Professional Documents

Culture Documents

1 Introduction To Marine Automation PDF

Uploaded by

Mira RedaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 Introduction To Marine Automation PDF

Uploaded by

Mira RedaCopyright:

Available Formats

Automation

Introduction to Marine Automation

ISA–The Instrumentation, Systems, and Automation Society

Learning Objectives

Define what is meant by “Instrumentation”

Define:

Process control

Measurement

Accuracy

Repeatability

Resolution

Hysteresis

Sensitivity

Precision

Reproducibility

ISA–The Instrumentation, Systems, and Automation Society

Learning Objectives

Explain the three (3) variables involve in process control

Manipulative variable

Disturbance

Controlled variable

Describe simple process control loops using a block

diagram

Explain the difference between open and closed loop

State the essential requirement for automatic operation

of machinery

ISA–The Instrumentation, Systems, and Automation Society

Learning Objectives

Differentiate pneumatic, hydraulic and electro-technical

control systems

Differentiate analog and digital device

ISA–The Instrumentation, Systems, and Automation Society

Short History of Instrumentation and

Control

3 BC – float valve on a water clock is the first control device

recorded being used

1750-1850 – Scottish Engineer James Watt devised the “flyball”

governor for steam engine was the 1st significant control

invention

1850-1900 - Siemens invented first dynamo machine. Brown

Instrument Co., Honeywell and Fisher governor companies’ were

established

1900-1920 – Ervin Bailey invents Bailey Boiler Meter,

pneumatically operated instruments are made available and On-

off controllers are widely used in the process industry

ISA–The Instrumentation, Systems, and Automation Society

Short History of Instrumentation and

Control (Continued)

1920-1940

Bailey Controls introduces the 1st multi-pointer guage and installs

1st recording instrument on a marine boiler.

Leeds & Northrup introduces the 1st conductivity recorder and

pioneered the development of glass pH electrodes.

Foxboro begins marketing the 1st proportional plus reset

recorder/controller. Instrumentation grows with over 600

companies selling instruments.

Taylor Instrument Co. markets its Model 56R the 1st adjustable

proportional controller.

Leeds & Northrup introduces the first conductivity gas analyzer

ISA–The Instrumentation, Systems, and Automation Society

Short History of Instrumentation and

Control (Continued)

1940-1960

Coleman B. Moore fouds Moore Products. G.B.

Hoadley receives a patent or LVDT.

Lead sulphide infrared detectors are develop by Gudden in

Germany.

Taylor Instruments develops the Fulscope 100 which has three

respnse sensitivity, automatic reset and a pre-act (PID).

John Ziegler and Nathaniel Nichols of Taylor Instruments develop

the “Ziegler-Nichols” method of basic controller tuning.

The ISA was born.

First all-electronic instrument was manufactured by Foxboro

named Dynalog.

ISA–The Instrumentation, Systems, and Automation Society

Short History of Instrumentation and

Control (Continued)

1940-1960

Miniature pneumatic controls were develop.

Computers were use in instrumentation and controls.

Electro-magnetic and ultrasonic flowmeters were

develop.

Capacitance pressure sensors was develop and

Beckmen Instruments markets the 1st gas

chromatograph.

The 1st transistorized temperature controller was

develop by Honeywell.

ISA–The Instrumentation, Systems, and Automation Society

Short History of Instrumentation and

Control (Continued)

1960-Present

Solid state electronics experience tremendous growth while

pneumatic controllers lose their dominance in the market.

Computers are used more often for industrial applications.

The vibrating viscocity meter is develop by Tough, McCormick

and Dask.

Bailey install 1st automated boiler control system aboard the S.S.

Wiliam G Mather and the S.S. CapeBreton Miner.

“Fuzzy logic” was termed and applied. Micro-miniaturization

started a revolution in the manufacturing industry.

ISA–The Instrumentation, Systems, and Automation Society

Short History of Instrumentation and

Control (Continued)

1960-Present

Chance Pilkington release 1st fiber optic and HP introduces

LEDs.

Honeywell begins development of DCS.

