Professional Documents

Culture Documents

Pfi List

Uploaded by

alay2986100%(1)100% found this document useful (1 vote)

177 views3 pagesList of PFI standards

Original Title

pfi list

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentList of PFI standards

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

177 views3 pagesPfi List

Uploaded by

alay2986List of PFI standards

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

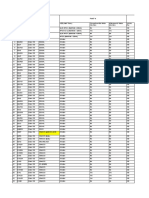

Standards Manager Web Standards List

PFI-Pipe fabrication institute

Id Number Title Year Organization Page

1 ES-4 Hydrostatic Testing of Fabricated Piping 2013 PFI 0

2 ES-5 Cleaning of Fabricated Piping 2013 PFI 0

3 ES-7 Minimum Length and Spacing for Welded Nozzles 2013 PFI 0

4 ES-2 Method of Dimensioning Piping Assemblies 2013 PFI 0

5 ES-16 Access Holes, Bosses and Plugs for Radiographic Inspection of Pipe Welds 2013 PFI 0

6 ES-20 Wall Thickness Measurement by Ultrasonic Examination 2013 PFI 0

7 ES-22 Recommended Practice for Color Coding of Piping Materials 2013 PFI 0

8 ES-24 Pipe Bending Methods, Tolerances, Process and Material Requirements 2013 PFI 0

9 ES-26 Welded Load Bearing Attachments to Pressure Retaining Piping Materials 2013 PFI 0

10 ES-32 Tool Calibration 2013 PFI 0

11 ES-44 Drafting Practices Standard 2013 PFI 0

12 ES-45 Recommended Practice for Local Post-Weld Heat Treatment 2013 PFI 0

13 ES-47 Welding Of Internally Clad Piping 2013 PFI 0

14 ES-48 Random Examination 2013 PFI 0

15 ES-49 Guidelines For Installation Of Integrally Reinforced Branch Connection Fittings 2013 PFI 0

16 TB-1 Pressure-Temperature Ratings of Seamless Pipe Used in Power Plant Piping Systems 2013 PFI 0

17 TB-3 Guidelines Clarifying Relationships and Design Engineering Responsibilities between Purchasers' Engineers and Pipe 2013 PFI 0

Fabricator or Pipe Fabricator Erector

18 TB-5 Minimum Information Required for the Bidding of Pipe Fabrication 2013 PFI 0

19 TB-8 Recommended Practice for the Fabrication of Polyvinylidene Fluoride (PVDF) Piping 2013 PFI 0

20 ES-36 Branch Reinforcement Work Sheets 2013 PFI 0

21 ES-43 Standard For Protection Of Austenitic Stainless Steel 2013 PFI 0

and Nickel Alloy Materials

22 ES-1 Internal Machining and Solid Machined Backing Rings for Circumferential Butt Welds 2010 PFI 0

23 ES-40 Method of Dimensioning Grooved Piping Assemblies 2010 PFI 0

24 ES-27 "Visual Examination" the Purpose, Meaning and Limitation of the Term 2010 PFI 0

25 ES-21 Internal Machining and Fit-Up of GTAW Root Pass Circumferential Butt Welds 2010 PFI 0

26 ES-3 Fabricating Tolerances 2009 PFI 0

27 ES-29 Internal Abrasive Blast Cleaning of Ferritic Piping 2006 PFI 0

28 ES-42 Standard For Positive Material Identification Of Piping Components Using Portable X-ray Emission Type Test Equipment 2005 PFI 0

