Professional Documents

Culture Documents

ICOLD - Austria - 2018 - Plug The Large Size Div Tunnel - REV02

Uploaded by

Harimukti RositaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ICOLD - Austria - 2018 - Plug The Large Size Div Tunnel - REV02

Uploaded by

Harimukti RositaCopyright:

Available Formats

Technical Stage to Plug The Large Size Diversion Tunnel of

Jatigede Dam at West Java, Republic of Indonesia, 2017

Anwar 1

Makmur , Tulus H. 2

Basuki , Dony 3

Faturochman , Rosita H. 4

1 Sr.Engineering Geologist; 2 Sr. Dam Designer; 3 Head of Dam Planer at Jatigede dam; 4 Hydrologist

( weak zone ).

Plugging works is a water blocking process in diversion tunnel to block the flow

U

of water from reservoir through the diversion tunnel. Plugging work in Jatigede

dam is scheduled to be done at the construction stage. After the diversion Upper Halang Claystone

tunnel is closed, concrete material is filled in to the tunnel. After the initial gate

closed at August 31st, 2015 then continued with the plugging process on Conduit

September 1st, 2015.

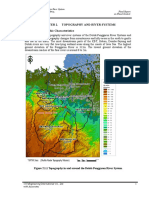

Jatigede dam is located at the abutments of Cimanuk River, in Gambar Error! No text of specified style in document.-1 Geological Long section of Diversion

Jatigede village, Wado district, Sumedang regency, West Java Regional geological condition

Tunnel

in Jatigede dam consists of Pliosen breccia, claystone

province, Republic of Indonesia. The site can be accessed by two from upper Halang formation, breccia from lower Halang Formation and claystone

alternate routes, from Jakarta through Bandung to site about ±265 from Cinambo Formation. All the formations were covered by sand layer and clay.

km, or from Jakarta through Cirebon to site ±195 km (see Fig. 1). Diversion tunnel trace is located at the right abutment, with 546.221 m length layered

on claystone rock, volcanic breccia and tuff breccia (lapilli tuff).

Primary Plugging Main Plugging

Primary Plugging 10 m

7m 2,2 m

Block Block

2,4 m A B

2,4 m

• This primary works aimed to strengthen 17,74 m

61 m

18 m 23 m

diversion tunnel’s gate against reservoir water Divertion Divertion

pressure which gradually becomes higher as Conduit Tunnel

reservoir water level increased. This works

Main Plugging

also serve as a means to counter weight

Position and length of diversion tunnel is stated below: against uplift pressure and minimize leakage

• The function of main plugging is to clog

a. Length of diversion conduit : 61.454 m (sta.0+120,002 ~ sta.0+181,456) which might occur from gates

the water flow through diversion tunnel

b. Length of diversion tunnel : 546.221 m (sta. 0+181,456 ~ sta. 0+727,677) • The construction of primary plugging was not

during impounding of Jatigede reservoir,

completed with cooling pipe and grouting pipe

which have accomplished before full

Plugging stage of diversion tunnel is divided into 2 (two) stages: because it is considered temporary

reservoir operation

1. Primary plugging: sta.0+120,002 ~ sta.0+137,742 (17.74 m) construction

• Main plugging construction is completed

2. Main plugging : sta.0+361,757 ~ sta.0+402,757 (41 m) • The primary plugging applied in the back of

with cooling pipe to reduce concrete

diversion tunnel with trap pattern until 70% of

temperature and grouting pipe which filled

tunnel height

in cement into the shrinkage concrete.

Primary Plugging Main Plugging Pipa Concrete Pump Concrete Pump 1

Block Block

A B

Divertion Divertion

Conduit Tunnel

Pintu Diversion

Primary Plugging Pipa Concrete Pump Concrete Pump 1 Concrete Pump 2 • Different with primary plugging, one concrete pump machine was occupied for concreting of

Tunnel

main plugging due to shorter distance between concrete pump to concreting area.

