Professional Documents

Culture Documents

Analysis and Comparison of Biofilter Mod

Uploaded by

Maribel Bonite PeneyraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analysis and Comparison of Biofilter Mod

Uploaded by

Maribel Bonite PeneyraCopyright:

Available Formats

CHEMICAL -

ENGINEERING

JOURNAL

ELSEVIER The Chemical EngineeringJournal 65 ( 1997) 55-61

Analysis and comparison of biofilter models

S.M. Zarook *, A.A. Shaikh

Received29 November 1995; accepted4 March 1996

Abstract

Realistic mathematical models are essential for the scaling-up or the design of biofilters. However, the mathematical models which describe

the steady-state and the transient operation of biofilters are very limited. Although some of these models are based on restrictive assumptions,

they have been widely used in industry for designing actual biofilter units. This study gives detailed analysis and comparison between these

models. The asymptotic behavior of recent models are presented. The results show that diffusion is an important phenomenon which should

not be neglected in developing biofilter models, and that neglecting oxygen transport and its effects on growth kinetics will give unrealistic

values for the effective as well as the actual film thickness.

Keywords: Biofilters; Volatile organic compounds

1. Introduction article, we focus on the models of classical type of bio-

filters.

An intense effort on reducing VOC (volatile organic com- A number of experimental studies have demonstrated that

pound) emissions has led to the development of biofiltration the removal of VOCs in biofilters is feasible, e.g. [l-3].

technology which is an environmentally friendly and cost- However, research into the theoretical studies regarding biof-

effective method compared to other alternative technologies, ilter models is rather limited. The most widely used model is

such as incineration, activated carbon adsorption and chem- the work of Ottengraf [ I ] and Ottengraf and van den Oever

ical washing in packed-columns for the treatment of VOC [ 21. This model is based on the following simplifying

emissions. Biofiltration is a technology based on the biolog- assumptions: (i) Kinetics: two limiting cases, zero-order [ 21

ical oxidation of VOCs using micro-organisms which are and first-order [ I ] in the nutrient concentration, were con-

immobilized forming biofilms or biolayers around solid par- sidered. Implicitly, oxygen was assumed to be in excess, thus

ticles such as peat, compost, and a peat/perlite mixture. These oxygen limitation on kinetics was ignored. (ii) The biofilm

immobilized particles are packed in a column known as a thickness ( 6*) was assumed small compared to the diameter

biofilter. The VOC pollutants in the contaminated air that of the support particles and a constant value for the film

pass through the biolilter, which is also known as a vapor thickness was used throughout the reactor despite the changes

phase bioreactor, are transported into the biofilm by diffusion. in the VOC concentration along the biofilter column. (iii)

The biooxidation reactions take place in the biofilm. If the The transport of the nutrients into the biofilm is by diffusion.

residence time and the size of the biofilter are large enough (iv) Gas phase is in plug flow. Although this model is based

then the existing stream will be pollutant-free air which will on some rather simplistic assumptions, it has been widely

meet any acceptable regulatory standards, such as the EPA used because of the ease of obtaining analytical expressions

regulations on VOCs. There are three different types of biof- from the solution of the model. The simple analytical expres-

ilters and the term trickling biofilter or bioscrubber is used in sions have been used not only in validating laboratory-scale

cases where a recirculating water stream flows continuously experimental data but also in the actual design of pilot-scale

through the biofilter. Classical biofilters do not have a con- biofilter units. For example, van Lith et al. [4] developed

tinuous liquid stream. The required moisture is provided by design criteria based on this model and applied them in

saturating the airstream before it enters the biofilter, and/or designing actual biofilter units at Clair-Tech, theNetherlands.

by supplying liquid water occasionally as required. In this Similarly, Dharmavaram [ 51 of E.I. DuPont de Nemours &

Co., DE, USA, also reports design criteria based on this

* Correspondingauthor. model.