29 ES-31 Standard For Protection Of Ends Of Fabricated Piping Assemblies 2004 PFI 0

30 TB-7 Guidelines for Fabrication and Installation of Stainless Steel High Purity Distribution Systems 2004 PFI 0

31 ES-35 Nonsymmetrical Bevels And Joint Configurations For Butt 2003 PFI 0

welds

32 ES-41 Standard For Material Control And Traceability Of Piping Components 2003 PFI 0

33 ES-30 Random Ultrasonic Examination of Butt Welds 2003 PFI 0

34 ES-34 Temporary Painting/Coating Of Fabricated Piping 2003 PFI 0

35 ES-37 Standard for Loading and Shipping of Piping Assemblies 2003 PFI 0

36 ES-39 Fabricated Tolerances for Grooved Piping Systems 2003 PFI 0

37 ES-11 Permanent Marking on Piping Materials 2003 PFI 0

38 ES-27 "Visual Examination" the Purpose, Meaning and Limitation of the Term 2003 PFI 0

39 ES-34 TEMPORARY PAINTING/COATING OF FABRICATED PIPING 2003 PFI 0

40 ES-37 Standard for Loading and Shipping of Piping Assemblies 2003 PFI 0

41 ES-42 STANDARD FOR POSITIVE MATERIAL IDENTIFICATION OF PIPING COMPONENTS USING PORTABLE X- 2002 PFI 0

RAY EMISSION TYPE TEST EQUIPMENT

42 ES-44 Drafting Practices Standard 2002 PFI 0

43 ES-45 Recommended Practice for Local Post-Weld Heat Treatment 2002 PFI 0

44 ES-46 Bar Coding 2002 PFI 0

45 TB-3 Guidelines Clarifying Relationships and Design Engineering Responsibilities between Purchasers' Engineers and Pipe 2002 PFI 0

Fabricator or Pipe Fabricator Erector

46 TB-5 Minimum Information Required for the Bidding of Pipe Fabrication 2002 PFI 0

47 ES-29 Internal Abrasive Blast Cleaning of Ferritic Piping 2002 PFI 0

48 ES-22 Recommended Practice for Color Coding of Piping Materials 2002 PFI 0

49 ES-25 Random Radiography of Pressure Retaining Girth Butt Welds 2002 PFI 0

50 ES-26 Welded Load Bearing Attachments to Pressure Retaining Piping Materials 2002 PFI 0

51 ES-5 Cleaning of Fabricated Piping 2002 PFI 0

52 TB-8 Recommended Practice for the Fabrication of Polyvinylidene Fluoride (PVDF) Piping 2001 PFI 0

53 ES-36 Branch Reinforcement Work Sheets 1999 PFI 0

54 ES-35 Nonsymmetrical Bevels and Joint Configurations for Butt Welds 1998 PFI 0

55 ES-41 Material Control and Traceability of Piping Components 1998 PFI 0

56 ES-11 Permanent Marking on Piping Materials 1998 PFI 0

57 ES-21 Internal Machining and Fit-Up of GTAW Root Pass Circumferential Butt Welds R(2001) 1998 PFI 0

58 ES-20 Wall Thickness Measurement by Ultrasonic Examination R(2002) 1997 PFI 0

59 TB-7 Guidelines for Fabrication and Installation of Stainless Steel High Purity Distribution Systems R(2000) 1997 PFI 0

60 ES-43 Protection of Austenitic Stainless Steel and Nickel Alloy Materials R(2002) 1996 PFI 0

61 ES-39 Fabricated Tolerances for Grooved Piping Systems R(2003) 1994 PFI 0

62 ES-40 Method of Dimensioning Grooved Piping Assemblies R(2000) 1994 PFI 0

63 TB-1 Pressure-Temperature Ratings of Seamless Pipe Used in Power Plant Piping Systems R(1999) 1994 PFI 0

64 ES-7 Minimum Length and Spacing for Welded Nozzles R(2002) 1994 PFI 0

65 ES-32 Tool Calibration R(2000) 1993 PFI 0

66 ES-1 Internal Machining and Solid Machined Backing Rings for Circumferential Butt Welds R(2001) 1992 PFI 0

67 ES-2 Method of Dimensioning Piping Assemblies R(2000) 1992 PFI 0

68 ES-31 Standard for Protection of Ends of Fabricated Piping Assemblies R(2000) 1992 PFI 0

69 ES-24 Pipe Bending Methods, Tolerances, Process and Material Requirements R(2001) 1992 PFI 0

70 ES-30 Random Ultrasonic Examination of Butt Welds R(1998) 1986 PFI 0

71 ES-4 Hydrostatic Testing of Fabricated Piping R(2002) 1985 PFI 0

72 ES-16 Access Holes, Bosses and Plugs for Radiographic Inspection of Pipe Welds R(2001) 1985 PFI 0

73 ES-3 Fabricating Tolerances R(2000) 1981 PFI 0

Hercules Ebooks Institute

www.herculesebooks.com info@herculesebooks.com +989141908737

You might also like

- Pfi Es-41 2003Document2 pagesPfi Es-41 2003bayu212100% (1)