Maturation of computer technology dramatically advances the

field of instrumentation and control.

Masoneilan revolutionizes control valves with the invention of the

Camflex the 1st general rotary stem valve.

First in-situ oxygen sensor was introduced by Westinghouse

Electric.

ISA–The Instrumentation, Systems, and Automation Society

Short History of Instrumentation and

Control (Continued)

1960-Present

Honeywell and Yokogawa introduced the 1st industrial application

of distribution digital electronics in process control.

Texas Instruments markets the 1st PLC with true process

capabilities.

Applications of microprocessors, telemetry, ultrasonics and

modeling techniques lead to major advances in biomedical

instrumentation.

Leeds & Northrrup develops the 1st self-tuning automatic

controller and fiber-optic data highway.

ISA–The Instrumentation, Systems, and Automation Society

Short History of Instrumentation and

Control (Continued)

1960 to Present

Honeywell introduces the St 3000 Smart transmitters.

USDATA introduces FactoryLink the 1st PC-based

application enabler software product for SCADA.

FieldBus becomes the talk of the town.

SAAB tank Control pioneers a new non-contact radar

method measurement for levels of liquid in LPG and

LNG tanks.

ISO 900X certification for Instrumentation

Manufacturers

ISA–The Instrumentation, Systems, and Automation Society

Matter

Is anything that occupies space and has weight

An important factor determining the form of

matter is its energy level

Matter exist in one of three physical forms

Solid

Liquid

Gas

ISA–The Instrumentation, Systems, and Automation Society

Properties of Matter

Physical Properties – the qualities of substances usually

identified to our senses of sight, sound, smell, touch and

taste

Color

Smell

Insolubility’

Chemical Properties – defined as how a substance

reacts during chemical change

Oxidation (rust)

Reduction

Corrosion

ISA–The Instrumentation, Systems, and Automation Society

Matter

Elements – a substance that cannot be broken down

into simpler chemical form

Atom – the smallest possible quantity of an element

Molecules – are the smallest quantity of a material

made up of multiple atoms/elements that still retains the

properties of that substance

Molecules can be broken down chemically in to

elemental atoms that have completely different

characteristics from the original molecule

ISA–The Instrumentation, Systems, and Automation Society

Matter

No matter what form , all molecules within a substance are in

constant motion

The higher the level of energy the higher the motion

The amount of space that a substance occupies is called volume

Solids have a definite shape and definite volume

Liquids have a definite volume but do not have a definite shape

Gasses do not have a definite volume and do not have a definite

shape. It’s volume and shape is defined by its container

Fluids is a liquid or a gas substance that can flow

ISA–The Instrumentation, Systems, and Automation Society

Energy

Energy is define as the capacity to do work

Potential energy is energy due to position

Kinetic energy is energy of motion

Kinetic energy of a process fluid can be determined by

measuring its flow rate

Internal energy comes from the motion of molecules

within the material

Internal energy will flow from a warmer body to a cooler

body until equilibrium is reached

ISA–The Instrumentation, Systems, and Automation Society

Energy

Heat is transferred in three ways:

Conduction – Heat flows through a material by

conduction from atom to atom. Materials that do not

conduct heat well are called thermal insulators.

Example is cooking with the use of frying pan

Convection – heat is transferred by the motion of

thermal current. Example is cooking by hot air furnace or

oven

Radiation – Heat is transferred via burst of radiation

energy. Example is the sun heats up the inside of a closed

car

ISA–The Instrumentation, Systems, and Automation Society

Measurement

Regardless of its use, every measurement must

have a number and a unit or label to have a

meaning

Measurement are made by comparing

something to a scale

Industry around the world uses either English,

Metric or International System of units (SI).

