Professional Documents

Culture Documents

A Brief History of Safety Valve

Uploaded by

Udhayakumar Venkataraman0 ratings0% found this document useful (0 votes)

221 views21 pagesPapin is usually credited with inventing the safety valve in 1682 when he applied it to his digester. However, Glauber was using safety valves as early as 1651 to prevent retorts and stills from bursting due to excessive pressure. He described using a conical valve fitted with a lead cap so that if vapor pressure became too high, the valve would slightly lift and release some vapor before closing again. Safety valves became more widely used after this to protect life and property from boiler explosions. The ASME developed codes to regulate safety valves and pressure vessels in response to many boiler explosions in the early 1900s in the US. Today, safety standards are regulated by organizations like the ASME and pressure equipment directive in

Original Description:

Safety valve history and details

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPapin is usually credited with inventing the safety valve in 1682 when he applied it to his digester. However, Glauber was using safety valves as early as 1651 to prevent retorts and stills from bursting due to excessive pressure. He described using a conical valve fitted with a lead cap so that if vapor pressure became too high, the valve would slightly lift and release some vapor before closing again. Safety valves became more widely used after this to protect life and property from boiler explosions. The ASME developed codes to regulate safety valves and pressure vessels in response to many boiler explosions in the early 1900s in the US. Today, safety standards are regulated by organizations like the ASME and pressure equipment directive in

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

221 views21 pagesA Brief History of Safety Valve

Uploaded by

Udhayakumar VenkataramanPapin is usually credited with inventing the safety valve in 1682 when he applied it to his digester. However, Glauber was using safety valves as early as 1651 to prevent retorts and stills from bursting due to excessive pressure. He described using a conical valve fitted with a lead cap so that if vapor pressure became too high, the valve would slightly lift and release some vapor before closing again. Safety valves became more widely used after this to protect life and property from boiler explosions. The ASME developed codes to regulate safety valves and pressure vessels in response to many boiler explosions in the early 1900s in the US. Today, safety standards are regulated by organizations like the ASME and pressure equipment directive in

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 21

A brief history

It is usually supposed that the Frenchman Papin was the inventor

of the safety valve, which he first applied about 1682 to his

digester

The safety valve was kept closed by means of a lever and movable

weight; sliding the weight along the lever enabled Papin to keep

the valve in place and regulate the steam-pressure. It appears now

that Papin was only the inventor of the improvements just

mentioned and that safety valves were already being used some

fifty years before by the German Glauber (who contributed many

valuable additions to the mechanical department of chemistry). In

his practise on philosophical furnaces, translated into English in

1651, he describes the modes by which he prevents retorts and

stills from bursting from an excessive pressure. A conical valve

was fitted, being ground air-tight to its seat, and loaded with a

"cap of lead", so that when the vapour became too "high" it slightly

raised the valve and a portion escaped; the valve then closed again

on itself, "being pressed down by the loaded cap and so kept

close".

The idea was followed up by others and we find in the art of

distillation, by John French, published soon afterward in London,

the following concerning the action of such safety-valves: "Upon

the top of a stubble (valve) there may be fastened some lead, that if

the spirit be too strong, it will only heave up the stubble and let it

fall down". It should be realised that the word steam was unknown

at the time, being of later coinage. In its place we find in every old

book the words vapour, spirit, smoke, Ayr and even ghost, whence

the modern word gas, for aeriform bodies, is doubtless derived

In the New England region of the USA, there were 1700 boiler

explosions resulting in 1300 deaths during the five years between

1905 and 1911.

The American Society of Mechanical Engineers was asked to

formulate a design code. The boiler & pressure vessel committee

was formed and hence the A.S.M.E. Section 1 for fired vessels was

formulated and became a mandatory requirement for all States,

which recognised the need for regulation. The sole purpose of a

pressure-relieving device (safety relief valve) is to protect LIFE and

PROPERTY.

With the expansion of process industries the need for a code for

unfired pressure vessels was identified which gave rise to A.S.M.E.

Section VIII.

The ASME Codes are mandatory in the USA and Canada. API

recommended practices and standards have been an important

guidance for users and engineering companies. In many European

countries, national ruIes for the protection against overpressure of

process equipment were developed and remained in force well into

the 20th century.

However, in order to allow free circulation of goods in the

European Community, Member States were prohibited from

making new technical rules and from updating the existing ones.

They have to conform to a new directive, the pressure equipment

directive PED which was published in 1997. lt has become

compulsory for equipment "put in the market" after 29/05/2002

(refer to Art.20 - par 3 of the PED).

