Professional Documents

Culture Documents

FDGDFG

Uploaded by

Fernando0 ratings0% found this document useful (0 votes)

8 views4 pagesgdgdgd

Original Title

fdgdfg

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentgdgdgd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views4 pagesFDGDFG

Uploaded by

Fernandogdgdgd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

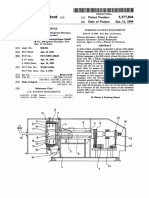

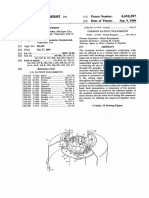

2,781,104

G, FISCHER

SLEEVE FILTER PLANT

Feb. 12, 1957

2 Sheets-Sheet 1

Filed Jan. 5, 1954

GhORE FISCHE TP

2 Se

Inventor.

Cttonury2

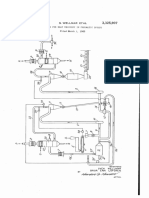

Feb. 12, 1957 G. FISCHER 2,781,104

SLEEVE FILTER PLANT

Filed Jan. 5, 1984 2 Sheats-Sheet 2

Fig.3

Fig.6

kore FISCHER

Inventor.

Naso tales bit. + beeasf

Cruse

me

United States Patent Office

2,781,104

Patented Feb. 12, 1957

2,781,104

SLEEVE FILTER PLANT

Georg Fischer, Porz (Rhine), Germiny

Application January 5, 1954, Serial No, 402,290

(Claims priority, application Geraiany January 14, 1953

7 Cisims. (Cl. 183—58)

‘The invention relates to a sleeve filter. lant for dist

Jaden air or other. gases containing dust and has for

its object to produce a, filter plast in which the cleaning

Of the filter sleeves can be. carried ot not only more

casily and with greater caré than inthe known plants but

also very. thoroughly. Another, object of, the invedtion

ig to produce a sleeve filter plant in which, the filter

sleeves. can be exchanged in a, very simple’ manier.

in the kriown sleeve filter plints the cleaning. Of the

filter sleeves is, in most cases, effecied by suddenly re-

leasing and stretehing the slesves whictiresults in con-

siderable wear because, on being relieved of tension the

sleeves are liable to buckle near the bottom end... It

hhas already been proposed t6 Keep the sleeves stistched

uring the cleaning operation «ind, taking advantage of

thelr elasticity, to subject them to more or less strong

tensioning in the direction of the sleeve axis. This, how-

fever, also results in very heavy stressing of the Sleeves

and, imoreover, does not ensure perfect cleaning.

It is also Known to maintain the filter sleeve’ of a

filter plant in.stretched state during the cleaning and to

impart thereto a linear jigging or shaking motion at

right. angles. to the axis of the sleeve. However, a

thorough cleaning cannot, evea be obtained in this man-

her, quite apart from the fact that the sleeves are sibjected

to one-sided mechanical stressing, the controlling ele-

ments, generally consisting of toe cams or the like, which

are,used for producing the linear shaking motion, being

subjected to very heavy wear and consequently making

the plants very noisy.

filter plant according to the invention are also kept taut

for stretched during the cleaning operation and in addi-

tion are subjected to a rotary oscillating motion in a

plane intersecting the axis of the sleeve, it being alo

Fecommended to add to this rotary oscillating motion a

vibrating motion, for ekample by allowing the parts

‘transmitting the retary oscillating motion to strike against

stationary paris of the sleeve filter plant while per=

forming the rotary oscillating motion.

To produce the rotary oscillating motioa of the sleeves,

the invention preferably provides 2 rotary unbalanced

device arranged concentrically in the filter chamber and

‘preferably above the set of filter sleeves, which device

‘transmits its movement to the filter sleeves, it being at

the same time considered advisable to allow the un-

balanced device to act om a frame which carries the

tightly stretched sieeves suspended by their upper ends.

Ta order to transmit the rotary oscillating movements

‘not only to the upper ends of the sleeves, whence these

movements can communicate themselves over the entire

length of the sleeves, the invention also provides for

the movements of the tinbalanced device to be positively

‘transmitted to the middle portion of the tightly stretched

sleeves, for example, by the fact that the filter sleeves

are guided at a point intermediate their ends by apertures

in a frame arranged in the casing of the filter chamber

and freely movable in a sectional plane of the sleeve

ws

20

25

30

0

50

55

60

10

2

axis and this frame aid also the’ frame cariyiag the

‘upper ends of the filter sleeves are carried by rods sus-

pended like pendulums the casing of the filter

chamber.