ISA–The Instrumentation, Systems, and Automation Society

Definitions

Instrumentation – a collection of instruments

or their applications for the purpose of

observation, measurement or control (ISA)

Measurement – is the extraction of signals

from physical and chemical systems or

processes which represents parameters or

variables

ISA–The Instrumentation, Systems, and Automation Society

Definitions

Process

a natural progressively continuing operation or

development marked by a series of gradual

changes that succeeds one another in a relatively

fixed way and leads towards a particular result or

end (Webster)

consist of an assembly of equipment and material

that relates to some manufacturing operation or

sequence (ISA)

Process Control

is a technique of balancing supply and demand

over a period of time at a pre-determined level of

operation called “set point”

ISA–The Instrumentation, Systems, and Automation Society

Definitions

Accuracy

conformity of an indicated value to an accepted

standard value or true value

Repeatability

the closeness of agreement among a number of

consecutive measurements of the output for the

same value of input under identical operating

conditions

Resolution

the smallest interval between two adjacent

discrete details which can be distinguished on

from the other

ISA–The Instrumentation, Systems, and Automation Society

Definitions

Hysteresis

the maximum difference obtained as an output for

the same input between the upscale and

downscale output values during a full range

transverse in each direction

Sensitivity

the ratio of change in output to the change in

input magnitudes

ISA–The Instrumentation, Systems, and Automation Society

Definitions

Precision

the closeness of agreement between test results

Reproducibility

the ability of a system of elements to maintain its

output/input precision over a relatively long period

of time

ISA–The Instrumentation, Systems, and Automation Society

Examples of a Process:

1. Mixing of fluids.

2. Heating or cooling of substances.

3. Pumping out of water.

4. Canning food.

5. Deriving gasoline from crude.

6. Many more…..

ISA–The Instrumentation, Systems, and Automation Society

Difference between a

System and a Process:

Often in the past, the term process was

applied to a plant, that is, to the process

itself as well as all of the piping, valves,

and equipment need to manufacture a

product. In order to use the term

accurately, process should describe what

is occurring within a system.

ISA–The Instrumentation, Systems, and Automation Society

Instrumentation Devices

Direct observation of actions or events

necessary to most processes, is not

possible but the observation or monitoring

of process parameters is a critical aspect of

control. Consequently, processes can be

monitored and controlled through the use of

various Instrumentation Devices.

ISA–The Instrumentation, Systems, and Automation Society

Process Variable

• Instrumentation systems are a group of

instruments or their application for the

purpose of observation, monitoring, or

control

• The system has the necessary

measurement and control components to

maintain the process within the proper

limits. In most cases, process parameters

are referred to as “Process Variables”.

ISA–The Instrumentation, Systems, and Automation Society

Process Variable

A variable is a property of a substance that may change

The devices used to measure and control process variables are called

process instruments

A measuring instrument may:

Determine if a particular process variable exist in a material

Determine value for that material

A control instrument may:

Cause a variable to be maintained at a set value or within set limits

Cause a change in the process that changes the value of the

variable in a known way

Cause another mechanism such as a valve to control process

variable

ISA–The Instrumentation, Systems, and Automation Society

Process Variable

A variable is a property of a substance that may change

The devices used to measure and control process variables are called

process instruments

A measuring instrument may:

Determine if a particular process variable exist in a material

Determine value for that material

A control instrument may:

