Professional Documents

Culture Documents

A Me Chem Fibers

Uploaded by

jainravi88Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Me Chem Fibers

Uploaded by

jainravi88Copyright:

Available Formats

FIBER PRODUCTION

Color, functional and multi-attribute solutions

for polyester fibers

V.G. Kulkarni, Americhem, Inc., Concord, NC/USA

Over the past 20 years, polyester (poly- ing disperse dyes. Cationic dyeable poly- portant parameters of color masterbatch

ethylene terephthalate) has emerged as ester fibers, with modified structure offer design are:

a leading polymer for fibers, film and enhanced dyeability. Solution dyeing (al- • product specification or end applica-

packaging. Recent publications [1, 2] put so referred to as mass dyeing or spin tion in which the product is used

the 2002 production of polyester fiber at dyeing or dope dyeing) offers a way of • spin performance - the term spin per-

20.9 million tons, slightly more than cot- coloring polyester fibers and is inde- formance relates to factors such as

ton during the same period. The contain- pendent of its chemistry. spin breaks, draw warps, yield rates,

er resin production during 2002 was - Solution dyeing filter pack life, and deposit build up on

about 9 million tons. The combined fore- spinneret and godets.

Solution dyeing can be defined as a

cast for 2010 is estimated to top 50 mil- Proper colorant selection is the first criti-

process for coloring polyester (and other

lion tons. Some of the applications for cal step in masterbatch design. Since

synthetic yarns) in which the colorant is

polyester include: the masterbatch is added to the polymer

added to the polymer melt, before it is

• textile products such as apparel, auto- melt prior to spinning, the colorant must

extruded through a spinneret in to indi-

motive, home furnishings and bedding withstand the high processing tempera-

vidual fibers. As a result, the colorant is

products etc. ture without color variation. Thermal sta-

permanently locked into the fiber and the

• nonwoven products such as filters, bility of the pigment is important for both

fiber is colored throughout. Solution dye-

medical and protective fabrics color control and specification control.

ing offers following advantages:

• technical fibers such as tire cord, Color concentration also has an effect on

• better color fastness to light (UV),

awnings, tents and sewing threads the color stability. Depending on the end

bleaching agents and ozone

• packaging applications including bot- application, weathering and other fast-

• very good migration stability under ad-

tles for soft drink, water and juice etc. ness requirements play an important

verse conditions

• polyester film - imaging, magnetics role in masterbatch design.

• tight lot to lot color uniformity

and other industrial specialties. The choice of carrier resin also plays an

• environmentally friendly manufactur-

In keeping with the explosion of the use important role in product performance.

ing process (energy efficient, since

of polyester resin in various applica- This is especially critical when producing

fiber spinning and coloring is done in

tions, Americhem, Inc., is constantly de- lower denier fibers. Incompatibility of

the same step; does not use water -

veloping new masterbatches for PET masterbatch carrier resin with host poly-

conventional dyeing on the other hand

that enhance the properties and value mer leads to problems such as

uses water extensively; effluent treat-

of the products in which they are incor- • bridging problems at the throat of the

ment may be necessary, since part of

porated. Properties that today's fibers extruder and polymer build up in the

the disperse dye is left behind in the

and packaging materials demand. Ex- feed section

dye bath - only about 85% or so be-

amples of such products include fibers • differences in recrystallization temper-

comes part of fiber)

with anti-microbial properties, fibers that ature can affect bulking conditions in

• high yields with low scrap

withstand the harsh effects of UV so that air-jet texturing.

• wide range of colors can be produced

articles made from such fibers last Very good dispersion of colorant in the

• customized products can be easily de-

longer, fibers that absorb odor or fibers polymer matrix and proper melt viscosity

signed for value added fibers.

and textiles that offer moisture manage- of the masterbatch are an absolute ne-

On the limitations inventory, control can

ment properties and packaging materi- cessity, without it, the spin pack is imme-

be an issue, since the decision to pro-

als that offer UV protection and ac- diately blocked or restricted. Poor pig-

duce colored yarn is done at the early

etaldehyde reduction. Here, solution ment dispersion also results in breakage

phase of the production process. Devel-

dyeing techniques for coloring polyester of fiber, especially in the drawing

opment of small lot capability and

and the use of the concept for producing process, which results in draw warps

speedy color matching are helpful in

value added fibers will be described. around the godets. Americhem has de-

overcoming this concern.

