Professional Documents

Culture Documents

Utilization of Waste Plastic in Manufacturing of Plastic Soil Bricks PDF

Uploaded by

cristinaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Utilization of Waste Plastic in Manufacturing of Plastic Soil Bricks PDF

Uploaded by

cristinaCopyright:

Available Formats

INTERNATIONAL JOURNAL OF TECHNOLOGY ENHANCEMENTS AND EMERGING ENGINEERING RESEARCH, VOL 2, ISSUE 4 102

ISSN 2347-4289

Utilization Of Waste Plastic In Manufacturing Of

Plastic-Soil Bricks

Puttaraj Mallikarjun Hiremath, Shanmukha shetty, Navaneeth Rai.P.G, Prathima.T.B

Department of Civil Engineering, K.V.G.College of engineering, Sullia, India

Email: puttaraj@mite.ac.in

ABSTRACT: There has been a considerable imbalance between the availability of conventional building materials and their demand in the recent past.

On the other hand the laterite quarry waste is abundantly available and the disposal of waste plastics (PET, PP,etc.) is a biggest challenge, as repeated

recycling of PET bottles pose a potential danger of being transformed to a carcinogenic material and only a small proportion of PET bottles are being

recycled. In this work an attempt has been made to manufacture the bricks by using waste plastics in range of 60 to 80% by weight of laterite quarry

waste and 60/70 grade bitumen was added in range of 2 to 5% by weight of soil in molten form and this bitumen- plastic resin was mixed with laterite

quarry waste to manufacture the bricks. The bricks manufactured possess the properties such as neat and even finishing, with negligible water

absorption and satisfactory compressive strength in comparison with laterite stone to satisfy the increasing demand of conventional building materials.

Keywords: Poly ethylene terephthalate (PET), Laterite quarry waste, Bitumen, plastic-soil bricks.

1 INTRODUCTION

Soil is a loose, unconsolidated material on the earth’s crust

and it is formed by the weathering of solid rocks. The laterite

formation was named in southern India1807, and it was de-

scribed by Francis Buchanan-Hamilton. He named it from the

Latin word “later” which means brick. This rock can be easily

cut into brick shaped blocks for building construction. The lat-

erite stone is rich in iron and aluminium and it is formed in hot

and wet tropical areas. A good reservoir of laterite stone is

present in the coastal Karnataka and some norhten parts of Fig.1. The chemical structure of PET monomer.

Karnataka and also in the northern parts of Kerala, due to

which lot of quarrying of laterite bricks takes place. In quarries 1.2 Properties of plastics [1]

while cutting out the laterite stones with the help of cutting ma- Physical properties of PET were as given in Table 1

chines which produces 15-20% of soil wastes which pose a

problem of disposal. The quantity of plastic waste in Municipal TABLE 1

Solid Waste (MSW) is expanding rapidly. It is estimated that PHYSICAL PROPERTIES OF POLY ETHYLENE TEREPHTHALATE

the rate of expansion is double for every 10 years, this is due

to rapid growth of population, urbanization, developmental Coefficient of Thermal Expansion 7 x 10-3/ºC

activities and changes in life style which leading widespread Long Term Service Temperature 115 - 170ºC

littering on the landscape. Thus disposal of waste plastic is a

Melting point 260ºC

serious problem globally, since they are non biodegradable

and also researchers have found that the plastic materials can Specific Gravity 1.3 – 1.4

remain on earth for 4500 years without degradation [1]. Plastic Water Absorption 0.07 – 0.10%

have many good characteristics which include versatility, light-

ness, hardness, and resistant to chemicals, water and impact

[9]. The test samples are collected from the laterite stone quarry

nearer to village Aletti, which is located in the Dakshina kan-

1.1 Chemical structure of a waste plastic (polyethylene nada district, Sullia taluka, Karnataka, India.

9

terephthalate) [technical news letter]

The monomer for the production of Poly ethylene terephtha-

late (PET) is ethylene teryphthalate and this consists of the

ethylene molecule (-CH2 - CH2-), two ester molecules (-COO-),

and the teryphthalate ring molecule. The only atomic species

present in PET are therefore hydrogen, oxygen, and carbon.

Burning PET generates only carbon dioxide (CO2) and water

(H2O). So there is no potential danger of harmful gas emission

even when PET is burnt but in the present work only melting of

PET was required. The structure of the PET monomer is

shown below

Fig. 2. Laterite Quary.

Copyright © 2014 IJTEEE.