Today, the term safety valve should be used to describe - Safety,

Safety/Relief and Relief Valves; this term is now used in European

Norms (EN) and ISO 4126 descriptions. Safety valves are included

as "Safety Accessories in the PED (Art. 1 par 2.1.3) and are

classified in risk category IV (the highest). The manufacturer, in

order to EC mark his product must undergo, for each product, a

conformity assessment comprising the EC type or design

examination and the assurance of the production quality system.

The procedures to certify the conformity to the PED are carried out

by a body notified by the Member States of the European

Community.

With the completion of the above, the manufacturer may stamp

the EC mark on his product.

Harmonized standards for safety valves

No standard is yet harmonised. A list of standards relative to

safety valves (and rupture discs), which are in the process of being

harmonised is given in Table 1. It is not compulsory to follow

harmonised standards, but if a manufacturer conforms to these

standards, he is presumed to conform to the PED (Art 5 of PED

Presumption of conformity). Otherwise the manufacturer himself

must prove that his products conform to the PED.

As a consequence of the "New Approach" there have been many

changes regarding safety valves, the more significant of which

being:

- Discharge coefficient in back pressure conditions.

When the back pressure exceeds 25% of the full lift pressure, the

manufacturer must obtain valve discharge coefficients after tests

carried out in actual backpressure conditions. Reference: par

7.1.2, 7.3.3.4 and 9.1 of prEN ISO 4126-1 (see Table 1).

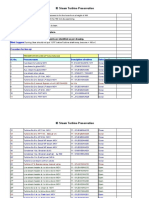

Table 1: CENTC 69/WG 10 Safety devices against excessive

pressures

PrEN ISO Safety devices for the protection against excessive

4126-1 pressure - Part 1 : Safety valves

PrEN ISO Safety devices for the protection against excessive

4126-2 pressure - Part 2: Bursting disc safety devices

PrEN ISO Safety devices for the protection against excessive

4126-3 pressure - Part 3: Safety valves and bursting disc safety

devices in combination

PrEN ISO Safety devices for the protection against excessive

4126-4 pressure - Part 4: Pilot operated safety valves

PrEN ISO Safety devices for the protection against excessive

D 4126-5 pressure - Part 5: Controlled safety pressure relief

systems (CSPRS)

PrEN ISO Safety devices for the protection against excessive

4126-6 pressure - Part 6: Application, selection and

installation of bursting disc safety devices

PrEN ISO Safety devices for the protection against excessive

4126-7 pressure - Part 7: Common data

- Bellows

If the bellows break, the valve must still open within 10% of the

maximum allowable pressure of the equipment being protected.

Reference: par 5.1.8 of prEN ISO 4126-1. If the valve is set at or

close to the design pressure of the protected vessel (as in the case

of 99% of the applications) a way to meet with requirements is to

install a balancing piston to back up the bellows.

- Pilot operated safety valves

It will be possible to install pilot operated valves in some Member

States (i.e. the Netherlands and Germany) where local authorities

have not approved pilot operated valves up to now. Reference:

prEN ISO 4126-4.

- Overpressure

The overpressure must not exceed 10% of the maximum allowable

pressure. Overpressures such as 16% (multiple pressure relief

devices) or 21 % (fire), which are acceptable in accordance with

ASME VIII division 1, are not permitted.

Commonly-used terminology

Safety valve - steam applications, characterised by rapid, full

opening or "pop" action.

Relief valve - liquid applications, the valves open in proportion

to the increase of system pressure over the opening pressure.

Safety/relief valve - pressure relieving device suitable for use

as a safety valve or a relief valve depending on its application.

Pilot-operated safety valve - in one such valve the spring

provides +/-75% of the disk loading; the gas or vapour

supplies the remainder through the pilot valve. When the

pressure in the vessel reaches the set pressure, the pilot valve

relieves the gas pressure (which contributes to the disk

loading) to the atmosphere causing the safety valve to open

wide. Both the pilot and the main valve contain flexible

membranes and, consequently, are limited to the design

factors of the membranes. These can be snap acting or

modulating and are non-flowing.

Conventional safety valve - a conventional safety relief valve is

a pressure relief valve characterised by rapid opening or pop

action, or by opening in proportion to the increase in pressure

over the opening, depending on the application. Such valves

may be used either for liquid or compressible fluids.

Balanced safety valve - A balanced safety relief valve is a

pressure relief valve, which incorporates a means of

minimising the effect of backpressure on the operational

characteristics (opening pressure, closing pressure, and

relieving capacity).

Full nozzle - inlet flow passage; only the nozzle and disc insert

are in contact with the process media when valve is in the

closed position.

Semi nozzle - the nozzle, disc insert and part of the valve body

are in contact with the process media.

