanmixiaNilotpal N SvetlanaNo ratings yet

- Soc5352 1331Document4 pagesSoc5352 1331ChinNo ratings yet

- Cessna 206 Chapter 24 Illustrated Parts CatalogueDocument33 pagesCessna 206 Chapter 24 Illustrated Parts Cataloguekanwar100% (1)

- 1198-Article Text-5716-1-10-20221219Document9 pages1198-Article Text-5716-1-10-20221219Hendarko AriNo ratings yet

- AscindiaDocument16 pagesAscindiaHeeman TrivediNo ratings yet

- Module-1-ISO 13485-DocumentDocument7 pagesModule-1-ISO 13485-Documentsri manthNo ratings yet

- Minibeasts Differentiated Reading Comprehension ActivityDocument15 pagesMinibeasts Differentiated Reading Comprehension Activitymariam helmyNo ratings yet

- RNA and Protein Synthesis Problem SetDocument6 pagesRNA and Protein Synthesis Problem Setpalms thatshatterNo ratings yet

- Australian TaxationDocument45 pagesAustralian TaxationEhtesham HaqueNo ratings yet

- Leviticus 12 Pulpit Commentary Homiletics PDFDocument16 pagesLeviticus 12 Pulpit Commentary Homiletics PDFEmiel AwadNo ratings yet

- Method Statement For Interlocking PavingDocument5 pagesMethod Statement For Interlocking Pavingdinidu3priyankara3saNo ratings yet

- LOKRING Technical Documentation Submittal Brass enDocument32 pagesLOKRING Technical Documentation Submittal Brass enYamilelcNo ratings yet

- "Mode One" Author & Dating Coach Alan Roger Currie Releases Criticism of Alleged Harvey Weinstein BehaviorDocument3 pages"Mode One" Author & Dating Coach Alan Roger Currie Releases Criticism of Alleged Harvey Weinstein BehaviorPR.com100% (1)

- 1-1FlowCharts For HaccpDocument3 pages1-1FlowCharts For HaccpPeter George0% (1)

- CT VT Basics SonnenbergDocument71 pagesCT VT Basics SonnenbergAnonymous OCDJg17Z67% (3)

- Personal Loan For JoiningDocument3 pagesPersonal Loan For JoiningAzim SengalNo ratings yet

- MahuaDocument12 pagesMahuaVinay ChhalotreNo ratings yet

- Recipes For Ceviche, Pebre and Pisco SourDocument4 pagesRecipes For Ceviche, Pebre and Pisco SourJoaquín Rolón CarrerasNo ratings yet

- VálvulasDocument44 pagesVálvulasCarlos LópezNo ratings yet

- Motor DeiselShip Latest PDFDocument154 pagesMotor DeiselShip Latest PDFCadet Prateek SaxenaNo ratings yet

- Civrev2 2019 Case TitlesDocument3 pagesCivrev2 2019 Case TitlesAnne VallaritNo ratings yet