Cause a variable to be maintained at a set value or within set limits

Cause a change in the process that changes the value of the

variable in a known way

Cause another mechanism such as a valve to control process

variable

ISA–The Instrumentation, Systems, and Automation Society

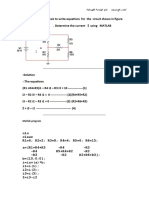

Typical Process Diagram

DISTURBANCE

MANIPULATIVE CONTROLLED

VARIABLE

PROCESS VARIABLE

ISA–The Instrumentation, Systems, and Automation Society

Simple Process Control Loop

SET-POINT

CONTROLLER

DISTURBANCES

INPUT CONTROL ELEMENT PROCESS OUTPUT

MEASUIREMENT

ISA–The Instrumentation, Systems, and Automation Society

Disturbances

input output

FCE PROCESS

Correction

Measurement

Feedback Primary

Measuring

(control loop) Element

Secondary

Element

Computation Comparison

The figure shows the relationship of the 4 Basic Functions of an

Automatic Control System and its 3 Control Elements

ISA–The Instrumentation, Systems, and Automation Society

Elements of a Control Loop

ISA–The Instrumentation, Systems, and Automation Society

Elements of a Control Loop

Measurement – conversion of the process variable in to

an analog or digital signal that can be use by the control

system

Evaluation – measurement value is examined, compared

with a desired value or set-point, and the amount of

corrective action needed to maintain proper control is

determined

Control – is the device in the control loop that exerts direct

influence on the process or the manufacturing sequence

ISA–The Instrumentation, Systems, and Automation Society

1. SELF REGULATING

HOT H2O

STM HEATER

COLD H2O

ISA–The Instrumentation, Systems, and Automation Society

2. MANUAL CONTROL W/ INDICATING

INSTRUMENT

HOT H2O

STM HEATER

COLD H2O

ISA–The Instrumentation, Systems, and Automation Society

3.AUTOMATIC CONTROL

HOT H2O

STM HEATER

COLD H2O

ISA–The Instrumentation, Systems, and Automation Society

Pneumatic Control Systems

Less expensive initially in spite of tubing and air supply

cost

No heat generation and safe in explosive atmosphere

Less susceptible to power supply variation but do have

time lag

Direct applications, without transducers to large final

power actuators

Simple system design

Short commissioning and set-up period

Higher maintenance cost

ISA–The Instrumentation, Systems, and Automation Society

Pneumatic Control Systems

ISA–The Instrumentation, Systems, and Automation Society

Hydraulic Control Systems

Similar to the advantages of pneumatic control

systems

More appropriate for high pressure, power or work

requirements

Generally more restricted in application

Requires hydraulic oil compared to pneumatics

which uses air which is free

Recovery-storage system is required for not

allowing fluid to escape

ISA–The Instrumentation, Systems, and Automation Society

Hydraulic Control Systems

ISA–The Instrumentation, Systems, and Automation Society

Electro-Technical Control System

Small and adaptable with cheap flexible transmission

lines

No moving parts, can however generate heat

Stable, generally accurate and very short time lag

Low power consumption, direct application to

computers, but often need final control element or

transducers

Lower maintenance cost

Better suited for long distance transmission

Superior dynamic response

ISA–The Instrumentation, Systems, and Automation Society

Electro-Technical Control System

ISA–The Instrumentation, Systems, and Automation Society

Definitions

Digital

A term applied to a signal or device that uses binary

digits to represent continuous values or discrete

states

Analog

A term applied to a physical signal or variable which

remains similar to another variable in so far as the

proportional relationship are the same over some

specific range (McGraw-Hill Dictionary)

a signal or a device that represents a variable which

may be continuously observed or continuously

represented over a range

ISA–The Instrumentation, Systems, and Automation Society

Difference Between Analog and

Digital Device

Analog Digital

Takes an infinite number Variables are limited to

values defined states

More accurate in reproducing Less susceptible to noise

a quantity, variable or signal

May be transmitted over long

May be transmitted over distance at greater efficiency

greater distance but subject

to energy loss Operator error is less likely

Operator error is more likely Conversion of signal may

incur error depending on

Instantaneous representation sampling rate

of measured variable

Uses Binary Number system

ISA–The Instrumentation, Systems, and Automation Society

You might also like

- Instrumentation and Measurement in Electrical EngineeringFrom EverandInstrumentation and Measurement in Electrical EngineeringRating: 3.5 out of 5 stars3.5/5 (5)

- Condition Monitoring Comparison Guide April 2020 EditionDocument14 pagesCondition Monitoring Comparison Guide April 2020 Editionkikayi8209No ratings yet

- Maintenance Planning, Coordination, Scheduling and ExecutionDocument19 pagesMaintenance Planning, Coordination, Scheduling and ExecutionBayu Prayoga Part II100% (1)

- Electronic Diesel Control EDC 2001Document97 pagesElectronic Diesel Control EDC 2001MarioSt93% (57)

- Introduction To Marine AutomationDocument46 pagesIntroduction To Marine AutomationHarvey Zabala60% (5)

- Researchwork Daduya Instru&ControlEng'gDocument10 pagesResearchwork Daduya Instru&ControlEng'ganon_237673928No ratings yet

