Professional Documents

Culture Documents

On Of: Optoelectronics Technology Research Laboratory (OTL) Tohkodai, Tsukuba, Ibaraki Japan

Uploaded by

Rajeev KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

On Of: Optoelectronics Technology Research Laboratory (OTL) Tohkodai, Tsukuba, Ibaraki Japan

Uploaded by

Rajeev KumarCopyright:

Available Formats

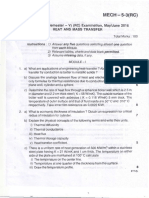

1:Npm - 2:mpm (Invited)

OMP5*l Scanning Tunneling Microscopy Observations of Molecular Beam Epitaxially Grown

Compound Semiconductor Surfaces

Shunsuke OHKOUCHI*and Nobuyuki IKOMA

Optoelectronics Technology Research Laboratory (OTL)

5-5 Tohkodai, Tsukuba, Ibaraki 300-26, Japan

With the advent of scanning tunneling microscopy (STM), it became possible to

observe individual atoms on the surfaces of semiconductors[l]. In this paper, we report on

the surface structures of compound semiconductor substrates, such as GaAs, InP and InAs,

and heteroepitaxially grown surfaces on these substrates, using a multi-chamber STM system

equipped with a molecular beam epitaxy (MBE) facility[2].

Figure 1 shows an STM image of an MBE grown GaAs (001) surface. This surface

shows a (2x4) reconstructed structure; that is, an ordered structure with about 1.6 nm

periodicity along the Ell01 direction and with about 0.8 nm periodicity along the [liO]

direction can be clearly observed. The STM images of an InP substrate thermally cleaned in

an arsenic flux at 510 "C showed a (4x2) reconstruction which depends on the thennal-

cleaning time. The surface structure of an InP substrate thus treated for 1 min showed a (4x2)

reconstructed structure comprising two In dimers and two missing dimers running in the [110]

direction (Fig. 2(a)). One of these In dimer rows desorbed by further annealing at the same

temperature in an arsenic flux. The STM image of the InP surface thermally cleaned for 3

min showed another (4x2) reconstructed structure, comprising one In dimer and three missing

dimers(Fig.2tb)). This structure was the same as that of InAs treated under the same

conditions (Fig.3(a)). This In-stabilized (4x2) reconstructed structure of an InAs surface

changed to an As-stabilized (2x4) reconstruction when the substrate temperature was lowered .

* below 480 "C (Fig. 3(b)). The feature of this (2x4) reconstructed structure is the same as that

of a GaAs surface.

Next, as examples of lattice-mismatched heteroepitaxy systems, heteroepitaxially

grown surfaces of GaAshnP, GaAsDnAs and vice versa were studied by STM. In these highly

lattice-mismatched systems, the growth-mode transition from two-dimensional (2D) to 3D

growth occurred during the initial stages. In the case of a GaAsbnP system, the growth-mode

transition occurred with more than 2.0 ML of GaAs deposition. 3D-islands were observed in

the STM image of a 2.5 ML GaAs-deposited surface (Fig. 4). In the case of a GaAsfinAs

system, the transition was confirmed for more than 0.75 ML of GaAs deposition. Figure 5

shows an STM image of a 1.0 ML GaAs-deposited InAs surface. On the other hand, in the

case of an InAs/GaAs system, 3D-island formation occurred when more than 1.8 ML of InAs

was deposited onto the GaAs surface. In the S T M image of a 2.0 ML InAs-deposited GaAs

surface, 3D-islands were observed (Fig. 6). Furthermore, when 2.0 ML of InAs was deposited

onto a GaAs vicinal surface tilted by 1" towards the [ l l O ] direction, 3D-islands were aligned

along the [ l i O ] direction (Fig. 7). That is, the island were selectively formed at steps running

relatively straight along the [liO] direction on the Ill01 tilted GaAs surface. These results

indicate the possibility of controlling the arrangement of InAs islands deposited on a surface

by controlling the step structure on the surface.

It was thus demonstrated that in-situ S T M observations are very useful for obtaining

atomic-scale information concerning MBE-grown compound semiconductor surfaces.

[l] G. Binnig et al.: Appl. Phys. Lett. 40 178 (1982).

[2] I. Tanaka et al.: J. Vac. Sci. & Technol. B9 2277 (1991).

