Professional Documents

Culture Documents

Sonatrach Casing Design

Uploaded by

Josue FishCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sonatrach Casing Design

Uploaded by

Josue FishCopyright:

Available Formats

GENERAL PROCEDURES Section : 22

SH - FOR

CASIGN DESIGN STANDARD Page : 1 de 8

CASING DESIGN STANDARD

DRAFT

1 Introduction

Present manual defines standards for the design of casings at Sonatrach.

2 Definitions

Conductor pipe : used in some cases to cover unstable surface soils.

Surface casing : casing used to isolate shallow zones and to install a BOP prior for drilling

lower zones.

Production Casing / Liner: the last Casing / Liner in the well. It isolates the different zones

during testing and production operations. For an exploratory well a casing / liner set before

drilling an objective is considered as a production casing / liner.

Intermediate Casing / Liner: Casing / Liner installed while drilling the well, to get a

competent shoe for a BOP of required capacity and/or to isolate zones such lost circulation

zones or unstable zones.

Critical service:

if maximum burst pressure can be higher than 350 bars

if there is a risk of corrosion by CO2 or H2S.

otherwise: normal service.

3 Casing design criteria

Casings are designed to withstand the loads that can be imposed on them during the

lifetime of the well. The expected loads are multiplied by a safety design factor, because of

the uncertainty of actual loads. The load multiplied by the design factor has to be lower

than the casing's strength.

For example if the design tension for a casing string is 150 t and the safety design factor is

1.60, then the tension strength has to be more than 150 * 1.60 = 240 t.

In the following sections are explained the different load cases used in the oil industry. The

calculation method, design factors and load cases selected by Sonatrach are also defined.

Préparé par: Visa : DOF Approbation : SH/FOR Révision N° : 0

ING / DOF Date : 09/07

GENERAL PROCEDURES Section : 22

SH - FOR

CASIGN DESIGN STANDARD Page : 2 de 8

Important Note: for a special operation such as: BOP pressure test, DST, FRAC, side-

track, etc.., the engineer in charge will insure that the casing will withstand the

loads which will be applied.

Connection type

A NEW VAM or similar connection must be used whenever the connection has to be gas

tight, particularly:

for production casings in case of critical service as defined above

for casings where gas is injected in gas lift wells.

4. Different load cases used in the oil industry

Here are some of the load cases used in the oil industry.

The name of the cases in StressCheck software is in italics.

Burst loads

- Well full of gas (Displacement to gas).

For gas gradient the conservative value: equivalent density 0.23 sg is commonly used. A

more accurate gas gradient might be used according well datas: gas composition, depth,

pressure, temperature, if previous gradient appears too conservative .

- Frac at shoe with gas (Frac@Shoe with Gas Gradient Above)

- Circulate a typical gas kick (Gas Kick Profile).Calculated pressure will depend on kick

intensity, mud weight and drilling depth.

Typically:

- for a development well, a gas kick of 11 m3 requiring an increase in mud weight of

+0.06 sg

- for an exploration well, a gas kick of 17 m3 requiring an increase in mud weight of

+0.24 sg

- Frac at shoe with water (Lost Returns With Water)

- Leak on top of the tubing while producing (Tubing Leak)

Préparé par: Visa : DOF Approbation : SH/FOR Révision N° : 0

ING / DOF Date : 09/07

GENERAL PROCEDURES Section : 22

SH - FOR

CASIGN DESIGN STANDARD Page : 3 de 8

Collapse loads

- hydrostatic pressure due to the cement slurry at the end of primary cement job

(Cementing)

- drop of mud level inside the casing when losing circulation while drilling (Lost Returns

With Mud Drop)

- casing totally or partially empty in production (Full/Partial Evacuation)

- in case of salt and plastic shales: with temperature and pressure salt and shales can

exhibit plastic flow and exert with time a pressure equal to the weight of soils above them,

with an equivalent density around 2.3 sg (1 psi/ft). They often have a dissymmetrical and

destructive effect (point loading) if the cement sheath is not uniform.The best solution is

often to reinforce the casing by a concentric casing / liner, with good centralization and

good cement.

Dissymmetrical action of salt with non Reinforcement of casing by concentric liner

uniform cement

Tension loads

- tension while pressure testing the casing at the end of the cement job (Green Cement

pressure Test).