Recent developments in functional and veloped a test that correlates laboratory

multi-attribute masterbatches for fibers - Product design for solution dyeing filtration analysis with the length of time

as well as masterbatches for packaging Proper masterbatch design is an impor- that the filter packs will last.

are discussed. Americhem has been tant aspect of solu-

serving the synthetic fibers industry with tion dyeing. Poorly

color and additive masterbatches for so- designed master-

lution dyeing (mass dyeing) for the past batches can lead

18 years. to spinning prob-

lems. There are a

Coloring of polyester fibers number of critical

Polyester fibers, because of their struc- factors which can

ture and well-developed order during affect spin per-

spinning, absorb little dye in convention- formance of solu-

al dye systems. Hence traditional poly- tion dyed polyester

ester fibers are predominantly dyed us- that can be con-

Lecture held at the 8th World Congress "The Poly-

trolled by means of

ester Chain", Polyester 2003 in Zurich/Switzerland, proper product de- Fig. 1 Antimicrobial efficiency of polyester fiber as a function of concen-

December 1-3, 2003 sign. Two of the im- tration of antimicrobial masterbatch

452 CHEMICAL FIBERS INTERNATIONAL Volume 53, December 2003

FIBER PRODUCTION

Black polyester yarn has been tradition- traviolet light. Light stabilizers, depend- containing activated carbon that absorbs

ally produced using the solution dyed ing on the chemical class (UVA, HALS) odor and offers moisture management,

process. The demand for solution dyed either absorb the harmful ultraviolet radi- and can be processed and handled sim-

colors is steadily increasing especially in ation or counteract the photo-degrada- ilar to traditional textile or industrial fiber!

automotive and specialty fabrics/textiles tion of synthetic fibers by UV and oxygen Americhem, in co-operation with Traptek

where higher performance offered by so- and help retain color and mechanical is working on developing such a master-

lution dyeing is preferred. One of the key properties. Using a customized ap- batch, based on activated carbon. Acti-

advantages that solution dyeing offers is proach and extensive weathering ex- vated carbon, well known for its out-

that customized products can be easily pertise, Americhem has developed mas- standing adsorptive properties is used in

designed for producing value-added terbatches, which stand up to tough a variety of applications such as treat-

fibers. For example customized colors weathering requirements. Fig. 2 shows ment of drinking water, decolorization of

(fluorescent, metallics), functional fibers the transmission spectrum of polyester sugar, pharmaceutical production and

and more importantly multi-attribute containing UV additive compared with automotive filters.

products can be produced. neat polyester. Polyester containing UV A range of other novel property and per-

Lastly, there are many colorants, which additive shows absorption of light to 380 formance enhancing additive master-

give the expected color, but only proper- nm, which extends the useful life of the batches are being explored at

ly designed masterbatches give both fiber/fabric. Data on tenacity of fiber as a Americhem research and development

color and performance. Communication function of extended UV exposure is be- laboratories.

in regards to which product values are ing developed.

critical is very important to assure prop- Multiattribute masterbatches

er product design. Flame retardant masterbatches Multiattribute masterbatches combine

Flame retardant masterbatches based color and functional properties or offer

Functional masterbatches on phosphorous chemistry are designed more than one functionality in a single

Functional masterbatches deliver func- to offer flexibility in producing niche fiber masterbatch, thereby providing a cus-

tional attributes without compromising products. At the present time, the use tom product that is easy to handle and

the processing properties. Typical func- rate of such masterbatches is rather highly effective. The concept can be

tions offered include high (in excess of 10%) and requires ad- used to design a wide range of products.

