Professional Documents

Culture Documents

Din 17100

Uploaded by

KhoirulAnwar0 ratings0% found this document useful (0 votes)

39 views1 pagestandar

Original Title

DIN 17100

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentstandar

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views1 pageDin 17100

Uploaded by

KhoirulAnwarstandar

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

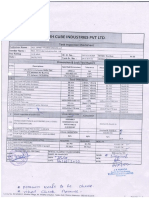

TENSION TEST BEND TEST IMPACT TEST

CHEMICAL COMPOSITION ( max ) Absorbtion

thickness : t Yield Point min Tensile Strength Elongation min

Temp

TYPE STANDARD GRADE Angle Inside energy

thick : t Kgf / mm

2

thick : t Kgf / mm

2

thick : t % min

C Si Mn P S N Cu OTHER ELEMENTS radius

mm. mm. [MPa ,N/mm2] mm. [MPa , N / mm2 ] mm. Lo=5.65*√So (Degree) ( 0C ) ( Joule )

t < 16 0.21 t < 16 24 [ 235 ] 35 - 48 Direction L T 3< t< 63

St 37 - 2 10< t < 16

- - 0.065 0.065 - 16< t < 40 23 [ 225 ] [340 - 3 < t < 40 26 24 180 L = 1t + 20

(t>25)1) 16 < t < 63 0.25 470]

40 <t < 63 22 [ 215 ] 40< t < 63 25 23 T = 2t 27

General 0.010* * It is permissible to exceed the maximum value

DIN 17 indicate , provided a P content per 0.001% N of t < 16 28 [ 275 ] 42 - 55 3 < t < 40 22 20 3< t< 63

Structural St 44 - 2 t < 40 0.24 10 <t < 63

100 ( - - 0.060 0.060 - 0.005% P below the maximum value indicated is 16 < t < 40 27 [ 265 ] 3< t < 100 [410 - 180 L = 2.5t + 20

1980 ) All t1) maintained. the N content may not , however , exceed 540] 40 <t < 63 21 19

Purposes 40 < t < 63 0.25 40 <t < 63 26 [ 255 ] T = 3t 27

a value of 0.014% N in the sample analysis.

t < 16 36 [ 355 ] 50 - 64 3 < t < 40 22 20 3< t< 63

St 52 - 3 t < 30 0.22 0 (U) , - 10<t< 63

0.60 1.70 0.050 0.050 - - 16 < t < 40 35 [ 345 ] [490 - 180 L = 2.5t

All t1) 630] 40 <t < 63 21 19 20 (N)

30 < t < 63 0.24 40 <t < 63 34 [ 335 ] T = 3t 27

NOTE

Delivery condition is Normalizing (N) and for usually normalized products the delivery is ordered in the hot-formed untreated condition (U) , the mechanical tests do not apply to the delivery condition.

1)

You might also like

- AXIALLY LOADED MEMBERS (Version 1)Document22 pagesAXIALLY LOADED MEMBERS (Version 1)Receb AgaNo ratings yet

- ATTAR AS3788 Assessment of Wall Thinning V1.02Document5 pagesATTAR AS3788 Assessment of Wall Thinning V1.02Ashraf BottaniNo ratings yet

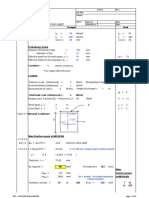

- BS 8110 Data Given: Calculation SheetDocument10 pagesBS 8110 Data Given: Calculation SheetLee See VoonNo ratings yet

- Annex D Bs 5500 Design Reference Temperature Adjustment: R D S C HDocument13 pagesAnnex D Bs 5500 Design Reference Temperature Adjustment: R D S C Hduf fuNo ratings yet

- COT 1 - Science 8 (Matter)Document4 pagesCOT 1 - Science 8 (Matter)joan marie Pelias100% (1)

- ASTM A106 Data SheetDocument4 pagesASTM A106 Data Sheetmarcelomaster88No ratings yet

- MTC-SML (1) - 4500528257 I - Ii - Tubos GB - SCH 6MT - 210251 - 210291 - 210377Document3 pagesMTC-SML (1) - 4500528257 I - Ii - Tubos GB - SCH 6MT - 210251 - 210291 - 210377Saul Omar Fernandez RojasNo ratings yet

- Calculation Procedure, Low-Finned Tubes: Exxon EngineeringDocument56 pagesCalculation Procedure, Low-Finned Tubes: Exxon Engineeringvin ssNo ratings yet