138%8947/97/$17.00 0 I997 Elsevier ScienceS A All rights reserved

PIIS1385.8947(96)03101-4

56 S.M. Zmook, A.A. Shaikh /The Chemicul Engmwing Journal 65 (I 997) 55-61

In a recent study, Zarook et al. [ 31 extended the work of 2. Theory and analysis

Ottengraf [ 21 and presented a detailed steady-state biofiltra-

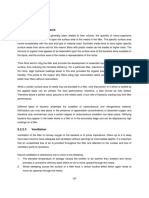

tion model for single VOCs. In this model: (i) The actual A steady-state biofiltration model constitutes a set of mass

kinetic expressions resulting from shake-flask experiments balances within the biofilm as shown in Fig. 1 and in the gas

were used instead of limiting cases such as zero- or first-order phase. The assumptions on which the model equations are

kinetics. (ii) Oxygen was also considered in the growth rate based are given in detail elsewhere [ 3,6]. Here, for compar-

expression, i.e. oxygen was not assumed to be in excess. (iii) ison purposes, we present the model equations for removal

The film thickness was not assumed to be constant throughout of a single VOC. The mass balance equations in the biofilm

the column and it was determined as the thickness of the are:

biolayer where one of the limiting substrates (either VOC or

oxygen) depletes before it reaches the biolayers/solid sup-

K xv

-y-/-4C,?GO) (1)

port interface. Model equations based on these improvements

Dz=

constituted a two point non-linear boundary value problem

for which analytical solutions were not possible. Since both D -~CIO= xv

u P(C,,Go) (2)

the models of Zarook et al. [ 31 and Ottengraf [ 1] and Otten- o dx’ o

graf and van den Oever [ 21 are valid for, steady-state, single with boundary conditions:

VOC removal, a detailed analysis and comparison between

these models are necessary and important so that the appro- c,= 2 and C,, = 59 at x=0 (3)

priate model can be used for the experimental validation of m m0

the models, and for designing or scaling-up of the biofilter

units. The major objective of the present study is to present dG Go

- =0 and - =0 atx=6 (4)

the results of the analysis and comparison between these dx dx

models. For biological systems, specific growth rate, II, has the

Ottengraf and van den Oever [2] have used the single form of either Monod-type kinetic dependence as given in

VOC biofiltration model to describe VOC mixture removal Eq. (5) or Andrews-type kinetic dependence as in Eq. (6),

in an additive sense. However, recent studies [6,7] have below.

shown that the degradation kinetics of mixed VOCs may be Monod kinetics:

significantly different. Baltizis and Zarook [ 61 have extended

their model to describe the biofiltration of VOC mixtures

under steady-state conditions. In their work, they took into

account competitive inhibition kinetics.

Andrews kinetics:

Biofiltration is a technology for treating VOC emissions.

The emission level is unlikely to be constant, thus biofilters

are more likely to operate under unsteady-state conditions.

However, theoretical studies on the transient performance of

biofilters are scarce. Deshusses and Dunn [ 71 reports a tran-

sient biofiltration model which is based on the assumption When oxygen also limits the biodegradation rate, then the

that oxygen is in excess and the kinetics are of the Michaelis- specific growth rate is given by an interactive model. In this

Menten or Monod type. For the VOCs considered, they exper- case Eqs. (5) and (6) need to be modified as follows.

imentally verified this assumption to be valid. Thus, this Interactive model from Monod kinetics:

model can be used only if oxygen is not limiting the process.

Recently, the steady-state model of Zarook et al. [3] was (7)

extended to describe the transient performance [ 81 of the

biofilters. This model took into account the adsorption phe- Interactive model from Andrews kinetics:

nomena as well as the reaction and mass transfer of both the

oxygen and VOC. While all the steady-state and transient

biofiltration models [ l-36-81 are based on the assumption

that substrates are transported into the biofilm through dif-

fusion, the very recent transient model of Hodge and Devinny

[9] treats the biofilm and the solid as a single phase, thus

diffusion in the biofilm and details of the adsorption process

are ignored. Furthermore, this model is also based on the

assumption of first-order kinetics for biodegradation rate and

of excess oxygen. Asymptotic behavior studies and a com-

parison between several model discussed above are also pre- X- 0 6 8

sented in this work. Fig. 1, Biofilm concept of the biofilter.

SM. Zurook. A.A. Shnikh /The Chemical Engineering Journal 65 (1997) 5541 51

to the model of Ottengraf [ 1] and Ottengraf and van den

(8) Oever [2].

