Professional Documents

Culture Documents

Limitations of The Bond Method

Uploaded by

Lito Saul Fernandez Quispe0 ratings0% found this document useful (0 votes)

29 views6 pagesk

Original Title

Limitations of the Bond Method

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentk

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views6 pagesLimitations of The Bond Method

Uploaded by

Lito Saul Fernandez Quispek

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 6

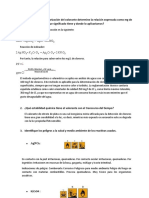

4.3.

5 Discussion of the Bond Method

4.3.5 discusión del Método de Bond

Limitations of the Bond Method

Limitaciones del Método Bond

Austin and Brame (1983) and Herbs and

Fuerstenau (1980) have reviewed the Austin y Brame (1983) y Herbs y

limitations of the Bond test. Perhaps the Fuerstenau (1980) han revisado las

most serious in a fundamental sense is limitaciones del test de Bond. Quizás el más

Bond’s claim that equation 4.2 is a serio en un sentido fundamental es la

“universal law”, whereas it is known that llamada Bond que la ecuación 4.2 es una

the specific grinding energy needed to take “ley universal”, considerando que se conoce

a feed with a certain 80% passing size to a la energía específica de molienda necesaria

product with a certain 80% passing size para tomar un alimento con un cierto 80%

cannot be the same for a batch test, the tamaño pasante a un producto con un

standard Bond locked-cycle test, or a cierto 80% tamaño pasante no puede ser el

steady-state continuous mill with a real mismo para una prueba batch, la prueba

residence time distribution. The method estandar de ciclo cerrado de Bond, o un

ignores the fact that the shape of the molino en estado –estable continuo con

product size distribution and the associated una distribución de tiempo de residencia

specific grinding energy is different for real. El método ignora el hecho que la

these three cases. forma de distribución de tamaño del

producto y la energía específica de

Criticism of Bond’s method as a “model” is molienda asociada es diferente para estos

not really warranted since it is not intended tres casos.

to be a model in any comprehensive sense.

Its real value is as a method of Críticos del método de Bond como un

distinguishing the grindability of different “modelo” realmente no garantiza desde

ores in design (though better test may be que no se piensa que es un modelo en

available), and as a yardstick to check the cualquier sentido comprensivo. Su valor

energy utilization of current operations. real es como un método de distinguir la

Experience in its use has demonstrated the moliendabilidad de minerales diferentes en

following limitations: el diseño (aunque la mejor prueba puede

estar disponible), y como una vara de

It tends to be a poor predictor of what medir para verificar la utilización de energía

happens in a real closed circuit when de operaciones actuales.

throughput is increased, unless Experiencia en su uso ha demostrado las

classifier performance is “adjusted” to siguientes limitaciones:

cope with the new conditions.

As implied earlier, it is not appropriate Tiende a ser una pobre predicción de lo

in system where size distribution slopes que pasa en un circuito cerrado real

change. cuando el rendimiento se incrementa, a

menos que la operación del clasificador

It is not a good predictor of the es “ajustado” para cubrir con las

grinding of large rocks, and specifically nuevas condiciones.

for AG/SAG mill behavior (though it has

been adapted to such circumstances - Como implicado antes, no es apropiado

see below). en un sistema dónde hay cambios en

las pendientes de distribución de

tamaños.

No es un buen predictor de la molienda

de rocas grandes, y específicamente

para el comportamiento en la molienda

AG/SAG (aunque se ha adaptado a

tales circunstancias - ver debajo).

It is unreliable for particles with

unusual screening characteristics (i.e.

of unusual shape), though this is a Es inestable para las partículas con las

general problem for any technique características de tamizado inusual (es

relying on sieving for the determination decir de forma inusual), aunque éste es

of particle size. un problema general para cualquier

técnica que confía en tamizar para la

The square root relationship determinación del tamaño de

assumed in equation 4,2 (arising from partículas.