- Rocess Nstrumentation: Easurement andDocument33 pagesRocess Nstrumentation: Easurement andmulatuNo ratings yet

- ISA Handbook of Measurement, Equations and Tables, Second EditionFrom EverandISA Handbook of Measurement, Equations and Tables, Second EditionRating: 5 out of 5 stars5/5 (2)

- 1 - Introduction To Control Chapter OneDocument13 pages1 - Introduction To Control Chapter Onesythepaul24No ratings yet

- Door Sensor: (Submitted in Partial Fulfillment of The Requirement ForDocument21 pagesDoor Sensor: (Submitted in Partial Fulfillment of The Requirement ForAvinash VishwakarmaNo ratings yet

- History and Development: Instrumentation Is A Collective Term ForDocument5 pagesHistory and Development: Instrumentation Is A Collective Term ForewbNo ratings yet

- Measurements and InstrumentationDocument76 pagesMeasurements and InstrumentationAyyar KandasamyNo ratings yet

- Instrumentation Is Defined As The Art and Science of Measurement and Control of ProcessDocument4 pagesInstrumentation Is Defined As The Art and Science of Measurement and Control of Processriz2010No ratings yet

- InstrumentationDocument4 pagesInstrumentationfemidagsNo ratings yet

- Electrical SystemsDocument5 pagesElectrical SystemsJames HillNo ratings yet

- Instrumentation Calibration: 3Tstrisu"T!:I " Ti!I3 Document Is UnlimitedDocument37 pagesInstrumentation Calibration: 3Tstrisu"T!:I " Ti!I3 Document Is UnlimitedVăn ST QuangNo ratings yet

- Ec2351 Mi NotesDocument93 pagesEc2351 Mi NotesChaitu KumarNo ratings yet

- Syllabus UTU EE 8th Sem 2009-10Document12 pagesSyllabus UTU EE 8th Sem 2009-10Atul KumarNo ratings yet

- History and Development: Pre-IndustrialDocument2 pagesHistory and Development: Pre-IndustrialdrbstesbtabtbatNo ratings yet

- Introduction To Instrumentation and MeasurementsDocument29 pagesIntroduction To Instrumentation and MeasurementsSYAFIQAH ISMAILNo ratings yet

- Story of Vibration AnalysisDocument14 pagesStory of Vibration AnalysisCrusherjpNo ratings yet

- Inst CNTRLDocument214 pagesInst CNTRLsohaib_86No ratings yet

- Process Control Lab ManualDocument338 pagesProcess Control Lab ManualMichael Edwards75% (4)

- Idea Prese NtationDocument7 pagesIdea Prese NtationdrbstesbtabtbatNo ratings yet

- EEE - R2013-Elective SyllubuDocument11 pagesEEE - R2013-Elective SyllubuAuse ElNo ratings yet

- DSRSSTMKNDL 2Document27 pagesDSRSSTMKNDL 2Yesi Indri HeryaniNo ratings yet

- Lesson 1 Introducton To Industrial Electronics ApplicationDocument11 pagesLesson 1 Introducton To Industrial Electronics ApplicationEarl Patrick EugenioNo ratings yet

- Contains:-1. History of Sensor 3. USE 4. How Engineers Use Sensors To MeasureDocument10 pagesContains:-1. History of Sensor 3. USE 4. How Engineers Use Sensors To Measurecb237flx5705No ratings yet

- Measurements and Instrumentation Lecture NotesDocument199 pagesMeasurements and Instrumentation Lecture NotesGaurav Vaibhav100% (6)

- Introduction To Control SystemDocument33 pagesIntroduction To Control Systemmarina890416No ratings yet

- Resumen Ingenieria de ControlDocument5 pagesResumen Ingenieria de ControlIsaudRodriguezNo ratings yet

- ABCQ Metrology HandbookDocument15 pagesABCQ Metrology HandbookAntonio Melgaço da SilvaNo ratings yet

- NPTEL Phase II - Electrical Engineering - Industrial InstrumentationDocument2 pagesNPTEL Phase II - Electrical Engineering - Industrial InstrumentationAkshat Rastogi100% (1)