2.2. Limiting cases

Along the biofilter column, mass balances in the gas phase

are:

2.2. I. Zero-order kinetics (diffusion limitation and reaction

limitation)

(9) When the biodegradation rate is assumed to be zero-order,

ug s

dh

=A,D, -

Go

I 1 dx X=0

one can clearly identify two regimes of operation: diffusion

limited and reaction limited regimes. In the diffusion limited

regime, the rate of diffusion is slow compared to the VOC

utilization rate in the biofilm [ 21. Ottengraf and van den

with initial conditions Oever [ 21 showed that the effective biofilm thickness for this

C, = C,, and C,o = Cso, at h = 0 region is given by

(11)

2Dc,

S= (17)

2.1 Asymptotic behavior of the model km

Here, one should be aware that equation 17 is based on the

Ottengraf and van den Oever [ 21 implicitly assume that assumption that the VOC gets completely consumed in a

oxygen is in excess and it does not exert any limitation on portion of the actual biofilm thickness. However, if oxygen

the biodegradation rate. In general, the biodegradation rate in is limiting then the effective biofilm thickness calculated

the biofilm can be expressed as using Eq. (17) may be invalid. The concentration profile

X” along the biofiltei for zero-order kinetics for the diffusion

--r= -P (12) limited regime is given by [ 21

Y

Although the authors [ 21 acknowledge that based on shake- (18)

flask experiments the biodegradation kinetics of single VOCs

follow the Monod model (Eq. (5) ) , they only consider two

In the reaction limited regime, the total biofilm is fully

limiting cases. At high concentrations they assumezero-order

active. For this case, the concentration profile in the gas phase

kinetics while at low concentration they assume first-order

is given by [ 21

kinetics. Thus, in the excess oxygen limitation (C,o B Ko)

for a large value of C,o, Eq. (7) gives a zero-order reaction

rate as,

(C,BK)

where 6* is the actual biofilm thickness

Similarly, a first-order reaction rate is given by 2.2.2. First-order kinetics

If the degradation rate is assumed to be first-order, one can

(C,eK) (14) not clearly distinguish between reaction and diffusion limited

regimes as in the zero-order case. This can be easily shown

Hence, for zero- and first-order kinetics, under no oxygen from the concentration profiles in the biofilm [ 11. For the

limitation, the biofilm side model equations are given as first-order case, the gas phase concentration profile is given

1121: by

C hASD+ tan 4

0% =k (15) A =exp - (20)

d? ” C,l 6*mu, >

where 4 is known as Thiele modulus [ 1,3] which is defined

as:

(16) -

Since oxygen was assumed to be in excess, boundary con-

ditions 3 and 4, involving C,, and Cso will not be necessary.

Similarly, under this condition, one needs only Eqs. (9) and Thiele modulus represents the ratio of biodegradation rate to

( 11) (C, = C,, at h = 0) for the gas phase side. Thus, the diffusion rate. From the value of the Thiele modulus one may

model equations of Zarook et al. [ 31 asymptotically reduce be able to distinguish the regimes of operation.

3. Results and discussion

For analysis and comparison of the models of Ottengraf

[ I] and Ottengraf and van den Oever [ 21 against the model

of Zarook et al. [ 31, steady-state experimental biofiltration

data published earlier [ 3 ] can be used. Analytical solutions

to the model (Eqs. ( 1)-( 11)) is not possible, hence the

model equations have been solved numerically. Parameters

needed to solve the model equations were more realistically

estimated and details of the methods and the solution proce-

dure were given elsewhere [ 31. It should be mentioned that

except for the parameter A,, all other parameters were found

experimentally or from the literature. The parameter As was

found as the value which minimized the sum of the squares

of the error between the experimental and the model predicted

concentrations. This value was unchanged and used to predict

the other experimental data. The first four entries of Table 1

were used for finding the parameter As and the last three

entries were used for predicting. In columns 2, 3 and 4 of

Table 1, superficial velocity, inlet concentration and volume

of packing are given, respectively. Results are given in terms

of the experimental and model predicted removal rates (col-

umn 5 and 6). Percentage error (E) is based on the experi-

mental values and it is given in column 7. Removal rate, also

known as elimination capacity, is defined as the amount of

VOC removed (gram) per volume ( m3) of packing material

per time (h). For the model of Zarook et al. [ 31, percentage

error (E) between the model predicted and experimentally

evaluated removal rates is given in column 7. Furthermore,

all the percentage errors (E, EDL, ERL and Eli& reported in

Table 1 are calculated in relation to the experimental values

given in column 5. Details of the experimental procedure

were reported elsewhere [ 31. The model predicted concen-

tration profiles along the biofilter column as well as the

removal rates were in excellent agreement with the experi-

mental data [3]. Furthermore, the results also showed that

the effective film thickness estimated did not exceed 110 pm.