- weight while running the casing + 45 t (Overpull Force)

- weight while running the casing (Running In Hole)

Compression loads

- weight on surface casing of casing strings which will be suspended on the first Casing

Head Housing

Préparé par: Visa : DOF Approbation : SH/FOR Révision N° : 0

ING / DOF Date : 09/07

GENERAL PROCEDURES Section : 22

SH - FOR

CASIGN DESIGN STANDARD Page : 4 de 8

5 Calculation method to be used

Several calculation methods are available:

- uni axial calculation: strengths are calculated independently for each load case. This

calculation can be done manually, or with a software (StressCheck, WellCat, etc..)

- tri axial calculation: strengths in tension/compression, and burst/collapse are calculated

simultaneously, taking into account dog legs, temperature effect, etc…This is usually done

with a software (StressCheck, WellCat or equivalent) ; it can be done by hand in simple

cases.

Perform a tri axial calculation if there are problems such as important doglegs, great

variations of pressure or temperature, particularly for:

- horizontal wells

- gas wells

- wells drilled UBD

- casings run after a side track

Otherwise a uni axial calculation is satisfactory. Uncertainties on load conditions are much

higher than the few percent of inaccuracy of the calculation.

For HP/HT wells the stability of the production casing has to be checked against pressure

and temperature effects. Stress-Check can't do this calculation, use Wellcat or equivalent.

6. Design factors

Design factors to be used at Sonatrach :

Surface casing

Production

Intermediate

casing / liner

casing / liner

Collapse 1.0 1.1

Burst

- normal service 1.1 1.1

- critical service N/A 1.25

Tension 1.6 1.6

Tri axial calculation 1.25 1.25

Compression 1.2 N/A

Préparé par: Visa : DOF Approbation : SH/FOR Révision N° : 0

ING / DOF Date : 09/07

GENERAL PROCEDURES Section : 22

SH - FOR

CASIGN DESIGN STANDARD Page : 5 de 8

7 Well's main characteristics.

The most important step in casing design is to collect the well's main characteristics, in

cooperation with geologists and production engineers, and studying the offset wells.

The Project Engineer will fill in this table and attach it to the Well Program.

Fill in values:

WELL : WELL'S CARACTERISTIKS

Exploration Producer Oil Injector Oil

Type of Well Delineation Producer Gas Injector Gas

Development

Maximum depth

………….m TVD Presence of H2S or CO2 Yes/No

Maximum Anticipated Surface Pressure :

BOP drilling- WP :…………..

…………

Presence of plastic yes / no From…………m TVD

salt or shales to…………..m TVD

Deviated well,

UBDrilling,

Particular

External Casing Packer,

conditions

Gas-lift producer

7’’ tie back to be set before production

……………………………………

RESERVOIR'S CARACTERISTIKS

Objectif 1 Objectif 2 Objectif 3

Etage géologique ……….. ……….. ………..

Depth ……….. ……….. ………..

Expected Fluid Oil Gas Oli Gas Oil Gas

GOR …..….m3/m3 …..….m3/m3 …..….m3/m3

Initial pressure ……bars at ……m ……bars at ……m ……bars at ……m

Present pressure ……bars at ……m ……bars at ……m ……bars at ……m

8 Exemption

A exemption must be requested of the Directeur de la Division Opération Forages if design

standards as defined in this manual could not be met.

Préparé par: Visa : DOF Approbation : SH/FOR Révision N° : 0

ING / DOF Date : 09/07

GENERAL PROCEDURES Section : 22

SH - FOR

CASIGN DESIGN STANDARD Page : 6 de 8

9 Design conditions

Load cases and design factors for Sonatrach :

Conductor pipe

Design factor Load case

Collapse 1.0 1) End of primary cementing :

- external pressure: cement slurry

- internal pressure: mud

2) Total losses while drilling

- external pressure: mud

- internal pressure: mud at equilibrium with pore

pressure in loss zone

Burst

Tension N/A

Compression

Préparé par: Visa : DOF Approbation : SH/FOR Révision N° : 0

ING / DOF Date : 09/07

GENERAL PROCEDURES Section : 22

SH - FOR

CASIGN DESIGN STANDARD Page : 7 de 8

Surface casing.

Intermediate casing / liner

Design factor Load case

Collapse 1.0 1) End of primary cementing :

- external pressure: cement slurries (and mud if any).