Effective discharge area - the nominal orifice size listed in API-

526, usually defined by a letter (D thru T)

Actual discharge area - the measured minimum net area,

which determines the flow through a valve.

Coefficient of discharge - ratio of the measured relieving

capacity to the theoretical relieving capacity.

Simmer - audible or visual escape of fluid between the seat

and disc. Applies to valves on compressible fluids, at around

98% of the set pressure.

Huddling chamber - annular pressure chamber located beyond

the valve seat, this generates the pop characteristics.

Safety valve nomenclature

M.A.W.P. (Maximum Allowable Working Pressure) - maximum

gauge pressure permissible at the top of a completed vessel for

a designated temperature.

Operating pressure - working pressure in a pipe or vessel.

· Set pressure - pressure at which a relieving device opens and

relieves.

Operating gap - difference between set pressure of the valve

and the operating pressure of the vessel or system.

Overpressure - increase over set pressure of a relief device.

Accumulation - increase over M.A.W.P.

Blowdown - difference between set pressure and re-seating

pressure of a safety valve.

Back pressure - pressure existing at the outlet of the pressure

relieving device.

Back pressure is either - constant or variable.

Built-up pressure - the pressure existing at the outlet of a

pressure relief device caused by the flow through that

particular device into a discharge system.

Superimposed - the static pressure existing at the outlet of a

pressure relief device at the time the device is required to

operate. It is the result of pressure in the discharge system

from other sources.

Back pressure limits (variable)

Conventional 10% Built-up

Bellows 25% Built-up /Superimposed

Pilots 70% Built-up /Superimposed

Codes and standards

Because of their critical safety function, pressure relief valve

design rules are very strict. Public safety laws in many countries

require special inspection and verification of compliance with

codes before allowing operation of the installed equipment.

The most widely used and recognised of these codes is the ASME

Boiler and Pressure Vessel Code. One of the key features of the

ASME Code is the rule for overpressure protection. These rules

provide for the accreditation of manufacturers and the certification

of pressure relief valves by tests in approved laboratories. Thus,

the specification of ASME Code symbol stamped pressure relief

valves assures the end-user that the performance requirements

defined in the Code has been verified.

ISO 4126 provides for design and performance standards, but no

accreditation process is in place to ensure compliance. Other

standards groups such as NEN (Europe) provide alliterative

specification and control rules. The balance of this article,

however, focuses on the rules of the ASME Code as it relates to

pressure relief valves. Also reviewed are contents of certain

American Petroleum Institute (API) Standards and Recommended

Practices, which are commonly applied in the petroleum and

petrochemical industry.

For safety valves, then, the general design codes are the American

Society of Mechanical Engineers (ASME) and the American

Petroleum Institute (API)

The ASME code is split into two main sections:

- ASME Section I (V) which covers Fired Pressure Vessels (Power

Boilers)

- ASME Section VIII (UV) which covers Process Installations

(Unfired Pressure Vessels)

Relevant American Petroleum Institute (API) recommended

practices are:

- API RP520 Part I. This design manual is widely used for sizing &

selection of relief valves.

- API RP520 Part II. This includes methods of installation.

- API RP521. Guide for pressure relief and de-pressurising

systems.

- API 526. Flanged steel safety/relief valves for use in the

petroleum industry. Gives industry standards for dimensions,

pressure-temperature rating, and maximum set pressure and

body materials.

- API RP527. Commercial seat tightness of safety/relief valves with

metal to metal & soft seats.

ASME Code requirements

The important sections of the ASME Code which deal with

pressure relief valves are Section I {Power Boilers}; Section 11

{Materials}; Section 111 {Nuclear}; Section IV {Heating Boilers};

Section VIII {Unfired Pressure Vessels}; and Section IX {Welding}.

As the applications of interest to the petroleum and chemical

industries are primarily covered in ASME Code Sections I and VIII,

only the requirements of these sections are reviewed. AII

manufacturers certified to these sections of the code also comply

with materials and welding requirements as

they may apply to pressure relief valves. Because of the specialised

nature of power boilers, the operating characteristics of pressure

relief valves are very strict. Spring operated valves are generally

required under Section I of the ASME Code.

Design principles

Pressure relief valves are designed to open automatically at a pre-

determined set pressure level of system pressure and to achieve a

rated relieving capacity at a specified pressure and temperature

above the set point (overpressure) before re-closing at a pressure

below the opening point (blowdown). Many manufacturers provide

special trim options for liquid service valves because of the

properties of incompressible fluids.

The simplest and most reliable type of pressure relief valve even to

this day some four hundred years on from the first design is the

spring-loaded design (Fig. 1) where a spring force opposes the

system pressure acting on the valve disc. When the system

pressure rises above the level of the spring force, the valve opens.