Following the same procedure as discussed in [ 31, we have

estimated the biolayer surface area, A,, through Eq. ( 18) in

combination with Eq. ( 13) for the case of zero-order kinetics

in the diffusion limited regimes. This parameter was found

to be 246.8 m’ rnm3. However, Zarook et al. [ 31 report a

value of 85.15 m2 m-3. Thus, the zero-order (diffusion lim-

ited) model predicts a three times larger value. Furthermore,

the effective film thickness estimated through Eq. ( 17)

ranges from 17OtS8800 pm. It should be mentioned that the

particle size used in the experiments [ 31 averages about4000

pm. Thus, the assumption of planner geometry for biofilm

side is questionable, if one assumes zero-order kinetics

instead of actual kinetics. The film thickness evaluated

through Eq. (17) is based on the depletion of VOC only. If

oxygen is also assumed to be a limiting compound, then a

more realistic value for the film thickness would have been

obtained. Fig. 2 shows the concentration profiles in the biof-

ilm as predicted by Zarook et al. [ 31. In this case, one can

see that it is oxygen that determines the value of 6 and not

the VOC. In columns 8 and 9 of Table 1, the removal rates

S.M. .&rook. A.A Shaikh /The Chemrcul Engineering Journul65 (1997) 5541 59

Go@p=) Cl UP-) values are very large and unrealistic. Also this model is based

107 J- 2000 on the assumption of a constant film thickness along the

biofilter. Furthermore, from Eq. (19), one can easily show

that the removal rate is given by A,6*k,. Thus, despite the

changes in the inlet concentration and flow rates, one gets

6.

constant removal rates (R,cm.RL) as shown in column 10 of

Table 1. The maximum percentage difference ( ERLin column

-1000

11) is as high as 67.7%.

4-

When the kinetics are assumed to be first-order, then one

can not clearly distinguish between different regimes. For

- 500

2- this case, an analytical solution was possible and it is given

in Eq. (20). The first-order reaction rate constant was esti-

01

mated through Eq. (14). As in the previous case, we have

0 5 10 ls 20 25 30 two parameters As and 6* which need to be found. However,

5 (w) as seen from Eq. (20)) here we can not lump (ASS*) simply

Fig. 2. Concentration profiles of oxygen and VOC in the biofilm at a pattic- as in the previous case. In order to find this parameter, Eq.

ular location in the biofilter. (20) is expanded using the Taylor series as follows

(Rrero.DL) and percentage errors ( EDL) calculated based on AsS*3k,

the zero-order (diffusion limited) model are given, respec- + ~

30

tively. The percentage errors of this model given in column

9 are larger compared to the percentage errors given in col-

(22)

umn 7. The removal rate is calculated based on the inlet and

exit concentrations. In Fig. 3, the intermediate as well as the

exit concentrations predicted by both models are compared When neglecting higher order terms one can write Eq. (22)

against the experimental values. In this case, the prediction as

by the zero-order model is not in good agreement ascompared

to the model of Zarook et al. [ 31. 2 zexp{- y} (23)

For the case of zero-order kinetics under a reaction limited

regime, as seen from Eq. ( 19)) we need to estimate As (bio-

layer surface area per reactor volume) and 6* (actual film Now as in the previous case, (ASS*) was found by fitting to

thickness). The actual film thickness is very difficult to esti- four sets of data. The value was found to be 0.38 which is

mate or measure experimentally and it varies along the biof- exactly l/4 of the value that we found for the case of zero-

ilter. Hence for this case, the combined parameter (A,6*) is order kinetics. Thus, the actual film thickness ( S*) was found

fitted to the first four data sets. Once the value was deter- to be 1.5 or 4.5 mm depending on the value used for As.

mined, then the same parameter was used to predict the other Although the lower value for A, seems to be reasonable, the

sets. The combined parameter was found to be 1.52. If one removal rates (R& calculated using this model (given in

uses a value 85.15 or 246.8 m2 m ’ for As. then S* will be 6 column 12) show that in almost all cases,the agreement with

the experimental data is poor. This can be easily seen from

or 18 mm, respectively. For an actual film thickness, these

the percentage errors (Z&J given in column 13.