Stationary abutments are preferably co-ordinated to the

pendulum rods to limit the amplitude of their oscillation

and to produce an additional shaking effect, and, in order

to be able to reguiate these shaking movements, arrange-

‘ments may be provided for braking the oscillating move-

ments of the pendulum rods.

If the filter sleeves are connected at their lower ends

to a stationary frame, the sleeve walls will be stressed

more heavily near this point of connection than at any

other point and so as to obviate the necessity of ex-

changing the whole sleeve when it becomes defective at

‘this point, it is proposed, according to the invention, to

divide the sleeves into sectiéns in their length, to con:

rect the ends of the coordinate sleeve sections to con-

necting sockets carried by. this intermediate frame near

the lower third of the entire length of the sleeves,

‘According to enother feature of the invention, the

casing of the filter plant accommodating the filter sleeve

‘aggregate is closed above the shaking device by 4 cover

giving easy access to the upper ends of the filter sleeves,

and the driving mechanism for the sheking device is

located outside this cover, the shaking device preferably

‘comprising a rotary shaking member which receives, its

drive from a shaft extending through the cover of the

casing of the filter plant.

A sleeve filier plant, according to thé invention is,

illustrated by way of example in the accompanying draw-

ings, in which:

Fig. 1 is a longitidinal section of a chamber of a

multiple chamber plant,

Fig. 2 is a top plan view of Fig. 1,

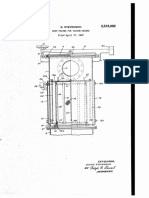

Fig. 3 shows in longitudinal section the upper end of

one of the pendulum rods of the plant and of the holding

device co-ordinated thereto,

Figure 4 is a cross-section of the pendulum rod and

its holder taken on line IV—IV of Fig. 3,

Fig. § shows in longitudinal section the lower end of

tie of the pendulum rods of this plant and the abut-

‘ments co-ordinated thereto, and

Fig. 6 is a section on line VI—VI of Fig. 5.

The filter plant, which is only illustrated in sufficient

detail to enable the invention to be understood, com-

prises several filter chambers each of which has a cs

1 which surrounds a filter sleeve assembly 2.

dividual filter sleeves are divided, into a short lower

section 2a and a longer upper section '2b. The upper

‘ends of the sleeve sections 2) are fixed on sleeve covers 4

which are Suspended in a frame 3 maintained at a certain

height but. freely movable in lateral direction. This

frame 3 has at its circumference apertures through which

rods 9 project which are suspended like pendulums at

10 on the casing 1 of the filter chamber. For supporting

these rods split clips 12 provided with a spherical bearing

surface are mounted in the casing 1 (Figs. 3 and 4), the

‘grip of these clips being adjustable by means of a scfew

60 or the like. Just below these clips the rods 9 are

each provided with an annular rim 61 and these rims

carry the frame 3.

‘A bottom frame 5, preferably of conical shape, is

fixed on casing 4 near the lower end of the sleeve sz

tions 2a and is provided with sockets 6 corresponding in

number to the number of sleeves.. The lower ends of

the sleeve sections 2a are stoured one to each of theie

sockets 6.

‘A freely miovable frame 8 provided. with coupling

sockets T'is located between the bottom 5 aind the frame 3

and has apertures between the coupling sockets to allow

the free passage of air. The lower ends of the sleeve

2,781,104

3

sections 2b are each secured to the upper end of a con-

necting collar 7 and the upper ends of the sleeve sections

2a to the lower ends of these collars. The frame 8, like

the frame 3, has apertures in its periphery through which

the lower ends of the pendulum rods 9 extend. Annular

flanges 62 on these rods 9 hold the frame at the proper

height, The position of the frame 8 is so chosen that

the lower sleeve sections 2a are about half as long as

the upper sleeve sections 2b.

‘Cup-shaped members 13 (Figs. $ and 6) are fitted on

the casing 1 of the filter chamber near the lower ends of

the pendulum rods 9 so that the free ends of these rods

extend into these members with clearance, The frames 3

and 8 are arranged in the casing 1 in such a manner that

the sleeve sections 2a and 26 are Kept taut or stretched.