INTERNATIONAL JOURNAL OF TECHNOLOGY ENHANCEMENTS AND EMERGING ENGINEERING RESEARCH, VOL 2, ISSUE 4 103

ISSN 2347-4289

In this context work was under taken with following objectives aggregates are transported on conveyor belts the shredded

To arrive at the optimum quantity of waste plastic (PET bottles) plastic is sprayed on it. So that plastic makes a coat on the

and also the bitumen that could result in a building material aggregate this plastic coated aggregate was later blended with

(brick) with good strength and less water absorption. To de- hot molten bitumen to result in plastic modified bitumen. The

velop a scientific way of reusing the waste plastic (PET bot- research concluded that this waste plastic usage in bituminous

tles) along with the utilization of laterite quarry waste that concrete mixes resulted in improved resistivity to water ab-

could result in an alternative building material with the satisfac- sorption and better bonding with reduced susceptibility to

tion of all the requirements of good building material. stripping. “Useful products from oil and organic chemistry”[8],

classifies the plastic as Thermo softening plastics (Thermo

2 LITERATURE REVIEW plastics) and Thermo setting plastics (Thermo set plastics).

According to a Technical newsletter “Focus on PET”, Poly eth- Thermo setting plastics can be made plastic and malleable at

ylene terephthalate belongs to the polyester family of poly- high temperatures only once. Modern thermoplastic polymers

mers, one of the largest and most diverse of the polymer fami- soften anywhere between 65 ºC and 200+ ºC. In this state

lies. This family of polymers is linked by the common feature of they can be moulded in a number of ways they differ from

having an ester (-COO-) link in the main chain, but the range thermo set plastics in that, they can be returned to this plastic

of polyester materials is probably the largest of all the polymer state by reheating. They are then fully recyclable. PET used in

families. And also the chemical structure of the PET is having this project belongs to thermo plastics. Thermo-set plastics

only atomic species that are carbon, hydrogen and oxygen. differ in that they are not re-mouldable. Strong cross links are

Therefore melting of PET won’t result in release of noxious formed during the initial moulding process that gives the mate-

gases and also its properties reveal that a melting temperature rial a stable structure. They are more likely to be used in situa-

of 260 ºC is required. Also from the properties of the PET it tions where thermal stability is required. They tend to lack ten-

can be understood that it has got good chemical resistance sile strength and can be brittle. Polyester resin, Urea formal-

and better resistance to UV rays [9]. In a paper “An review on dehyde etc. belongs to this type. An attempt to utilize the later-

waste plastic utilization in asphalting of roads” [1], the tech- ite wastes available abundantly in the laterite quarry for the

niques to use plastic waste for construction purpose of roads manufacture of laterite soil bricks using cement as a stabilizing

and flexible pavements, which were developed by various re- agent [2]. This can be used as an alternative to the usual later-

searchers has been reviewed. And collectively emphasises the ite stone. The laterite soil was procured from the laterite quarry

concept of utilization of waste plastic in construction of flexible near sullia. The study concluded that laterite soil stabilized

road pavement. In the construction of flexible pavements, bi- with 7% cement for manufacturing of interlocking bricks with a

tumen plays the role of binding the aggregate together by good compressive strength of 4.72 N/mm2. The concept of

coating over the aggregate. It also helps to improve the interlocking bricks of size 30x20x18cm was adopted which

strength and life of road pavement. But its resistance towards resulted in a cost effective construction [2]. As per the re-

water is poor. A common method to improve the quality of bi- search work on “Use of Cement-Sand Admixture in Laterite

tumen is by modifying the rheological properties of bitumen by Brick Production for Low Cost Housing” [4], in Makurdi (Nige-

blending with synthetic polymers like rubber and plastics. This ria) and other locations within Benue State, abundant lateritic

bitumen mix show better binding property, stability, density and soil deposits exist which can be harnessed for brick produc-

more resistant to water. And also emphasized the availability tion. Results showed that laterite used in this study cannot be

of plastic in various forms as given in Table 2. stabilized for brick production within the economic cement con-

tent of 5% specified for use in Nigeria. However, bricks made

TABLE 2 with laterite admixed with 45% sand and 5% cement attained a

ORIGIN OF PLASTIC compressive strength of 1.80 N/mm2 which is greater than the

Waste Plastic Available As specified minimum strength value of 1.65 N/mm2. Cost com-

Poly ethylene terephthalate Drinking water bottles parison of available walling materials in Makurdi metropolis

(PET) etc. showed that the use of bricks made from 45% sand and 5%

High Density Poly ethylene Carry bags, bottle caps, cement resulted in a saving of 30 - 47% when compared with

(HDPE) house hold articles etc. the use of sand concrete blocks while the use of fired clay

Milk pouches, sacks, bricks resulted in a savings of 19% per square meter of wall.