A direct comparison of the model of Hodge and Devinny

cg/cgi

[ 91 is not possible as they ignore the diffusion phenomenon

1

Ottengraf and van den Oever [2]

in the biotilm. The ratio of [A,6*m] in Eq. (23) can be easily

~ &rook et al. [3]

written as [AsG*C,Cg] which is the ratio of mass of VOC in

A Experiment [3] the biofiim to the mass of VOC in the air. A symbol k, is

given for this term in Hodge and Devinny’s [ 91 work. Thus,

it is interesting to note that in the limit, their model and the

model of Ottengraf [ 1] for the case of first-order kinetics are

identical. When neglecting higher order terms in Eq. (22),

the diffusivity terms get canceled out, thus the diffusion phe-

nomenon is ignored. It is needless to state that the results of

the comparison that we made for the case of first-order model

0

of Ottengraf [ 1J is also valid for this case. A more elaborate

0 0.2 0.4 0.6 0.8 1 analysis can be made through the notion of Thiele modulus

h/H and the effectiveness factor which is defined as the ratio of

Fig. 3. Comparison of biofilter models with the experimental data. actual rate of reaction to the rate of reaction that would result

60 S.M. Zarook. A.A. Shaikh /The Chemical Engineering Journal 65 (1997) 5541

I.5 -

l-

0.5 -

^ ^_ I 0,.

U.U5 U5 5

0 0.25

0 dimensianleYGheight (hG5

Fig. 4. Effectiveness factor versus Thiele modulus alongthe biofiltercolumn. Fig. 5 Effectiveness factor versus dimensionless height along the biofilter

Curves 1, 2, 3 and 4 are for first four sets of data given m Table I. column. The curve is for the data set 7 given in Table 1.

if the entire biofilm was exposed to the concentration at the 4. Conclusion

gas/biofilm interface. Zarook et al. [3] and Zarook and

Baltzis [ 81 define the Thiele modulus as

In this work, models of Ottengraf [ l] and Ottengraf and

van den Oever [ 21 have been compared against the model of

(24) Zarook et al. [ 31. The results indicate that the effective film

thickness calculated for zero-order kinetics under diffusion

and effectiveness factor as limited regimes is larger than the particle size used. This large

value contradicts the assumption of planner geometry. Sim-

ilarly, the zero-order reaction limited model predicts unreal-

istically large values for the actual film thickness and that the

(25)

?-I= 8X” removal rates calculated from it are the same for all the seven

y [ (G.Go)l,=o sets of data. This is not in agreement with the experimental

data. The first-order reaction kinetic model shows the highest

Model Eqs. ( 1)-( 4) related to mass balances in the biofilm, percentage deviation between the model predicted and the

and Eq. (9)-( 11) related to the mass balances in the gas experimentally found removal rates. The results also show

phase along with the growth rate expression (Eq. (S) ) have that one can not simply assume that oxygen is in excess, thus

been solved numerically. The effectiveness factor and Thiele the transport of oxygen as well as its limitation on growth

modulus are found using Eqs. (24) and (25), respectively. kinetics should be considered so that meaningful results can

The effectiveness factor versus Thiele modulus along the be obtained.

column are plotted on a log-log scale as shown in Fig. 4. The effectiveness factor calculations have shown that dif-

Curves 1, 2, 3 and 4 are for the first 4 sets of data given in fusion is a very important phenomenon which should not be

Table 1. Fig. 4 shows that when Thiele modulus is large neglected when modeling the biofiltration process. It is also

(4 > 5 ) , the effectiveness factor 77can be as low as 0.15. shown that the limit the Zarook et al.1~ model [ 31 asymptot-

Thus, a low value for 7) implies that the rate of diffusion is ically reaches all other models when oxygen is assumed to

slow as compared to the biodegradation rate, and diffusion be in excess, kinetics are of simple type and of constant film

may control the overall process. The same observation was thickness. In summary, careful consideration should be given

found for experimental data sets 5 and 6 of Table 1. However, to the choice of the biofilter model and the assumptions on

for data set 7, the effectiveness factor along the bed increased which these biofilter models are based for the purpose of

to a value of 1.7 at the exit of the biofilter column as shown validating experimental data or designing or scaling-up of

in Fig. 5. Since the biofilm thickness (6) varies along the biofilters.

biofilter column, due to consumption of VOC of oxygen, the

Thiele modulus and the effectiveness factor will vary with F

for the same inlet concentration of VOC to the biofilter. Thus,

from the inlet to the exit of the biofilter, the overall process Acknowledgments

may vary from diffusion control to reaction control regimes

or vice versa. The results clearly show that diffusion is an The authors are grateful to King Fahd University of Petro-

important phenomenon in the biofiltration process which leum and Minerals for the support of this work. One of the

should not be neglected. authors (SMZ) is grateful to Professor B.C. Baltzis of New