- internal pressure: mud

2) Total losses while drilling

- internal pressure: mud at equilibrium with pore

pressure in loss zone

3) UBD drilling (in case of UBD)

- internal pressure: according to UBD conditions

External pressure for case 2) and 3):

- mud of preceding phase,

- gradient 2.3 EqMW in front of plastic salt/ shale :

zones. (See note below).

Burst 1) Circulation of a kick

1.1 Normal 11 m3 of gas which requires + 0.06 kg/dm3 increased

Service mud weight ( development well)

17 m3 of gas which requires + 0.24 kg/dm3 increased

mud weight ( exploration well)

2) If a Frac would occur at shoe while circulating a gas kick

as above, including in the case of Horizon B:

FRAC at shoe with the fluid which would invade the wellbore

(either water, gas, salt water 1.25 sg in case of horizon B).

3) Exploration well: Gas blow out above the gas producing

zone.

Gas gradient

Default EqMW = 0.23sg. Use actual anticiated

gradient if previous value seems too conservative

- Outside pressure : Fluid gradients with pore pressure.

Tension 1.6 1) Running the casing : weight while running the casing

Uni axial 2) Tension while pressure testing the casing at the end of the

calculation cement job (Green Cement pressure Test).

Tension. 1.25 1) Running the casing with overpull + 45 t (Overpull Force)

Tri axial 2) Tension while pressure testing the casing at the end of the

calculation cement job (Green Cement pressure Test).

Compression 1.2 Weight on surface casing of casing strings which will be

suspended to the first Casing Head Housing

Note : in case of concentric casings, the 2.30 collapse external gradient will apply to the

external casing, but not to the internal casing / liner.

Préparé par: Visa : DOF Approbation : SH/FOR Révision N° : 0

ING / DOF Date : 09/07

GENERAL PROCEDURES Section : 22

SH - FOR

CASIGN DESIGN STANDARD Page : 8 de 8

Production casing / liner

Design factor Load case

Collapse 1.1 1) End of primary cementing :

- external pressure: cement slurries (and mud if any).

- internal pressure: mud

2) Total losses while drilling

- internal pressure: mud at equilibrium with pore

pressure in loss zone

3) UBD drilling (in case of UBD)

- internal pressure: according to UBD conditions

4) Partial evacuation in production

- internal pressure:

evacuation up to 2500 m

fresh water below 2500 m.

Section of a casing/ liner which will be covered by a

concentric casing /liner before production of the well

has not to withstand this load.

External pressure for case 2) 3)and 4):

- mud of preceding phase, gradient 2.3 EqMW in

front of plastic salt/ shale : zones.

(seer note at bottom of preceding page)

Burst 1.10 normal 1) Circulation of a gas kick

service 11 m3 of gas which requires + 0.06 kg/dm3 increased

mud weight ( development well)

1.25 critical 17 m3 of gas which requires + 0.24 kg/dm3 increased

service mud weight ( exploration well)

2) ) If a Frac would occur at shoe while circulating a gas kick

as above, including in the case of Horizon B:

FRAC at shoe with the fluid which would invade the wellbore

(either water, gas, salt water 1.25 sg in case of horizon B).

3) Exploration well: Gas blow out above the gas producing

zone

4) Leak on top of the tubing while producing (Tubing Leak),

tubing / casing annulus filled with brine 1.25 sg.

Gas gradient

Default EqMW = 0.23sg. Use actual anticiated

gradient if previous value seems too conservative

5) Acid Frac of perforations, with a packer at 100 m above the

top of the liner.

Section of a casing/ liner which will be covered by a

concentric casing /liner before production of the well

has not to withstand the load cases 4) and 5).

- Outside pressure : Fluid gradients with pore pressure.

Tension 1.6 1) Running the casing / liner

Uni axial 2) Tension while pressure testing the casing / liner at the end

calculation of the cement job (Green Cement pressure Test).

Tension 1.25 1) Running the casing / liner with overpull + 45 t (Overpull

Tri axial Force).

calculation 2) Tension while pressure testing the casing / liner at the end

of the cement job (Green Cement pressure Test).

