Professional Documents

Culture Documents

Exp 2-Pressure Measurement

Uploaded by

hanis24Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exp 2-Pressure Measurement

Uploaded by

hanis24Copyright:

Available Formats

UNIVERSITI KUALA LUMPUR

MALAYSIAN INSTITUTE OF CHEMICAL & BIOENGINEERING TECHNOLOGY

CLD 20202

PROCESS INSTRUMENTATION

BACHELOR OF CHEMICAL ENGINEERING

TECHNOLOGY

EXPERIMENT 2

Pressure Measurement & Calibration

SEMESTER

January 2013

Experiment 2: Pressure Measurement & Calibration System

EXPERIMENT 2

PRESSURE MEASUREMENT & CALIBRATION SYSTEM

1.0 EXPERIMENT PROCEDURES

1.1 Plant Start-up Procedures

1. Switch ON the main power supply. The switch is at the front of the

panel/cubicle.

2. Check that all the manual valves including the vent (V) and bottom drain (D)

valves are shut.

3. Open the manual valve MV3 at the Pressure Gauge (PG). Check the reading at

Pressure Gauge (PG). If the Pressure Gauge (PG) shows some value of pressure in

Tank TI, open the Vent (V) or bottom drain (D) valves to release the pressure in

tank. This is done until the Pressure Gauge (PG) shows a ‘zero’ reading.

4. Connect the Manometer (AMETEK JOFRA CPC-200 INDG) properly to the

Tester Tapping Point, MV 8.

1.2 Experiment 1 (Measurement)

1. Check that the main power supply at the front panel is switched ON.

2. Open manual valves MV1 connected to PT1, MV2 connected to PT2 and MV3

connected PG. Check that all other manual valves are fully shut.

3. Check that the AFR is at the set pressure of 30 psig.

4. Open manual valve MV6 next to AFR to fill up the Pressure Tank, T1.

5. Check that the Manometer is properly connected to the tester tapping point, MV8.

Open fully the manual valve, MV8.

6. Check the readings at the Manometer and Pressure Gauge (PG). Once the

pressure readings in both the instruments are stabilized, manual valve MV6 is

shut fully.

7. Run the experiment

Suggested pressure: 30 psig

Experiment 2: Pressure Measurement & Calibration System

Check the readings at the Manometer and Pressure Gauge (PG). Once the

pressures readings in both the instruments are stabilized shut the vent (V)

valve and record the data in Table 1.

Open the Vent (V) valve to release the pressure to the next suggested

pressure.

Continue measure the pressure from 25 psig until 0 psig.

1.3 Experiment 2 (PT1 Site Calibration)

1. Check that all the manual valves including the vent (V) and bottom drain (D)

valves are shut.

2. Shut MV1 valve to isolate PT1 from the plant.

3. Remove the tubing connected to the transmitter.

4. Then, fix a vacuum pump (AMETEK MODEL T-750) to the transmitter to obtain

a pressure. FIGURE 1.1

5. Connect the Manometer properly to PT1. FIGURE 1.1

6. Once this is done, a Multimeter (GW MODEL GDM-391A) is connected to

PT1 to obtain the output signal from the transmitter for all the tested site

calibration ranges. FIGURE 1.2

7. Configuration of PT1 can be carried out to access information of the transmitter.

1.4 Experiment 3 (PT2 Site Calibration)

1. Check that all the manual valves including the vent (V) and bottom drain (D)

valves are shut.

2. Shut MV2 valve to isolate PT2 from the plant.

3. Remove the tubing connected to the transmitter.

4. Then, fix a vacuum pump (AMETEK MODEL T-750) to the transmitter to obtain

a pressure.

5. Connect the Manometer properly to PT2.

6. Once this is done, a Multimeter (GW MODEL GDM-391A) is connected to

PT2 to obtain the output signal from the transmitter for all the tested site

calibration ranges.

7. Configuration of PT2 can be carried out to access information of the transmitter.

Experiment 2: Pressure Measurement & Calibration System

Plant Shut-down

1. Make sure that the remaining air in pressure tank, T1 is released with vent (V)

valve fully open.