• antimicrobial ditional handling solutions for large vol- Some examples of multi-attribute prod-

• weathering/UV protection ume runs. ucts include

• customized optical whitening effects • color and UV

• flame retardants. Smart masterbatches • color and antimicrobial

In addition to these, Americhem is devel- Active research is underway to develop • delustrant and optical brighteners.

oping several novel masterbatches that novel masterbatches that can impart Fig. 3 shows the reflectance spectrum of

offer unique functional attributes to fibers unique functional and performance prop- delustured polyester fiber containing op-

such as odor adsorption, moisture man- erties to polyester fibers. tical brightener compared to a typical

agement and low abrasion/friction prop- For example, imagine a polyester fiber delustured fiber. Customized optical

erties.

Antimicrobial masterbatches

Antimicrobial masterbatches based on

silver chemistry are designed to stand

up to high processing temperatures at

which polyester fibers are produced. Be-

ing non-migratory in nature, the concen-

trate becomes part of the synthetic fiber,

thereby offering protection throughout

the life of the product. A unique com-

pounding process, specifically devel-

oped for this application offers excellent

dispersion and makes possible higher

loading of the antimicrobial additive in

the polymer matrix. At the recommended Fig. 2 Transmission spectrum of polyester film containing 0.5% of light stabilizer compared with poly-

use rate of 1.5-4% the products offer ester film containing no additive

very good spin performance and high

yields. Fibers and articles containing

Americhem's antimicrobial masterbatch-

es display very good efficiency against

gram positive (Staphylococcus aureus)

and gram negative (Klebsiella pneumo-

nia) bacteria as shown in Fig. 1.

Light stabilizer masterbatches

Polyester fibers are increasingly used in

exterior applications, such as automotive

fabrics, awnings and flexible signs etc.

These applications require that the fiber

be stabilized against degradation by ul- Fig. 3 Reflectance curve of polyester fiber showing optical whitening effect

Volume 53, December 2003 CHEMICAL FIBERS INTERNATIONAL 453

FIBER PRODUCTION

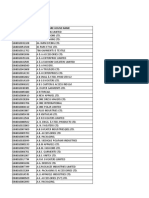

whitening masterbatches impart cool, Advantages of solid masterbatches over liquid and wax systems

bluish white appearance to polyester

fibers. Customization in regards to Advantage Eliminates

brightness, tone and use rate can be

decrease plasticizing time by 5-7% injection-molder screw slippage & recovery times

done to suit specific needs caused by lubrication of liquid and wax carriers

Solid color solutions for solids color change can be 50% faster longer purge times typically observed

compared to liquid with liquid colors

PET packaging

no lost time from shutting line down to clean residue build-up on screw resulting in

Polyester bottles and packaging materi- machine lost time

als are colored using masterbatches no bridging bridging caused by low melt resins adhering

comprising various carrier systems rang- to PET pellets

ing from liquid to low melting wax to sol- no volatiles during recycling recycled reclaim problems caused by volatiles

id resin. Americhem color and additive cleaner to use and easier house keeping general housekeeping problems of liquids

masterbatches based on polyester carri-

er resin with melting point of greater than its advantages in terms of performance tribute masterbatches offer an effective

220 °C offer several advantages over such as weathering, migration as well as means to produce value added products

other systems as shown in the table. a environmentally friendly manufacturing with color and functionality or multifunc-

processes are described here. Further- tional fibers.

Summary more functional, multi-attribute products References

In conclusion, the solution dyeing ap- are described and novel smart master- [1] Chemical Fibers International 53 (2003) 216

proach to coloring polyester fibers and batch concepts are introduced. Multiat- [2] International Fiber Journal 18 (2003)

454 CHEMICAL FIBERS INTERNATIONAL Volume 53, December 2003

You might also like

- Statistics Question Bank VTDocument7 pagesStatistics Question Bank VTjainravi88No ratings yet

- Mill at A Glimpse - An IntroductionDocument50 pagesMill at A Glimpse - An Introductionjainravi88No ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Rapier Dornier LoomDocument5 pagesRapier Dornier Loomjainravi88100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hardox 450 PDFDocument2 pagesHardox 450 PDFmcrajpuraNo ratings yet