This valve type may also be fitted with a bellows, for better

emission control performance (Fig 2).

Fig. 1 Spring-loaded pressure relief valve.

Fig. 2 Spring-loaded relief valve fitted with a bellows and a

balanced piston.

The significant elements of all spring-loaded pressure relief

designs are the springs and the seats.

The springs must provide the desired compression rate and a

reasonable range of adjustment. They must also fit into the valve

bonnet and stay within the design perimeters.

The seats may be flat or angled, metal or soft. As the seat area

usually defines the load transmitted to and from the spring, very

high precision is essential to ensure proper valve operation.

A second type of valve, which is more sophisticated and offers

operating advantages in selected applications is the pilot operated

pressure relief valve (Fig. 3)

Fig. 3 Pilot operated pressure relief valve

This type of valve consists of a main valve and a pilot valve. The

pilot responds directly to system pressure and communicates with

the main valve. As with the spring loaded valve, many unique

models exist. However, some common design features of pilot

operated pressure relief valves include: the sensing line, the pilot

valve and the main valve.

The sensing line is either connected to the valve inlet or a remote

location and conveys system pressure to the pilot.

The pilot valves senses and responds to the system pressure. The

pilot is the controlling member of the valve system and determines

all of the operating characteristics of the valve. It consists of many

small parts and passages and usually relies on elastomer seals for

operation.

The main valve operates in response to the pilot and provides the

main rated flow capacity to reduce excess pressure.

Application codes

The American Petroleum Institute has developed the most

commonly applied standards and recommended practices for the

petroleum and chemical industries in addition to the ASME Code.

API Recommended Practice 521 provides excellent guidance for

evaluating causes of overpressure and pressure relief systems.

API Recommended Practice 520 Part I is the design manual which

is most widely used for the design. sizing and selection of

components for pressure relief systems. Part II includes guidelines

for recommended piping practices and methods for determining

the reactive force created during valve discharge. If not properly

evaluated, these reactive forces can cause chattering when

conventional piping designs are applied. These high performance

liquid service designs ensure smooth, stable operation and full

relieving capacity on liquid service.

API also provides handling and storage recommendations. API

Recommended Practice 526 provides an industry standard to

manufacturers of flanged pressure relief valves and includes a

common set of installation dimensions, pressure and temperature

ratings, set pressure limits, capacities, and materials. This set of

industry standards ensures that valves from different

manufacturers will be interchangeable functionally and

dimensionally. As many valves may not comply with this standard,

these variables should be verified before substituting one model for

another.

API Recommended Practice 527 provides a basis for testing and

acceptance for set pressure and seats tightness of pressure relief

valves.

Inspection and maintenance codes

As pressure relief valves contain neither instrumentation nor

external operators it is necessary to establish an effective program

for inspection and maintenance to ensure that they will operate

when called upon in emergency situations.

A number of guidelines exist for recommending the basic structure

of an effective pressure relief valve inspection and maintenance

program. API Recommended Practice 510 is the Pressure Vessel

Inspection Code. Also, the API Guide for Inspection of Refinery

Equipment, Chapter XVI, provides excellent guidance for review of

relief valves to ensure operational readiness.

The best policy for assurance of safety is also the best policy for

economic considerations. The risk associated with the lack of

attention to suspect pressure relief devices cannot be tolerated

and is a major threat to both life and plant availability.

When purchasing new valves, always make certain that you are

dealing with a reputable and reliable distributor/manufacturer.

Verify that your vendor has current authorisation to sell

advise/manufacture or assemble the products that you purchase.

Testing (set pressure verification)

Safety relief valve testing is one of the most important elements of

an effective maintenance program. There are many techniques

available for conducting pressure relief valve tests. Obviously, the

most desirable type of test is one that subjects the pressure relief

valves to the full operating conditions that it is expected to endure.

Such a test has the advantage of assuring that all of the operating

characteristics of the valve, set pressure, lift and blowdown are

acceptable. However, this type of test is often impractical if not

impossible.

The most practical valve test is usually the bench-testing

alternative because a controlled environment can be created. By

transporting valves to a central shop, consistency of test

techniques and record keeping of test data can be monitored.

Reference to the manufacturer's instructions for testing and

adjustment is an essential part of any testing program. These

documents are most easily accessed in a shop environment.

There are many contract services that provide pressure relief valve

testing capabilities. It is important to review and qualify these

service contractors in the same manner that valve suppliers are

reviewed. The best choice is the manufacturer directly. If this

option is impractical then the manufacturer's authorised service

centre would be recommended. Many manufacturers offer training

programs to qualify plant maintenance personnel for testing and

repair of pressure relief valves.