- Intro To SensorsDocument30 pagesIntro To SensorsPraneshNo ratings yet

- Fundamentals of RF and Microwave Measurements (Part 4) : AgilentDocument24 pagesFundamentals of RF and Microwave Measurements (Part 4) : AgilentaceofspadesNo ratings yet

- Introduction To Control SystemsDocument31 pagesIntroduction To Control SystemsDyan AngelicaNo ratings yet

- Chapter 01Document54 pagesChapter 01Şirin AdaNo ratings yet

- Ch1 Introduction To Control SystemsDocument10 pagesCh1 Introduction To Control SystemsNasiha MokhtaruddinNo ratings yet

- Hall-Effect Sensors: Theory and ApplicationFrom EverandHall-Effect Sensors: Theory and ApplicationRating: 5 out of 5 stars5/5 (1)

- Mechatronics AssignmentDocument60 pagesMechatronics Assignmentkavindya GeemaduNo ratings yet

- Control 2Document26 pagesControl 2Shawqi AssiNo ratings yet

- Chapter One by BKDocument43 pagesChapter One by BKAklilu AyeleNo ratings yet

- Bmtf183t60 Sensors and Actuators 1Document158 pagesBmtf183t60 Sensors and Actuators 1Ganagadhar CHNo ratings yet

- 1 Mechatronics - Control - DevicesDocument40 pages1 Mechatronics - Control - DevicesAdrian GCNo ratings yet

- Notes For Students 1 1Document58 pagesNotes For Students 1 1marryjohnopalla05No ratings yet

- Introduction To Process Control SystemDocument15 pagesIntroduction To Process Control Systembsme MEfreeNo ratings yet

- Measurement and Error ConceptsDocument5 pagesMeasurement and Error Conceptsbylehira21No ratings yet

- Regulation of The Liquid-Mass-Fraction of The Refrigerant Exiting An EvaporatorDocument175 pagesRegulation of The Liquid-Mass-Fraction of The Refrigerant Exiting An EvaporatorPeejay Baroña MaguelangNo ratings yet

- Name M.Imran Baig REG EE083050 Section 4 Subject Control System Lab Report 4 Submitted To Sir SohailDocument4 pagesName M.Imran Baig REG EE083050 Section 4 Subject Control System Lab Report 4 Submitted To Sir SohailMuhammad Imran BaigNo ratings yet

- John Mitchell PaperDocument14 pagesJohn Mitchell PaperCharles MatosNo ratings yet

- Measurement - WikipediaDocument53 pagesMeasurement - WikipediaBashiir NuurNo ratings yet

- Curs 1Document41 pagesCurs 1Marin DumanNo ratings yet

- Lesson PlanDocument8 pagesLesson PlanSheela RaviNo ratings yet

- Basics RoboticsDocument10 pagesBasics Roboticsrohit mittalNo ratings yet

- Instrumentation & Measurement SystemsDocument13 pagesInstrumentation & Measurement SystemsAnkit KumarNo ratings yet

- SCADA HistoryDocument16 pagesSCADA HistoryIsrael CarrilloNo ratings yet

- Experiment - 1: OBJECTIVE - Study and Demonstration of Mechatronic System and ItsDocument8 pagesExperiment - 1: OBJECTIVE - Study and Demonstration of Mechatronic System and ItshiteshNo ratings yet

- Automation in Mining, Mineral and Metal Processing: Proceedings of The 3Rd Ifac Symposium, Montreal, Canada 18-20 August 1980From EverandAutomation in Mining, Mineral and Metal Processing: Proceedings of The 3Rd Ifac Symposium, Montreal, Canada 18-20 August 1980J. O'SheaNo ratings yet

- Modelling and Control of Biotechnical Processes: Proceedings of the First IFAC Workshop, Helsinki, Finland, August 17-19, 1982From EverandModelling and Control of Biotechnical Processes: Proceedings of the First IFAC Workshop, Helsinki, Finland, August 17-19, 1982A. HalmeNo ratings yet