- PNSC0001Document17 pagesPNSC0001Nasser KunjuNo ratings yet

- Hydrostatic Testing GuideDocument10 pagesHydrostatic Testing Guidepraveentien100% (1)

- Method For Spool PipingDocument13 pagesMethod For Spool PipingrealstrojmanNo ratings yet

- Fabrication of Pipes PDFDocument2 pagesFabrication of Pipes PDFLakeisha0% (1)

- Plant Piping Pressure Testing: (Exam For Inspectors Performing Test PKG & Sis Sheet Calculation Reviews)Document3 pagesPlant Piping Pressure Testing: (Exam For Inspectors Performing Test PKG & Sis Sheet Calculation Reviews)aslam.ambNo ratings yet

- Eil Spec For PmiDocument8 pagesEil Spec For Pmisachinchavan1981No ratings yet

- PFI ES-32-1993 Tool Calibration PDFDocument4 pagesPFI ES-32-1993 Tool Calibration PDFHello WorldNo ratings yet

- Astm 890Document3 pagesAstm 890bsnegi111No ratings yet

- Iqwq Ce1092 Qpqac 00 0002 - 0 Quality Control Procedure for Piping管道质量控制程序Document54 pagesIqwq Ce1092 Qpqac 00 0002 - 0 Quality Control Procedure for Piping管道质量控制程序Ali Majeed100% (1)

- SP PI PP 001 (General Piping System)Document49 pagesSP PI PP 001 (General Piping System)Ari IndrajayaNo ratings yet

- PFI ES 27 (2000) VisualExaminationDocument4 pagesPFI ES 27 (2000) VisualExaminationWilson AnteNo ratings yet

- Nioec SP 90 02Document77 pagesNioec SP 90 02aminNo ratings yet

- 1) P&Id Latest Revision. 2) Vendor Drawings of Equipments and In-Line Instruments. 3) Line List. 4) Piping Material Specification. 5) Updated ModelDocument3 pages1) P&Id Latest Revision. 2) Vendor Drawings of Equipments and In-Line Instruments. 3) Line List. 4) Piping Material Specification. 5) Updated ModelNavaneeth PurushothamanNo ratings yet

- Nickel Alloy Fittings Standard SpecificationDocument13 pagesNickel Alloy Fittings Standard SpecificationAVINASH CHAVANNo ratings yet

- WSM-PSFP-01 Piping Spool Fabrication Procedure PDFDocument14 pagesWSM-PSFP-01 Piping Spool Fabrication Procedure PDFMiky AndreanNo ratings yet

- Piping Inspection Procedure GuideDocument8 pagesPiping Inspection Procedure Guidemohd as shahiddin jafriNo ratings yet

- PFI-ES-05 (1999) - Cleaning PDFDocument4 pagesPFI-ES-05 (1999) - Cleaning PDFRamesh Kumar Ramisetti100% (1)

- PFIDocument81 pagesPFIMarcos Omana100% (1)

- Process Industry Practices Piping: PIP PNSC0001 ASME B31.3 Metallic Piping Fabrication and Examination SpecificationDocument17 pagesProcess Industry Practices Piping: PIP PNSC0001 ASME B31.3 Metallic Piping Fabrication and Examination SpecificationRIVFNo ratings yet

- Quality Surveillance ReportDocument1 pageQuality Surveillance Reportsiva8000No ratings yet

- Duplex Material PDFDocument4 pagesDuplex Material PDFmengelito almonteNo ratings yet