2. Shut the manual valve MV6 next to AFR and all other manual valves fully.

3. Reconnect the original tubing of both PT1 and PT2.

4. Switch OFF the main power supply to the plant at the front of the panel/ cubical.

Fig. 1.1: Connection of instrument to Pressure Transmitter, Hand Held & Manometer

Fig. 1.2: Connection between Multimeter & the Pressure Transmitter terminal

Experiment 2: Pressure Measurement & Calibration System

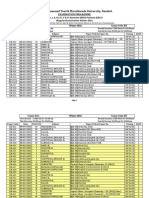

2.0 RESULTS

TABLE 1: Pressure Measurement

RUN I SET 1 SET 2 Average

A Suggested Pressure, psig 30.00 30.00 30.00

B Actual Gauge Pressure, psig

C Gauge Pressure, psig

D Gauge Pressure, psig

E Absolute Pressure, psia

F=B+ 14.70 Calculated Absolute Pressure, psia

G1 = | B — C |

At Pressure Gauge

Gauge Pressure

Deviation, psig

G2 = | B — D | At Pressure Indicator,

P12

H=|F—E| Absolute Pressure Deviation, psia

RUN II SET 1 SET 2 Average

A Suggested Pressure, psig 25.00 25.00 25.00

B Actual Gauge Pressure, psig

C Gauge Pressure, psig

D Gauge Pressure, psig

E Absolute Pressure, psia

F=B+ 14.70 Calculated Absolute Pressure, psia

G1 = lB — Cl

At Pressure Gauge

Gauge Pressure

Deviation, psig

At Pressure Indicator,

G2 = lB — Dl

P12

H = IF — El Absolute Pressure Deviation, psia

Experiment 2: Pressure Measurement & Calibration System

RUN III SET 1 SET 2 Average

A Suggested Pressure, psig 20.00 20.00 20.00

B Actual Gauge Pressure, psig

C Gauge Pressure, psig

D Gauge Pressure, psig

E Absolute Pressure, psia

F=B+ 14.70 Calculated Absolute Pressure, psia

G1 = lB — Cl

At Pressure Gauge

Gauge Pressure

Deviation, psig

G2 = lB — Dl At Pressure Indicator,

P12

H = IF — El Absolute Pressure Deviation, psia

RUN IV SET 1 SET 2 Average

A Suggested Pressure, psig 15.00 15.00 15.00

B Actual Gauge Pressure, psig

C Gauge Pressure, psig

D Gauge Pressure, psig

E Absolute Pressure, psia

F=B+ 14.70 Calculated Absolute Pressure, psia

G1 = lB — Cl

At Pressure Gauge

Gauge Pressure

Deviation, psig

G2 = lB — Dl At Pressure Indicator,

P12

H = IF — El Absolute Pressure Deviation, psia

Experiment 2: Pressure Measurement & Calibration System

RUN V SET 1 SET 2 Average

A Suggested Pressure, psig 10.00 10.00 10.00

B Actual Gauge Pressure, psig

C Gauge Pressure, psig

D Gauge Pressure, psig

E Absolute Pressure, psia

F=B+ 14.70 Calculated Absolute Pressure, psia

G1 = lB — Cl

At Pressure Gauge

Gauge Pressure

Deviation, psig

G2 = lB — Dl At Pressure Indicator,

P12

H = IF — El Absolute Pressure Deviation, psia

RUN VII SET 1 SET 2 Average

A Suggested Pressure, psig 0.00 0.00 0.00

B Actual Gauge Pressure, psig

C Gauge Pressure, psig

D Gauge Pressure, psig

E Absolute Pressure, psia

F=B+ 14.70 Calculated Absolute Pressure, psia

G1 = lB — Cl

At Pressure Gauge

Gauge Pressure

Deviation, psig

G2 = lB — Dl At Pressure Indicator,

P12

H = IF — El Absolute Pressure Deviation, psia

Experiment 2: Pressure Measurement & Calibration System

RUN VI SET 1 SET 2 Average

A Suggested Pressure, psig 5.00 5.00 5.00

B Actual Gauge Pressure, psig

C Gauge Pressure, psig

D Gauge Pressure, psig

E Absolute Pressure, psia

F=B+ 14.70 Calculated Absolute Pressure, psia

G1 = lB — Cl

At Pressure Gauge

Gauge Pressure

Deviation, psig

G2 = lB — Dl At Pressure Indicator,

P12

H = IF — El Absolute Pressure Deviation, psia

Remarks:

B: Read from the Manometer (AMETEK JOFRA CPC-200 INDG).