Low Density Poly ethylene carry bags, bin linings, The study therefore recommends the use of laterite bricks in

(LDPE) cosmetics and detergent Makurdi and other locations because it is more economical

bottles. and environmental friendly than fired clay bricks.

Bottle caps and closures,

Poly propylene (PP) wrappers of detergents, 3 METHODOLOGY

biscuit etc. The main objective of this research work is to develop an effi-

Electrical fittings cient way to effectively utilize the waste plastic which is a great

Urea formaldehyde

,handles and knobs threat for the sustainment of ecological balance, With the later-

Casting, bonding fibers ite quarry waste to manufacture an alternative building mate-

Polyester resin (glass, Kevlar, carbon rial by which both the questions of a scientific disposal of

fiber) waste plastic as well as scarcity of traditional building materi-

als can be answered. The laterite quarry waste was collected

Research on “The Use of Recycled Materials in Highway con- from Aletti. When the laterite stone is cut from the quarry

struction” [6] and “Utilization of waste plastic in Bituminous nearly 15-20% of laterite waste is obtained. This waste was

Concrete mixes” [7] to determine the suitability of plastic waste crushed using rammers and sieved in a 2.36mm IS sieve. This

modifier in construction of bituminous mixes, where the heated sieved laterite soil was brought to laboratory for preparation of

Copyright © 2014 IJTEEE.

INTERNATIONAL JOURNAL OF TECHNOLOGY ENHANCEMENTS AND EMERGING ENGINEERING RESEARCH, VOL 2, ISSUE 4 104

ISSN 2347-4289

bricks. This soil was sun-dried to reduce the water content. A Gravel = 10% Sand = 83% Silt & Clay = 7% Uniformity co-

mould of size 20x10x10cm was prepared. Bricks of different efficient (Cu) = 15.31 Co-efficient of curvature (Cc) =

mix proportions were prepared, for each brick 3kg of the later- 1.03

ite soil was added with varying bitumen content of 2, 5 and

10% along with variation in percentage of plastic. Bricks were The Cu > 15 & Cc is between 1 and 3 hence it is considered

prepared by compacting through vibration. 9kg of clean sieved as well graded soil. The various preliminary test results are

laterite quarry waste is collected. 70% of plastic (PET) by given in Table 3.

weight of soil is cleaned and heated to a molten state. Then

sieved soil is added at intervals with proper mixing. At the final TABLE 3

stage 2% of bitumen by weight of soil is added and mixed for INDEX PROPERTIES OF LATERITE SOIL

uniform distribution to prepare 3 bricks. The hot mix is poured Sl.No Experiments Results

into the moulds and then compacted by vibration. The bricks 1 Natural Water Content (%) 10.7

are demoulded after 30 min and air dried for a period of 24hr 2 Specific Gravity 2.48

for proper heat dissipation. Of each mix proportion bricks were

3 Unit Weight (g/cc) 1.59

prepared and tested for compressive strength in the compres-

4 Liquid Limit (%) 38.50

sive testing machine (CTM).

5 Plastic Limit (%) 27.48

6 Shrinkage Limit (%) 13.48

7 Optimum Moisture Content (%) 21.40

8 Optimum Dry Density (g/cc) 1.78

4.2 Properties of bitumen

Bitumen is primarily used to improve the binding property of

molten plastic and also it serves the purpose of transforming a

Fig.3. Weighing of PET Plastics & Hot molten mix thermoplastic into thermosetting plastic.The various tests are

conducted on the bitumen. The results are obtained are tabu-

lated in Table 4.

TABLE 4

INDEX PROPERTIES OF BITUMEN

Sl.No Experiments Results

1 Penetration (mm) 67.5

2 Ductility (cm) 59

Fig.4. Mould used & Prepared Specimen 3 Softening point (◦c) 58

4 Specific Gravity 1.01

4 MATERIAL PROPERTIES

5 EXPERIMENTAL RESULTS

4.1 Preliminary test results

Sieve analysis test was conducted for the laterite quarry 5.1 General

waste; The gradation curve obtained from the test is shown in The results of experiments conducted for various percentages

Fig. 5 of plastic mixed with laterite quarry waste with varying per-

centage of bitumen are discussed.

5.2 Effect of water cooling on strength of plastic-soil

bricks

For manufacturing of plastic-soil bricks a minimum of 60% of

plastic by weight of soil was required as determined by trial

and error method, so 65% of plastic by weight of soil is con-

sidered as a starting proportion. Compression strength was

conducted on bricks of size 20x10x10cm.The compression

strength test results are given in Table 5.

Fig. 5. Grain Size Analysis.

Copyright © 2014 IJTEEE.