- 01NC0B02Document4 pages01NC0B02raobabar21No ratings yet

- Astm GradesDocument3 pagesAstm GradeszackjipangNo ratings yet

- MSS SP-97 2012 Integrally Reinforced Forged Branch Outlet Fittings - Socket Welding, Threaded and Buttwelding EndsDocument22 pagesMSS SP-97 2012 Integrally Reinforced Forged Branch Outlet Fittings - Socket Welding, Threaded and Buttwelding EndsJuliusMaximus12No ratings yet

- MSS SP 6Document6 pagesMSS SP 6d1a9v8i3d100% (1)

- ES 49BranchConnections PDFDocument7 pagesES 49BranchConnections PDFprabuharan89No ratings yet

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDocument4 pagesA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16No ratings yet

- AWS List of Welding CodesDocument16 pagesAWS List of Welding CodesLee Chong EeNo ratings yet

- Class 1CB2S01 (Pip PN01CB2S01 - 2005)Document6 pagesClass 1CB2S01 (Pip PN01CB2S01 - 2005)Zvonko BešlićNo ratings yet

- Pfi - Es 39 1997 PDFDocument4 pagesPfi - Es 39 1997 PDFДенис ПекшуевNo ratings yet

- Engineering Standards-All (Ocr)Document551 pagesEngineering Standards-All (Ocr)Jim StreitmatterNo ratings yet

- Piping Classes for Various MaterialsDocument24 pagesPiping Classes for Various MaterialsThân KhaNo ratings yet

- Piston ValveDocument28 pagesPiston ValveDamien BouticourtNo ratings yet

- High Frequency Induction Bending PDFDocument22 pagesHigh Frequency Induction Bending PDFMohd AshrafNo ratings yet

- 2 Specification For GRP PipingDocument4 pages2 Specification For GRP Pipinggc_panchaNo ratings yet

- Piping 5.0 - Introduction to Piping EngineeringDocument32 pagesPiping 5.0 - Introduction to Piping EngineeringSteve WanNo ratings yet

- Quality Contol Plan Piping Erection (Above & Underground) 2542-000-QCP-1320-001 - 0 PDFDocument33 pagesQuality Contol Plan Piping Erection (Above & Underground) 2542-000-QCP-1320-001 - 0 PDFZohrab Dadashov100% (1)

- 04 1 Sec IV STD Specs PipingDocument152 pages04 1 Sec IV STD Specs PipingdzungNo ratings yet

- Case 2864 9Cr–1Mo–VDocument1 pageCase 2864 9Cr–1Mo–VAlevj Db100% (1)

- PipingDocument8 pagesPipingAhmed ElalfyNo ratings yet

- Types of Flanges-Definition of FlangesDocument4 pagesTypes of Flanges-Definition of FlangesindikumaNo ratings yet

- Cigweld-Deposited Rates PDFDocument7 pagesCigweld-Deposited Rates PDFNam_HitechNo ratings yet

- Daniel Orifice Flanges Provide Accurate Flow MeasurementDocument45 pagesDaniel Orifice Flanges Provide Accurate Flow MeasurementSammyNo ratings yet

- Astm 1.05Document3 pagesAstm 1.05asprclms durgapurNo ratings yet

- Welding Hygienic RequirementsDocument5 pagesWelding Hygienic RequirementsZmanNo ratings yet

- Bonney Forge Branch ConnectionsDocument45 pagesBonney Forge Branch ConnectionsperoooNo ratings yet

- Connecting Hdpe To Di PVC PipeDocument28 pagesConnecting Hdpe To Di PVC PipeadjeibaldanNo ratings yet

- Pipe Fabrication Institute ES-37 Copyright GuidelinesDocument3 pagesPipe Fabrication Institute ES-37 Copyright GuidelinesДенис ПекшуевNo ratings yet

- Gruvlok CatalogDocument276 pagesGruvlok CatalogFerdie WakeUp FromAdversityNo ratings yet

- VMS PaliDocument61 pagesVMS Palichintan100% (2)