C: Read from the Pressure Gauge (PG).

D: Read from the Pressure Indicator (PI2) on the front panel.

E: Read from the Pressure Indicator (PI1) on the front panel.

Experiment 2: Pressure Measurement & Calibration System

TABLE 2: PT1 Site Calibration Check

RUN I PT1 Site Calibration

Product Code:

Serial Number:

Maximum deviation : 0.075 (Zero Ini. Err = 0.03)

Tag Name:

Calibration Range:

A B C D E F G H

Input Output Measured Theoretical % Accuracy % Deviation Dev. Remarks

Pressure Applied, Pressure, Output, Output, mA C D mA

x 100

C DmA x 100 Limit Pass: If Deviation % <±

20 - 4mA

Dev. Limit

psig/psia psia mA D mA

Fail : If Otherwise

at% of Calibration

Range

0.30/ 15.00 at 25.0% 8.00 ± 0.075

15.30/ 30.00 at 50.0% 12.00 ± 0.075

30.30/ 45.00 at 22.5% 16.00 ± 0.075

45.30/ 60.00 at 100.0% 20.00 ± 0.075

Remarks:

B: Read from the Pressure Indicator (PI1) on the front panel.

C: Read from the Multimeter (GW MODEL GDM-391A).

Experiment 2: Pressure Measurement & Calibration System

TABLE 2: PT2 Site Calibration Check

RUN II PT2 Site Calibration

Product Code:

Serial Number:

Maximum deviation : 0.075 (Zero Ini. Err = 0.03)

Tag Name:

Calibration Range:

A B C D E F G H

Input Output Measured Theoretical % Accuracy % Deviation Dev. Remarks

Pressure Applied, Pressure, Output, Output, mA C D mA

x 100

C DmA x 100 Limit Pass: If Deviation % <±

20 - 4mA

Dev. Limit

psig psig mA D mA

Fail : If Otherwise

at% of Calibration

Range

0.00 at 0.0% 4.00 0.03

7.50 at 25.0% 8.00 ± 0.075

15.00 at 50.0% 12.00 ± 0.075

22.50 at 22.5% 16.00 ± 0.075

30.00 at 100.0% 20.00 ± 0.075

Remarks:

B: Read from the Pressure Indicator (PI2) on the front panel.

C: Read from the Multimeter (GW MODEL GDM-391A).

Experiment 2: Pressure Measurement & Calibration System

3.0 QUESTIONS

1. State whether the pressure is higher/lower/equal at the bottom of a tank filled with

a gas than at the top.

2. Differentiate absolute pressure and gauge pressure.

3. If the contents of a tank holding 20m3 of gas are transferred to a tank with twice

as much volume and all other factors remain unchanged, what will happen to gas

pressure?

4. If the gas in a tank heated and all other factors remain unchanged, what will

happen to the gas pressure?

5. What is the pressure measuring instrument used in this plant?

6. Discuss briefly the possible errors affecting the accuracy in pressure measurement

as observed in the experiment.

4.0 REFERENCES

1. Experiment Manual PMC 200, QDR Marketing Sdn Bhd

Experiment 2: Pressure Measurement & Calibration System

Experiment 2: Pressure Measurement & Calibration System

You might also like

- Pressure Measurement and Calibration Lab ReportDocument16 pagesPressure Measurement and Calibration Lab ReportYuliya100% (3)

- Exp 2Document4 pagesExp 2Abdul AddaharyNo ratings yet

- Final Practice Examination Answer Key: Rade HysicsDocument40 pagesFinal Practice Examination Answer Key: Rade HysicsNenbon NatividadNo ratings yet