INTERNATIONAL JOURNAL OF TECHNOLOGY ENHANCEMENTS AND EMERGING ENGINEERING RESEARCH, VOL 2, ISSUE 4 105

ISSN 2347-4289

TABLE 6

TABLE 5 COMPRESSIVE STRENGTH OF WATER COOLED PLASTIC-SOIL

COMPRESSIVE STRENGTH OF WATER COOLED PLASTIC-SOIL BRICKS

BRICKS Percentage of

Type of Percentage Average Type of Water

SL plastic by weight

heat of plastic compressive heat absorption

Sl.no. Days NO of soil (with 2% of

disssipat (with 2% strength dissipation (%)

bitumen)

ion bitumen) (N/mm2)

1 3 7.20 0 (0%plastic and

1 NA

2 Water 65 7 7.14 0%bitumen)

3 cooled 28 7.18 2 Air cooled 65 1.8242

3 70 0.9536

There is no much effect on compressive strength of plastic-soil 4 75 0.7962

bricks on water cooling since for 3,7 and 28 days of water 5 80 0.5954

cooling the compressive strength is almost same. Therefore

only air cooling is adopted. The compressive strength test results of plastic-soil bricks for

65 and 70% of plastic containt by weight of soil with constant

5.3 Effect of variation in plastic content on compres- binder content of 2% by weight of soil, gives same compres-

sive strength and water absorption of plastic-soil sive strength(8.16 N/mm2), but 70% plastic containt is consi-

bricks dered as optimum in the view of workabality criteriaduring

The effect of variation in percentage of plastic on compression manufacture. From the test results it was observed that the

strength of plastic soil bricks and the water absorption are rep- water absorption also decreases with increase in percentage

resented by bar diagram in Fig.6 and tabulated in the Table 6 of plastic. The plastic-soil brick containing 70% plastic & 2%

respectively. bitumen gives negligible water absorption of 0.9536%.

5.4 Effect of binder content variation on compressive

strength of plastic-soil bricks

TABLE 7

EFFECT OF BINDER CONTENT VARIATION ON COMPRESSIVE

STRENGTH

Bitumen Optimum

Compressive Strength

content plastic content

(N/mm2)

(%) (%)

0 70 2.5

2 70 7.82

5 70 10

Fig. 6. Compressive Strength of Air Cooled Plastic-Soil 10 70 2.04

Bricks.

From the test results it is evident that for 5% bitumen by

weight of soil gives maximum compressive strength of 10

N/mm2 but from economical considerations 2% of bitumen

content is taken as optimum binder content (refer table 9),

which has a compressive strength of 8.16 N/mm2 which would

be satisfactory. On increasing the percentage of binder (bitu-

men) the compressive strength of brick also increases up to

5%, but further increase in bitumen decreases the strength.

Also serves the purpose of transforming a thermoplastic into

thermosetting plastic.

5.5 Compression strength test and water absorption on

laterite stone

Fig.7. Compression testing of spaceman & A Part of Failed

The Compressive strength and water absorption test on late-

Spaceman

rite stone of size 30x20x15cm was conducted and the test

result is as shown Table 8.

From the test results it was found that as the percentage of

plastic increased, the compressive strength of the brick also

increased. So it shows that the strength of plastic-soil bricks is

dependent on the percentage of plastic.

Copyright © 2014 IJTEEE.

INTERNATIONAL JOURNAL OF TECHNOLOGY ENHANCEMENTS AND EMERGING ENGINEERING RESEARCH, VOL 2, ISSUE 4 106

ISSN 2347-4289

TABLE 8 TABLE 9

COMPRESSIVE STRENGTH AND WATER ABSORPTION OF LAT- ESTIMATION OF EACH INTERLOCKING PLASTIC-SOIL BRICK

ERITE STONE (30X20X15 CM) Unit

ntity

Unit

Qua

Average Compressive Water Sl. Amount

Item rate

s

Material Load Strength absorption no Rs - ps

Rs - ps

(kN) (N/mm2) (%) Plastic (col-

Laterite lection &

191 3.18 14.58 1 7.00 Kg 0.5 3.50

stone Transporta-

tion)