- Energy Autonomy of Batteryless and Wireless Embedded Systems: Aeronautical ApplicationsFrom EverandEnergy Autonomy of Batteryless and Wireless Embedded Systems: Aeronautical ApplicationsNo ratings yet

- Radio Control for Model Ships, Boats and AircraftFrom EverandRadio Control for Model Ships, Boats and AircraftRating: 5 out of 5 stars5/5 (1)

- Distributed Computer Control Systems 1981: Proceedings of the Third IFAC Workshop, Beijing, China, 15-17 August 1981From EverandDistributed Computer Control Systems 1981: Proceedings of the Third IFAC Workshop, Beijing, China, 15-17 August 1981No ratings yet

- 1FN19100AA000AA0 Datasheet en PDFDocument1 page1FN19100AA000AA0 Datasheet en PDFMira RedaNo ratings yet

- ZARA Supply ChainDocument32 pagesZARA Supply ChainM. Yasser100% (4)

- Production Planning and ControlDocument43 pagesProduction Planning and ControlAnurag SrivastavaNo ratings yet

- MultimeterDocument18 pagesMultimeterweb1_webteam100% (2)

- ZARA Supply ChainDocument32 pagesZARA Supply ChainM. Yasser100% (4)

- DHL Supply Chain StudyDocument11 pagesDHL Supply Chain StudySudeep D'SouzaNo ratings yet

- TB015-The Eight Step Preventive Maintenance ProgramDocument5 pagesTB015-The Eight Step Preventive Maintenance Programapi-3732848100% (5)

- Proposed Electrical ProjectDocument40 pagesProposed Electrical Projectjtparaon95% (21)

- Rohde Mike Sketchnote Workshop That Conference 2013 PDFDocument26 pagesRohde Mike Sketchnote Workshop That Conference 2013 PDFMira RedaNo ratings yet

- Servo Valve Coloring BookDocument18 pagesServo Valve Coloring BooksaikatmeNo ratings yet

- MaintenanceDocument9 pagesMaintenanceKumar GaneshNo ratings yet

- Pre Commissioning Manual PDFDocument44 pagesPre Commissioning Manual PDFMira Reda100% (2)

- Maintenance Planning and Scheduling PPT 2Document9 pagesMaintenance Planning and Scheduling PPT 2Sunday Paul100% (1)

- 00002Document55 pages00002Mónica CarriónNo ratings yet

- Automotive Electronics Vol 2 PDFDocument40 pagesAutomotive Electronics Vol 2 PDFMira RedaNo ratings yet

- 91 Flow Control Valves PDFDocument15 pages91 Flow Control Valves PDFMira RedaNo ratings yet

- Precommissioning Test FormatDocument72 pagesPrecommissioning Test FormatMahmod MohamedNo ratings yet

- Detailed Planning ProcessDocument18 pagesDetailed Planning ProcessBayu Prayoga Part II100% (1)

- Operation and Maintenance Best PracticesDocument215 pagesOperation and Maintenance Best Practicesbinunair_66100% (19)

- Automotive Microelectronics 2001Document93 pagesAutomotive Microelectronics 2001sayapopai100% (16)

- Automotive Electronics Vol 2 PDFDocument40 pagesAutomotive Electronics Vol 2 PDFMira RedaNo ratings yet

- Automotive Electronics 1Document108 pagesAutomotive Electronics 1Victor Balas89% (54)

- VW Harness Inspection and Repair PDFDocument42 pagesVW Harness Inspection and Repair PDFMira RedaNo ratings yet

- Engine Porting and PolishingDocument8 pagesEngine Porting and Polishingmoparman1100% (10)

- Automotive Electronics Part 3 PDFDocument40 pagesAutomotive Electronics Part 3 PDFMira RedaNo ratings yet

- Matlab TutorialDocument173 pagesMatlab TutorialSaurabh Tiwari100% (8)

- VW Harness Inspection and Repair PDFDocument42 pagesVW Harness Inspection and Repair PDFMira RedaNo ratings yet

- How To Read Wiring DiagramsDocument24 pagesHow To Read Wiring Diagramsagoudimies100% (7)