- Warehouse CodeDocument348 pagesWarehouse CodeSaddamHossain100% (1)

- BCA Energy Performance Points CalculatorDocument96 pagesBCA Energy Performance Points CalculatorRidwan ArifinNo ratings yet

- EDW1400ADocument1 pageEDW1400ABenoit LevesqueNo ratings yet

- 08 KFR-70GW-NA1 Service ManualDocument58 pages08 KFR-70GW-NA1 Service ManualLcj RefrigeraNo ratings yet

- Hydraulic Questions For StudentsDocument8 pagesHydraulic Questions For StudentsJowi100% (1)

- Modal Analysis of Support Bracket For Air Compressor SystemDocument4 pagesModal Analysis of Support Bracket For Air Compressor SystemAnonymous kw8Yrp0R5rNo ratings yet

- Engine Control System Diagram: Ls430 - New Features 8Document1 pageEngine Control System Diagram: Ls430 - New Features 8bob loblawNo ratings yet

- Alfa Laval SB Carlsberg Flask Instruction Manual Ese02966enDocument18 pagesAlfa Laval SB Carlsberg Flask Instruction Manual Ese02966enpacocurroNo ratings yet

- WS Services Pipe Fittings & Its Reference PDFDocument1 pageWS Services Pipe Fittings & Its Reference PDFbilal almelegyNo ratings yet

- OperationsDocument5 pagesOperationsArun PandeyNo ratings yet

- Metode Pemasangan Pipa HDPEDocument13 pagesMetode Pemasangan Pipa HDPEBudi SantonyNo ratings yet

- Prokon - 12m Octagonal Light Pole FoundationDocument5 pagesProkon - 12m Octagonal Light Pole FoundationJohn G Jose100% (1)

- Minimum Oil Circuit BrakaerDocument7 pagesMinimum Oil Circuit BrakaerShoaib Iqbal KhanNo ratings yet

- Gr-500exl R S GDocument16 pagesGr-500exl R S GRizka RokhimNo ratings yet

- Composition With Large Red Plane, Yellow, Black, Grey and BlueDocument5 pagesComposition With Large Red Plane, Yellow, Black, Grey and BluerogertitleNo ratings yet

- Safegard Septic TanksDocument6 pagesSafegard Septic TankscivilaskarNo ratings yet

- Teco SRL - Catalogo 2015 - ItaDocument66 pagesTeco SRL - Catalogo 2015 - ItaDaniel AchovskiNo ratings yet

- Legends CatalogDocument88 pagesLegends Catalognmbriggs10No ratings yet

- Cashier Balance SheetDocument1 pageCashier Balance SheetMirAfghan GhulamiPoorNo ratings yet

- Jaguar Land Rover LTD - 2017 - New Range Rover BrochureDocument25 pagesJaguar Land Rover LTD - 2017 - New Range Rover BrochureLaboratorio ElectronicaNo ratings yet

- 9 Health and SafetyDocument2 pages9 Health and SafetyHéctorNo ratings yet

- The Principle of Unity in ArchitectureDocument6 pagesThe Principle of Unity in Architecturecarl_bautista_30% (1)

- SSCWG7 Repan3 Convers Fact Solar CollectorsDocument3 pagesSSCWG7 Repan3 Convers Fact Solar CollectorsMeng SunNo ratings yet

- A-10C Capes Nov 13 PDFDocument29 pagesA-10C Capes Nov 13 PDFbouchard1050% (2)

- Mdp36 The EndDocument42 pagesMdp36 The Endnanog36No ratings yet

- Tests For BricksDocument31 pagesTests For BricksTeddy0% (1)

- Cylinder Management 1Document31 pagesCylinder Management 1Falgon IslamNo ratings yet

- Hot Water Compare Between Basco and IFCDocument28 pagesHot Water Compare Between Basco and IFCEslam ElsayedNo ratings yet