2 Bitumen 0.20 Kg 40.00 8.00

Properties of plastic-soil bricks are uniform but in the case

laterite stone whose properties are varied widely depending on Soil

the quarry from which it was obtained. 3 (transporta- 10.00 Kg 0.15 1.50

tion)

lump-

6 CONCLUSIONS 4 Labour

sum

3.50

The compressive strength test results for plastic-soil bricks

TOTAL Rs. 16.50

with 70% plastic content by weight of soil with the

binder(bitumen) content of 2% by weight of soil will gives a

compressive strength of 8.16N/mm2 which is higher than late- Therefore for each plastic-soil brick =16.50 Rs

rite stone (3.18N/mm2).And has a lesser water absorp- Plastic soil bricks required for 1m3 =93 no’s

tion(0.9536%) than laterite stone (14.58%). So it can be a bet- Amount required for 1m3 = 93 x 16.50 =1534.50 Rs

ter alternative building material From the compressive strength Labour =165.00 Rs

test results of plastic-soil bricks for various percentages of Total =1699.50 Rs /m3

binder(bitumen) content by weight of soil with constant plastic

content of 70% by weight of soil, it is obsorved that on B. Abstract for Plastic-Soil Brick for Wall Construction:

increasing the percentage of binder(bitumen) the compressive

strength of brick also increases upto 5% (10 N/mm2), but TABLE 10

further increase in bitumen decreases the ABSTRACT FOR PLASTIC-SOIL BRICK WALL

strength(2.04N/mm2). But from economical considerations 2% Unit

ntity

Unit

Qua

Sl. Amount

of bitumen content is taken as optimum binder content which Item rate

no Rs

results in compressive strength 8.16 N/mm2 that is greater Rs

than laterite stone (3.18 N/mm2). The efficient usage of waste Plastic

1 44.545 m3 1699.5 75704.23

plastic in plastic-soil bricks has resulted in effective usage of soil brick

2

plastic waste and thereby can solve the problem of safe dis- 2 Pointing 230.26 m 20.9 4812.59

posal of plastics, also avoids its wide spread littering. And the Wall

utilization of quarry waste has reduced to some extent the painting

3 496.26 m2 49.7 24664.49

problem of its disposal. (water

proof)

APPENDIX TOTAL Rs 1,05,181.31

COST ANALYSIS

C. Abstract for Laterite Stone for Wall Construction:

A. Estimation for Plastic-Soil Brick with Wall Interlocking TABLE 11

System - size 30x20x18cm ABSTRACT FOR LATERITE STONE WALL

For all materials, it is required to know well in advance the

Unit

Quan-

approximate cost. Therefore, an attempt is made to work out

Unit

Sl. Amount

the cost of a brick as in the table 9 which is giving considera- Item rate

no Rs

tity

bly good strength. For this purpose, schedule of rates (2012- Rs

2013) Mangalore circle is used. However, the cost of laterite Laterite

quarry waste is not considered because, it is abundantly avail- stone 44.54 m3 2593 115505.18

able in the quarry. 1 masonry

Plaster-

496.26 m2 126.5 62777.83

2 ing

2

3 Pointing 230.26 m 20.9 4812.59

Wall 2

496.26 m 34.6 17170.85

4 painting

TOTAL Rs 2,00,266.47

The cost for walls of the building was estimated for both late-

rite stone and plastic-soil bricks. From the results, it was found

that plastic-soil bricks are approximately 48% cheaper than

laterite stone. Therefore, a plastic- soil brick proves

Copyright © 2014 IJTEEE.

INTERNATIONAL JOURNAL OF TECHNOLOGY ENHANCEMENTS AND EMERGING ENGINEERING RESEARCH, VOL 2, ISSUE 4 107

ISSN 2347-4289

ACKNOWLEDGMENT

The authors are grateful to K.V.G College of Engineering for

providing infrastructural facelities for testing the spcemans.

The authors also like to thank H.O.D & Faculties of Civil Engi-

neering Department, K.V.G.C.E.

REFERENCES

[1] Amit Gawande, G. Zamare., V.C Renge., Saurabh

Tayde, G. Bharsakale.. “an overview on waste plastic

utilization in asphalting of roads”, Journal of Engineering

Research And Studies (JERS) ,Vol. III, Issue II, April-

June 2012,pp 01-05.

[2] Bharath Raj,Varshith A,Rashmitha Kotian, N.G. Ash-

wath. “Study on Laterite-Cement bricks” Project report,

K.V.G College of Engineering, Sullia.DK. 2011-2012.

[3] Dr. B.C Punmia, “Soil Mechanics and Foundations”,

Lakshmi Publications, sixteenth edition, New Delhi,

2010,pp 37-66 & 87-107.

[4] Isaac Olufemi Agbede and Manasseh Joel, “Use of Ce-

ment-Sand Admixture in Laterite Brick Production for

Low Cost Housing” Department of Civil Engineering,

University of Agriculture, Makurdi Benue State, Nige-

ria.,Issue 12,Jan –June 2008,pp 163-174.

[5] S.K Khanna. and C.E.G Justo. “Highway Engineering”,

Nem chand and Bros. Publications, Ninth Edition, New

Delhi.2001, pp 301-310.

[6] L.R Schroceder, “The Use of Recycled Materials in

Highway construction”, Public Roads, Vol 58,Issue 2,

1994.