S.M. .&rook. A.A. Shaikh /The Chermcul Engmeering Journal 65 (1997) 5561 61

Jersey Institute of Technology (NJIT), USA, for invaluable X” biofilm density defined as the dry weight of cell

advice on biofiltration research and his excellent teaching. per volume of biofilm

Y amount of biomass produced per amount of VOC

consumed

Appendix A: Nomenclature yo amount of biomass produced per amount of oxy-

gen consumed

AS biolayer surface area per unit volume of biofilter

C6 concentration of VOC in the gas phase at a height, Greek letters

h, along the column

C6, concentration of VOC at the entrance of the active biofilm thickness as shown in Fig. 1

biofilter actual biofilm thickness as shown in Fig. 1

C60 concentration of oxygen in the gas phase at a effectiveness factor as defined by Eq. (25)

height, h, along the column specific growth rate of the biomass on VOC

C601 concentration of oxygen at the entrance of the the maximum specific growth rate in Eqs. (5)

biofilter and (7)

Cl concentration of VOC at a position x in the kinetic constant in Eq. (6)

biofilm Thiele modulus as defined by Eq. (2 I )

CIO concentrations of oxygen at a position x in the

biofilm Subscripts

D effective diffusion coefficient of VOC in the

biofilm DL diffusion limited

Do effective diffusion coefficient of oxygen in the i entrance conditions at h = 0

biofilm g gas phase

E percentage error between model predicted and 1 liquid phase

experimentally evaluated removal rates RL reaction limited

h height of the biofilter at any point

ko zero-order reaction rate constant

k, first-order reaction rate constant References

km ratio of mass of VOC in the biofilm to mass of

[ I] S.P.P. Ottengraf, in W. Shonbom (ed.), Biotechnology, Vol. 8 VCH,

VOC in the gas phase as defined in Ref. [ 91 Weinheim. 1986, p. 425.

K kinetic constant in Eqs. (5) and (6) [2] S.P.P. Ottengraf and A.H.C. van den Oever. Biofechnd Bioeng., 25

Ko kinetic constant in Eqs. (7) and (8) (1983) 3089.

KI kinetic constant in Eq. (6) [ 31 S.M. Zarook, B.C. Bahzis, Y.-S. Oh and R. Bartha, Biorechnol. Bioeng.,

m air/biofilm distribution coefficient for the VOC 41 (1993) 512.

[4] C. van Lith, S.L. David and R. Marsh, Truns. IChemE., 68 ( 1990) 127.

as dictated by Henry’s law [ 51 S. Dharmavaram, in Proceedings of the 84th Annual A&WMA Meeting,

m0 air/biofilm distribution coefficient for the oxy- Paper No. 91-103.2, Vancouver, B.C., June 1621. 1991.

gen as dictated by Henry’s law [6] B.C. Baltzis and SM. Zarook, in Proceedings of the 86th Annual

-r biodegradation reaction rate A&WMA Meeting, Paper No. 93-TP-52A.03, Denver, CO, 13-18 June,

R removal rate defined as the mass of VOC 1993.

[7] M.A. Deshusses and I.J. Dunn, in Proceedings of the 6th European

removed per volume of packing per time Congress on Biotechnology, Florence. 13-17 June, 1993.

% superficial velocity of the air stream [ 8 ] SM. Zarook and B.C. Bahzis, Chem. Eng. Sci.. 49 (24A) ( 1994) 4347.

X distance in the biofilm [9] D.S. Hodgeand J.S. Devinny.J. Env. Eng., 12 (1) (1995) 21.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Cocktail RecipesDocument39 pagesCocktail RecipesMão Direita100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Ra 10915 (Phil Agicultural & Biosystems Eng'g Act of 2016Document34 pagesRa 10915 (Phil Agicultural & Biosystems Eng'g Act of 2016almorsNo ratings yet

- Hydrology Principles Analysis DesignDocument477 pagesHydrology Principles Analysis DesignCarel De Jager81% (16)

- Government Procurement Reform Act SummaryDocument24 pagesGovernment Procurement Reform Act SummaryAnonymous Q0KzFR2i0% (1)

- Term Exam Me2aDocument3 pagesTerm Exam Me2aJonathan Ampis67% (3)