In the middie of the frame 3 a rotary vibrating device 11

is arranged which is driven by an electric motor 47

‘which, through the intermediary of a belt 63 and pulley

64, drives a shaft extending through a cover 14, 13, 16

of the casing 1 and carrying at its lower end the vibrat-

ing device 11. ‘The outer parts 14-and 18 of the cover

(Fig. 2) are removable so as to afford easy access to the

frame 3 and the sleeves 2 connected thereto. The middle

ppart 16 of the cover forms a rigid bridge extending across

the casing 1 and has two flaps 17 and 18 mounted on

binges. The flap 18 serves for opening and closing the

communication aperture between the casing 1 and the

air outlet conduit 22 through which the cleansed air

escapes from the filter chamber in the direction of the

arrow 23. The flap 17 communicates with the atmos-

phere. The flaps 17 and 18 are interconnected by a

parallelogram system of links 19, 20, 21 in such a way

‘that when the flap 18 closes the flap 17 opens and vice

versa, The flaps 17 and 18 are actuated from time to

time by a device 25, such as a centrifugal pendulum or

fan electromagnet, which is not described in detail, and

alink system 26.

Closable apertures are provided in the casing 1 at 27,

27 to allow easy access to the lower ends of the sleeve

sections 2b and the lower and upper ends of the sleeve

sections 2a. The filter sleeves can be suspended in the

‘chamber not only through the openings exposed by the

cover parts 14, 15 at the upper end of the casing 1 but

algo through the apertures 27, 27.

The dust-laden air enters tangentially at 28 at the

lower end of the filter chamber, passes first through a

pre-separator arranged below the bottom § but not herein

described, and then enters the filter sleeves 2 through

the sockets 6 on the bottom 5. The particles of dust

which do not drop out at the bottom of the filter sleeves,

settle on the walls thereof and the cleansed air flows

through the filter chamber and passes into the outlet

passage or conduit 22 through the open fap 18.

If the filter sleeves become very dirty they must be

cleaned. For this purpose the filter chamber is rendered

inoperative by temporarily closing the flap 18. At the

same time the motor 47 is switched on which starts up

the vibrating or shaking device. This device transmits

its rotary oscillating movements to the frame 3 and,

through the intermediary of the pendulum rods 9, also to

the intermediate frame 8, whereby, owing to the pendulum

suspension of the rods 9, the amplitude of oscillation of

the intermediate frame 8 is greater than that of the upper

sleeve frame 3, Due to the rotary oscillating movements

‘combined with the shaking movements which are pro-

duced by the free lower ends of the pendulum rods 9

striking against the walls of the cup-shaped members 13,

the dust adhering to the walls of the sleeves drops off

and descends to the outlet 30 which is provided with

closing means, whence it is removed in a suitable manner

not herein described. When the sleeves have been cleaned,

the flap 18 is again opened and the filter chamber is once

‘more ready for use. By shaking the sleeves in the

10

20

30

40

“6

50

60

0

4

manner described, they are saved from wear and tear,

which is a particularly important factor when the sleeves

are made of delicate material. At the same time the

‘whole structure of the filter chambers is extremely simple

‘and the sleeves are easily accessible.

Telaim:

1, In a filter device, a casing having a fixed lower

horizontal frame, a. plurality of freely swinging rods

pivotally carried in the casing, an upper movable frame

supported by said rods, a series of vertical sectional filter

sleeves suspended from the upper frame and attached to

the lower frame in stretched condition, a vibrator acting

on the movable frame to impart a rotary oscillating move-

‘ment fo the sleeves, and a second movable frame pivotally

5 supported on the lower free ends of the rods, and collars

(on said second movable frame for connection with the

‘opposite sections of said sleeves,

2, In a filter device as set forth in claim 1, wherein

stationary abutments are arranged in said casing adjacent

the free ends of said rods limiting the amplitude of oscil-

lation of said rods and at the same time producing an

additional shaking movement.

3. In a filter device as set forth in claim 1, wherein

‘means are provided for braking the oscillating movement

of the rods.

4, In a filter device as set forth in claim 1, wherein

the filter sleeves are divided into sectional lengths which

are united by collars carried by the second movable

Trame at a point near the bottom third of the sleeve

ength.

5S. In a filter device as set forth in claim 1, wherein

the filter chamber is closed at its upper end above the

vibrator for imparting the rotary oscillating movement to

the sleeve assombly through the intermediary of said

frames, by a cover allowing easy access to the upper ends

of the filter sleeves, and motor means arranged outside

this cover for driving the vibrator for imparting the

6. In a filter device as set fort in claim 1, wherein

the device for imparting the rotary oscillating motion to

the sleeve aggregate through the intermediary of said

frames consists of an unbalanced member arranged in the

ceasing of the filter chamber, a cover above the unbal-

anced member, motor means for driving the unbalanced

member arranged outside the casing of the filter cham-

ber and connected to the unbalanced member by a shaft

extending through the said cover.

