Professional Documents

Culture Documents

Pulse Generator For 12v Lead Acid Battery Desulfation

Uploaded by

stefanov.mail3860Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pulse Generator For 12v Lead Acid Battery Desulfation

Uploaded by

stefanov.mail3860Copyright:

Available Formats

2011−07−23

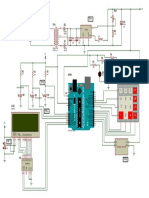

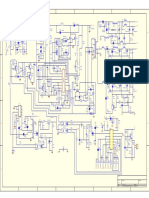

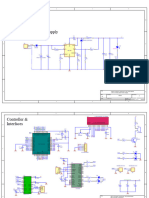

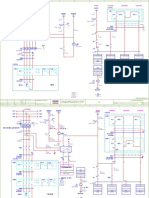

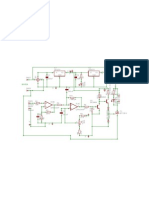

Pulse Generator For 12v Lead Acid Battery Desulfation

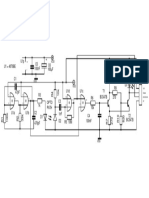

ChargerPos L5 1mH

LM7812 D5

C1A C1B LM78xx C1C C1D 1n4002

U2 R1 100 L4 1mH BattPos

100nF 100uF 10uF 100nF

3 1

+Vout +Vin

L1

Ground F1

2 DLLED 3A−200V

1mH

Fast

D2

FR602

L2

DE1

DLED

220uH

1n4148

1n4002

C3 RLED 1k C4

4n7F

R2

D

LM555 220uF

1 8

Ground Vcc IRFZ44 Low ESR

15k

DE3 1n4148 RE1 2k2 Q1

G

2 7

Trigger Discharge

R4

D4

S

3 6

DE2

E

Output Threshold ChargerNeg

D3

R5

4 5

270k

1n4148

Q2

Reset Control Volt

C5

1n4002

15k

1n4002

U1

C

10nF

BattNeg

R2 is pulse width? Can add thermistor (20k).

0.01ohm resistor in series with the negative battery terminal and an oscilloscope can show waveform pulses. Ohm’s Law for current.

5" of 22g wire will be about 0.01ohm.

Add a FR602 diode in front of L5 for better protection?

Once a day, put a very heavy load (close to a short) across the battery terminals to prevent dendrite growth and cells shorting out.

This is a moderately enhanced version from previous circuits by Alastair Coputer, Ron Ingraham, and Alastair Evans. Where possible,

part numbers have been kept for consistency.

L1 and L2 inductors should be at least 1amp rated (the fatter/larger the better). D2 can be doubled for higher current. C4 can be doubled

for lower ESR. Q1 can be paralleled for higher current. Capacitors and other parts not protected by the regulator should be voltage rated

for the highest peak the pulser can put out. This can sometimes be 3−4x the battery voltage on a badly sulfated battery. F1 probably won’t

provide that much protection and may be omitted by expert users. If parts start overheating, change R2 and R4 to reduce the pulse width

for lower current. R2 and R4 may be pots for starting out and calibration. MOSFET gates are known to be static sensitive, so be careful.

Some MOSFET gates saturate at 5v and some closer to 10v. To avoid overheating, enough voltage needs to be given to the gate for full on.

My main contribution is adding a voltage regulator to help protect and stabilize the signal level circuits. Previous zener shunt regulators

are easily overloaded and do not provide quite the protection they should. A trickle charger can be added at the indicated points to help

keep the voltage consistent. Given the voltage drop of the LM78xx series, a trickle charger is mandatory on a low battery. The L5 inductor

should protect it reasonably well from the pulses. Increasing L4 and L5 is permissible. L5 will get hot with heavy current pulses.

DLLED should only flash when there is a pulse. Since the pulses are 1kHz, it will look like it is solid on. L1+L2 will also whine a little.