- Asme B 16.34 InterpretacionDocument21 pagesAsme B 16.34 InterpretacionJuan Manuel Montoya G.No ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- PFI piping standards documentsDocument2 pagesPFI piping standards documentsgigiphi1No ratings yet

- Pfi Es-47Document10 pagesPfi Es-47Ecruz Cruz LNo ratings yet

- PFI ES 16 - 2013 EditionDocument11 pagesPFI ES 16 - 2013 EditionArcadio Duran100% (1)

- FABRICATION & ERECTION PROCEDURE PipingDocument36 pagesFABRICATION & ERECTION PROCEDURE PipingnuntaricherdchaiNo ratings yet

- Pip Stf05520 - 2003 Details For BarandalesDocument14 pagesPip Stf05520 - 2003 Details For Barandalesviridiana.noyolaNo ratings yet

- Pfi Es-24Document10 pagesPfi Es-24kingstonNo ratings yet

- Final - Draft Specification - BWSC Pipe Revise1Document21 pagesFinal - Draft Specification - BWSC Pipe Revise1Chief Engineer Hydro Project & Quality ControlNo ratings yet

- RecipeDocument1 pageRecipealay2986No ratings yet

- RecipeDocument1 pageRecipealay2986No ratings yet

- RecipeDocument1 pageRecipealay2986No ratings yet

- Gajar Ka Halwa-3Document1 pageGajar Ka Halwa-3alay2986No ratings yet

- Recipe Gajar HalwaDocument1 pageRecipe Gajar Halwaalay2986No ratings yet

- RecipeDocument1 pageRecipealay2986No ratings yet

- RecipeDocument1 pageRecipealay2986No ratings yet

- Gajar Ka Halwa-1Document1 pageGajar Ka Halwa-1alay2986No ratings yet

- IdliDocument11 pagesIdlialay2986No ratings yet

- Rava IdliDocument2 pagesRava Idlialay2986No ratings yet

- Gajar Ka Halwa-2Document1 pageGajar Ka Halwa-2alay2986No ratings yet

- Sambha RDocument8 pagesSambha Ralay2986No ratings yet

- Chole BhatureDocument2 pagesChole Bhaturealay2986No ratings yet

- Technical Analysis GuideDocument38 pagesTechnical Analysis Guidealay2986100% (1)

- RotiDocument12 pagesRotialay2986No ratings yet

- BroccoliDocument7 pagesBroccolialay2986No ratings yet

- Utta PamDocument2 pagesUtta Pamalay2986No ratings yet

- History: Rasam, Chaaru, Saaru or Kabir Is ADocument2 pagesHistory: Rasam, Chaaru, Saaru or Kabir Is Aalay2986No ratings yet

- LasagneDocument3 pagesLasagnealay2986No ratings yet

- History: Rasam, Chaaru, Saaru or Kabir Is ADocument2 pagesHistory: Rasam, Chaaru, Saaru or Kabir Is Aalay2986No ratings yet

- LasagneDocument1 pageLasagnealay2986No ratings yet

- PastaDocument1 pagePastadownloadNo ratings yet

- MomosDocument2 pagesMomosalay2986No ratings yet

- Broccoli Is An Edible Green Plant in The: Cabbage Family Flowering HeadDocument7 pagesBroccoli Is An Edible Green Plant in The: Cabbage Family Flowering Headalay2986No ratings yet

- Etymology: Cabbages Leafy Green Vegetables Brussels BelgiumDocument4 pagesEtymology: Cabbages Leafy Green Vegetables Brussels Belgiumalay2986No ratings yet

- Etymology: Cabbages Leafy Green Vegetables Brussels BelgiumDocument4 pagesEtymology: Cabbages Leafy Green Vegetables Brussels Belgiumalay2986No ratings yet

- Recipe PastaDocument11 pagesRecipe Pastaalay2986No ratings yet

- Mechanical Engineerig Recommended BooksDocument4 pagesMechanical Engineerig Recommended BooksSandeepNo ratings yet

- Pipe Stress Analysis Tutorial: Basic ConceptsDocument32 pagesPipe Stress Analysis Tutorial: Basic ConceptsRene RenanNo ratings yet