7. Tn a filter device, a fixed horizontal lower frame, @

vertically spaced movable horizontal upper frame, a series

of vertical filter sleeves connecting said frames, a

bbrator acting on the movable frame to impart 2 trans-

verse rotary oscillating movement to the sleeves, and

‘means operated from the movable frame and connected

‘with the sleeves at intermediate points thereon to trans-

mit transverse oscillation.

References Cited in the file of this patent

UNITED STATES PATENTS

1,512,776 Oct. 21, 1924

1,791,102, Feb. 3, 1931

2)143,668 Jan. 10, 1939

21167,236 July 25, 1939

2,335,315 TL Nov. 30, 1943,

21519082 ‘Aug. 15, 1950

2,667,233, Tan. 26, 1954

FOREIGN PATENTS

17,899 France Dee. 6, 1913

(ist addition to No. 445,994)

332475 Great Britain uly 24, 1930

351,588 aly ‘Avg. 16, 1937

699,348 Germany Nov. 27, 1940

758,640 France ‘Nov. 7, 1933

om gp

You might also like

- GFDFGDGDocument10 pagesGFDFGDGFernandoNo ratings yet

- NBVNCDocument10 pagesNBVNCFernandoNo ratings yet

- FGDGDocument20 pagesFGDGFernandoNo ratings yet

- United States Patent (19) : KingdomDocument7 pagesUnited States Patent (19) : KingdomFernandoNo ratings yet

- JHKHKDocument7 pagesJHKHKFernandoNo ratings yet

- GFGHDocument14 pagesGFGHFernando100% (1)

- HGFHDocument7 pagesHGFHEduardo Fernandez DazaNo ratings yet

- Us20140202122a1 PDFDocument8 pagesUs20140202122a1 PDFFernandoNo ratings yet

- GFFHGHDocument4 pagesGFFHGHFernandoNo ratings yet

- BNNBVDocument3 pagesBNNBVFernandoNo ratings yet

- FGDFGDocument14 pagesFGDFGFernandoNo ratings yet

- TEPZZ 66 - 44A - T: European Patent ApplicationDocument22 pagesTEPZZ 66 - 44A - T: European Patent ApplicationFernandoNo ratings yet

- Tipos de Separadores PDFDocument46 pagesTipos de Separadores PDFLily Deza100% (7)

- Art05 PDFDocument8 pagesArt05 PDFAnthony FloresNo ratings yet

- BCBDocument13 pagesBCBFernandoNo ratings yet

- GFGHDocument14 pagesGFGHFernando100% (1)

- United States Patent (19) : Hansen Et AlDocument5 pagesUnited States Patent (19) : Hansen Et AlFernandoNo ratings yet

- FGDFGDocument14 pagesFGDFGFernandoNo ratings yet

- NNNDocument9 pagesNNNFernandoNo ratings yet

- BCBDocument13 pagesBCBFernandoNo ratings yet

- United States Patent (19) 11 Patent Number: 6,083,547: Katta Et Al. (45) Date of Patent: Jul. 4, 2000Document9 pagesUnited States Patent (19) 11 Patent Number: 6,083,547: Katta Et Al. (45) Date of Patent: Jul. 4, 2000FernandoNo ratings yet

- HGFHDFGDocument14 pagesHGFHDFGEduardo Fernandez DazaNo ratings yet

- Us2287659a PDFDocument4 pagesUs2287659a PDFFernandoNo ratings yet

- HGFHFGDocument4 pagesHGFHFGFernandoNo ratings yet

- TEPZZ 66 - 44A - T: European Patent ApplicationDocument22 pagesTEPZZ 66 - 44A - T: European Patent ApplicationFernandoNo ratings yet

- Us2287659a PDFDocument4 pagesUs2287659a PDFFernandoNo ratings yet

- GFGDSGDocument9 pagesGFGDSGFernandoNo ratings yet

- United States Patent (19) 11 Patent Number: 6,083,547: Katta Et Al. (45) Date of Patent: Jul. 4, 2000Document9 pagesUnited States Patent (19) 11 Patent Number: 6,083,547: Katta Et Al. (45) Date of Patent: Jul. 4, 2000FernandoNo ratings yet

- JHHJDocument3 pagesJHHJFernandoNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)