*Present address: Opto-electronics Research Laboratories, NEC Corporation,

34 Miyukigaoka, Tsukuba, Ibaraki 305, Japan.

' 110

1.6nm

i.6nm

[iio]

Fig. 1: STM image of a GaAs Fig. 2: STM images of an Ine Fig. 3: STM images of an InAs

(2x4) reconstructed surface. surface thennall cleaned in an surface. (a) is the In-stabilized

arsenic flux. (a7 is an image (4x2) reconstructed surface; (b)

after 1 min in which the is the As-stabilized (2x4)

substrate temgerature was reconstructed surface.

raised to 510 C; (b) is an

image after 3 min.

Fig. 4: STM image of a 2.5 ML GaAs-deposited Fig. 5: STM image of a 1.0 ML GaAsdeposited

InP (001) surface. InAs (001) surface.

#ited J3d

GgAs (001) vicinal surface tilted by 1' towaids the

[1101 direction.

111

You might also like

- Simulation of The Structure and Stability of Sphalerite (ZNS) SurfacesDocument6 pagesSimulation of The Structure and Stability of Sphalerite (ZNS) Surfacesmauricio rojas alvarezNo ratings yet

- Ultrahigh vacuum scanning tunnelling microscopy studies of the decapped InAs quantum dots on GaAs(001) surface after desorption of a protective As layer (Surface and Interface Analysis, vol. 27, issue 5-6) (1999)Document4 pagesUltrahigh vacuum scanning tunnelling microscopy studies of the decapped InAs quantum dots on GaAs(001) surface after desorption of a protective As layer (Surface and Interface Analysis, vol. 27, issue 5-6) (1999)sepot24093No ratings yet

- Vol33 No3 633Document4 pagesVol33 No3 633juan davidNo ratings yet

- Lecture2 (Surface-Structure) 2022Document17 pagesLecture2 (Surface-Structure) 2022최종윤No ratings yet

- High-Cycle Fatigue Properties at Cryogenic Temperatures in INCONEL 718 Nickel-Based SuperalloyDocument4 pagesHigh-Cycle Fatigue Properties at Cryogenic Temperatures in INCONEL 718 Nickel-Based SuperalloyB Bala Venkata GaneshNo ratings yet

- SurfaceDocument11 pagesSurfaceXuân Giang NguyễnNo ratings yet

- 3ème Version CMSMDocument3 pages3ème Version CMSMKaouther KawtharNo ratings yet

- Effect of Deformation Twinning On Micro Structure and Texture Evolution During Cold Rolling of CP TitaniumDocument11 pagesEffect of Deformation Twinning On Micro Structure and Texture Evolution During Cold Rolling of CP TitaniumQi ChaoNo ratings yet

- J.C. Zhao, V. Ravikumar, A.M. Beltran, Met. Trans. A. Phase Precipitation and Phase Stability in Nimonic 263Document2 pagesJ.C. Zhao, V. Ravikumar, A.M. Beltran, Met. Trans. A. Phase Precipitation and Phase Stability in Nimonic 263Henry León HenaoNo ratings yet

- Growth and Structure of L1 Ordered Fept Films On Gaas (001) : Submitted To: J. Phys.: Condens. MatterDocument16 pagesGrowth and Structure of L1 Ordered Fept Films On Gaas (001) : Submitted To: J. Phys.: Condens. MatterarslansaeedarslanNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: FundamentalsFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: FundamentalsNo ratings yet

- The Effect of Cold Rolling Process On THDocument6 pagesThe Effect of Cold Rolling Process On THSrikanth SrikantiNo ratings yet

- The Precipitation of A1N and NBC and The Hot Ductility of Low Carbon SteelsDocument11 pagesThe Precipitation of A1N and NBC and The Hot Ductility of Low Carbon SteelsChanthar SoeNo ratings yet

- Safi ASS 12Document6 pagesSafi ASS 12Safiul MollickNo ratings yet

- A-33 Mmt31a11Document13 pagesA-33 Mmt31a11Syafri WardiNo ratings yet

- Deformation Mechanism Map of Cu/Nb Nanoscale Metallic Multilayers As A Function of Temperature and Layer ThicknessDocument20 pagesDeformation Mechanism Map of Cu/Nb Nanoscale Metallic Multilayers As A Function of Temperature and Layer ThicknessMiguel MonclusNo ratings yet

- Ame014 QPDocument3 pagesAme014 QPMech HodNo ratings yet

- An Efficient Way To Induce Recrystallization of Deformed Al0.1CoCrFeNiDocument3 pagesAn Efficient Way To Induce Recrystallization of Deformed Al0.1CoCrFeNi陳杰甫(Jeff)No ratings yet