- MILL TEST CERTIFICATE FOR H.F.W. STEEL PIPEDocument2 pagesMILL TEST CERTIFICATE FOR H.F.W. STEEL PIPEClarkFedele27100% (1)

- Test PDFDocument1 pageTest PDFMichael FelixrajNo ratings yet

- CHEMICAL COMPOSITION AND MECHANICAL PROPERTIES OF CARBON STEEL GRADESDocument1 pageCHEMICAL COMPOSITION AND MECHANICAL PROPERTIES OF CARBON STEEL GRADESThanh Xuan NguyenNo ratings yet

- QF Qa 30 Visual Dimension Final Inspection ReportDocument8 pagesQF Qa 30 Visual Dimension Final Inspection ReportVikas Mani TripathiNo ratings yet

- Dywidag: Calculation of Tendon ElongationDocument1 pageDywidag: Calculation of Tendon ElongationwirawanwillyNo ratings yet

- $SEC14384Document1 page$SEC14384rakshithdmNo ratings yet

- Material YieldDocument2 pagesMaterial YieldKaushik SalemNo ratings yet

- $SEC14382Document1 page$SEC14382rakshithdmNo ratings yet

- Project Report: Tension Rod Design AnalysisDocument1 pageProject Report: Tension Rod Design AnalysisMarkNo ratings yet

- ST 37-2 Steel, ST 37-2 Structure Steel, ST 37-2 Equivalent-Seed SteelDocument1 pageST 37-2 Steel, ST 37-2 Structure Steel, ST 37-2 Equivalent-Seed SteelPeddi Raja MohanNo ratings yet

- Beam Number: Project Name: 15-Mar-20 Engr. Mark Christian D. Esguerra Passed Engineer: DateDocument2 pagesBeam Number: Project Name: 15-Mar-20 Engr. Mark Christian D. Esguerra Passed Engineer: DateMark Christian EsguerraNo ratings yet

- PROIECT C.C.M.A.I.A.R. BMW 316Document7 pagesPROIECT C.C.M.A.I.A.R. BMW 316Claudia MădălinaNo ratings yet

- 8.tabla de Cálculo GRP v.2.1Document105 pages8.tabla de Cálculo GRP v.2.1Ariel OrihuelaNo ratings yet

- Proposed 2-Storey Residence Beam Design AnalysisDocument1 pageProposed 2-Storey Residence Beam Design AnalysisMark Christian EsguerraNo ratings yet

- E7808 1 05 16 - PFMD PFHD - KatalogversionDocument9 pagesE7808 1 05 16 - PFMD PFHD - KatalogversionleandroschroederNo ratings yet

- Material For Seawater ServiceDocument3 pagesMaterial For Seawater ServiceVivi OktaviantiNo ratings yet

- Toshniwal Domestic Water MeterDocument1 pageToshniwal Domestic Water Meteranita shindeNo ratings yet

- L Gi LE PM T PMD 059 F129 LR 5 54 HTB 440 450 M V1 30 30 and 15 Frame Scientist V19 0860168025Document2 pagesL Gi LE PM T PMD 059 F129 LR 5 54 HTB 440 450 M V1 30 30 and 15 Frame Scientist V19 0860168025Radu SburlanNo ratings yet

- Mass Flow SiloDocument17 pagesMass Flow SiloBùi Hắc HảiNo ratings yet

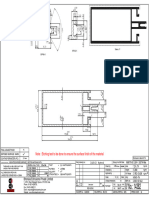

- Perhitungan Cantilever Bracket ChannelDocument1 pagePerhitungan Cantilever Bracket ChanneltRiaS eGanTeaNo ratings yet

- Appendix A3Document6 pagesAppendix A3Thomas Stephen100% (1)

- Zest Packing LTDDocument1 pageZest Packing LTDSinamm Engineering LimitedNo ratings yet

- MCHADocument3 pagesMCHARoboToolNo ratings yet

- BBS D-2751Document1 pageBBS D-2751Seeni VasanNo ratings yet

- Hoja Calculo Alcantarilllado PAVCODocument31 pagesHoja Calculo Alcantarilllado PAVCOjose jerezNo ratings yet

- Oka JKR T-Beams - M-BeamsDocument2 pagesOka JKR T-Beams - M-Beamsrobert ongNo ratings yet

- Simora As Staked Adv PDFDocument29 pagesSimora As Staked Adv PDFVictor DlreyesNo ratings yet

