Professional Documents

Culture Documents

Hoist Classification: Cmaa Service Class C and D

Uploaded by

Jesús Alberto Díaz CostaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hoist Classification: Cmaa Service Class C and D

Uploaded by

Jesús Alberto Díaz CostaCopyright:

Available Formats

Hoist Classification

CMAA SERVICE CLASS C AND D

Within the crane industry, there has been considerable confusion as to the definitions of CMAA C and D

services, as well as HMI ratings of H3 and H4. In the past, Class C has been regarded as packaged hoist

equipment, while Class D has been regarded as open deck machinery. As packaged hoist manufacturers

increased the duty ratings of their hoists from H3 to H4, packaged hoists then began to be used for Class D

service. In some cases, this has resulted in premature failures of Class D packaged hoists when operating in a

Class D rating.

Crane Manufacturers Association Specification No. 70

defines Class C and D service as:

Class C (Moderate Service)

This service covers cranes which may be used in machine shops or papermill machine rooms, etc., where

service requirements are moderate. In this type of service, the crane will handle loads which average 50% of

the rated capacity with 5 to 10 lifts per hour, averaging 15 feet, not over 50% of the lift at rated capacity

Class D (Heavy Service)

This service covers cranes which may be used in heavy machine shops, foundries, fabricating plants, steel

warehouses, container yards, limber mills, etc., and standard duty bucket and magnet operations where heavy

duty production is required. In this type of service, loads approaching 50% of the rated capacity will be handled

constantly during the working period. High speeds are desirable for this type of service with 10 to 20 lifts per

hour averaging 15 feet, not over 65 percent of the lists at rated capacity

Hoist Manufacturers Institute Specifications

define Class H3 and H4 service as:

H3

General machine shop, fabricating, assembly, storage, and warehousing. Loads and utilization randomly

distributed. Total running time not over 25% of the work period.

H4

High Volume handling of heavy loads, frequently near rated load in steel warehousing, machine and fabricating

shops, mills, and foundries, with a total running time not over 50% of the work period.

ACECO has found that the following applications generally require Class C service cranes.

CMAA Class C/HMI H3 Service Applications

Job Shop

Steel Fabrication

Machine Shop

Maintenance Activity

Papermill Wet End

For Class D, the heavy service class, we have found the following applications require the Class D service.

CMAA Class D/HMI H4 Service Applications

Steel Warehouse

Structural Steel Fabrication

Papermill Dry End

Production Cranes

What do the C/H3 and D/H4 ratings mean in practical terms?

ACECO differentiates between Class C and Class D in the choice of wheels for top running cranes and hoists for

Class C, ACECO uses the gear rim type wheels. This is an economical design choice and has demonstrated

years of satisfactory service in the Class C applications. For Class D service, ACECO specifies rotating axle type

wheel and bearing systems. This system allows for longer bearing life.

Changes a customer can expect to see on a crane when ordering a D, instead of a C crane includes a slight

increase in girder section, as a result of the weld allowable stress range. As the class of service increases, the

allowable stress range decreases, which may necessitate an increase in girder section size to reduce stresses.

Please note this is a cyclic design issue as the allowable static stress is the same for both Class C and D service.

Several mechanical items also increase in size or rating when moving to Class D. Sheaves and drums both

increase in size. Class C sheaves and drums are required to be 18 times the rope diameter, whereas in Class D

it is required to be 20 times rope diameter. This increase in diameter reduces rope stresses and thereby

increases rope life. Changes also occur in the gearing design to produce gears of greater durability for Class D

service. The major change in the mechanical is the increase in L-10 bearing life from 5000 hours at Class C

service to 10,000 hours in Class D service. In a Class D application, the electrical design also may change. A

Class D application may require increasing the contactor size for the motor controller based on its rating

(horsepower).

The HST design standard requires a 20% of ultimate strength design similar to the CMAA design standard.

However, the HST has an exception requiring 35% of ultimate strength design where deformation of the

material can occur. Diameter requirements under the HST standard do not increase with increasing duty cycle.

In the HST, the minimum drum diameter requirement is 16 times rope diameter. Note that this is a smaller

diameter than either Class C or D service. The drum diameter in the HST standard is 16 times the rope

diameter, which would be equivalent to CMAA Class C service. Bearing life for H3 and H4 is similar to CMAA

Class C and CMAA Class D, respectfully.

It should be understood that the above are general guidelines. When questions arise, please consult ACECO's

Engineering Department for a complete duty cycle sizing analysis to assure the hoist and crane selected

performs adequately for the service.