For different voltage batteries, change L2 accordingly: 24v=330uH, 36v=470uH, 48v=680uH. L1 may need to be doubled at higher

voltages. R1 may need to be increased for higher voltages. Note that the LM78xx series can only take voltages so high before it will get

blown. I’m guessing the 555 circuit and output should be getting at least 100mA for consistent performance.

??? L2 was increased but timing didn’t seem to change? Used as a resivoir only???

Use very thick wire (18g for small batteries, 8g for large batteries) on the output high current section. For the battery hook ups, tin, crimp,

and solder the connectors to help avoid corrosion problems. Keep the output wires as short as practically possible to avoid losses.

L1 and L2 need to be big enough to provide the charging and current pulses. L5 needs to be big enough to allow large currents to be

received from the charger. Smaller inductors will limit this, warm up, and increase charging/desuflation time.

The 1n400X diodes can handle much higher pulse currents than the 1n4148’s, but react slower. There are "UF" versions (for ultra fast)

and those should be used when available. For battery voltages higher than 12v, use a 1n4002 or better.

You might also like

- TV Sankey DiagramaDocument5 pagesTV Sankey DiagramaRafael QuiaroNo ratings yet

- (C) F5RDH - F5HW 2002: VIN VoutDocument5 pages(C) F5RDH - F5HW 2002: VIN VoutDUDULE0% (1)

- Solar Panel Charger Circuit DiagramDocument1 pageSolar Panel Charger Circuit DiagramMario MarcioNo ratings yet

- VCC 12 +IN 1 1 - IN 1 2 3 C1 8 E1 9 11 Ref Out 14Document1 pageVCC 12 +IN 1 1 - IN 1 2 3 C1 8 E1 9 11 Ref Out 14Jhon Hermes Mulato MarriagaNo ratings yet

- Circuit DiagramDocument1 pageCircuit Diagramalidjem26No ratings yet

- Hansol Iphs4l17 Ice2as01 LCD Power Supply SCHDocument1 pageHansol Iphs4l17 Ice2as01 LCD Power Supply SCHdenys92500No ratings yet

- BLOOD - UNO Done EditDocument1 pageBLOOD - UNO Done EditdieliaNo ratings yet

- DC-DC Step Down On XL4016Document1 pageDC-DC Step Down On XL4016Raghu Vutukuru100% (3)

- Carregador Flyback 6baterias Ent220vDocument1 pageCarregador Flyback 6baterias Ent220vArmando Cavero MirandaNo ratings yet

- Schematic - Power Meter - 2020-06-10 - 08-59-36Document1 pageSchematic - Power Meter - 2020-06-10 - 08-59-36Yoshua M FANo ratings yet

- Branson - 8210 SchematicDocument1 pageBranson - 8210 SchematicjonatechNo ratings yet

- Audio Mixer SkemaDocument1 pageAudio Mixer SkemakalabendaNo ratings yet

- TDA2013Document1 pageTDA2013PhuongNo ratings yet

- Ellenberg ltv3231Document52 pagesEllenberg ltv3231NeilNo ratings yet

- Entrenador BasicoDocument3 pagesEntrenador BasicoJuan Esteban Lopez BedoyaNo ratings yet

- EEE418 Embedded SystemDocument13 pagesEEE418 Embedded SystemABDULLAH AL BAKINo ratings yet

- SchematicDocument2 pagesSchematicYevhen SafronovNo ratings yet

- RF circuit board component identification guideDocument1 pageRF circuit board component identification guideMuhammet ŞekerNo ratings yet

- X-Altra HPA-1 Headphone Amplifier: This Project Uses SMD Components Down To SOT23 and 0805Document40 pagesX-Altra HPA-1 Headphone Amplifier: This Project Uses SMD Components Down To SOT23 and 0805bobannesicNo ratings yet

- 9101.220LED (298NEW-S14-D5730) SchematicDocument1 page9101.220LED (298NEW-S14-D5730) Schematicluis palominoNo ratings yet

- Control circuit with Arduino Nano and MPU-6050Document1 pageControl circuit with Arduino Nano and MPU-6050FranklinNo ratings yet

- LDORF - Out (200ma) : TendaDocument12 pagesLDORF - Out (200ma) : TendaOlegNo ratings yet