[7] Sunil Bose, Sridhar Raju,“Utilization of waste plastic in

Bituminous Concrete mixes”, Roads and Pavements,

vol 3 2004.

[8] “Useful products from oil and organic chemistry”, Topic

11/5 available at

http://www.tep.org.uk/a2z_glossary/a2z/plastics.htm

[9] “Zeus Industrial Products”, Technical newsletter, Inc.

3737 Industrial Boulevard Orangeburg, SC 29118, pp 2-

4 available at

http://www.zeusinc.com/technicalservices/technicalbulle

tins/technicalnewsletters.asp

Copyright © 2014 IJTEEE.

You might also like

- Production of hollow blocks using waste plastic and sandDocument17 pagesProduction of hollow blocks using waste plastic and sandMauricio David Ruiz Odar100% (1)

- Resource Oriented Public Toilet Design For Developing CountriesDocument148 pagesResource Oriented Public Toilet Design For Developing CountriesadijalanNo ratings yet

- LiteratureDocument5 pagesLiteraturestardennisNo ratings yet

- Utilisation of Waste Plastic in Manufacturing of Paver BlocksDocument7 pagesUtilisation of Waste Plastic in Manufacturing of Paver BlocksAbhishek ChaurasiaNo ratings yet

- Experimental Study On Strength Behaviour of Plastic Sand BricksDocument4 pagesExperimental Study On Strength Behaviour of Plastic Sand Brickstesfalem kiros100% (1)

- SWM Project Report NewDocument20 pagesSWM Project Report NewKarthik MadhokNo ratings yet

- Moral Education - Need of Today's Education SystemDocument2 pagesMoral Education - Need of Today's Education SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Bottle Wall Construction Seminar Report 2014Document18 pagesBottle Wall Construction Seminar Report 2014Safalsha BabuNo ratings yet

- Solid Waste Management ProjectDocument12 pagesSolid Waste Management ProjectShahbaz Nasir KhanNo ratings yet

- Hyperloop Train of FutureDocument5 pagesHyperloop Train of FuturesanketNo ratings yet

- Environmental Initiatives in Nagpur Metro - IricenDocument10 pagesEnvironmental Initiatives in Nagpur Metro - IricenNavneet SoniNo ratings yet

- MSW Yearly Report 2018 19Document84 pagesMSW Yearly Report 2018 19Thug LifeNo ratings yet

- Turnitin Report PDFDocument12 pagesTurnitin Report PDFAmer ZainulNo ratings yet

- How Values Education Shapes Character Development in AdolescentsDocument7 pagesHow Values Education Shapes Character Development in AdolescentsJose Ric Catarus Bataluna Jr.No ratings yet

- Analysis and Design of Shear Wall For An Earthquake Resistant Building Using ETABSDocument7 pagesAnalysis and Design of Shear Wall For An Earthquake Resistant Building Using ETABSIJIRSTNo ratings yet

- Tribal Educational Development in Andhra PradeshDocument8 pagesTribal Educational Development in Andhra PradeshAppan Kandala VasudevacharyNo ratings yet

- Bamboo in Low Cost HousingDocument6 pagesBamboo in Low Cost Housingckbose3296No ratings yet

- Dissertation Body - Final For Printing PDFDocument54 pagesDissertation Body - Final For Printing PDFLivya RobyNo ratings yet

- Use of Plastic Waste in Road ConstructionDocument21 pagesUse of Plastic Waste in Road Constructiontomson mathachanNo ratings yet

- Polli BrickDocument10 pagesPolli BrickAkshay SahuNo ratings yet

- Research Paper On PmayDocument6 pagesResearch Paper On PmayReeta SinghNo ratings yet

- Pollution of Air and Water: A Threat to Our EnvironmentDocument27 pagesPollution of Air and Water: A Threat to Our EnvironmentUjjwal SinghNo ratings yet

- Waste Management Techniques and ChallengesDocument21 pagesWaste Management Techniques and ChallengesRaghavendra SreeramaNo ratings yet

- 14 Principles of ManagementDocument5 pages14 Principles of ManagementVictoria Beltran SubaranNo ratings yet

- Recruitment & SelectionDocument49 pagesRecruitment & SelectionDeepak Chauhan100% (2)

- Eco Blac BricksDocument21 pagesEco Blac BricksShashankSharma0% (1)

- Utilization of Plastic Waste For Making Plastic BricksDocument3 pagesUtilization of Plastic Waste For Making Plastic BricksEditor IJTSRD100% (1)

- Handling Solid Waste Using Design Thinking Principle in BengaluruDocument5 pagesHandling Solid Waste Using Design Thinking Principle in BengaluruAnonymous izrFWiQNo ratings yet