Préparé par: Visa : DOF Approbation : SH/FOR Révision N° : 0

ING / DOF Date : 09/07

You might also like

- Women's Prints & Graphics Forecast A/W 24/25: Future TerrainsDocument15 pagesWomen's Prints & Graphics Forecast A/W 24/25: Future TerrainsPari Sajnani100% (1)

- IEC 584-2-1989, Thermocouples, Tolerances PDFDocument18 pagesIEC 584-2-1989, Thermocouples, Tolerances PDFJosue FishNo ratings yet

- Formulas Well ControlDocument6 pagesFormulas Well ControlJosue FishNo ratings yet

- Tillotson HD & HR Service ManualDocument11 pagesTillotson HD & HR Service ManualBeckyNo ratings yet

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceFrom EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceNo ratings yet

- TAMU - Pemex: Well ControlDocument54 pagesTAMU - Pemex: Well Controldriller22100% (2)

- Bit Hydraulics OptimizationDocument24 pagesBit Hydraulics OptimizationRebar Kaka100% (1)

- Mud Engineer User ManualDocument48 pagesMud Engineer User ManualstevebeardsleyNo ratings yet

- Abnormal Pore Pressure PredictionDocument41 pagesAbnormal Pore Pressure PredictionSandesh Chavan100% (2)

- 1 Casing DesignDocument73 pages1 Casing DesignHasril Fauzul AziNo ratings yet

- Tubular Designer Rule SetDocument28 pagesTubular Designer Rule SetSudish BhatNo ratings yet

- BG Group - Casing Design ManualDocument51 pagesBG Group - Casing Design ManualHamza Lahbiben100% (1)

- Reference Guide: Directional DrillingDocument67 pagesReference Guide: Directional DrillingRakhmad HanifNo ratings yet

- Guía para Tapones de CementoDocument15 pagesGuía para Tapones de CementoJunnior López PintadoNo ratings yet

- Bit SelectionDocument19 pagesBit SelectionFernando AybarNo ratings yet

- IADC/SPE 72290 Drilling Fluids Design and Management For Extended Reach DrillingDocument7 pagesIADC/SPE 72290 Drilling Fluids Design and Management For Extended Reach Drillinggplese0No ratings yet

- Drilling Programme - ChecklistDocument5 pagesDrilling Programme - ChecklistFill Jose100% (1)

- Casing DesignDocument10 pagesCasing DesignAry Rachman0% (1)

- PETE 661: Drilling EngineeringDocument50 pagesPETE 661: Drilling Engineeringcmrig74No ratings yet

- Cementing - Cementing Plugs HalliburtonDocument12 pagesCementing - Cementing Plugs HalliburtonHenry MataNo ratings yet

- Cement Stinger Balanced PlugDocument13 pagesCement Stinger Balanced Plugjsever1No ratings yet

- The Value of Comprehensive Well Integrity Analysis in Deep-Ultradeepwater High-Pressure, High-Temperature ScenariosDocument12 pagesThe Value of Comprehensive Well Integrity Analysis in Deep-Ultradeepwater High-Pressure, High-Temperature ScenariosVishal100% (1)

- CSG Type & DesignDocument45 pagesCSG Type & Designcrown212100% (2)

- OBS II The Adjustable Wellhead For Exploration Drilling FullDocument24 pagesOBS II The Adjustable Wellhead For Exploration Drilling FullAli Boubenia100% (1)

- Casing Seat Selection - How To Select Casing Setting Depth - Drilling Formulas and Drilling CalculationsDocument1 pageCasing Seat Selection - How To Select Casing Setting Depth - Drilling Formulas and Drilling CalculationsAanuNo ratings yet

- Casing Drilling - Wellbore StabilityDocument6 pagesCasing Drilling - Wellbore StabilityJenny100% (1)

- Well PlanningDocument4 pagesWell PlanningSibte Hassan ButtNo ratings yet

- Well Integrity Test ProgrammeDocument5 pagesWell Integrity Test ProgrammeDianna Ariza RNo ratings yet

- Formation Pressure While Drilling Technology - Game Changer in Drilling Overpressured ReservoirsDocument6 pagesFormation Pressure While Drilling Technology - Game Changer in Drilling Overpressured ReservoirsJamalNo ratings yet

- Openhole CompletionsDocument9 pagesOpenhole CompletionsShaktim DuttaNo ratings yet

- Deepwater CementingDocument18 pagesDeepwater CementingAhmed Ali AlsubaihNo ratings yet

- Kick Tolerance Calculations For Well Design and Drilling OperationsDocument2 pagesKick Tolerance Calculations For Well Design and Drilling Operationsi oNo ratings yet

- ENM210 Cementing Operations Lecture 2 - Stage Cementing - 1 StageDocument8 pagesENM210 Cementing Operations Lecture 2 - Stage Cementing - 1 StageHamid Reza BabaeiNo ratings yet