Bond’s assumption that work is

proportional to new crack tip length) La relación de la raíz cuadrada asumida

does not always hold. See also Figure en la ecuación 4,2 (proviene de la

2.1. asunción de Bond que el trabajo es

proporcional a la nueva longitud de

There is also a perception that Bond’s rotura punta de crujido) no siempre

method failed to predict the performance of sostenga. También Vea Figura 2.1.

the very large ball mills introduced in the

early 1970s, though this was probably more Hay también una percepción que el método

to do with the early learning curve de Bond no predijo la acciòn de los molinos

associated with operating these mills and de bolas muy grandes introducida en los

their associated classification process. tempranos 1970s, aunque éste era

Certainly there was never a dedicated Bond probablemente más hacer con la curva de

test for the Ag and SAG mills now in aprendizaje temprana asociado con operar

common use. estos molinos y su proceso de la

clasificación asociado. Había nunca una

Other problems and inconveniences of the prueba de Bond ciertamente especializada

Bond standard procedure include the need para los molinos AG y SAG ahora en uso

to use a Bond mill (which may not be comun.

readily available), the requirement of about

10 kilograms of feed sample, which needs Otros problemas y inconvenientes de la

special preparation, and the fact that Atadura el procedimiento estándar de Bond

conducting the test is time consuming. A incluye la necesidad de usar un molino de

number of attempts have been made in the Bolas (qué no puede estar prontamente

past to determine the Bond Work index by disponible), el requisito de

means of simplified procedures (Yap et al aproximadamente 10 kilogramos de

1982). muestra del alimento que necesita la

preparación especial y el hecho que

dirigiendo la prueba es el tiempo

Empirical methods which allow for a direct consumiendo. Varios esfuerzos han sido

calculation of the work index using a hecho en el pasado determinar el índice de

straight forward procedure are often more Trabajo de Atadura por medio de los

practical and better suited for plant procedimientos simplificados (Ladre el et al

application. For example the Anaconda 1982).

simplified method (Yap et al 1982) which

uses an ordinary laboratory mill and only 2 Métodos empíricos que permiten un cálculo

kilograms of sample, is not time consuming directo del índice de trabajo que usa un

and has proven to be very practical and procedimiento delantero recto son a

flexible in a number of different menudo más prácticos y buenos satisfecho

applications. However, the full Bond test para la aplicación de la planta. Por ejemplo

gives the maximum confidence in el Anaconda simplificó el método (Ladre el

prediction. et al 1982) qué usa un molino del

laboratorio ordinario y sólo 2 kilogramos de

muestra, no es tiempo que consume y ha

demostrado ser muy práctico y flexible en

varios aplicaciones diferentes. El embargo

del pecado, prueba del la del la la Atadura

llena da la confianza máxima en la

predicción.

The Bond method attempts to partially

compensate for idealizations in the test The Bond method attempts to partially

procedure and shortcomings of the model compensate for idealizations in the test

by making use of correlations between procedure and shortcomings of the model

grindability test result obtained in a by making use of correlations between

“standard” 2,44 m diameter milling circuit. grindability test result obtained in a

Complete compensation is not possible “standard” 2,44 m diameter milling circuit.

because this procedure cannot, for Complete compensation is not possible

instance, take into account inevitable because this procedure cannot, for

deviations in transport and classification instance, take into account inevitable

characteristics of the commercial circuit deviations in transport and classification

from those of the “standard” circuit. characteristics of the commercial circuit

from those of the “standard” circuit.

Since the method does not incorporate the

above – order effects, it cannot be used as Since the method does not incorporate the

a guide to optimize a given system, from above – order effects, it cannot be used as

either the operating point of view or the a guide to optimize a given system, from

economic point of view. Its is valid only as either the operating point of view or the

a gross method for mills operating under economic point of view. Its is valid only as

normal closed circuit conditions. a gross method for mills operating under

normal closed circuit conditions.

In spite of these limitations, the Bond

method has two main advantages: it is very In spite of these limitations, the Bond

simple, and experience has shown that it method has two main advantages: it is very

works for many circumstances to a simple, and experience has shown that it

reasonable degree of accuracy, since the works for many circumstances to a

corrections are based on a large industrial reasonable degree of accuracy, since the

database. corrections are based on a large industrial

database.