Note that operator techniques on test benches can influence

results! Therefore proper training and qualification of operators is

a must for consistent and reliable test results.

Repair

In the event that a valve is in need of repair, only personnel who

have been trained in the appropriate repair techniques should

conduct repairs. In addition, a full reference manual of

manufacturer's instructions should be accessible.

Usually, the manufacturer's instruction manual will provide limits

for inspection and rework of this critical part. The seat step, seat

diameters and disc holder bearing surfaces are of particular

interest.

Re-machining of control rings is not recommended. If damaged,

they should be replaced.

The points listed above are also applicable to pilot operated valves.

In addition, all elastomers should be replaced as part of any

disassembly.

Records should be kept of the "as found" adjustment of adjusting

bolt and adjusting rings. This allows for resetting of adjustable

members after overhaul prior to final testing.

Valves should be reassembled in the reverse order of disassembly.

After reassembly of restored components, final testing and

adjustment must be completed. Depending upon the test

apparatus employed, final ring adjustments may not be made until

after the set pressure has been determined. lf a low volume test

stand is used, a "bench setting" will be employed for pressure

adjustment. The rings may then be replaced in the "as found"

position. AII final adjustments must be sealed. Seals should be

traceable and assigned only to qualified personnel.

Records and data registration

Records should be kept which provide equipment history. This is

helpful for establishing a proper inspection interval as well as

evaluating the suitability of the equipment employed for the

application.

Valves requiring major repair should have their inspection interval

shortened. Those in excellent condition may have their interval

lengthened until the optimum balance of economic and safety

concerns has been established. These records are a basis for

compliance with all safety concerns

You might also like

- Introduction PSVDocument11 pagesIntroduction PSVNguyen Anh TungNo ratings yet

- Low Pressure System Protection - Groth PDFDocument12 pagesLow Pressure System Protection - Groth PDFyusoffdNo ratings yet

- Relief Valve - TypesDocument2 pagesRelief Valve - Typesyushveer002No ratings yet

- DP Level Measurement BasicsDocument2 pagesDP Level Measurement Basicsjsrplc7952No ratings yet

- CMPAPPP Separator Vessel and Filter Design GuideDocument18 pagesCMPAPPP Separator Vessel and Filter Design GuideJWilson73No ratings yet

- Basic Function of Breather ValveDocument29 pagesBasic Function of Breather ValveManojkumarNo ratings yet

- Pressure RegulatorDocument4 pagesPressure RegulatorRICHIHOTS2No ratings yet

- A 01 Pumps, Valves & CoolersDocument24 pagesA 01 Pumps, Valves & CoolersСергей КороткийNo ratings yet

- Restriction Orifice RO Flow Control InstrumentDocument3 pagesRestriction Orifice RO Flow Control Instrumentmsr22No ratings yet

- Temp and Pressure InstrumentDocument5 pagesTemp and Pressure InstrumentAnniza Cornelia AugustyNo ratings yet

- Relief System Sizing For RunawayDocument13 pagesRelief System Sizing For RunawayShiva Kumar S M100% (1)

- Oilfield Processing Measurement and Control Oil and Gas SeparationDocument8 pagesOilfield Processing Measurement and Control Oil and Gas SeparationAnonymous 8te2h1No ratings yet

- TSV and PSV PDFDocument5 pagesTSV and PSV PDFMetoo ChyNo ratings yet

- Impact of Emergency Shutdown Devices On Relief System Sizing and Design PDFDocument21 pagesImpact of Emergency Shutdown Devices On Relief System Sizing and Design PDFB rgNo ratings yet

- Level GaugeDocument3 pagesLevel Gaugemerijan10No ratings yet

- General Separator 1636422026Document55 pagesGeneral Separator 1636422026mohamed abdelazizNo ratings yet

- 29 Cavitation & FlashingDocument90 pages29 Cavitation & FlashingSureshbabu ThamburajNo ratings yet

- HANDBOOK Blanket Gas Regulators PDFDocument8 pagesHANDBOOK Blanket Gas Regulators PDFfrankz89No ratings yet

- Heater TreaterDocument3 pagesHeater TreaterfructoraNo ratings yet

- Process Engineer - Blowdown Valve (BDV) To Flare SystemDocument2 pagesProcess Engineer - Blowdown Valve (BDV) To Flare Systemkenoly123No ratings yet

- Guide For Loading and Unloading of Cryogenic Liquid TankersDocument14 pagesGuide For Loading and Unloading of Cryogenic Liquid Tankersmohsin husen BargirNo ratings yet