- TAMU - Pemex Offshore DrillingDocument43 pagesTAMU - Pemex Offshore Drillingdriller22100% (1)

- A Process Used in Evaluation of Managed-Pressure Drilling Candidates and Probabilistic Cost-Benefit AnalysisDocument13 pagesA Process Used in Evaluation of Managed-Pressure Drilling Candidates and Probabilistic Cost-Benefit AnalysisMaulana Alan MuhammadNo ratings yet

- Formation Pressure For Well DesignDocument20 pagesFormation Pressure For Well DesignadeniyiNo ratings yet

- Well InterventionDocument83 pagesWell InterventionJosue FishNo ratings yet

- WELLCAT Data SheetDocument8 pagesWELLCAT Data SheetErik Rodriguez100% (1)

- Casing Design LoadsDocument4 pagesCasing Design LoadsRichard More LeonNo ratings yet

- HPHT Well Design-Seymour1994Document5 pagesHPHT Well Design-Seymour1994Mygroup 5544No ratings yet

- 5B. High Pressure RiserDocument10 pages5B. High Pressure Riserdriller22No ratings yet

- Hole Problems Pipe StickingDocument56 pagesHole Problems Pipe StickingJohn100% (1)

- Overview of Drilling OperationDocument106 pagesOverview of Drilling OperationTemitope Bello100% (1)

- PtrE 521 - Lecture 6 - Horizontal and Multilateral WellsDocument116 pagesPtrE 521 - Lecture 6 - Horizontal and Multilateral WellsGhoulemEllah Haithem IfreneNo ratings yet

- Group 4 - Expandable TubularDocument20 pagesGroup 4 - Expandable TubularAzka Roby AntariNo ratings yet

- Well PlanningDocument13 pagesWell Planningkeen dela cruzNo ratings yet

- Advanced Drilling Practices - Casing DesignDocument92 pagesAdvanced Drilling Practices - Casing DesignGFarizNo ratings yet

- Borehole StabilityDocument73 pagesBorehole StabilityNilthson Noreña Valverde100% (2)

- Integrated EDM™ WorkflowsDocument7 pagesIntegrated EDM™ WorkflowsEnrique DiazNo ratings yet

- Well PlanningDocument18 pagesWell PlanningBrahim Letaief100% (3)

- Wellbore Sidetracking GuidelinesDocument4 pagesWellbore Sidetracking Guidelinesmadonnite3781No ratings yet

- MPD UBD ReportDocument76 pagesMPD UBD ReportArjit KumarNo ratings yet

- Well CompletionDocument82 pagesWell CompletionFlorian Ananias ByarugabaNo ratings yet

- Well Completion & StimulationDocument50 pagesWell Completion & StimulationShourovjossNo ratings yet

- Directional Drilling CalcuationsDocument43 pagesDirectional Drilling CalcuationsNourden Al100% (1)

- 10 Under Balance DrillingDocument13 pages10 Under Balance DrillingZiad AouichatNo ratings yet

- 1production EngineeringDocument42 pages1production EngineeringSha BazNo ratings yet

- Riserless DrillingDocument22 pagesRiserless DrillingAbraham RojasNo ratings yet

- Wellbore Failure Diagnostic Chart KSIDocument1 pageWellbore Failure Diagnostic Chart KSIhamza72No ratings yet

- Well Design CriteriaDocument42 pagesWell Design CriteriaYesar Bin Mustafa AlmalekiNo ratings yet

- Drilling and Completion Egy Petroleum Engineer PDFDocument208 pagesDrilling and Completion Egy Petroleum Engineer PDFRahma MejriNo ratings yet

- Corrosion - M-506r2 - IFE - 06-2005Document59 pagesCorrosion - M-506r2 - IFE - 06-2005Yosmar GuzmanNo ratings yet

- Aws A5.3Document28 pagesAws A5.3ahmedNo ratings yet

- Jis Z2352-2010 PDFDocument32 pagesJis Z2352-2010 PDFJosue Fish50% (2)

- Metric Conversions: To Convert From TO Multiply by Symbol Unit Symbol Unit LengthDocument1 pageMetric Conversions: To Convert From TO Multiply by Symbol Unit Symbol Unit LengthJosué Emmanuel Blásquez ContrerasNo ratings yet