- DSPDocument5 pagesDSPKarishma SavNo ratings yet

- Datasheet Growatt MIC 3000 TL-XDocument2 pagesDatasheet Growatt MIC 3000 TL-XYongki Adi Pratama PutraNo ratings yet

- Datasheet PDFDocument3 pagesDatasheet PDFSamvel KhachatryanNo ratings yet

- Fault Detection ClassificationDocument210 pagesFault Detection ClassificationAnonymous GRb9L95LwzNo ratings yet

- Technical Data UM202 - UM203Document6 pagesTechnical Data UM202 - UM203Anonymous 8rb48tZSNo ratings yet

- LED ChaserDocument7 pagesLED ChaserMegan Skinner100% (1)

- Brochure Ref 670Document4 pagesBrochure Ref 670veerabossNo ratings yet

- DDE 1313 Digital Electronics 1 LODocument6 pagesDDE 1313 Digital Electronics 1 LOAhmad FadzlyNo ratings yet

- User Man Ita Adv Conf RepeDocument24 pagesUser Man Ita Adv Conf RepeFabio ComunettiNo ratings yet

- Altivar Process ATV600 - ATV630C31N4Document13 pagesAltivar Process ATV600 - ATV630C31N4Lester MuscaNo ratings yet

- Ehlers (CG Oscillator)Document4 pagesEhlers (CG Oscillator)seanunr100% (1)

- Resistive Transducer NotesDocument3 pagesResistive Transducer NotesqwertyNo ratings yet

- Lecture 16: Nodal/Mesh Analysis, Source Transformation: Lecturer: Dr. Vinita Vasudevan Scribe: Shashank ShekharDocument5 pagesLecture 16: Nodal/Mesh Analysis, Source Transformation: Lecturer: Dr. Vinita Vasudevan Scribe: Shashank ShekharAniruddha RoyNo ratings yet

- Tait Tm8100 Tm8200 Service ManualDocument620 pagesTait Tm8100 Tm8200 Service ManualJuan Carlos CancioNo ratings yet

- Ee Problem Solving PogiDocument123 pagesEe Problem Solving PogiJohn leeNo ratings yet

- 3m Peltor Communications Catalogue PDFDocument52 pages3m Peltor Communications Catalogue PDFRa UlNo ratings yet

- Standard 22 Compact GYRO COMPASS and Standard 22 GYRO COMPASSDocument54 pagesStandard 22 Compact GYRO COMPASS and Standard 22 GYRO COMPASSMojtaba TorkiNo ratings yet

- Aperture Coupled Fed Micro-Strip Patch AntennaDocument5 pagesAperture Coupled Fed Micro-Strip Patch AntennaemremiranNo ratings yet

- SBAS365710027ENR0Document24 pagesSBAS365710027ENR0Rizqi PerdanaNo ratings yet

- Drive Spares Old PDFDocument3 pagesDrive Spares Old PDFmiguel angel vanegas medinaNo ratings yet

- MIS February 2017Document4 pagesMIS February 2017Nayeem PashaNo ratings yet

- The Components of Computer SystemDocument54 pagesThe Components of Computer SystemMac John Teves Poblete100% (1)

- NRR-1 v3.0.0 User ManualDocument11 pagesNRR-1 v3.0.0 User ManualLuca De RosaNo ratings yet

- R1 6Ω R4 4Ω R5 6Ω V1 10 VDocument63 pagesR1 6Ω R4 4Ω R5 6Ω V1 10 Vď èNo ratings yet

- LA6541Document7 pagesLA6541Mango VerdeNo ratings yet

- Interfacing S1 - 568 S1 - 1068 To PowerDB-En - V01Document6 pagesInterfacing S1 - 568 S1 - 1068 To PowerDB-En - V01MIRCEA MIHAINo ratings yet

- 3 Transmission Line Modelling and PerformanceDocument22 pages3 Transmission Line Modelling and PerformanceDharamNo ratings yet

- SKIIP11NAB06Document4 pagesSKIIP11NAB06Cucu Catalin100% (1)