- Pigging System PDFDocument4 pagesPigging System PDFeka resmanaNo ratings yet

- Pressure Relief ValvesDocument12 pagesPressure Relief ValvesyvhtejaswaroopNo ratings yet

- Venting of Atmospheric and Low Pressure Storage TanksDocument8 pagesVenting of Atmospheric and Low Pressure Storage TanksArun SankarNo ratings yet

- 7.2.24 - Breather ValvesDocument28 pages7.2.24 - Breather Valvessav33No ratings yet

- Hydrate Formation in ValvesDocument6 pagesHydrate Formation in ValvesChem.EnggNo ratings yet

- Flare Pilot System SafetyDocument5 pagesFlare Pilot System SafetyBehnam HosseinzadehNo ratings yet

- Separator ComponentsDocument16 pagesSeparator ComponentsvsroilgasNo ratings yet

- X ViberDocument4 pagesX ViberHenry CruzNo ratings yet

- Gorter r200Document6 pagesGorter r200Manish SaraswatNo ratings yet

- Ratio Pressure Reducing ValvesDocument4 pagesRatio Pressure Reducing Valveskanem1No ratings yet

- Storage Tank Venting For ConservationDocument9 pagesStorage Tank Venting For Conservationkenoly123No ratings yet

- Relief Valves - NCCDocument26 pagesRelief Valves - NCCNour HNo ratings yet

- Joule-Thomson EffectDocument15 pagesJoule-Thomson EffectTurab GhummanNo ratings yet

- Design and Use of Check ValvesDocument10 pagesDesign and Use of Check Valvesjenshid0% (1)

- The Design and Operation of Offshore Relief - Venting SystemsDocument24 pagesThe Design and Operation of Offshore Relief - Venting SystemsMichael HaiseNo ratings yet

- Why Choose Intrinsic SafetyDocument4 pagesWhy Choose Intrinsic Safetysandystays100% (1)

- Procedure Natural Gas Piping Purging HazardsDocument4 pagesProcedure Natural Gas Piping Purging HazardsEko KurniawanNo ratings yet

- Manual Esd ExproDocument2 pagesManual Esd ExprofurnaNo ratings yet

- Super Green BurnerDocument2 pagesSuper Green BurnerShima Rahmanian100% (1)

- ATEX Explained: The Explosion Protection RegulationsDocument4 pagesATEX Explained: The Explosion Protection RegulationsenviroashNo ratings yet

- 2 Phase Seperator PDFDocument66 pages2 Phase Seperator PDFKanthan DevanNo ratings yet

- Valve Cavity Relief 2Document2 pagesValve Cavity Relief 2Azar DeenNo ratings yet

- Design of 3 Phase Production SeparatorDocument8 pagesDesign of 3 Phase Production Separatormyself_riteshNo ratings yet

- Orifice SizingDocument2 pagesOrifice SizingAvinav Kumar100% (1)

- Level Measurement Using Gauge Glass TechniqueDocument3 pagesLevel Measurement Using Gauge Glass TechniqueYeabsira WorkagegnehuNo ratings yet

- FlareDocument10 pagesFlareAgus SuriptoNo ratings yet

- Workbook For Chemical Reactor Relief System SizingDocument123 pagesWorkbook For Chemical Reactor Relief System SizingRicardo BecNo ratings yet

- Pressure GaugeDocument11 pagesPressure GaugeM.A.K. S. Pathan0% (1)

- SV80 Safety Valve-Installation Maintenance ManualDocument24 pagesSV80 Safety Valve-Installation Maintenance ManualAriyo AninditoNo ratings yet

- I/p ConverterDocument6 pagesI/p ConverterAMIT KUMARNo ratings yet

- Fine Tune Relief Calculations For Supercritical FluidsDocument10 pagesFine Tune Relief Calculations For Supercritical FluidsPeter PerezNo ratings yet

- Pressure Systems - Safety and YouDocument8 pagesPressure Systems - Safety and YouadammzjinNo ratings yet

- Nitrogen Blanketing For Storage and TransportationDocument5 pagesNitrogen Blanketing For Storage and TransportationHoang-Vu BuiNo ratings yet

- Safety Relief ValvesDocument9 pagesSafety Relief ValvesSubbarayan SaravanakumarNo ratings yet

- Block 9 Safety ValvesDocument85 pagesBlock 9 Safety ValvesBabu AravindNo ratings yet

- Safety Valve SelectionDocument56 pagesSafety Valve Selectionganesh82No ratings yet

- Safety ValvesDocument65 pagesSafety Valvesserturkbudak_3448365No ratings yet

- Microsoft Word - SVDocument62 pagesMicrosoft Word - SVaftabulalamNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Fly Ash S Type F Data SheetDocument1 pageFly Ash S Type F Data SheetUdhayakumar VenkataramanNo ratings yet