- Application LetterDocument3 pagesApplication LetterRangga Maulana ArrazyNo ratings yet

- Thermal Engineering Course OverviewDocument3 pagesThermal Engineering Course OverviewneerubandaNo ratings yet

- Abcm Notes Sem 6Document18 pagesAbcm Notes Sem 6Sahil pamnani100% (1)

- Bus and IE 2-2012 PDFDocument18 pagesBus and IE 2-2012 PDFsbloinazNo ratings yet

- Wyche Torsion in AS5100 Austroads Bridge Conf 06Document13 pagesWyche Torsion in AS5100 Austroads Bridge Conf 06mohammed_fathelbabNo ratings yet

- Jntuk M Tech r13 Cad&cam Syllabus PDFDocument60 pagesJntuk M Tech r13 Cad&cam Syllabus PDFLohitha PolisettyNo ratings yet

- 02 Technical Folder Stora Enso Building Solutions CLTDocument325 pages02 Technical Folder Stora Enso Building Solutions CLTAurelia AxenteNo ratings yet

- 08 MTechConstructionTechnology PDFDocument2 pages08 MTechConstructionTechnology PDFSyed Yameen AndrabiNo ratings yet

- 01 GCB History enDocument25 pages01 GCB History enInsan AzizNo ratings yet

- AASHTO Completa DesbloqueadaDocument604 pagesAASHTO Completa DesbloqueadaRodrigo Ortúzar IzquierdoNo ratings yet

- Math156 Ie Feb 2019Document7 pagesMath156 Ie Feb 2019Josef CatiggayNo ratings yet

- Project ReportDocument28 pagesProject ReportD G PrasathNo ratings yet

- Verco Floor Vf5 120914Document150 pagesVerco Floor Vf5 120914diogogrebNo ratings yet

- Design Freeze Monitoring - 17dec19Document74 pagesDesign Freeze Monitoring - 17dec19kramlester1982No ratings yet

- Pipe Support Design Guidelines SummaryDocument4 pagesPipe Support Design Guidelines SummaryNitya Sheel RohillaNo ratings yet

- Stress Analysis of Reactor Nozzle to Head JunctionDocument5 pagesStress Analysis of Reactor Nozzle to Head JunctionMohamed Rafeek0% (1)

- UESI Presentation Webinar March 29 2016 PDFDocument65 pagesUESI Presentation Webinar March 29 2016 PDFmunim87No ratings yet

- Nirvesh ResumeDocument2 pagesNirvesh ResumenirveshdagarNo ratings yet

- Course File Jigs & FixturessDocument18 pagesCourse File Jigs & FixturessYogendra KumarNo ratings yet

- Network Engineering Resume ExampleDocument24 pagesNetwork Engineering Resume ExampleSandip Pudasaini100% (1)

- Ashrae Journal - Specifying or EqualDocument6 pagesAshrae Journal - Specifying or EqualFalak KhanNo ratings yet

- MT308 Ia Fe 2019Document7 pagesMT308 Ia Fe 2019khalil alhatabNo ratings yet

- Answer - Questions On Regulation On Professional ConductDocument23 pagesAnswer - Questions On Regulation On Professional Conducthisterling100% (2)

- Nixit Consultants (OPC) Pvt Ltd Civil & Structural Works ProfileDocument24 pagesNixit Consultants (OPC) Pvt Ltd Civil & Structural Works ProfileSurendran RajendranNo ratings yet

- Life Cycle Models (Lecture 2) Prof. R. Mall Dept. of CSE, IIT, KharagpurDocument63 pagesLife Cycle Models (Lecture 2) Prof. R. Mall Dept. of CSE, IIT, KharagpurAnuj NagpalNo ratings yet

- Critical Success Factors of Information Technology ProjectsDocument5 pagesCritical Success Factors of Information Technology Projectsravi196100% (1)

- Population List 2016Document29 pagesPopulation List 2016Dipayan MondalNo ratings yet

- Gs 2009 GuideDocument32 pagesGs 2009 GuidengawuuNo ratings yet