You might also like

- Chp7 Cranes Revision 2011Document64 pagesChp7 Cranes Revision 2011Shruti IyengarNo ratings yet

- Maj Concslb 043 0Document1 pageMaj Concslb 043 0Mohammed JassimNo ratings yet

- Anupam - TowerCrane - A806Document6 pagesAnupam - TowerCrane - A806JnanamNo ratings yet

- Compliance Assistance Checklist For PrecastDocument6 pagesCompliance Assistance Checklist For PrecasttatonyNo ratings yet

- Gantry CraneDocument9 pagesGantry Craneyuza_maulana020% (1)

- Podem - Crane Components - Technical Catalogue (En)Document32 pagesPodem - Crane Components - Technical Catalogue (En)GogyNo ratings yet

- Method Statement For Lifting Operations: 1 - IntroductionDocument3 pagesMethod Statement For Lifting Operations: 1 - Introductiontravman1No ratings yet

- February 2012 Wire Rope ExchangeDocument80 pagesFebruary 2012 Wire Rope ExchangeWire Rope ExchangeNo ratings yet

- Alternative Lifting MethodsDocument31 pagesAlternative Lifting MethodsKunjan MandaviyaNo ratings yet

- Lifting Beams vs. Spreader BeamDocument10 pagesLifting Beams vs. Spreader BeamAkram BadranNo ratings yet

- Offshore Latticed Structures - Analysis of The Lattice Crane BoomDocument1 pageOffshore Latticed Structures - Analysis of The Lattice Crane BoomGogyNo ratings yet

- Tower Crane Cop 2006Document58 pagesTower Crane Cop 2006ooi100% (1)

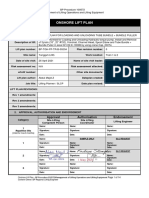

- Complex Lift Plan and ChecklistDocument3 pagesComplex Lift Plan and Checklistsudeesh kumar100% (1)

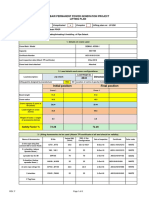

- BP TGH PF TR B 0020a - 022 e 1002b - by Crane 200te (BPP Puller)Document36 pagesBP TGH PF TR B 0020a - 022 e 1002b - by Crane 200te (BPP Puller)Abdul Majid ZNo ratings yet

- Offshore - Appointed Person Lifting NewDocument335 pagesOffshore - Appointed Person Lifting NewAdnan Abdul RehimNo ratings yet

- Hydraulic Crawler Crane: S P E C I F I C A T I O N SDocument8 pagesHydraulic Crawler Crane: S P E C I F I C A T I O N SSANDEEP PRASAD100% (1)

- Riggers Quiz: Name: - DateDocument1 pageRiggers Quiz: Name: - Dategunnery02No ratings yet

- Sling Length and TensionDocument4 pagesSling Length and TensionMo'tasem SerdanehNo ratings yet

- Critical Lift Critical Lift Plan Required YES: (Note: Never Exceed 75% of Each Crane's Capacity in A Multi-Crane Lift.)Document4 pagesCritical Lift Critical Lift Plan Required YES: (Note: Never Exceed 75% of Each Crane's Capacity in A Multi-Crane Lift.)cute1t100% (1)

- Generators, and A Wide Variety of Other Building MaterialsDocument17 pagesGenerators, and A Wide Variety of Other Building MaterialsAmeerUlHaqNo ratings yet

- Specifications - Tower Crane - TC7030BDocument13 pagesSpecifications - Tower Crane - TC7030BfiarNo ratings yet

- OECP Crane Operator Candidate ManualDocument66 pagesOECP Crane Operator Candidate ManualkhalidNo ratings yet

- CraneDocument17 pagesCraneJustin ChongNo ratings yet

- Multiple Crane LiftingDocument11 pagesMultiple Crane LiftingAbdul Majid ZulkarnainNo ratings yet

- Rigger 3 Written TestDocument47 pagesRigger 3 Written TestMahdi AlbinalshaikhNo ratings yet

- NLP 296 LoadingUnloading Positioning of Pipe Stack 500TDocument8 pagesNLP 296 LoadingUnloading Positioning of Pipe Stack 500TAhmed AliNo ratings yet

- Mewps Operator Practical Only Assessment Sheets 2021 MercuryDocument4 pagesMewps Operator Practical Only Assessment Sheets 2021 MercuryWILLIAM KEAGUE100% (1)

- General: Capacity Chart Manual IndexDocument184 pagesGeneral: Capacity Chart Manual Indextoppen_76No ratings yet

- Construction Technology-Static CranesDocument14 pagesConstruction Technology-Static CranesPrarthana roy RNo ratings yet

- 5810 ManualDocument50 pages5810 ManualkrmchariNo ratings yet

- Crane DictionaryDocument15 pagesCrane DictionarySandeep SolankiNo ratings yet

- Lashing Project CargoDocument1 pageLashing Project CargoBHAUMIK SOLANKINo ratings yet