- Ash Utilisation in TATADocument5 pagesAsh Utilisation in TATAUdhayakumar VenkataramanNo ratings yet

- 660 MW IIoT AspectsDocument17 pages660 MW IIoT AspectsUdhayakumar VenkataramanNo ratings yet

- Battery Room Design AspectsDocument4 pagesBattery Room Design AspectsUdhayakumar VenkataramanNo ratings yet

- Accidents To ReadDocument21 pagesAccidents To ReadUdhayakumar VenkataramanNo ratings yet

- Fly Ash S Type F Data SheetDocument1 pageFly Ash S Type F Data SheetUdhayakumar VenkataramanNo ratings yet

- Valve MOC and ImportantDocument22 pagesValve MOC and ImportantUdhayakumar VenkataramanNo ratings yet

- BFP Performance Assessment Article HelpfulDocument10 pagesBFP Performance Assessment Article HelpfulUdhayakumar VenkataramanNo ratings yet

- Boiler CommissioningDocument29 pagesBoiler Commissioningbratishkaity100% (8)

- Top 5 Troubleshooting Issues For Blower SystemsDocument4 pagesTop 5 Troubleshooting Issues For Blower SystemsUdhayakumar VenkataramanNo ratings yet

- Woven Sacks DPR Input - Odissa GoIDocument3 pagesWoven Sacks DPR Input - Odissa GoIUdhayakumar VenkataramanNo ratings yet

- Different Type of Motors For Industrial DrivesDocument5 pagesDifferent Type of Motors For Industrial DrivesUdhayakumar VenkataramanNo ratings yet

- Foundation DetailDocument1 pageFoundation DetailUdhayakumar VenkataramanNo ratings yet

- Extend Gear Coupling Life: of Can Be ofDocument5 pagesExtend Gear Coupling Life: of Can Be ofUdhayakumar VenkataramanNo ratings yet

- Energy Audit of Combined Cycle Power Plant: A Case Study: Umair Ahmed, Prof. Javed Ahmad ChatthaDocument6 pagesEnergy Audit of Combined Cycle Power Plant: A Case Study: Umair Ahmed, Prof. Javed Ahmad ChatthaUdhayakumar VenkataramanNo ratings yet

- An Overview of Power Sector of BangladeshDocument36 pagesAn Overview of Power Sector of BangladeshJahid MasudNo ratings yet

- Keeping Your Lubrication Program in The CrosshairsDocument4 pagesKeeping Your Lubrication Program in The CrosshairsUdhayakumar VenkataramanNo ratings yet

- Technical Specification ColtcsDocument60 pagesTechnical Specification Coltcsproloy12No ratings yet

- Sliding Pressure Operation of Large Conventional Steam Power UnitDocument6 pagesSliding Pressure Operation of Large Conventional Steam Power UnitUdhayakumar VenkataramanNo ratings yet

- Faults On Electrical SystemDocument21 pagesFaults On Electrical Systemjosh bradley100% (3)

- Bus Bar Installation Guiding PrincipleDocument11 pagesBus Bar Installation Guiding PrincipleUdhayakumar VenkataramanNo ratings yet

- Different Type of Motors For Industrial DrivesDocument5 pagesDifferent Type of Motors For Industrial DrivesUdhayakumar VenkataramanNo ratings yet

- Energy Efficient Motor AspectsDocument3 pagesEnergy Efficient Motor AspectsUdhayakumar VenkataramanNo ratings yet

- Electrical Testing ProeduresDocument9 pagesElectrical Testing ProeduresUdhayakumar VenkataramanNo ratings yet

- Electrical Quality DeviesDocument12 pagesElectrical Quality DeviesUdhayakumar VenkataramanNo ratings yet

- Handbook - Energy Management For Motor Driven Systems PDFDocument123 pagesHandbook - Energy Management For Motor Driven Systems PDFmnt6176No ratings yet

- Sliding Pressure Control BasicsDocument4 pagesSliding Pressure Control BasicsUdhayakumar VenkataramanNo ratings yet

- Master Wall Catalogue August 2019Document152 pagesMaster Wall Catalogue August 2019Udhayakumar VenkataramanNo ratings yet

- Lesson Learnt From Biomass PlantsDocument31 pagesLesson Learnt From Biomass PlantsUdhayakumar VenkataramanNo ratings yet

- IB Steam Turbine PreservationDocument6 pagesIB Steam Turbine PreservationUdhayakumar VenkataramanNo ratings yet