- From Microstructure Investigations to Multiscale Modeling: Bridging the GapFrom EverandFrom Microstructure Investigations to Multiscale Modeling: Bridging the GapDelphine BrancherieNo ratings yet

- Aluminizing SiX, JMST (2009) 433Document4 pagesAluminizing SiX, JMST (2009) 433Marin RomeoNo ratings yet

- Microstructural Evolution of New Type Al ZN MG Cu Alloy With Er and ZR Additions During HomogenizationDocument7 pagesMicrostructural Evolution of New Type Al ZN MG Cu Alloy With Er and ZR Additions During HomogenizationMITUSHI AGRAWALNo ratings yet

- Dynamic Analysis of A Filtered Tailings Deposit With Simplified and Numerical Methods Felipe Rojas 1Document8 pagesDynamic Analysis of A Filtered Tailings Deposit With Simplified and Numerical Methods Felipe Rojas 1RICHARD SEBASTIAN CHAVEZ CASTRONo ratings yet

- Statistical Distributions of Fracture Strengths of Cast Al 7si MG AlloyDocument6 pagesStatistical Distributions of Fracture Strengths of Cast Al 7si MG AlloybbeeNo ratings yet

- Evolution of Texture and Microstructure During Accumulative Roll Bonding of Aluminum AA5086 AlloyDocument13 pagesEvolution of Texture and Microstructure During Accumulative Roll Bonding of Aluminum AA5086 AlloyAmel HalimiNo ratings yet

- Fatigue Behaviour of Boron Free and Boron Containing Heat Treated Ti-13Zr-13Nb Alloy For Biomedical ApplicationsDocument6 pagesFatigue Behaviour of Boron Free and Boron Containing Heat Treated Ti-13Zr-13Nb Alloy For Biomedical ApplicationsPramod KumarNo ratings yet

- VHCF Behavior of ASS 347, 904L With Different Surface Morphologies - Smaga2022 PDFDocument11 pagesVHCF Behavior of ASS 347, 904L With Different Surface Morphologies - Smaga2022 PDFMac NeryNo ratings yet

- CCL GD MeP 3Document14 pagesCCL GD MeP 3dgg3565No ratings yet

- Low Cycle Fatigue Behaviour of Nitrided Layer of 42crmo4 SteelDocument10 pagesLow Cycle Fatigue Behaviour of Nitrided Layer of 42crmo4 SteelkarimNo ratings yet

- Subduction Dynamics: From Mantle Flow to Mega DisastersFrom EverandSubduction Dynamics: From Mantle Flow to Mega DisastersGabriele MorraNo ratings yet

- 3te Bericht 05.03 EntwurfDocument23 pages3te Bericht 05.03 EntwurfmandbackNo ratings yet

- Effect of Surface Nanocrystallization On Fatigue Behavior of Pure TitaniumDocument9 pagesEffect of Surface Nanocrystallization On Fatigue Behavior of Pure TitaniumFrancoNo ratings yet

- Metallurgical Characterization of Electrical Discharge Textured Roll SurfaceDocument8 pagesMetallurgical Characterization of Electrical Discharge Textured Roll Surfacevishalbhojak vishalbhojakNo ratings yet

- Recrystallization Texture Development IN Commercial Al-Mn-Mg AlloysDocument23 pagesRecrystallization Texture Development IN Commercial Al-Mn-Mg AlloysRavinder JhorarNo ratings yet

- Investigation of Precipitation Behavior and Related Micro Structural and Mechanical Properties After FSP of Aluminum AlloyDocument5 pagesInvestigation of Precipitation Behavior and Related Micro Structural and Mechanical Properties After FSP of Aluminum AlloyiajerNo ratings yet

- Design and Analysis of Tubular Permanent Magnet Linear Generator For Small-Scale Wave Energy ConverterDocument16 pagesDesign and Analysis of Tubular Permanent Magnet Linear Generator For Small-Scale Wave Energy ConvertersyazanaNo ratings yet

- Heat Transfer July 2023Document8 pagesHeat Transfer July 2023arjunguttula11No ratings yet

- Development of Cube Recrystallization Texture in Strip Cast AA3004 Aluminium AlloyDocument9 pagesDevelopment of Cube Recrystallization Texture in Strip Cast AA3004 Aluminium AlloysuchchasinghNo ratings yet

- Applications of NanocompositesDocument5 pagesApplications of Nanocompositesjd_sweetuNo ratings yet

- Self-Standing Graphene Sheets Prepared With Chemical Vapor Deposition and Chemical EtchingDocument19 pagesSelf-Standing Graphene Sheets Prepared With Chemical Vapor Deposition and Chemical EtchingLuis Enrique Tlalpan RomeroNo ratings yet