The operating Bond Work Index

Work indices obtained from operating data The operating Bond Work Index

on any mill can be compared to grindability Work indices obtained from operating data

test results. The operating work index, on any mill can be compared to grindability

WIo, can be obtained using equation 4.2, test results. The operating work index,

by defining W as the specific energy being WIo, can be obtained using equation 4.2,

used (power draw + new federate), F80 by defining W as the specific energy being

and P80 as the actual feed and product used (power draw + new federate), F80

80% passing sizes, and WI as the operating and P80 as the actual feed and product

work index, WIo. Once corrected for the 80% passing sizes, and WI as the operating

particular application and equipment – work index, WIo. Once corrected for the

related factors, WIoC, can be compared on particular application and equipment –

the same basis as grindability test result. related factors, WIoC, can be compared on

This allows a direct comparison of grinding the same basis as grindability test result.

efficiency. Ideally WI should be equal to This allows a direct comparison of grinding

WIoC and grinding efficiency should be efficiency. Ideally WI should be equal to

unity. Power draw is determined using WIoC and grinding efficiency should be

equation 4.7, assuming grinding efficiency unity. Power draw is determined using

is unity. equation 4.7, assuming grinding efficiency

is unity.

Application of Bond Theory to Autogenous

Mills. Application of Bond Theory to Autogenous

For the case of autogenous and semi Mills.

autogenous milling it has been determined For the case of autogenous and semi

that the work indices obtained from autogenous milling it has been determined

standard Bond grindability tests cannot be that the work indices obtained from

used (Section 9,6). It is necessary, standard Bond grindability tests cannot be

therefore, to calculate a Work index from used (Section 9,6). It is necessary,

operating data(e.g. from a pilot plant) so therefore, to calculate a Work index from

that power draw and mill sizing can be operating data(e.g. from a pilot plant) so

calculated . In some cases the feed is not that power draw and mill sizing can be

used in the calculation as the factor calculated . In some cases the feed is not

10/√F80 becomes insignificant because of used in the calculation as the factor

the large size of the ROM feed. For open 10/√F80 becomes insignificant because of

circuit AG/SAG mills, the discharge can be the large size of the ROM feed. For open

hypothetically classified at the desired circuit AG/SAG mills, the discharge can be

closing screen size to provide a more hypothetically classified at the desired

realistic P80 value for the work index closing screen size to provide a more

calculation. realistic P80 value for the work index

calculation.

Macpherson has developed a test

procedure for the design of AG/SAG mill Macpherson has developed a test

circuits. It includes the conduct of standard procedure for the design of AG/SAG mill

Bond rod mill and ball mill grindability test, circuits. It includes the conduct of standard

together with a dry autogenous test in a 45 Bond rod mill and ball mill grindability test,

cm air – swept Aerofall mill. A 250 kg together with a dry autogenous test in a 45

sample of -3.175 mm ores is required. The cm air – swept Aerofall mill. A 250 kg

autogenous test is used to compute an sample of -3.175 mm ores is required. The

autogenous work index, which is then autogenous test is used to compute an

corrected for a full scale installation using autogenous work index, which is then

empirical scaling procedures (based on corrected for a full scale installation using

historical data) and by comparison with the empirical scaling procedures (based on

rod and ball mill WIs. The autogenous WI historical data) and by comparison with the

and the other data are then used to rod and ball mill WIs. The autogenous WI

determine AG/SAG milling suitability, power and the other data are then used to

requirement and circuit configuration. determine AG/SAG milling suitability, power

Further details can be found in Knight et al requirement and circuit configuration.

(1989). Further details can be found in Knight et al

(1989).

Using the Bond Work Index in a Process

Model Using the Bond Work Index in a Process

Although Bond chose to use the results of Model

his laboratory ball mill test to determine an Although Bond chose to use the results of

operating work index, much more his laboratory ball mill test to determine an

information about grinding of an ore can in operating work index, much more

principle be extracted. His test is a physical information about grinding of an ore can in

model which approximates a closed circuit principle be extracted. His test is a physical

ball mill, and so product sizing and model which approximates a closed circuit

flowrates of each stream can be obtained ball mill, and so product sizing and

from it. Research currently underway at the flowrates of each stream can be obtained

JKMRC is testing the use of these data to from it. Research currently underway at the

determine the relevant parameters for a JKMRC is testing the use of these data to

ball mill model. The model is then used to determine the relevant parameters for a

predict the performance of a full scale ball ball mill model. The model is then used to

mill. This approach has the advantage of predict the performance of a full scale ball

simultaneously generating a Bond ball mill mill. This approach has the advantage of

work index and set of model parameters, simultaneously generating a Bond ball mill

which can be used in a complementary work index and set of model parameters,

fashion in design and optimization. which can be used in a complementary

fashion in design and optimization.