- Assembly & FastenersDocument16 pagesAssembly & Fastenersinesh100No ratings yet

- Second Floor Girder Design: GRID 3 (BEAM 39-49) (Left Section)Document4 pagesSecond Floor Girder Design: GRID 3 (BEAM 39-49) (Left Section)CYNDRILLE JOHN BRAGATNo ratings yet

- Design of Two Way Slab with Short Span of 3.62m and Long Span of 3.92mDocument1 pageDesign of Two Way Slab with Short Span of 3.62m and Long Span of 3.92mPipoy ReglosNo ratings yet

- DBT 163 TutorialDocument5 pagesDBT 163 Tutorialmirfan0225No ratings yet

- Tuerca 1-1-1 2HDocument1 pageTuerca 1-1-1 2Hcomercial 3No ratings yet

- Table 1 - Pressure Ratings For Internal Threaded End orDocument1 pageTable 1 - Pressure Ratings For Internal Threaded End orAbdul Rafiq SoudagarNo ratings yet

- National standard for carbon structural steel grades in ChinaDocument10 pagesNational standard for carbon structural steel grades in ChinaharshNo ratings yet

- EN-GB8308 - TopLab Vertical Material Properties - 2.1Document2 pagesEN-GB8308 - TopLab Vertical Material Properties - 2.1OnebigunicornNo ratings yet

- B-TL U - , R #Ffi: - Iel! - :'.!e.Document13 pagesB-TL U - , R #Ffi: - Iel! - :'.!e.kaushik21185No ratings yet

- Tehnicke Karakteristike Asistal Alu OkapnicaDocument2 pagesTehnicke Karakteristike Asistal Alu OkapnicaDARKO RADICEVICNo ratings yet

- GGB Anchor BoltDocument1 pageGGB Anchor Boltargometer tzarNo ratings yet

- Tutorial Manning RAS 2000 sanitary sewerDocument31 pagesTutorial Manning RAS 2000 sanitary sewerALEXANDER ROJAS GONZALESNo ratings yet

- Printing & Pouching Film Matte, Non Heat Sealable: PCT-2 (M)Document1 pagePrinting & Pouching Film Matte, Non Heat Sealable: PCT-2 (M)U KsNo ratings yet

- Cutting Time T: ExternalDocument2 pagesCutting Time T: ExternalMECHANICAL ENGINEERINGNo ratings yet

- KEMET Part Number: T520V226M020ATE045: General InformationDocument1 pageKEMET Part Number: T520V226M020ATE045: General Informationvax1No ratings yet

- CapCitor KemetDocument1 pageCapCitor KemetTato YudayanaNo ratings yet

- WeldDocument4 pagesWeldmjohnNo ratings yet

- Alcantarillado N Manning PAVCO-RAS 2017 20-12-2018 .Document31 pagesAlcantarillado N Manning PAVCO-RAS 2017 20-12-2018 .ANA MARIA CARLOSAMA HOYOSNo ratings yet

- Barden - 107Document1 pageBarden - 107Linh LạiNo ratings yet

- Alcantarillado N Manning PAVCO-RAS 2017 20-12-2018Document33 pagesAlcantarillado N Manning PAVCO-RAS 2017 20-12-2018Juan SepulvedaNo ratings yet

- Alcantarillado PAVCO-RAS 2000 (12-10-05)Document30 pagesAlcantarillado PAVCO-RAS 2000 (12-10-05)DALGYNo ratings yet

- ASTM A53 Data Sheet PDFDocument3 pagesASTM A53 Data Sheet PDFmarcelomaster88No ratings yet

- C-Section PropertiesDocument1 pageC-Section Propertiesmd habibur rahman shamimNo ratings yet

- BBS For Pier Cap & Pedestal P7Document1 pageBBS For Pier Cap & Pedestal P7SAYAN SARKARNo ratings yet

- MB8851 Spec Sheet - EngDocument1 pageMB8851 Spec Sheet - Engclinica celsocabralNo ratings yet

- FontsDocument1 pageFontsKhoirulAnwarNo ratings yet

- Paper DividerDocument3 pagesPaper DividerKhoirulAnwarNo ratings yet

- Nilai PerlogDocument2 pagesNilai PerlogKhoirulAnwarNo ratings yet

- Paper DividerDocument3 pagesPaper DividerKhoirulAnwarNo ratings yet

- Work and HeatDocument21 pagesWork and HeatKhoirulAnwarNo ratings yet

- Work and HeatDocument21 pagesWork and HeatKhoirulAnwarNo ratings yet

- Vapor Power System (Rankine Cycle)Document42 pagesVapor Power System (Rankine Cycle)KhoirulAnwarNo ratings yet