• Before concreting work, additional equipment had been prepared, i.e. cooling pipe, grouting

pipe, and thermometer. The said equipment has to be installed and examined for it to

Divertion Divertion

Conduit Tunnel

• The first step before concreting the primary plugging is to prepare temporary access to diversion function perfectly, including water cooling or chiller is in normal condition.

tunnel by composing soil and rock embankment at the right abutment of plunge pool to the

adjacent of the diversion tunnel’s inlet. The preparation of temporary access aimed to make it Preparation before Plugging Concreting

easier to operate the concrete mixer car, and to move grouting equipment and staff to adjacent the CL

Concrete Type "G"

diversion tunnel’s inlet. a. Cooling pipe type 1, installation (2 unit)

Cooling pipe

Thermometer

The next step was placing concrete pump machine at the outlet of diversion tunnel, one concrete

Copper Grouted stop

• 1.70

Lift 5 1.50

pump in the middle of diversion tunnel due to the distance between concreting area and the

Concrete Type "G"

1.90

A B 2.40 Lift 4 1.50 Concrete Type "G"

Copper Grouted stop Copper Grouted stop

in put-1

Lift 3

concrete pump is quite far,and shot to concreting area two times due to limitation on concrete

1.75 1.75 in put-2 2.00 1.50

10.00 2.40

0.50 0.50

1.50

Lift 2

3 2 3 2

4 3 4 5 2.00

pump’s capacity.

4 4

out put-2 2.40

10.00 3 5 10.00 out put-1 1.50

4 3 4 5

4 4

3 2 3 2

2.40 Lift 1 Temporary drain pipe

• Concrete type “F+ (plus)” (which using material of 20 mm maximum diameter) were taken into 1.75

18.00

41.00

23.00

1.75

consideration for concreting on plugging works. A B

0.80 1.20 1.20 1.20 1.20

10.00

1.20 1.20 1.20 0.80

No Lift Area (m2) Length (m) Vol (m3) b. Grout pipe installation

1 1 14.49 17.74 257,05 About 943.17 m³ volume of concrete CL

has been completed for executing the

Concrete Type "G"

Concrete Type "G"

Contact Grout Outlet AXIS OF MAINDAM Contact Grout Outlet Distribution Joint Grout

2 2 22.78 16.24 369.95 Copper Grouted stop Copper Grouted stop

Pipe Horizontal Grout Outlet

primary plugging work.

1.75

Distribution Joint Grout

3 3 21.45 14.74 316.17 5.25

Grout Supply/return

Pipe Vertical 1.70

Lift 5 1.50

Contact Grout Supply/return 1.90 Lift 4 1.50 Concrete Type "G"

Total 58.72 943.17 10.00

Contact Grout Supply/return

10.00

3.00

10.00

2.00 Lift 3 1.50

Grout Supply/return Check Hole Pipe 1.50

Contact Grout supply /

Lift 2

3.50 2.00 return headel

❑ Plugging work on a large diversion tunnel with 10 m diameter and 41 m length

1.50

1.75

2.40 Lift 1 Temporary drain pipe

18.00 23.00

in Jatigede Dam has been accomplished without any significant difficulties.

41.00

Contact Grout Outlet Contact Grout Outlet

0.80 1.20 1.20 1.20 1.20 1.20 1.20 1.20 0.80

PLUG BLOCK A (18.00 m) PLUG BLOCK B (23.00 m)

The primary plugging work begun on September 2nd, 2015 and finished by 10.00

September 13th, 2015 by using “F+(plus)” type (only for material with c. Thermometer installation

maximum size of 20 mm), by consuming 943.17 m3 volume of concrete. Concrete Type "G" Monitoring of temperature

during and after concreting

Copper Grouted stop Copper Grouted stop

❑ The following phase was preparing main plugging concrete work. Main

1.75

5.25

Thermometer No.2 Thermometer No.3

Thermometer No.1

plugging work with 41 m length begun on September 20th, 2015 and finished

10.00 10.00

3.00

Thermometer No.4 Thermometer No.5 Thermometer No.6

3.50

by October 26th, 2015, which spends grouting material about 30,907.50 kg of

1.75

18.00 23.00

41.00

Portland Cement. PLUG BLOCK A (18.00 m) PLUG BLOCK B (23.00 m)

❑ The obstacles of both primary and main plugging work was how to

manufacture groove for placing cooper plate water stop. Cooper

plate water stop should be installed precisely into the grip of uneven

groove. Similar precised work should be applied when connecting

cooper plate’s segment by using welding.