- Gullapalli2020 Chapter EffectOfSoilStructureInteractiDocument10 pagesGullapalli2020 Chapter EffectOfSoilStructureInteractiManikanta SharmaNo ratings yet

- Behaviors and Persistence of Nanomaterials in Biomedical ApplicationsFrom EverandBehaviors and Persistence of Nanomaterials in Biomedical ApplicationsNo ratings yet

- Stability Analysis of Steep Nailed Slopes Under Seismic Condition Using 3-D Finite Element MethodDocument5 pagesStability Analysis of Steep Nailed Slopes Under Seismic Condition Using 3-D Finite Element Methodjacs127No ratings yet

- Crystal Structure Control of Au-Free Inas and Inas/Gasb Heterostucture Nanowires Grown On Si (111) by Metal-Organic Chemical Vapor DepositionDocument5 pagesCrystal Structure Control of Au-Free Inas and Inas/Gasb Heterostucture Nanowires Grown On Si (111) by Metal-Organic Chemical Vapor DepositionAnonymous jxm0WNS7QaNo ratings yet

- Rr210104 Surveying IDocument8 pagesRr210104 Surveying ISrinivasa Rao GNo ratings yet

- Srivastav A 2008Document5 pagesSrivastav A 2008FARID MIFTAHUL ANWARNo ratings yet

- MSM Ese 2020-1Document2 pagesMSM Ese 2020-1GuriNo ratings yet

- Galiyev ActaMat 2001Document9 pagesGaliyev ActaMat 2001Chandra ClarkNo ratings yet

- Effect of Domain Size On The Coercive Field of Orthorhombic (Li, K, Na) Nbo CeramicsDocument4 pagesEffect of Domain Size On The Coercive Field of Orthorhombic (Li, K, Na) Nbo CeramicsYasir AliNo ratings yet

- Chatelaine, Feb 2011Document4 pagesChatelaine, Feb 2011emediageNo ratings yet

- Austenite Grain Growth Calculation of 0.028% NB Steel: D. Priadi, R.A.M. Napitupulu and E.S. SiradjDocument11 pagesAustenite Grain Growth Calculation of 0.028% NB Steel: D. Priadi, R.A.M. Napitupulu and E.S. SiradjYlich SchmittNo ratings yet

- Heat and Mass Transfer June 2016 PDFDocument3 pagesHeat and Mass Transfer June 2016 PDFAshwin kumarNo ratings yet

- 1 s2.0 S0167577X20316244 MainDocument4 pages1 s2.0 S0167577X20316244 MainJianye XIAONo ratings yet

- Geography Revsion Booklet 12Document473 pagesGeography Revsion Booklet 12Ronald RomNo ratings yet

- CH 068Document8 pagesCH 068Cătălin CăpraruNo ratings yet

- Deformation Microstructure in (001) Single Crystal Strontium Titanate by Vickers IndentationDocument9 pagesDeformation Microstructure in (001) Single Crystal Strontium Titanate by Vickers Indentationkelsiu1No ratings yet

- Influence of Volume Percentage of NanoTiB2 Particles On Tribological &2017Document6 pagesInfluence of Volume Percentage of NanoTiB2 Particles On Tribological &2017Varun DuttaNo ratings yet

- Supporting Information: Carbon Nanotube Active Matrix Backplanes For Conformal ElectronicsDocument6 pagesSupporting Information: Carbon Nanotube Active Matrix Backplanes For Conformal ElectronicsRavi KakaniNo ratings yet

- C E1152 Pages: 2: Answer Any Two Full Questions, Each Carries 15 MarksDocument2 pagesC E1152 Pages: 2: Answer Any Two Full Questions, Each Carries 15 MarksirshadNo ratings yet

- Study of Dislocations in Znse and Zns by Scanning Force MicrosDocument8 pagesStudy of Dislocations in Znse and Zns by Scanning Force MicrosReuven BallabanNo ratings yet

- MRD-101 June 2016Document4 pagesMRD-101 June 2016Rajeev KumarNo ratings yet

- RDD-6 June 2016 PDFDocument6 pagesRDD-6 June 2016 PDFRajeev KumarNo ratings yet

- MOCVD Technology and Material GrowthDocument19 pagesMOCVD Technology and Material GrowthRajeev KumarNo ratings yet

- Clean Room Dos and DontsDocument2 pagesClean Room Dos and DontsRajeev KumarNo ratings yet