- Cocolife HealthCare Schemes & Medical BenefitsDocument7 pagesCocolife HealthCare Schemes & Medical BenefitsMaribel Bonite Peneyra0% (1)

- Ozonation and UV Disinfection for Aquaculture Water TreatmentDocument62 pagesOzonation and UV Disinfection for Aquaculture Water Treatmentraju1559405No ratings yet

- Honda BreakerDocument5 pagesHonda BreakerMaribel Bonite PeneyraNo ratings yet

- Essential Rendering OperationsDocument21 pagesEssential Rendering OperationsMauricio GuanellaNo ratings yet

- Biological Wastwwater TreatmentDocument35 pagesBiological Wastwwater TreatmentAG-Metal /Tretman Otpadnih Voda/Wastewater Treatment100% (2)

- Biological Filters For AquacultureDocument16 pagesBiological Filters For AquacultureAdi SucandraNo ratings yet

- A Passion For SoulsDocument1 pageA Passion For SoulsJonathan MalabananNo ratings yet

- Ra 10601 Bsa PDFDocument11 pagesRa 10601 Bsa PDFRonalie DavaNo ratings yet

- A New Name in GloryDocument6 pagesA New Name in GloryMaribel Bonite PeneyraNo ratings yet

- Modernizing Philippine Agriculture and Fisheries Through the Agriculture and Fisheries Modernization ActDocument57 pagesModernizing Philippine Agriculture and Fisheries Through the Agriculture and Fisheries Modernization ActMaribel Bonite PeneyraNo ratings yet

- How To Read A Topographic Map and Delineate A WatershedDocument4 pagesHow To Read A Topographic Map and Delineate A Watershedjojox123No ratings yet

- Cce Form - FinalDocument12 pagesCce Form - FinalMaribel Bonite PeneyraNo ratings yet

- NBC 461 Guidelines CCE and QCEDocument83 pagesNBC 461 Guidelines CCE and QCEjun del rosario100% (3)

- Pota-AssiumDocument14 pagesPota-AssiumMaribel Bonite PeneyraNo ratings yet

- Final Candle Paper PDFDocument15 pagesFinal Candle Paper PDFMaribel Bonite PeneyraNo ratings yet

- BSP Needs Assessment FormDocument1 pageBSP Needs Assessment FormMaribel Bonite PeneyraNo ratings yet

- Parametric and Non-Parametric Analysis in Socio-Economics Research Using STATA For BNAC PersonnelDocument1 pageParametric and Non-Parametric Analysis in Socio-Economics Research Using STATA For BNAC PersonnelMaribel Bonite PeneyraNo ratings yet

- Stage-Discharge Relation PDFDocument32 pagesStage-Discharge Relation PDFAnonymous 1n5HpBjNo ratings yet

- Small Capacity BiomassDocument9 pagesSmall Capacity BiomassMaribel Bonite PeneyraNo ratings yet

- NBC 461Document26 pagesNBC 461Rene FernandoNo ratings yet

- Training On STAR Topical OutlineDocument1 pageTraining On STAR Topical OutlineMaribel Bonite PeneyraNo ratings yet

- Evaluation of Full-Scale Biofilter MediaDocument7 pagesEvaluation of Full-Scale Biofilter MediaMaribel Bonite PeneyraNo ratings yet

- 2019UndergApp PDFDocument6 pages2019UndergApp PDFMaribel Bonite PeneyraNo ratings yet

- MUST Faculty Manual 06.18.14 PhotosDocument76 pagesMUST Faculty Manual 06.18.14 PhotosMaribel Bonite PeneyraNo ratings yet

- Training On STAR Topical OutlineDocument1 pageTraining On STAR Topical OutlineMaribel Bonite PeneyraNo ratings yet

- Curriculum SUMMARYDocument3 pagesCurriculum SUMMARYMaribel Bonite PeneyraNo ratings yet

- Egg DietDocument1 pageEgg DietMaribel Bonite PeneyraNo ratings yet

- Low-Density Culture of Red Abalone Juven PDFDocument8 pagesLow-Density Culture of Red Abalone Juven PDFMaribel Bonite PeneyraNo ratings yet

- Microbial Bioremediation and Bioreactor Design PDFDocument20 pagesMicrobial Bioremediation and Bioreactor Design PDFLISETH JOHANA CHACON MOLINANo ratings yet