The work item that accomplished in this area During concrete process, temperature has

❑ Monitoring of temperature during and after concreting was one of

consist of : been examined and configured in the

the essential parts, this part is expected to gradually cools down into

1. Backfill Grouting/Mortar Grout graphics. The Figure shows graphic of

its normal condition about 77oF – 86oF, and to achieve that is by

2. Contact Grouting and Joint Grouting correlation between time and temperature

installing cooling pipe properly. High temperature concrete flow in

3. Check Hole of Joint Grouting Work during concreting process, the temperature is

concrete pipe should be well supervised, to avoid any unexpected

4. Backfill Grout for Access Gallery expected to go down gradually to its normal

clogging, curing was applied.

5. Backfill/Mortar Grouting of Access Gallery condition about 77°F – 86°F.

You might also like

- Group Case Study Rubric 3Document3 pagesGroup Case Study Rubric 3Saraswathi Asirvatham67% (3)

- Hydraulic Simulation of Pressurized Pipe Networks by Using: EPANET SoftwareDocument21 pagesHydraulic Simulation of Pressurized Pipe Networks by Using: EPANET Softwarehendikwaluyo100% (1)

- 12951-Guidelines On Road Drainage-2Document62 pages12951-Guidelines On Road Drainage-2suaddadNo ratings yet

- JUnit 5 User GuideDocument90 pagesJUnit 5 User GuideaawaakNo ratings yet

- Darkle Slideshow by SlidesgoDocument53 pagesDarkle Slideshow by SlidesgoADITI GUPTANo ratings yet

- TR-55 ManualDocument164 pagesTR-55 Manualsuman59100% (1)

- Jak Se Svařuje Potrubí Na Mořském DněDocument2 pagesJak Se Svařuje Potrubí Na Mořském DněJakub ČížekNo ratings yet

- Poster Agu ZZ ESDocument1 pagePoster Agu ZZ ESAlfanNo ratings yet

- Third Party Risk Management Solution - WebDocument16 pagesThird Party Risk Management Solution - Webpreenk8No ratings yet

- Dog & Kitten: XshaperDocument17 pagesDog & Kitten: XshaperAll PrintNo ratings yet

- MRT Phase 1 - Part 2Document232 pagesMRT Phase 1 - Part 2Donny. B TampubolonNo ratings yet

- 2002 - Angeles Et Al. - Geology and Alteration Mineralization Characteristics of The Cibaliung Epithermal Gold Deposit Banten IndonesiaDocument11 pages2002 - Angeles Et Al. - Geology and Alteration Mineralization Characteristics of The Cibaliung Epithermal Gold Deposit Banten IndonesiaHarisArmadiNo ratings yet

- Construction of The Seikan Undersea Tunnel - IIDocument7 pagesConstruction of The Seikan Undersea Tunnel - IIAbdelali SolNo ratings yet

- CR18 076 Summary Geology GuideDocument16 pagesCR18 076 Summary Geology Guideমেহেদী MehediNo ratings yet

- 08 Philippine DamsDocument1 page08 Philippine DamsArrantxa IbaleNo ratings yet

- Paper 2 Cibaliung 2005Document14 pagesPaper 2 Cibaliung 2005Irvan HabibiNo ratings yet

- OceansDocument1 pageOceanstxwvwjn2vhNo ratings yet

- Geological and Geotechnical Characteristics of Ntem Formations: Insight of Its Applications in The Memve'ele Dam Construction (Southern Cameroon)Document19 pagesGeological and Geotechnical Characteristics of Ntem Formations: Insight of Its Applications in The Memve'ele Dam Construction (Southern Cameroon)NTOMBA Sylvestre MartialNo ratings yet

- 8-30 Design Challenges of Bored Tunnelling For Deep Underground Water Pipe Installation in Downtown SingaporeDocument6 pages8-30 Design Challenges of Bored Tunnelling For Deep Underground Water Pipe Installation in Downtown SingaporefreezefreezeNo ratings yet