- Polyfort FPP 40 T: Engineering PlasticsDocument3 pagesPolyfort FPP 40 T: Engineering PlasticsFida GhanmiNo ratings yet

- (TDBFP-Hihi Vibraiton of Pump BearingDocument3 pages(TDBFP-Hihi Vibraiton of Pump BearingCharu ChhabraNo ratings yet

- 5.plant Layout - Relief SystemDocument7 pages5.plant Layout - Relief Systemhalder_kalyan9216No ratings yet

- HVAC Calculations GuideDocument36 pagesHVAC Calculations GuideAS HASNo ratings yet

- Turbo ChargerDocument28 pagesTurbo ChargerCharles ChivengahNo ratings yet

- Nasa TM-106943Document29 pagesNasa TM-106943LizardladNo ratings yet

- DZH Installation and Operation ManualDocument34 pagesDZH Installation and Operation ManualvijayNo ratings yet

- CDM (Slides + TD)Document178 pagesCDM (Slides + TD)bahaajaber35No ratings yet

- Electrical CircuitsDocument12 pagesElectrical CircuitsSrinath Gadeela100% (3)

- Pavetest DivisionDocument46 pagesPavetest DivisionjohanNo ratings yet

- Hose Ends - Field AttachableDocument64 pagesHose Ends - Field AttachableSasan AbbasiNo ratings yet

- Psych Rome TryDocument13 pagesPsych Rome TryAmira BagumbaranNo ratings yet

- Physics: 2009 National Qualifying ExaminationDocument12 pagesPhysics: 2009 National Qualifying ExaminationKolisetty SudhakarNo ratings yet

- 9202Document80 pages9202leninks_1979No ratings yet

- Service Repair Manual: English All Language: Geographic Region: Serial Number RangeDocument83 pagesService Repair Manual: English All Language: Geographic Region: Serial Number RangeAnne S. Sokolovska100% (1)

- Steelwise Nov-2014 PDFDocument5 pagesSteelwise Nov-2014 PDFJatinTankNo ratings yet

- Kadix Clima Manual Baxi Duo Tec MP 35-110 Engl PDFDocument5 pagesKadix Clima Manual Baxi Duo Tec MP 35-110 Engl PDFVasil PascuNo ratings yet

- Its All UphillDocument2 pagesIts All Uphillmelissa0% (1)

- Introduction To HVAC SystemsDocument23 pagesIntroduction To HVAC SystemsstayNo ratings yet

- Technical Documentation Engine Spare Parts Catalogue: MAN Diesel & TurboDocument450 pagesTechnical Documentation Engine Spare Parts Catalogue: MAN Diesel & TurboMrberkNo ratings yet

- Triple Gear Pump (S - N 512915200 & Above, 517711001 & Above, 516711001 & Above) - 331Document4 pagesTriple Gear Pump (S - N 512915200 & Above, 517711001 & Above, 516711001 & Above) - 331Juan Esteban TabordaNo ratings yet

- Hydraulic Cylinder For Use WTH:-HVL, HPS, HLS, HSS, Has, HHS, HHR, Hda & HgsDocument8 pagesHydraulic Cylinder For Use WTH:-HVL, HPS, HLS, HSS, Has, HHS, HHR, Hda & HgsKundan Kumar MishraNo ratings yet

- Kawasaki 1100 STX DI Service ManualDocument288 pagesKawasaki 1100 STX DI Service Manualnoname618483% (12)

- Bermad: Level Control ValveDocument4 pagesBermad: Level Control ValveSupolNo ratings yet

- Steam Turbine Maintenance Inspections or Repairs: Turbine Restart After MajorDocument3 pagesSteam Turbine Maintenance Inspections or Repairs: Turbine Restart After Majordreamboy87No ratings yet

- MCC1106 - Industrial Automation and Robotics - MTech SEM 1Document1 pageMCC1106 - Industrial Automation and Robotics - MTech SEM 1Arvind KatyayanNo ratings yet

- Private Admission Launch 2022 - 2023Document4 pagesPrivate Admission Launch 2022 - 2023YannickNo ratings yet

- Le Ngoc Lieu - Lecture 1 - Chapter 1Document28 pagesLe Ngoc Lieu - Lecture 1 - Chapter 1lieu_hyacinthNo ratings yet

- Wsat-Xee: Installation Use and Maintenance ManualDocument68 pagesWsat-Xee: Installation Use and Maintenance ManualAncuta CosmanNo ratings yet

- Geothermal Power Plants: Principles, Applications, Case Studies and Environmental ImpactDocument1 pageGeothermal Power Plants: Principles, Applications, Case Studies and Environmental ImpactJuan Ponce ManríquezNo ratings yet