You might also like

- ASTM D86-15 DISTILLATION OF PETROLEUM PRODUCTS (1) .En - EsDocument28 pagesASTM D86-15 DISTILLATION OF PETROLEUM PRODUCTS (1) .En - EsLito Saul Fernandez QuispeNo ratings yet

- HaccpDocument3 pagesHaccpLito Saul Fernandez QuispeNo ratings yet

- 017 ASTM D7321 - 16a CONTAMINACION POR PARTICULAS - En.esDocument6 pages017 ASTM D7321 - 16a CONTAMINACION POR PARTICULAS - En.esLito Saul Fernandez QuispeNo ratings yet

- 4 Principios de Cromatografía CalibracionDocument15 pages4 Principios de Cromatografía CalibracionLito Saul Fernandez QuispeNo ratings yet

- Aleaciones en Base A ZincDocument3 pagesAleaciones en Base A ZincLito Saul Fernandez QuispeNo ratings yet

- Ambiental TDSDocument5 pagesAmbiental TDSLito Saul Fernandez QuispeNo ratings yet

- Cuestionario Lab 9 Quimica AnaliticaDocument4 pagesCuestionario Lab 9 Quimica AnaliticaLito Saul Fernandez QuispeNo ratings yet

- Principales Yacimientos Polimetalicos Del PeruDocument47 pagesPrincipales Yacimientos Polimetalicos Del PeruLuis Cózar91% (22)

- 2 Teoria de HeadspaceDocument10 pages2 Teoria de HeadspaceLito Saul Fernandez QuispeNo ratings yet

- 2 Diagramas P Id PDFDocument43 pages2 Diagramas P Id PDFFreddy YugchaNo ratings yet

- 3 Principios de Cromatografía IntegracionDocument22 pages3 Principios de Cromatografía IntegracionLito Saul Fernandez QuispeNo ratings yet

- Reactivo de FehlingDocument37 pagesReactivo de Fehlingmechita251053% (17)

- Cinética química: problemas de velocidad de reacciónDocument5 pagesCinética química: problemas de velocidad de reacciónXiomiBellQuispeRiveraNo ratings yet

- TEMA 11 Eq Acido-Base PDFDocument15 pagesTEMA 11 Eq Acido-Base PDFxxmilitaxx1No ratings yet

- Tabla Pks PDFDocument5 pagesTabla Pks PDFLito Saul Fernandez QuispeNo ratings yet

- Ejercicios Entropia Gibbs 2017Document3 pagesEjercicios Entropia Gibbs 2017Jerson Fernando ArroyoNo ratings yet

- Verde de BruswickDocument2 pagesVerde de BruswickLito Saul Fernandez QuispeNo ratings yet

- Equilibrio químico y energía libreDocument3 pagesEquilibrio químico y energía libreLito Saul Fernandez QuispeNo ratings yet

- TermoquimicaDocument21 pagesTermoquimicaThamara Cienfuegos MondragonNo ratings yet

- EjerciciosgasesDocument3 pagesEjerciciosgasesLito Saul Fernandez QuispeNo ratings yet

- Problemas de electroquímicaDocument3 pagesProblemas de electroquímicaLito Saul Fernandez QuispeNo ratings yet

- TallerDocument2 pagesTallerLito Saul Fernandez Quispe100% (1)

- Ejercicios 2Document2 pagesEjercicios 2Lito Saul Fernandez QuispeNo ratings yet

- Ejercicios 2 PDFDocument2 pagesEjercicios 2 PDFLito Saul Fernandez QuispeNo ratings yet

- Apuntes Aire HumedoDocument15 pagesApuntes Aire HumedoGonzalo Alonso QuintanaNo ratings yet

- Industrial 1Document14 pagesIndustrial 1Lito Saul Fernandez QuispeNo ratings yet

- Taller BmeDocument2 pagesTaller BmeguiovanaNo ratings yet

- Ejercicios 1Document2 pagesEjercicios 1Lito Saul Fernandez QuispeNo ratings yet

- Industrial 1Document14 pagesIndustrial 1Lito Saul Fernandez QuispeNo ratings yet

- Industrial 1Document14 pagesIndustrial 1Lito Saul Fernandez QuispeNo ratings yet

- Abrasivos piedras limas discosDocument12 pagesAbrasivos piedras limas discosJose Andres Jimenez CasallasNo ratings yet