- Three Member FrameDocument72 pagesThree Member FrameSampanna 37No ratings yet

- 2.2 Design of Flexural MemberDocument26 pages2.2 Design of Flexural MemberNazihah100% (1)

- Chapter 4Document49 pagesChapter 4Ibrahim Al-HammadiNo ratings yet

- Shell Momentum BalancesDocument48 pagesShell Momentum BalancesDianah NajeebNo ratings yet

- Construction of Attainable Region Using Modeling ToolsDocument43 pagesConstruction of Attainable Region Using Modeling ToolsLorena BelloNo ratings yet

- Kuliah 9 PDFDocument51 pagesKuliah 9 PDFZulfansyah zulNo ratings yet

- Experiment #2 Calibration of A Pressure SensorDocument8 pagesExperiment #2 Calibration of A Pressure SensorMoh BadjahNo ratings yet

- Creii 5Document37 pagesCreii 5Amit KananiNo ratings yet

- Swayam-Nptel - July 2019Document21 pagesSwayam-Nptel - July 2019Gaurab SarkarNo ratings yet

- Fluid Flow Measurement and Analysis ExperimentDocument11 pagesFluid Flow Measurement and Analysis ExperimentJohn TomlinsonNo ratings yet

- 4 Temperature MeasurementDocument113 pages4 Temperature MeasurementAhmed M. El-DyastyNo ratings yet

- Linear and Quadratic Programming ExamplesDocument14 pagesLinear and Quadratic Programming ExamplesMiNiTexasNo ratings yet

- Pressure MeasurementDocument29 pagesPressure MeasurementKuwer ThakurNo ratings yet

- Fundamentals of Temperature MeasurementDocument2 pagesFundamentals of Temperature MeasurementAhmed M. El-DyastyNo ratings yet

- Lecture Note Chapter 11 PID Controller Design Tuning and Troubleshooting 2016Document61 pagesLecture Note Chapter 11 PID Controller Design Tuning and Troubleshooting 2016Rama KrishnaNo ratings yet

- Introduction To Temperature MeasurementDocument20 pagesIntroduction To Temperature MeasurementjimsistiNo ratings yet

- Basic of Instrumentation EyassDocument34 pagesBasic of Instrumentation EyassLu'ay ElyaeNo ratings yet

- Psychrometrics 120339802285862 4Document31 pagesPsychrometrics 120339802285862 4Wilfred ThomasNo ratings yet

- Humidity and Temperature Measurement Using Arduino: Submitted ByDocument22 pagesHumidity and Temperature Measurement Using Arduino: Submitted Byhandsome03No ratings yet

- Homework 2Document4 pagesHomework 2Paul LeeNo ratings yet

- Mechanical Measurements and InstrumentationDocument71 pagesMechanical Measurements and InstrumentationanandakumarmtsNo ratings yet

- Pressure Measurement: Muhajir Ab. RahimDocument19 pagesPressure Measurement: Muhajir Ab. Rahimprasaad08No ratings yet

- CDB 3062 Chemical Engineering Lab 3 MAY 2016: Group: 03 Date Experiment Group MembersDocument14 pagesCDB 3062 Chemical Engineering Lab 3 MAY 2016: Group: 03 Date Experiment Group MembersZen AlkaffNo ratings yet

- Temperature MeasurementDocument38 pagesTemperature MeasurementTarun Singhal100% (1)

- Calibration of A Vacuum Gauge by Comparison With A U-Tube ManometerDocument8 pagesCalibration of A Vacuum Gauge by Comparison With A U-Tube ManometerNazario Emil LintagNo ratings yet

- Process Intensification ReportDocument12 pagesProcess Intensification ReportSushma SusmitaNo ratings yet

- Measurement Course MateialDocument56 pagesMeasurement Course Mateialkalaivani1408No ratings yet

- 63697Document18 pages63697Thirunavuk KarasuNo ratings yet

- Chen4352 PDC Lab ManualDocument26 pagesChen4352 PDC Lab ManualmohammedNo ratings yet

- Transport 1Document28 pagesTransport 1Dianah NajeebNo ratings yet

- Real-World-Modeling PDFDocument12 pagesReal-World-Modeling PDFGATOMICONo ratings yet