- A Comparison of An Organic Biofilter and An Inorganic Biofilter For The Treatment of Residual Odors Emanating From A Biosolids de Watering FacilityDocument19 pagesA Comparison of An Organic Biofilter and An Inorganic Biofilter For The Treatment of Residual Odors Emanating From A Biosolids de Watering FacilityRahmi ArslanNo ratings yet

- Design Manual For Small Wastewater Works 2009-4Document73 pagesDesign Manual For Small Wastewater Works 2009-4VichekaNo ratings yet

- Aquaponics Journal 10 GuidelinesDocument4 pagesAquaponics Journal 10 GuidelinesJesus Jimenez SaenzNo ratings yet

- Degremont WTP MBRDocument29 pagesDegremont WTP MBRCHIN FelleNo ratings yet

- BioscrubberDocument4 pagesBioscrubberApoorv Goel100% (1)

- Inventarisasi Mikroalga Dan Protozoa Pada Instalansi Pengolahan Air Limbah Karet Sistem Biofilter Skala LaboratoriumDocument7 pagesInventarisasi Mikroalga Dan Protozoa Pada Instalansi Pengolahan Air Limbah Karet Sistem Biofilter Skala LaboratoriumAqil RafliNo ratings yet

- Greywater Pollution and Its Treatment in MalaysiaDocument3 pagesGreywater Pollution and Its Treatment in MalaysiaamirafatinNo ratings yet

- Summary: THE INTEGRATED AQUACULTURE-VEGETABLE PRODUCTION SYSTEMDocument10 pagesSummary: THE INTEGRATED AQUACULTURE-VEGETABLE PRODUCTION SYSTEMAquaponicsNo ratings yet

- Odour Emission Factors For Assessment and PredictionDocument7 pagesOdour Emission Factors For Assessment and PredictiondiscolettoNo ratings yet

- Handbook About PUDocument181 pagesHandbook About PUMayara OliveiraNo ratings yet

- Bio-Oxidation - A TechnologyDocument17 pagesBio-Oxidation - A Technologyshankhey bhagwatNo ratings yet

- Research Graduate 4Document48 pagesResearch Graduate 4Allen ChristianNo ratings yet

- Critical Review of Technologies To Eliminate Methane Emissions in Alberta Oil and Gas Industry - Final ReportDocument21 pagesCritical Review of Technologies To Eliminate Methane Emissions in Alberta Oil and Gas Industry - Final Reportnavid parsaNo ratings yet

- EPA (2001) Odour Impacts and Odour Emission Control Measures For Intensive AgricultureDocument145 pagesEPA (2001) Odour Impacts and Odour Emission Control Measures For Intensive AgricultureFiochra FinnNo ratings yet

- Biotechnology Applications in Hazardous Waste Treatment - DuphaneDocument13 pagesBiotechnology Applications in Hazardous Waste Treatment - DuphaneAlejandro Castro YaruroNo ratings yet

- Hargreaves USSEC Wastewater Treatment Tech - Compatibility ModeDocument10 pagesHargreaves USSEC Wastewater Treatment Tech - Compatibility ModeDiel MichNo ratings yet

- Chitosan Filtration PDFDocument48 pagesChitosan Filtration PDFHery MursitoNo ratings yet

- Optimized Fluidized S PDFDocument13 pagesOptimized Fluidized S PDFPoseidonNo ratings yet

- Biofilter System For Air Pollution Control: A ReviewDocument8 pagesBiofilter System For Air Pollution Control: A ReviewAdeeb ParkarNo ratings yet

- Recirculating Aquaculture: Tank Production Systems: A Review of Current Design PracticeDocument24 pagesRecirculating Aquaculture: Tank Production Systems: A Review of Current Design Practiceshuvatheduva123123123No ratings yet

- Biofiltration-Nitrification Design PDFDocument54 pagesBiofiltration-Nitrification Design PDFBokJrNo ratings yet

- Water Chemistry and Pretreatment Biological Fouling PreventionDocument3 pagesWater Chemistry and Pretreatment Biological Fouling PreventionAbdiel AlonsoNo ratings yet

- 9 Module9 Disinfection 29-03 2022 LFPDocument27 pages9 Module9 Disinfection 29-03 2022 LFPArjun RanabhatNo ratings yet

- 10 - Filtration - IndustrialDocument8 pages10 - Filtration - IndustrialMilenko TulencicNo ratings yet

- Review of Related LiteratureDocument7 pagesReview of Related LiteraturePrincess CabardoNo ratings yet