- Manual de Serviço D 461 - ESQ - ELET. FONTE - BDocument1 pageManual de Serviço D 461 - ESQ - ELET. FONTE - BElebrane Honorato dos Santos0% (1)

- 03/09/2015 17:57:37 F 1.05 F:/ - Program Files Bis/CAD/EAGLE-4.13/projects/LP2 Alimentation HT-380V/Labalim New Ed36.sch (Sheet: 1/1)Document1 page03/09/2015 17:57:37 F 1.05 F:/ - Program Files Bis/CAD/EAGLE-4.13/projects/LP2 Alimentation HT-380V/Labalim New Ed36.sch (Sheet: 1/1)Eugenio Martin CuencaNo ratings yet

- Vin+ Vout+: MJE2955 Q1 R10 Con2 L1Document1 pageVin+ Vout+: MJE2955 Q1 R10 Con2 L1SANDEEP KUMAR RAHEJANo ratings yet

- Mach Dien V3Document1 pageMach Dien V3Tran Duc XuanNo ratings yet

- ECHOFEX SchematicDocument1 pageECHOFEX SchematicHristoIlievNo ratings yet

- SMPSDocument1 pageSMPSbrijkamaniNo ratings yet

- Schematic ATU 100 Mini V2.0 Autotuner by DFDocument1 pageSchematic ATU 100 Mini V2.0 Autotuner by DFDmitry Kuklin80% (5)

- Wirepad4,16O1,6 Fr104 VCC D3: Spiceorder 1 Spiceorder 2Document1 pageWirepad4,16O1,6 Fr104 VCC D3: Spiceorder 1 Spiceorder 2AndrianovitNo ratings yet

- Power 2Document1 pagePower 2Chandana KarunapalaNo ratings yet

- Testing circuit board schematicDocument2 pagesTesting circuit board schematicJAIR VIEIRA DE SOUZA JUNIORNo ratings yet

- Schematic - ATU 100 7x7Document1 pageSchematic - ATU 100 7x7Frusescu Lucian0% (1)

- Schematic - ATU 100 7x7 PDFDocument1 pageSchematic - ATU 100 7x7 PDFClaudemirNo ratings yet

- Ebs Multicomp2 Guitareffects SchematicsDocument1 pageEbs Multicomp2 Guitareffects SchematicsMarcantonio InfascelliNo ratings yet

- GameMax-1050 SchematicDocument1 pageGameMax-1050 SchematicRumen J.No ratings yet

- Trafo Tester Schematics-2Document4 pagesTrafo Tester Schematics-2Chandana KarunapalaNo ratings yet

- PREAMP INTERFACE CIRCUIT DIAGRAMDocument9 pagesPREAMP INTERFACE CIRCUIT DIAGRAMJohn govan100% (1)

- Appendix 6 TemplateDocument30 pagesAppendix 6 TemplateCakasana AlifNo ratings yet

- SmartScope Schematics v1.1Document9 pagesSmartScope Schematics v1.1clownNo ratings yet

- 4n1 SPK Protect (Sla) - CombinedDocument11 pages4n1 SPK Protect (Sla) - CombinedCarlos Romero GonzalesNo ratings yet

- 96PCAI00012 FilterPCBADocument2 pages96PCAI00012 FilterPCBAassistenzadavidoffstoreNo ratings yet

- Power Supply: Tobias Brown-HeftDocument1 pagePower Supply: Tobias Brown-Heftdborcic61No ratings yet

- Diagrama EsquemáticoDocument2 pagesDiagrama EsquemáticoJuan Sebastian GiraldoNo ratings yet

- Expert Apple Repair Forum Document SummaryDocument31 pagesExpert Apple Repair Forum Document SummaryAlberto Angoa Santamaria100% (1)

- DA18K4 Complete SchematicsDocument5 pagesDA18K4 Complete SchematicsLucas FigueiredoNo ratings yet

- Pedal - PCBWay CommunityDocument1 pagePedal - PCBWay Communityheric fernandesNo ratings yet