- Harry Tan One North Station Excavation in 30m of Jurong Residual Soils in SGDocument8 pagesHarry Tan One North Station Excavation in 30m of Jurong Residual Soils in SGAshrethNo ratings yet

- Key Developments of Tunnels in MalaysiaDocument4 pagesKey Developments of Tunnels in MalaysiaIrving ChanNo ratings yet

- Geosynthetics Applications and Performance ReviewsDocument10 pagesGeosynthetics Applications and Performance Reviewsshanu104No ratings yet

- Design of Pyongtaek LPG Storage Terminal UnderneathDocument16 pagesDesign of Pyongtaek LPG Storage Terminal UnderneathNhật LêNo ratings yet

- Seepage Through Till Foundations of Dams of The Eastmain-Opican-La Grande DiversioDocument18 pagesSeepage Through Till Foundations of Dams of The Eastmain-Opican-La Grande DiversioRaul Robles BustiosNo ratings yet

- Delta Mahakam - PERHAPI KaltimDocument39 pagesDelta Mahakam - PERHAPI KaltimFajar AlamNo ratings yet

- Operation and Maintenance of Hydro Tunnels 13th December 2018 Kathmandu, NepalDocument28 pagesOperation and Maintenance of Hydro Tunnels 13th December 2018 Kathmandu, NepalAbhushan NeupaneNo ratings yet

- SoSo R0 3Document27 pagesSoSo R0 3api-3699967No ratings yet

- Ground Treatment Design For 200km Electrified Double Tracks Railway Project at Northern Peninsular MalaysiaDocument15 pagesGround Treatment Design For 200km Electrified Double Tracks Railway Project at Northern Peninsular Malaysiajinwook75No ratings yet

- Topography and River Systems 2.1 Topographic CharacteristicsDocument12 pagesTopography and River Systems 2.1 Topographic CharacteristicsPRAS PrasetyoNo ratings yet

- Halpin Et Al Rocky Cape Group GeochronologyDocument1 pageHalpin Et Al Rocky Cape Group GeochronologyPeter McGoldrickNo ratings yet

- SoSo R2 7aDocument27 pagesSoSo R2 7aapi-3699967No ratings yet

- 1550926702potential Economic Deposit in Kutain Basin Fajar Alam PDFDocument39 pages1550926702potential Economic Deposit in Kutain Basin Fajar Alam PDFjames bondNo ratings yet

- Article Geotextile Tubes As A Replacement For Rockfill For The Polder Dike in Saemangeum South Korea 133 2 PDFDocument14 pagesArticle Geotextile Tubes As A Replacement For Rockfill For The Polder Dike in Saemangeum South Korea 133 2 PDFgiapleNo ratings yet

- YanuarDocument8 pagesYanuarAjiNo ratings yet

- Dynamic Slope Stability Subject To Blasting VibratDocument22 pagesDynamic Slope Stability Subject To Blasting VibratallopezbNo ratings yet

- Tunnelling in The Himalayan Region: Geological Problems and SolutionsDocument6 pagesTunnelling in The Himalayan Region: Geological Problems and SolutionsBilal MirNo ratings yet

- Naskah Publikasi PDFDocument15 pagesNaskah Publikasi PDFChalvin YansenNo ratings yet

- Angeles Et Al-2002-Resource GeologyDocument11 pagesAngeles Et Al-2002-Resource GeologyNahdiahNo ratings yet

- Watkins Glen FinalDocument16 pagesWatkins Glen Finalapi-330979027No ratings yet

- SoSo R2 0Document27 pagesSoSo R2 0api-3699967No ratings yet

- Material Testing - JMPDocument1 pageMaterial Testing - JMPKausik AdhikaryNo ratings yet

- Tunnel Geologic: Right & Left LaneDocument12 pagesTunnel Geologic: Right & Left LaneFirdaus Dauz SNo ratings yet

- Lithology and Characteristic of Landslide in Gombel Hill by 2D Geoelectric Resistivity Method Using Dipole-Dipole ConfigurationDocument9 pagesLithology and Characteristic of Landslide in Gombel Hill by 2D Geoelectric Resistivity Method Using Dipole-Dipole Configurationade dosmariaNo ratings yet