- Planta de Beneficio Oroconcent S.ADocument1 pagePlanta de Beneficio Oroconcent S.AJoseph ManuelNo ratings yet

- Relainado de Molino Sag 32x32Document2 pagesRelainado de Molino Sag 32x32Anonymous YMobgjv5No ratings yet

- Planta Paragsha - Costo - Presupuesto-2009Document29 pagesPlanta Paragsha - Costo - Presupuesto-2009Elvis Jhoan Herrera MelchorNo ratings yet

- In 4146 CLC 01 Esmeril AngularDocument6 pagesIn 4146 CLC 01 Esmeril Angularjoserojas141298No ratings yet

- Mortero (Utensilio)Document6 pagesMortero (Utensilio)amerbach55No ratings yet

- DISA BOSCH Del 15 Al 28feb23Document16 pagesDISA BOSCH Del 15 Al 28feb23Raulin Lopez100% (1)

- GRUPO - 2 - BRUÑIDO DE CILINDROS - CompressedDocument59 pagesGRUPO - 2 - BRUÑIDO DE CILINDROS - CompressedDaniel GuamanNo ratings yet

- Apu 2018Document148 pagesApu 2018Erika RodriguezNo ratings yet

- 1 Formato Work-FactorDocument2 pages1 Formato Work-FactorDianey Morales AguilarNo ratings yet

- APU - Desarme de Estructuras Metálicas LivianasDocument1 pageAPU - Desarme de Estructuras Metálicas LivianasedozammoNo ratings yet

- Resumen TeóricoDocument171 pagesResumen TeóricoFran BotteroNo ratings yet

- Check List Arranque Plantas Tecnológicas.Document212 pagesCheck List Arranque Plantas Tecnológicas.Carlos ArancibiaNo ratings yet

- Utensilios de La Casa Maya Español Maya Español: So'oy Otoch K'alabche' K'éek'en NajDocument7 pagesUtensilios de La Casa Maya Español Maya Español: So'oy Otoch K'alabche' K'éek'en NajReneé SeguraNo ratings yet

- Cangilones. Cadena DINDocument2 pagesCangilones. Cadena DINjesusinacomNo ratings yet

- Lista de Materiales (Matemáticas, Química, Física y Biología)Document4 pagesLista de Materiales (Matemáticas, Química, Física y Biología)YUZULY ANDREA AMAYA HERNANDEZNo ratings yet

- Serviacoples Y Mangueras Del Llano LtdaDocument200 pagesServiacoples Y Mangueras Del Llano Ltdacamilo parrNo ratings yet

- Análisis granulométrico y cálculo de parámetros de moliendaDocument12 pagesAnálisis granulométrico y cálculo de parámetros de moliendaFernando HerreraNo ratings yet

- Molino SAGDocument6 pagesMolino SAGHugot ToledoNo ratings yet

- Laboratorio #1 y 2 - Chancado - MoliendaDocument26 pagesLaboratorio #1 y 2 - Chancado - MoliendaNaylhe Yamilet Mamani PaccoNo ratings yet

- Molienda y Clasificación ProblemasDocument2 pagesMolienda y Clasificación Problemasanon_421255512No ratings yet

- RepeDocument9 pagesRepeHarry Vara MarceloNo ratings yet

- Lista de precios de productos automotrices 3MDocument6 pagesLista de precios de productos automotrices 3MOmar NuñezNo ratings yet

- Reporte Molienda y Tamizado Panchana Yagual Dougles 3-1Document7 pagesReporte Molienda y Tamizado Panchana Yagual Dougles 3-1Paul PanchanaNo ratings yet

- Norton AgostoDocument18 pagesNorton AgostoconsorciomagnoNo ratings yet

- Lista de UtilesDocument1 pageLista de UtilesElisa Salas VillaseñorNo ratings yet

- Parte 1Document172 pagesParte 1Skill DeadNo ratings yet

- Inv AbracolDocument3 pagesInv AbracolruichardNo ratings yet

- Discos de fibra VSM: soluciones de lijado para todo tipo de aplicacionesDocument8 pagesDiscos de fibra VSM: soluciones de lijado para todo tipo de aplicacionesJhon Jairo Arango MarquezNo ratings yet

- Abrasivos CompletoDocument160 pagesAbrasivos CompletoproduccionlatinagroupNo ratings yet