- Part7 ModelDocument1 pagePart7 ModelKhoirulAnwarNo ratings yet

- Transfer Functions, Poles and ZerosDocument20 pagesTransfer Functions, Poles and ZerossubratNo ratings yet

- Tank Level Control Simulation and PID Controller DesignDocument5 pagesTank Level Control Simulation and PID Controller DesignSimon CalloNo ratings yet

- Natural Convection Heat Transfer From Vertical Helical Coils in OilDocument8 pagesNatural Convection Heat Transfer From Vertical Helical Coils in Oilnaval1908No ratings yet

- CHP 2... Safety in Pressure System (Controllable Units)Document56 pagesCHP 2... Safety in Pressure System (Controllable Units)kira ENTERTAINMENT100% (2)

- PhET Gas Laws Simulation ExplainedDocument3 pagesPhET Gas Laws Simulation Explainedx0% (1)

- Gen. Physics 1 Summative ReviewerDocument3 pagesGen. Physics 1 Summative ReviewerMARIELLE ANDREA ZAMORASNo ratings yet

- Soil Exploration and Foundation SettlementDocument4 pagesSoil Exploration and Foundation SettlementSuryakant MangajNo ratings yet

- Compression Power CalculationDocument72 pagesCompression Power CalculationexandriNo ratings yet

- Molecular Dynamics Simulation of Crack Propagation in AluminumDocument40 pagesMolecular Dynamics Simulation of Crack Propagation in AluminumodoalawayeNo ratings yet

- Experiment 3-1Document7 pagesExperiment 3-1Cyrus DavidNo ratings yet

- Design of Hydrodynamic BearingDocument9 pagesDesign of Hydrodynamic Bearingjason patelNo ratings yet

- Mid Question FluidDocument1 pageMid Question FluidSubrata DebnathNo ratings yet

- AlfaNova U - TurnDocument2 pagesAlfaNova U - Turnevrimk100% (1)

- Hydraulics and Hydraulic Machinery by DR Nekkanti KumaraswamyDocument39 pagesHydraulics and Hydraulic Machinery by DR Nekkanti KumaraswamyAnonymous zwnFXURJNo ratings yet

- SCIENCE 4 Q3 W4 Activity Sheets 2Document3 pagesSCIENCE 4 Q3 W4 Activity Sheets 2Rerai CaielleNo ratings yet

- 6.1 Applications of Darcy's Law: Figure 6.1 Model For Radial Flow of Fluids To The WellboreDocument33 pages6.1 Applications of Darcy's Law: Figure 6.1 Model For Radial Flow of Fluids To The Wellborekhan.pakiNo ratings yet

- 01.intro To BS5950Document12 pages01.intro To BS5950bsitlerNo ratings yet

- Chapter 11 - Refrigeration CyclesDocument25 pagesChapter 11 - Refrigeration CyclesPaul RodgersNo ratings yet

- Lab 1Document12 pagesLab 1yash saragiyaNo ratings yet

- Taller de Calor EstDocument2 pagesTaller de Calor EstDiegoMuñozNo ratings yet

- Esfueros Insitu Colombia SPE 81074 FDocument13 pagesEsfueros Insitu Colombia SPE 81074 Fsantiago ruedaNo ratings yet

- Theory of Combustion PDFDocument9 pagesTheory of Combustion PDFMuthu Kumar100% (1)

- Sample5 PVElite PDFDocument35 pagesSample5 PVElite PDFגרבר פליקסNo ratings yet

- Connecting Rod Design and AnalysisDocument29 pagesConnecting Rod Design and Analysisumair talashNo ratings yet

- Lecture 8 of Tropical MeteorologyDocument22 pagesLecture 8 of Tropical MeteorologyMelvin BadonNo ratings yet

- Application of Multichannel Analysis of Surface Waves and Seismic Refraction To Define The Engineering Properties of SoilDocument37 pagesApplication of Multichannel Analysis of Surface Waves and Seismic Refraction To Define The Engineering Properties of Soilbestelot yinesuNo ratings yet

- MODULE 5.6 OrificeDocument19 pagesMODULE 5.6 OrificeFrancis HernandezNo ratings yet

- Theoretical 3 Tornado SolutionDocument7 pagesTheoretical 3 Tornado Solutionjas dwanNo ratings yet

- Chiller EngDocument1 pageChiller EngemonwreNo ratings yet