- Aws A5.3Document28 pagesAws A5.3ahmedNo ratings yet

- What's New in PERFORM 7.50!: Worst-Case Discharge Scenario Report For Offshore WellsDocument6 pagesWhat's New in PERFORM 7.50!: Worst-Case Discharge Scenario Report For Offshore WellsrafaelNo ratings yet

- IELTS Task 2 Writing Band DescriptorsDocument2 pagesIELTS Task 2 Writing Band DescriptorsIrfan PrabowoNo ratings yet

- IELTS Daily Planner PDFDocument1 pageIELTS Daily Planner PDFJosue FishNo ratings yet

- Assessment Criteria - WRITING TASK 1 - Band Descriptors PDFDocument1 pageAssessment Criteria - WRITING TASK 1 - Band Descriptors PDFIbrahim Babatunde OladapoNo ratings yet

- Writing Academic Essays @ieltsieltsDocument23 pagesWriting Academic Essays @ieltsieltsJosue FishNo ratings yet

- Sub-Spec 022 - Vam CDS, EIS, VAM Express: Visual InspectionDocument3 pagesSub-Spec 022 - Vam CDS, EIS, VAM Express: Visual InspectionJosue FishNo ratings yet

- Routine IeltsDocument2 pagesRoutine IeltsJosue FishNo ratings yet

- SS025 Inspection of Installed Unused IntelliCoils NS2 PDFDocument1 pageSS025 Inspection of Installed Unused IntelliCoils NS2 PDFJosue FishNo ratings yet

- Sub-Spec 023 - Tenaris DSTJ, WT™Document4 pagesSub-Spec 023 - Tenaris DSTJ, WT™Josue FishNo ratings yet

- SS026 Wired Drill String Electrical Inspection NS2 PDFDocument1 pageSS026 Wired Drill String Electrical Inspection NS2 PDFJosue FishNo ratings yet

- Sub-Spec 021 - Grant Prideco GPDS™, HT™, XT™, XT-M™, TT™, TT-M™Document4 pagesSub-Spec 021 - Grant Prideco GPDS™, HT™, XT™, XT-M™, TT™, TT-M™Josue FishNo ratings yet

- Sub-Spec 023 - Tenaris DSTJ, WT™Document4 pagesSub-Spec 023 - Tenaris DSTJ, WT™Josue FishNo ratings yet

- SS025 Inspection of Installed Unused IntelliCoils NS2 PDFDocument1 pageSS025 Inspection of Installed Unused IntelliCoils NS2 PDFJosue FishNo ratings yet

- Table 12b: Used HWDP Dimensional Acceptance Criteria - Grant Prideco DSDocument1 pageTable 12b: Used HWDP Dimensional Acceptance Criteria - Grant Prideco DSJosue FishNo ratings yet

- Sub-Spec 027 - DP Master DS, MT and High Torque PAC: Visual InspectionDocument3 pagesSub-Spec 027 - DP Master DS, MT and High Torque PAC: Visual InspectionJosue FishNo ratings yet

- T12 Rev1 Used HWDP and Connection Dimensional Acceptance Criteria NS2Document1 pageT12 Rev1 Used HWDP and Connection Dimensional Acceptance Criteria NS2Josue FishNo ratings yet

- Table 12a: Used HWDP Dimensional Acceptance Criteria - Grant Prideco XTDocument1 pageTable 12a: Used HWDP Dimensional Acceptance Criteria - Grant Prideco XTJosue FishNo ratings yet

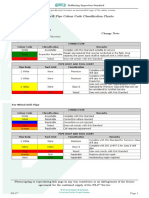

- T3 Bottomhole Assembly Colour Code Classification Chart NS2Document1 pageT3 Bottomhole Assembly Colour Code Classification Chart NS2Josue FishNo ratings yet

- Table 12c: Used HWDP Dimensional Acceptance Criteria - Grant Prideco TTDocument1 pageTable 12c: Used HWDP Dimensional Acceptance Criteria - Grant Prideco TTJosue FishNo ratings yet

- T4 Drill Pipe Colour Code Classification Chart NS2Document1 pageT4 Drill Pipe Colour Code Classification Chart NS2Josue Fish100% (2)

- Table 13a: Bevel Diameters On BHA Bit Box ConnectionsDocument1 pageTable 13a: Bevel Diameters On BHA Bit Box ConnectionsJosue FishNo ratings yet

- Table 2: Inspection Equipment Calibration FrequencyDocument1 pageTable 2: Inspection Equipment Calibration FrequencyJosue FishNo ratings yet