- E4 Depot - 20211010-00Document6 pagesE4 Depot - 20211010-00Ernesto SugihartoNo ratings yet

- ShirlawformCSMa23 6 2016aDocument50 pagesShirlawformCSMa23 6 2016aflashtronNo ratings yet

- Lumpur LapindoDocument1 pageLumpur LapindoadzysNo ratings yet

- Geology: Africa Seismic Evidence For A Deep Upper Mantle Thermal Anomaly Beneath EastDocument5 pagesGeology: Africa Seismic Evidence For A Deep Upper Mantle Thermal Anomaly Beneath EastJrNo ratings yet

- Wrench-Slip Reversals and Structural Inversions Ce 230818 104831Document18 pagesWrench-Slip Reversals and Structural Inversions Ce 230818 104831muhmus88No ratings yet

- Characteristic WorkDocument7 pagesCharacteristic Workmuhammad hisyam taufiqNo ratings yet

- Top Ten Buildings-WPS OfficeDocument8 pagesTop Ten Buildings-WPS Officerenzjho13No ratings yet

- SoSo R0 0Document24 pagesSoSo R0 0api-3699967No ratings yet

- Manual de Usuario Obulb ProDocument1 pageManual de Usuario Obulb ProPere Civit QuiterioNo ratings yet

- Water Transfer Adduction D'eau Italy ItalieDocument1 pageWater Transfer Adduction D'eau Italy ItalieParmeshwar KushwahaNo ratings yet

- YELLmap 2Document1 pageYELLmap 2scottcnelsonNo ratings yet

- 12 PLTA B ReducedDocument37 pages12 PLTA B ReducedHiezya Maryasha AbimanyuNo ratings yet

- Construction Material Assessment From Quarry Sites at Chaktan-Ghasa-Kaligandaki River Area, Western NepalDocument6 pagesConstruction Material Assessment From Quarry Sites at Chaktan-Ghasa-Kaligandaki River Area, Western NepalsavvymovNo ratings yet

- 15-Geotour Routes enDocument2 pages15-Geotour Routes enAlger Danielle BallonNo ratings yet

- Turbidity Barriers - Mine Site Reclamation ProjectDocument57 pagesTurbidity Barriers - Mine Site Reclamation ProjectatierazainolNo ratings yet

- REE Depósitos OroDocument15 pagesREE Depósitos Oroescaflowne4002No ratings yet

- Elisabeth L. Rowan (2003)Document3 pagesElisabeth L. Rowan (2003)Afonso ElvaNo ratings yet

- Amaia Alabang 2Document3 pagesAmaia Alabang 2John Michael ParcoNo ratings yet

- Geotube Waterways & ImpoundmentsDocument8 pagesGeotube Waterways & ImpoundmentsVictor Hugo Chavez GonzalezNo ratings yet

- SoSo R4 2aDocument28 pagesSoSo R4 2aapi-3699967No ratings yet

- Hyperbaric Welding Zawtika Brochure ADocument2 pagesHyperbaric Welding Zawtika Brochure AAlfredo MunarNo ratings yet

- Reliance East West Pipeline Punj LoydDocument3 pagesReliance East West Pipeline Punj LoydPuneet Zaidu100% (1)

- DAY Resv Water Level Date InformationDocument4 pagesDAY Resv Water Level Date InformationHarimukti RositaNo ratings yet

- Chapter 1 - English - IntroductionDocument6 pagesChapter 1 - English - IntroductionHarimukti RositaNo ratings yet

- Suggestion On Flood Standard of Diversion TunnelDocument2 pagesSuggestion On Flood Standard of Diversion TunnelHarimukti RositaNo ratings yet

- IntroductionDocument3 pagesIntroductionHarimukti RositaNo ratings yet

- Outflow CalculationDocument38 pagesOutflow CalculationHarimukti RositaNo ratings yet

- Linear Programming Using Excel PDFDocument7 pagesLinear Programming Using Excel PDFHarimukti RositaNo ratings yet

- 1286 Vertical Drain in Porous Pavement RoadsDocument16 pages1286 Vertical Drain in Porous Pavement RoadsHarimukti RositaNo ratings yet