- ME8501 - Metrology and Measurements - Unit - IDocument30 pagesME8501 - Metrology and Measurements - Unit - Iarunpdc100% (1)

- Introduction To InstrumentationDocument126 pagesIntroduction To InstrumentationbelaynehNo ratings yet

- Closed Loop Response of Temperature Control SystemDocument6 pagesClosed Loop Response of Temperature Control SystemsjsujiprasadNo ratings yet

- Bactron Anaerobic ChamberDocument8 pagesBactron Anaerobic ChamberAsvene SharmaNo ratings yet

- Separation Process Engineering CHEN 312: Ys18@aub - Edu.lbDocument28 pagesSeparation Process Engineering CHEN 312: Ys18@aub - Edu.lbsoe0303No ratings yet

- INSTRUDocument130 pagesINSTRUJustine-Denisse OngNo ratings yet

- Density Measurement DP PressureDocument5 pagesDensity Measurement DP PressureIrfanNo ratings yet

- Transport Phenomena Quiz 1 SolutionDocument2 pagesTransport Phenomena Quiz 1 SolutionAyman Al Kafrawy100% (1)

- BME2303 Tutorial 2Document6 pagesBME2303 Tutorial 2Zarif IzzatNo ratings yet

- PC Lab ManualDocument47 pagesPC Lab ManualAoiNo ratings yet

- Driving Forces For The Transport PhenomenaDocument10 pagesDriving Forces For The Transport Phenomenadppriya1984No ratings yet

- Transport Phenomenon NotesDocument7 pagesTransport Phenomenon Notesvishakha goelNo ratings yet

- Class 3 - Performance CharacteristicsDocument30 pagesClass 3 - Performance CharacteristicsMaher Abu-ElolaNo ratings yet

- Process Temperature Control Using PID and LabVIEWDocument17 pagesProcess Temperature Control Using PID and LabVIEWManish SinghNo ratings yet

- Lecture 1Document7 pagesLecture 1Paulo Pollo100% (1)

- Temperature MeasurementDocument14 pagesTemperature Measurementarkadjyothiprakash100% (1)

- Orifice and Venturi Meter - PrelabDocument6 pagesOrifice and Venturi Meter - Prelableo besaNo ratings yet

- Venturi MeterDocument51 pagesVenturi MeterPriteshShahNo ratings yet

- 4 - Flapper Nozzle SystemDocument3 pages4 - Flapper Nozzle SystemfaizsyauqiNo ratings yet

- Basic Inst.Document15 pagesBasic Inst.mahesh4975No ratings yet

- Practica CDocument2 pagesPractica CAlejandroCalleRuizNo ratings yet

- FugacityDocument20 pagesFugacityFernando J. Correa DelgadoNo ratings yet

- Pressure Measurement 2022-1Document38 pagesPressure Measurement 2022-1Varun VelrajNo ratings yet

- 3141709Document3 pages3141709Lakum Hitesh100% (2)

- Pitot Static TubeDocument2 pagesPitot Static TubeMelvin MagbanuaNo ratings yet

- Experiment 3: Pressure Measurement & CalibrationDocument12 pagesExperiment 3: Pressure Measurement & CalibrationFatih RushdiNo ratings yet

- Exp 1-Pressure MeasurementDocument12 pagesExp 1-Pressure MeasurementdarlianaNo ratings yet

- Result and DiscussionDocument7 pagesResult and DiscussionZulfitri ZulkarnainNo ratings yet

- Instrument Technology: Measurement of Pressure, Level, Flow and TemperatureFrom EverandInstrument Technology: Measurement of Pressure, Level, Flow and TemperatureRating: 4 out of 5 stars4/5 (1)

- Physics WS 1Document4 pagesPhysics WS 1Anonymous SOQFPWBNo ratings yet

- Physicalsciences Grade 12 Term 1 PDFDocument141 pagesPhysicalsciences Grade 12 Term 1 PDFRose Ann CruzadoNo ratings yet