- Table 1: Requirement For Qualification of Inspection PersonnelDocument1 pageTable 1: Requirement For Qualification of Inspection PersonnelJosue FishNo ratings yet

- Chapter 11Document10 pagesChapter 11NungkiwidyasNo ratings yet

- Poem Summary - Keeping QuietDocument3 pagesPoem Summary - Keeping QuietVignesh Mohan100% (2)

- Industrial TYROLITc 21Document611 pagesIndustrial TYROLITc 21kamilNo ratings yet

- GTE LAB MANUAL Ver 4 - 1Document135 pagesGTE LAB MANUAL Ver 4 - 1akhilaNo ratings yet

- Nature Generator (Emtech Concept Paper)Document3 pagesNature Generator (Emtech Concept Paper)Min SugaNo ratings yet

- Coronary Stents: Current StatusDocument42 pagesCoronary Stents: Current StatusMANSI SALUNKENo ratings yet

- Polymer Structures: Issues To Address..Document34 pagesPolymer Structures: Issues To Address..Eugene Embalzado Jr.No ratings yet

- I-R Nirvana IRN250-300H-2S Parts ManualDocument28 pagesI-R Nirvana IRN250-300H-2S Parts ManualMistysParts100% (4)

- (Complete) BLC 201 Assignment Intro Logistics SCM Sep 2021 - McdonaldDocument12 pages(Complete) BLC 201 Assignment Intro Logistics SCM Sep 2021 - McdonaldHf CreationNo ratings yet

- القطع بالبلازماDocument27 pagesالقطع بالبلازماsamehNo ratings yet

- Castlegar & Slocan Valley Pennywise Dec. 9, 2014Document49 pagesCastlegar & Slocan Valley Pennywise Dec. 9, 2014Pennywise PublishingNo ratings yet

- Introduction On Photogrammetry Paul R WolfDocument33 pagesIntroduction On Photogrammetry Paul R Wolfadnan yusufNo ratings yet

- Bright Ideas 2 Unit 1 Test-Fusionado-Páginas-1-33Document33 pagesBright Ideas 2 Unit 1 Test-Fusionado-Páginas-1-33Eleonora Graziano100% (1)

- Internship ReportDocument50 pagesInternship ReportSachinNo ratings yet

- ERIC Section4 Hadrian - C. AlbinusDocument83 pagesERIC Section4 Hadrian - C. AlbinusDarko SekulicNo ratings yet

- Biology: Higher Tier Paper 1HDocument28 pagesBiology: Higher Tier Paper 1HkaruneshnNo ratings yet

- Jurnal Praktikum Dasar-Dasar Pemisahan Kimia Pembuatan Membran Polysulfon (PSF)Document9 pagesJurnal Praktikum Dasar-Dasar Pemisahan Kimia Pembuatan Membran Polysulfon (PSF)Rizki AuNo ratings yet

- External Otitis (OE)Document24 pagesExternal Otitis (OE)Hannah BLissNo ratings yet

- The Interrelationship Between Fashion andDocument17 pagesThe Interrelationship Between Fashion andpushpak navandarNo ratings yet

- Ketron 1000 PEEK PDS E 30032019 01Document1 pageKetron 1000 PEEK PDS E 30032019 01jorgepradaco1No ratings yet

- A Report On External Analysis of Construction in NepalDocument13 pagesA Report On External Analysis of Construction in Nepalsubash upretiNo ratings yet

- Ok TC FlotationDocument4 pagesOk TC FlotationWilliam SalcedoNo ratings yet

- New Magic Grammar TE3BDocument34 pagesNew Magic Grammar TE3BYume ZhuNo ratings yet

- Synthesis of Sentences Is The Opposite ofDocument9 pagesSynthesis of Sentences Is The Opposite ofSpsc AspirantsNo ratings yet

- Designing Hopping Animal PDFDocument3 pagesDesigning Hopping Animal PDFAntonio Francisco Muñoz100% (1)

- Bolt Group Coefficient For Eccentric Loads PDFDocument5 pagesBolt Group Coefficient For Eccentric Loads PDFdvelchevNo ratings yet

- Grade 8 MAPEH ReviewerDocument4 pagesGrade 8 MAPEH ReviewerVictoria DelgadoNo ratings yet

- Iec 62031 PDFDocument16 pagesIec 62031 PDFAlbertoNo ratings yet