- STATIEDocument1 pageSTATIEMeleaca GeorgianNo ratings yet

- Regulator and LED circuit diagramDocument4 pagesRegulator and LED circuit diagramAlex LandaNo ratings yet

- 13/07/2015 7:40:49 C:/Documents and Settings/zeh/Mis documentos/eagle/fuentes/FUENTE ELEKTOR/Fuente1.sch (Sheet: 1/1)Document1 page13/07/2015 7:40:49 C:/Documents and Settings/zeh/Mis documentos/eagle/fuentes/FUENTE ELEKTOR/Fuente1.sch (Sheet: 1/1)Carlos Juan Quispe MartinezNo ratings yet

- User Manual: Manufacture by ItalyDocument64 pagesUser Manual: Manufacture by ItalyFreeFM67% (6)

- SP 01 en Schnellladegeraet - UFC 2 PDFDocument4 pagesSP 01 en Schnellladegeraet - UFC 2 PDFfpertreusNo ratings yet

- Daylight BlockingDocument1 pageDaylight BlockingAMANNo ratings yet

- 2.8Document1 page2.8Pisu Miau Pisu MiauNo ratings yet

- TinySA V2 Control-SchematicDocument1 pageTinySA V2 Control-SchematicPisu Miau Pisu MiauNo ratings yet

- Experimental Study of The Direct Approach For Control of Magnetic Field - 2015 - WebDocument6 pagesExperimental Study of The Direct Approach For Control of Magnetic Field - 2015 - Webstefanov.mail3860No ratings yet

- Giza Power Plant in RussianDocument358 pagesGiza Power Plant in Russianstefanov.mail3860No ratings yet

- Rotary Valve Engines BookDocument107 pagesRotary Valve Engines Bookstefanov.mail3860No ratings yet

- Dimension wastewater treatment tanksDocument23 pagesDimension wastewater treatment tanksmothman22No ratings yet

- Copper Recovery Using Leach Solvent Elect Row Inning ExtractionDocument6 pagesCopper Recovery Using Leach Solvent Elect Row Inning Extractionstefanov.mail3860No ratings yet

- Intro GalDocument15 pagesIntro GalFilozófus ÖnjelöltNo ratings yet

- A221hqv PDFDocument88 pagesA221hqv PDFЕвгений ТокаревNo ratings yet

- Denon-S32!52!52DAB Wireless Music SysDocument102 pagesDenon-S32!52!52DAB Wireless Music SyscesarlcaNo ratings yet

- MR 198CVS Video Processor User Manual V1.0 20140505 PDFDocument120 pagesMR 198CVS Video Processor User Manual V1.0 20140505 PDFMauricio DiazNo ratings yet

- Series 90 Programmable Coprocessor Module and Support Software User's Manual, GFK-0255Kgfk0255kDocument316 pagesSeries 90 Programmable Coprocessor Module and Support Software User's Manual, GFK-0255Kgfk0255kARTURO TZITZIHUA HERNANDEZ100% (1)

- PM5100 User GuideDocument96 pagesPM5100 User GuideGerson ChavarriaNo ratings yet

- High-Speed Low-Power Viterbi Decoder Design For TCM DecodersDocument16 pagesHigh-Speed Low-Power Viterbi Decoder Design For TCM DecodersShruti Tajne100% (1)

- Lab Manual: Digital System Design (PR) : COT-215 Digital Electronics (P) : IT-211Document7 pagesLab Manual: Digital System Design (PR) : COT-215 Digital Electronics (P) : IT-211rajeshforallNo ratings yet

- A600 User Guide - (Homemade) - Manual-ENG PDFDocument27 pagesA600 User Guide - (Homemade) - Manual-ENG PDFMikiPopovicNo ratings yet

- Práctica 1 TiristoresDocument15 pagesPráctica 1 TiristoresDorian JesusNo ratings yet

- Two Marks Questions with Answers on Computer ArchitectureDocument19 pagesTwo Marks Questions with Answers on Computer ArchitectureAKASH KSNo ratings yet