- Review Safety Rigging and LiftingDocument4 pagesReview Safety Rigging and Liftingferry ferdiansyah pradanaNo ratings yet

- Heavy Lifting WorkshopDocument63 pagesHeavy Lifting WorkshopRinda Purwanto IMM BontangNo ratings yet

- A59 Q&a 3Document15 pagesA59 Q&a 3Jason ConnellNo ratings yet

- TUV LE Inspection BrochuresDocument1 pageTUV LE Inspection Brochuresshoaib2scribedNo ratings yet

- Outrigger Pads Brochure Low ResDocument8 pagesOutrigger Pads Brochure Low Resfcesar1986No ratings yet

- E Hebetec APSDocument11 pagesE Hebetec APSCHAVEZ26No ratings yet

- Sling AnglesDocument1 pageSling AnglesyogihardNo ratings yet

- Serious Lift Calculation and Authorization FormDocument2 pagesSerious Lift Calculation and Authorization FormAbdulKather100% (1)

- 2 Chapter Two-Earthmoving Materials and OperationDocument19 pages2 Chapter Two-Earthmoving Materials and OperationFiraol TayeNo ratings yet

- Safe Use of CranesDocument33 pagesSafe Use of Craneswasim Akram100% (1)

- Lifting Plan: Lifting Appointed Person / Supervisor Site InspectionDocument4 pagesLifting Plan: Lifting Appointed Person / Supervisor Site Inspectionkhaled redaNo ratings yet

- Comparison Between Lattice Boom and Knuckle BoomDocument2 pagesComparison Between Lattice Boom and Knuckle BoomG.SWAMI100% (2)

- 科尼起重机 ShipyardDocument16 pages科尼起重机 ShipyardHui ChenNo ratings yet

- Procedure For Making Tandem Crane Lifts in The USA PDFDocument5 pagesProcedure For Making Tandem Crane Lifts in The USA PDFparamarthasom1974No ratings yet

- SWF RopeHoists CraneKits 09 2012 enDocument21 pagesSWF RopeHoists CraneKits 09 2012 enGogyNo ratings yet

- A17 Telescopic Handler: General Safety Information For CPCS Technical TestDocument12 pagesA17 Telescopic Handler: General Safety Information For CPCS Technical TestNicolae Burca0% (1)

- LP-0008 - Load and Off-Load Rental MEWP 17teDocument6 pagesLP-0008 - Load and Off-Load Rental MEWP 17teRustam36No ratings yet

- Design of A Counterbalance Forklift Based On A Predictive Anti-Tip-Over ControllerDocument16 pagesDesign of A Counterbalance Forklift Based On A Predictive Anti-Tip-Over ControllerHo Van RoiNo ratings yet

- Skidding System Data SheetDocument1 pageSkidding System Data Sheetm4l4ysiaNo ratings yet

- Dockside Container Crane Workshop StructuralDocument30 pagesDockside Container Crane Workshop StructuralMAGSTNo ratings yet

- TaiLing by Duo CraneDocument9 pagesTaiLing by Duo CraneHaGun Gunawan100% (1)

- Lifting PlanDocument2 pagesLifting PlanMidhunRameshThuvasseryNo ratings yet

- Cmaa Classifications As Per Spec 70Document2 pagesCmaa Classifications As Per Spec 70JESUSCALVILLONo ratings yet

- Class C vs. Class D: TechnicalDocument1 pageClass C vs. Class D: TechnicalKhaled RabeaNo ratings yet

- Overhead Crane Supporting Structures 115Document3 pagesOverhead Crane Supporting Structures 115Gogy100% (1)

- 102-CMAA Crane ClassificationDocument3 pages102-CMAA Crane Classification윤홍민No ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Asme B36-10M-2004 (Schedule STD)Document1 pageAsme B36-10M-2004 (Schedule STD)Jesús Alberto Díaz CostaNo ratings yet

- ASME B16 - ASME B16.5 Square FlangesDocument7 pagesASME B16 - ASME B16.5 Square FlangesJesús Alberto Díaz CostaNo ratings yet

- Standard Trench Dimensions - Trench Width For HDPE Pipe - Minimum Trench Widths PDFDocument2 pagesStandard Trench Dimensions - Trench Width For HDPE Pipe - Minimum Trench Widths PDFJesús Alberto Díaz CostaNo ratings yet

- C2137-Equipos Pipiing RBXDocument12 pagesC2137-Equipos Pipiing RBXJesús Alberto Díaz CostaNo ratings yet

- Standard Trench Dimensions - Trench Width For HDPE Pipe - Minimum Trench WidthsDocument2 pagesStandard Trench Dimensions - Trench Width For HDPE Pipe - Minimum Trench WidthsJesús Alberto Díaz CostaNo ratings yet