- Media Violence and Aggression and Parents and TelevisionDocument2 pagesMedia Violence and Aggression and Parents and Televisionapi-260339450No ratings yet

- 384 A Study of Recruitment and Selection Process On HCLDocument101 pages384 A Study of Recruitment and Selection Process On HCLKalpita MandavaleNo ratings yet

- Waste Water Punjab - 21 March 2019Document48 pagesWaste Water Punjab - 21 March 2019Mohd IshfaqNo ratings yet

- Women EmpowermentDocument10 pagesWomen EmpowermentNova Empire LLCNo ratings yet

- Study On Present Scenario of Water Sector in IndiaDocument44 pagesStudy On Present Scenario of Water Sector in Indiajohn_himani50% (2)

- SYNOPSIS On Effect of Leachate On SoilDocument32 pagesSYNOPSIS On Effect of Leachate On SoilAbhilashaNo ratings yet

- Case Study On Mumbai Metro Project Report: Submitted in Partial Fulfillment of The Requirements For The Degree ofDocument31 pagesCase Study On Mumbai Metro Project Report: Submitted in Partial Fulfillment of The Requirements For The Degree ofanil100% (1)

- Project MSWDocument126 pagesProject MSWMohammed PatrawalaNo ratings yet

- Recycled Decorative Pots: Effects On SBCA's Bottle Wastes ManagementDocument44 pagesRecycled Decorative Pots: Effects On SBCA's Bottle Wastes ManagementLloyd DechavezNo ratings yet

- Solid Waste and Solid Waste ManagementDocument14 pagesSolid Waste and Solid Waste ManagementClarice FranciscoNo ratings yet

- Review of Solid Waste Management For Smart Cities in IndiaDocument5 pagesReview of Solid Waste Management For Smart Cities in IndiaGJESRNo ratings yet

- Forest, Land, Water and Energy Resources and Threats AnalysisDocument10 pagesForest, Land, Water and Energy Resources and Threats AnalysisLoveleen GargNo ratings yet

- Green BuildingDocument3 pagesGreen BuildingEr Govind Singh ChauhanNo ratings yet

- Slum UpgradingDocument62 pagesSlum Upgradingtroelsvejby100% (1)

- Impact of Covid-19 On Digital PaymentsDocument21 pagesImpact of Covid-19 On Digital PaymentsShubam SinghNo ratings yet

- The Project Summary Descriptive Definition of The ProjectDocument28 pagesThe Project Summary Descriptive Definition of The ProjectDexela PalenNo ratings yet

- UrbanDesign PranjaliRaiThesis PDFDocument99 pagesUrbanDesign PranjaliRaiThesis PDFVic AshNo ratings yet

- Barriers' Analysis For Implementing Green Supply Chain: A Case Study in MoroccoDocument11 pagesBarriers' Analysis For Implementing Green Supply Chain: A Case Study in MoroccoinventionjournalsNo ratings yet

- Dairy Extension Education PDFDocument87 pagesDairy Extension Education PDFlikhithaNo ratings yet

- Research Paper On VermicompostingDocument14 pagesResearch Paper On VermicompostingBariktrilochan80% (5)

- Illiteracy in Rural IndiaDocument2 pagesIlliteracy in Rural IndiaVicky VermaNo ratings yet

- List of Symbols and Abbreviations GuideDocument51 pagesList of Symbols and Abbreviations Guideganesh100% (1)

- An Architecture For Marginalised South Africans: The Role of EducationDocument4 pagesAn Architecture For Marginalised South Africans: The Role of EducationWanda VersterNo ratings yet

- Self Study Report: 2 Cycle of AccreditationDocument132 pagesSelf Study Report: 2 Cycle of AccreditationB VAMSI KRISHNANo ratings yet

- EIA Report Environmental Impact Assessment of Construction ProjectsDocument5 pagesEIA Report Environmental Impact Assessment of Construction ProjectsRohan Chaugule100% (1)

- Unit 3-DW PDFDocument36 pagesUnit 3-DW PDFMohamedRaahimNo ratings yet

- ReportDocument20 pagesReportteko denisNo ratings yet

- 2nd Avinash Kumar 7june19Document11 pages2nd Avinash Kumar 7june19Anshuman SinghNo ratings yet

- Properties of Plastic Mortar Made With Recycled Polyethylene PDFDocument6 pagesProperties of Plastic Mortar Made With Recycled Polyethylene PDFAniel DiasNo ratings yet

- Irjet V5i11145Document10 pagesIrjet V5i11145Ashadi PwNo ratings yet

- Plastic Waste Bricks: A Sustainable Construction MaterialDocument16 pagesPlastic Waste Bricks: A Sustainable Construction MaterialGgggnek OhculNo ratings yet