- Pune. Sir, We Are Keen Interested To Join The Workshop As It Would Give Us BrightDocument2 pagesPune. Sir, We Are Keen Interested To Join The Workshop As It Would Give Us BrightRajeev KumarNo ratings yet

- Detection of Faulty Semiconductor Wafers Using Dynamic Growing Self Organizing MapDocument6 pagesDetection of Faulty Semiconductor Wafers Using Dynamic Growing Self Organizing MapRajeev KumarNo ratings yet

- Kung University, Tainan,: Tuesday Afternoon QelsDocument2 pagesKung University, Tainan,: Tuesday Afternoon QelsRajeev KumarNo ratings yet

- Front Door GuardDocument2 pagesFront Door GuardmozammilNo ratings yet

- Pune - University - Vlsi Book - Study - Plan XeroxDocument4 pagesPune - University - Vlsi Book - Study - Plan Xeroxanshu4u06No ratings yet

- Top242 250 9213Document53 pagesTop242 250 9213Léo MineliNo ratings yet

- AutoreclosingDocument38 pagesAutoreclosingRK K100% (1)

- CommunicationsDocument6 pagesCommunicationsRaine LopezNo ratings yet

- Analog IC Layout Services 1v2Document14 pagesAnalog IC Layout Services 1v2KumarNo ratings yet

- Advantages of Computer-Based Processing (5 Files Merged)Document45 pagesAdvantages of Computer-Based Processing (5 Files Merged)Simple FunNo ratings yet

- 87 CT Class ExplanationDocument11 pages87 CT Class ExplanationdskymaximusNo ratings yet

- Application of Diodes Rectifier Circuits Clipper Circuits - PPT Video Online DownloadDocument7 pagesApplication of Diodes Rectifier Circuits Clipper Circuits - PPT Video Online DownloadAlejandroNo ratings yet

- S3 Electronic ComponentsDocument28 pagesS3 Electronic ComponentsChesley CarolinoNo ratings yet

- Half-Duplex RS-485/RS-422 Transceivers in DFN: General Description FeaturesDocument16 pagesHalf-Duplex RS-485/RS-422 Transceivers in DFN: General Description FeaturesNguyễn HoàngNo ratings yet

- Data Sheet Led 5mm RGBDocument3 pagesData Sheet Led 5mm RGBMuhammad Nuzul Nur مسلمNo ratings yet

- Assembly Features: Front ViewDocument4 pagesAssembly Features: Front ViewTaQuangDucNo ratings yet

- Makalah Bahasa Inggris: Disusun Oleh: Teknik ElektroDocument9 pagesMakalah Bahasa Inggris: Disusun Oleh: Teknik ElektroRandy 'Nara' IrawanNo ratings yet

- Chapter 3Document97 pagesChapter 3Mohamed NabilNo ratings yet

- DC To AC Converters PDFDocument4 pagesDC To AC Converters PDFrizwanNo ratings yet

- ECD Lab 03 MultisimDocument4 pagesECD Lab 03 Multisimahnaf abbasiNo ratings yet

- VarshaDocument46 pagesVarshavarshaNo ratings yet

- Syllabus 3Document34 pagesSyllabus 3Debiprasad PattnaikNo ratings yet

- Types of Automotive RelaysDocument5 pagesTypes of Automotive RelaysGopi Krishna100% (1)

- Voltage Control Gyanendra Sharma Npti DelhiDocument56 pagesVoltage Control Gyanendra Sharma Npti DelhiNPTINo ratings yet

- BibiDocument2 pagesBibijubin329No ratings yet

- Power DiodesDocument46 pagesPower DiodesJay R BallonNo ratings yet

- LICADocument184 pagesLICAgkk001No ratings yet

- Ceramic - WikipediaDocument67 pagesCeramic - WikipediasonymadridNo ratings yet

- BT7 Bio Tuner (Brain Tuner)Document5 pagesBT7 Bio Tuner (Brain Tuner)jaba2233No ratings yet

- Effect of Pulse Reverse Plating Using Silver On Printed Circuit BoardsDocument3 pagesEffect of Pulse Reverse Plating Using Silver On Printed Circuit Boards許家銘No ratings yet

- Uni Vs Bi Directional TVS Diode (On Semi)Document3 pagesUni Vs Bi Directional TVS Diode (On Semi)ShiguMiku TheyNo ratings yet

- Manual Adjustment Elex - 4FDocument54 pagesManual Adjustment Elex - 4FBagus Trilaksono100% (1)

- Tio2 Photocatalysis ThesisDocument7 pagesTio2 Photocatalysis Thesisicatryhig100% (2)