- Fiberglass Reinforced Thermoset PlasticDocument9 pagesFiberglass Reinforced Thermoset PlasticJesús Alberto Díaz CostaNo ratings yet

- ASTM A193 Specification - Portland BoltDocument3 pagesASTM A193 Specification - Portland BoltJesús Alberto Díaz CostaNo ratings yet

- Utah Point Multi-User Bulk Export Facility Port Hedland: Servicing Australia's Future Trade GrowthDocument30 pagesUtah Point Multi-User Bulk Export Facility Port Hedland: Servicing Australia's Future Trade GrowthJesús Alberto Díaz CostaNo ratings yet

- 2019 Cold Chain IndiaDocument32 pages2019 Cold Chain IndiaKavitha Reddy GurrralaNo ratings yet

- Total Cost of Ownership in The Services Sector A Case Study PDFDocument12 pagesTotal Cost of Ownership in The Services Sector A Case Study PDFfayyazhussainNo ratings yet

- Godown Creation in TallyDocument3 pagesGodown Creation in TallySanjeev kumarNo ratings yet

- Resume of Syed Anwar Hussain Material ControllerDocument4 pagesResume of Syed Anwar Hussain Material ControllerrafiuddinNo ratings yet

- MCQ MBA IVth 403 OSCM E Supply Chains and LogisticsDocument30 pagesMCQ MBA IVth 403 OSCM E Supply Chains and LogisticsAbhishek A. Nadgire100% (1)

- Passport Automation SystemDocument140 pagesPassport Automation SystemjimNo ratings yet

- Ignou Mba Operation Project ReportDocument28 pagesIgnou Mba Operation Project ReportRecruitment100% (1)

- Discussion DDocument2 pagesDiscussion DVarunNo ratings yet

- Dynamics 365 Supply Chain UK enDocument25 pagesDynamics 365 Supply Chain UK enVenu MadhuriNo ratings yet

- On Farmer Buying Behavior Toward PesticideDocument31 pagesOn Farmer Buying Behavior Toward Pesticidejaanbaaz1No ratings yet

- Module 2 LSCMDocument214 pagesModule 2 LSCMrajitha revannaNo ratings yet

- Catalog Dahua Wisualarm Fire Alarm Products V1.0 en 202204 (24P)Document17 pagesCatalog Dahua Wisualarm Fire Alarm Products V1.0 en 202204 (24P)Haekal anandaNo ratings yet

- KEX SF Company Profile 2023Document18 pagesKEX SF Company Profile 2023Ilham RamadhanNo ratings yet

- 1210 Ac 0801Document2 pages1210 Ac 0801suljo1234No ratings yet

- 1 Notes - Warehouse ManagementDocument7 pages1 Notes - Warehouse Managementmaria luzNo ratings yet

- Property ContentDocument5 pagesProperty ContentAbner ParedesNo ratings yet

- Barcodes CS1Document16 pagesBarcodes CS1harrysan69No ratings yet

- Warehousing: Business StudiesDocument29 pagesWarehousing: Business StudiesRadhika JaiswalNo ratings yet

- Semana 14-II Ingles NI EXAMENDocument9 pagesSemana 14-II Ingles NI EXAMENSOLANO VIDAL RIJKAARD MAINNo ratings yet

- How To Configure of Quality Management in Embedded EWMDocument37 pagesHow To Configure of Quality Management in Embedded EWMGhassan SharafNo ratings yet

- A Construction Materials Management System For Gaza Strip Building ContractorsDocument171 pagesA Construction Materials Management System For Gaza Strip Building ContractorsAsyran SyafiqNo ratings yet

- SRF PresentationDocument28 pagesSRF PresentationSajeev KumarNo ratings yet

- Rohan Chauhan Internship Report - For MergeDocument23 pagesRohan Chauhan Internship Report - For MergeRohan ChauhanNo ratings yet

- Doh Revised Guidelines On Current Good ManufacturingDocument25 pagesDoh Revised Guidelines On Current Good Manufacturingcharlimagne100% (3)

- Customs Law & Foreign Trade Policy PDFDocument17 pagesCustoms Law & Foreign Trade Policy PDFABC 123No ratings yet

- CONCORDocument32 pagesCONCORIsha Varma100% (2)

- File 2.144368 001 PDFDocument108 pagesFile 2.144368 001 PDFfpttmmNo ratings yet

- Phase VI - Warehouse Management V2.23Document59 pagesPhase VI - Warehouse Management V2.23girishalluruNo ratings yet

- Entrepreneurship: For Shs LearnersDocument11 pagesEntrepreneurship: For Shs LearnersPrincess Jean GalabinNo ratings yet

- Portal Frame ProposalDocument15 pagesPortal Frame ProposalCaleb KhisaNo ratings yet