- Bio-aggregate-based Building Materials: Applications to Hemp ConcretesFrom EverandBio-aggregate-based Building Materials: Applications to Hemp ConcretesSofiane AmzianeNo ratings yet

- Ahmed 2022Document20 pagesAhmed 2022Mariela Estefanía Marín LópezNo ratings yet

- TDS - RheoFIT 762Document2 pagesTDS - RheoFIT 762Alexi ALfred H. TagoNo ratings yet

- Operator Identities 2Document3 pagesOperator Identities 2jasmonNo ratings yet

- Effect of Usage of Sinter in BOF Steelmaking As A Replacement To Iron Ore As Coolant For Thermal BalanceDocument11 pagesEffect of Usage of Sinter in BOF Steelmaking As A Replacement To Iron Ore As Coolant For Thermal BalancesomnathNo ratings yet

- RenderingDocument6 pagesRenderingJuno PajelNo ratings yet

- English 6 Action Research Contextualized Materials ProposalDocument41 pagesEnglish 6 Action Research Contextualized Materials ProposalJake YaoNo ratings yet

- Feasibility Analysis of ORC Systems for Flexible DesignDocument227 pagesFeasibility Analysis of ORC Systems for Flexible DesignAwais SalmanNo ratings yet

- The UFO MonthlyDocument21 pagesThe UFO MonthlySAB78No ratings yet

- Pic24fj256ga705 Family Data Sheet Ds30010118eDocument424 pagesPic24fj256ga705 Family Data Sheet Ds30010118eD GzHzNo ratings yet

- Fakeaway - Healthy Home-Cooked Takeaway MealsDocument194 pagesFakeaway - Healthy Home-Cooked Takeaway MealsBiên Nguyễn HữuNo ratings yet

- DCT PIR insulation technical data sheetDocument4 pagesDCT PIR insulation technical data sheetHenky MantophaniNo ratings yet

- Techint Group Brochure 2013Document100 pagesTechint Group Brochure 2013MD AFROZ RAZANo ratings yet

- RUDDER PLATING DIAGRAMDocument1 pageRUDDER PLATING DIAGRAMMuhammad Ilham AlfiansyahNo ratings yet

- Kerr Injection WaxesDocument1 pageKerr Injection WaxesmarosnaxNo ratings yet

- Portland Traffic Crash Report 2021Document11 pagesPortland Traffic Crash Report 2021KGW NewsNo ratings yet

- 1625-De Dwks Parts ListDocument69 pages1625-De Dwks Parts ListSasan AbbasiNo ratings yet

- Sony Ericsson K610i, K610m, and V630i Service ManualDocument53 pagesSony Ericsson K610i, K610m, and V630i Service ManualJane TodoroskiNo ratings yet

- Week 2 - Risk AssessmentDocument35 pagesWeek 2 - Risk AssessmentTahir BashirNo ratings yet

- Strategic Capacity ManagementDocument36 pagesStrategic Capacity ManagementRahul KhannaNo ratings yet

- LRV Reference TableDocument6 pagesLRV Reference TableVaishnavi JayakumarNo ratings yet

- MSE Admission and Degree RequirementsDocument6 pagesMSE Admission and Degree Requirementsdeathbuddy_87No ratings yet

- Wiper & Washer Circuit PDFDocument1 pageWiper & Washer Circuit PDFluis eduardo corzo enriquezNo ratings yet

- CrankDocument9 pagesCrankKresna BayuNo ratings yet

- W2AEW Videos (Apr 29, 2017) Topics Listed NumericallyDocument12 pagesW2AEW Videos (Apr 29, 2017) Topics Listed Numericallyamol1agarwalNo ratings yet

- Culinary History and Nouvelle CuisineDocument4 pagesCulinary History and Nouvelle CuisineARPITA BHUNIANo ratings yet

- Fischer Carbene Complexes in Organic SynthesisDocument9 pagesFischer Carbene Complexes in Organic SynthesisNorah AltayyarNo ratings yet

- MP Birla Group: Training MatrixDocument3 pagesMP Birla Group: Training MatrixAprilia kusumaNo ratings yet

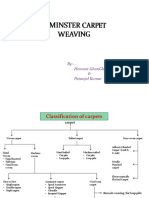

- Axminster CarpetDocument19 pagesAxminster Carpetrohit sinhaNo ratings yet

- Heidegger On Destruction - Chung ChinDocument16 pagesHeidegger On Destruction - Chung ChinAprilo DielovaNo ratings yet

- House Service Connection NEW BSR 2020-1Document1 pageHouse Service Connection NEW BSR 2020-1Deshraj BairwaNo ratings yet