- TOPIC 2dedited (Autosaved)Document19 pagesTOPIC 2dedited (Autosaved)AzWia MkhtrNo ratings yet

- 2.9 - Exponential Functions and The Natural Exponential Filled inDocument3 pages2.9 - Exponential Functions and The Natural Exponential Filled injpaim1008No ratings yet

- m3 m4 Oblique CollisionsDocument48 pagesm3 m4 Oblique Collisionsjeetchoudhary7890No ratings yet

- Interference Using A Fresnel Biprism: 1 Introduction and TheoryDocument4 pagesInterference Using A Fresnel Biprism: 1 Introduction and TheoryMirza Khurram BaigNo ratings yet

- Some Tips For The Revised CSIR UGC NET For Physical SciencesDocument15 pagesSome Tips For The Revised CSIR UGC NET For Physical SciencesJijo P. Ulahannan100% (12)

- Grating and Expanded Metal CatalogDocument68 pagesGrating and Expanded Metal CatalogsivaNo ratings yet

- Swami Ramanand Teerth Marathwada University, NandedDocument19 pagesSwami Ramanand Teerth Marathwada University, NandedsmpopadeNo ratings yet

- CAT 320 Reparar BaldeDocument46 pagesCAT 320 Reparar BaldeTaller PahrNo ratings yet

- Bachelor of Science in Civil EngineeringDocument4 pagesBachelor of Science in Civil EngineeringRadge Den DCNo ratings yet

- UNIT-5 Introduction To Statistical Thermodynamics: Dr. Uttam Mohan Assistant Professor D.H.S.K. College, Dibrugarh AssamDocument33 pagesUNIT-5 Introduction To Statistical Thermodynamics: Dr. Uttam Mohan Assistant Professor D.H.S.K. College, Dibrugarh Assamyamanappagouda gudagaladinnyNo ratings yet

- Lab2 Control SystemDocument43 pagesLab2 Control Systemعبدالملك جمالNo ratings yet

- CUET 2022 Physics Book CompDocument822 pagesCUET 2022 Physics Book CompAnvesh SriramulaNo ratings yet

- NEW Atlanta Permaline 2019Document2 pagesNEW Atlanta Permaline 2019gregNo ratings yet

- Free Electron TheoryDocument68 pagesFree Electron TheoryV Sree Suswara SuswaraNo ratings yet

- (A) IDF Curve by Polynomial MethodDocument5 pages(A) IDF Curve by Polynomial MethodaineenaNo ratings yet

- Pastor M Tamagnini C Numerical Modelling in GeomechanicsDocument351 pagesPastor M Tamagnini C Numerical Modelling in GeomechanicsBrysnerNo ratings yet

- Methods of Interstellar TravelDocument4 pagesMethods of Interstellar TravelTimurNo ratings yet

- Sarmand 1Document19 pagesSarmand 1Saroo MusicNo ratings yet

- Crack in Steel StructuresDocument9 pagesCrack in Steel StructuresronxyNo ratings yet

- 12 National Certification Examination - October, 2011 FOR Energy Managers & Energy AuditorsDocument8 pages12 National Certification Examination - October, 2011 FOR Energy Managers & Energy AuditorssamirNo ratings yet

- Cantika Laksmi Bunga Imam Al-Hakim Nisa Fathul JannahDocument9 pagesCantika Laksmi Bunga Imam Al-Hakim Nisa Fathul JannahrahmadaniyantiNo ratings yet

- 3A 3 HYB19 017 Presentation Schoemann Oliver WebDocument25 pages3A 3 HYB19 017 Presentation Schoemann Oliver Webamina bu bakerNo ratings yet

- Sintering ProcessDocument9 pagesSintering ProcessRendy AsahinaNo ratings yet

- Retirement ThicknessDocument7 pagesRetirement ThicknessKamal UddinNo ratings yet

- Creep Behavior of Type 310 Stainless Steel. Part 1: Parameters From The Norton, Arrhenius and Monkman-Grant RelationsDocument13 pagesCreep Behavior of Type 310 Stainless Steel. Part 1: Parameters From The Norton, Arrhenius and Monkman-Grant Relationssezgin bayramNo ratings yet