- 03 Tugas Model Alokasi - 01 Kerugian BanjirDocument3 pages03 Tugas Model Alokasi - 01 Kerugian BanjirHarimukti RositaNo ratings yet

- Epanet ManualDocument200 pagesEpanet ManualFelicia MichaelNo ratings yet

- All DocsDocument13 pagesAll DocsHarimukti RositaNo ratings yet

- Negeri 5 MenaraDocument220 pagesNegeri 5 MenaraHatta MNo ratings yet

- Data Management: Data, Databases and WarehousingDocument13 pagesData Management: Data, Databases and WarehousingHarimukti RositaNo ratings yet

- Diverging Lenses - Object-Image Relations: Previously in Lesson 5 Double Concave LensesDocument2 pagesDiverging Lenses - Object-Image Relations: Previously in Lesson 5 Double Concave LensesleonNo ratings yet

- Core CompetenciesDocument3 pagesCore Competenciesapi-521620733No ratings yet

- ISO Position ToleranceDocument15 pagesISO Position ToleranceНиколай КалугинNo ratings yet

- CL Honours Report NamanDocument11 pagesCL Honours Report NamanNaman VermaNo ratings yet

- 4. Nguyễn Thị Minh Khai, Sóc TrăngDocument15 pages4. Nguyễn Thị Minh Khai, Sóc TrăngK60 TRẦN MINH QUANGNo ratings yet

- Moral GPS: A Positive Ethic For Our Multicultural WorldDocument279 pagesMoral GPS: A Positive Ethic For Our Multicultural WorldLeonard Bowman75% (4)

- FIR FliterDocument10 pagesFIR FliterasfsfsafsafasNo ratings yet

- Abilash - Subramanian CV - 003 PDFDocument4 pagesAbilash - Subramanian CV - 003 PDFAbilash SubramanianNo ratings yet

- Stability Analysis of Geocell Reinforced Slopes by Considering Bending EffectDocument13 pagesStability Analysis of Geocell Reinforced Slopes by Considering Bending EffectRakesh KapoorNo ratings yet

- RH-A Catalog PDFDocument1 pageRH-A Catalog PDFAchmad KNo ratings yet

- KIA SONET BookingDocketDocument7 pagesKIA SONET BookingDocketRajesh ThulasiramNo ratings yet

- IPA Smith Osborne21632Document28 pagesIPA Smith Osborne21632johnrobertbilo.bertilloNo ratings yet

- Poster-Shading PaperDocument1 pagePoster-Shading PaperOsama AljenabiNo ratings yet

- Cap1 - Engineering in TimeDocument12 pagesCap1 - Engineering in TimeHair Lopez100% (1)

- Class 12 Physics Derivations Shobhit NirwanDocument6 pagesClass 12 Physics Derivations Shobhit Nirwanaastha.sawlaniNo ratings yet

- Engineering Management: Class RequirementsDocument30 pagesEngineering Management: Class RequirementsMigaeaNo ratings yet

- Six Sigma PresentationDocument17 pagesSix Sigma PresentationDhular HassanNo ratings yet

- Homework 9Document1 pageHomework 9Nat Dabuét0% (1)

- Resume - James MathewsDocument2 pagesResume - James Mathewsapi-610738092No ratings yet

- Applications of Wireless Sensor Networks: An Up-to-Date SurveyDocument24 pagesApplications of Wireless Sensor Networks: An Up-to-Date SurveyFranco Di NataleNo ratings yet

- Basic Terms/Concepts IN Analytical ChemistryDocument53 pagesBasic Terms/Concepts IN Analytical ChemistrySheralyn PelayoNo ratings yet

- How Transformers WorkDocument15 pagesHow Transformers Worktim schroderNo ratings yet

- Week 3 Lab Arado, Patrick James M.Document2 pagesWeek 3 Lab Arado, Patrick James M.Jeffry AradoNo ratings yet

- 5.1 Behaviour of Water in Rocks and SoilsDocument5 pages5.1 Behaviour of Water in Rocks and SoilsHernandez, Mark Jyssie M.No ratings yet

- Pam8610 PDFDocument15 pagesPam8610 PDFRaka Satria PradanaNo ratings yet