- BA3880S Audio IC ReproductionDocument10 pagesBA3880S Audio IC ReproductionManish KubawatNo ratings yet

- SMPS - (Switch Mode Power Supply)Document20 pagesSMPS - (Switch Mode Power Supply)Karthi Keyan VeeraNo ratings yet

- Dipole-Disk Antenna With Beam-Forming RingDocument6 pagesDipole-Disk Antenna With Beam-Forming RingtamilarasansrtNo ratings yet

- Pinout at Haval M4 PDFDocument4 pagesPinout at Haval M4 PDFErasmo Israel Garcia OchoaNo ratings yet

- Synchronous Step-Down11Document57 pagesSynchronous Step-Down11ed251No ratings yet

- Optical Computer Advantages and ChallengesDocument26 pagesOptical Computer Advantages and Challengesshruti shuklaNo ratings yet

- Health Monitoring GloveDocument7 pagesHealth Monitoring GloveYashNo ratings yet

- Characteristics of Crystal-Video Receivers PDFDocument24 pagesCharacteristics of Crystal-Video Receivers PDFlazarosNo ratings yet

- MONITRAN Mtn1100c Series (Ing)Document2 pagesMONITRAN Mtn1100c Series (Ing)biotech666No ratings yet

- Microelectronics: Circuit Analysis and Design Donald A. NeamenDocument10 pagesMicroelectronics: Circuit Analysis and Design Donald A. NeamenBhandari PrakashNo ratings yet

- CH 07 Solutions Practice ProblemsDocument4 pagesCH 07 Solutions Practice ProblemsChris RosasNo ratings yet

- Computer Book MaterialDocument69 pagesComputer Book MaterialAqib Asad100% (1)

- REN R20ut0757ej3500-Pgfp5-List MAN 20201006Document35 pagesREN R20ut0757ej3500-Pgfp5-List MAN 20201006KingNo ratings yet

- Constant Electricity Generation From Self-Charging InverterDocument5 pagesConstant Electricity Generation From Self-Charging InverterMichael Adeiza EmmanuelNo ratings yet

- Electronics - Theory and PracticeDocument773 pagesElectronics - Theory and Practicesulayajanny100% (1)

- What Is Meant by Accuracy Class of A CT?Document3 pagesWhat Is Meant by Accuracy Class of A CT?Trishna Singh BundhooNo ratings yet

- SSt-U 5 Blink & Error CodesDocument1 pageSSt-U 5 Blink & Error CodesAzizi SamNo ratings yet

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (542)

- 8051 Microcontroller: An Applications Based IntroductionFrom Everand8051 Microcontroller: An Applications Based IntroductionRating: 5 out of 5 stars5/5 (6)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsFrom EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsRating: 4 out of 5 stars4/5 (1)

- The Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026From EverandThe Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Rating: 5 out of 5 stars5/5 (1)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4 out of 5 stars4/5 (331)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersFrom Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersRating: 5 out of 5 stars5/5 (1)

- Lithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsFrom EverandLithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsRating: 5 out of 5 stars5/5 (2)

- Off-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemFrom EverandOff-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemNo ratings yet

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)From EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Rating: 4.5 out of 5 stars4.5/5 (2)

- Ramblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowFrom EverandRamblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowNo ratings yet

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesFrom EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesRating: 5 out of 5 stars5/5 (1)

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 5 out of 5 stars5/5 (8)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- C++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingFrom EverandC++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingRating: 4 out of 5 stars4/5 (1)

- Current Interruption Transients CalculationFrom EverandCurrent Interruption Transients CalculationRating: 4 out of 5 stars4/5 (1)

- Digital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsFrom EverandDigital Gold: The Beginner's Guide to Digital Product Success, Learn Useful Tips and Methods on How to Create Digital Products and Earn Massive ProfitsRating: 5 out of 5 stars5/5 (3)

- The Graphene Revolution: The Weird Science of the Ultra-thinFrom EverandThe Graphene Revolution: The Weird Science of the Ultra-thinRating: 4.5 out of 5 stars4.5/5 (4)