Professional Documents

Culture Documents

Manual Regulador de Velocidade Gac Esd 5111 PDF

Uploaded by

Gugui68Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Regulador de Velocidade Gac Esd 5111 PDF

Uploaded by

Gugui68Copyright:

Available Formats

ENGINE G OVERNORS

GOVERNING ESD5100 Series A MERICA

SYSTEM Speed Control Unit C ORP. ®

• Simple Installation and Adjustment • Auxiliary Accessory Input

• Isochronous, Droop, & Variable Speed Operation • 10 Amp Drive Circuit

• Adjustable PID • Inputs for Accessories

• Idle Speed Circuit

Introduction

The ESD5100 Series electronic speed device is designed

to control engine speed with fast and precise response to

transient load changes. This closed loop control, when con-

nected to a proportional electric actuator and supplied with

a magnetic speed sensor signal, will control a wide variety

of engines in an isochronous or droop mode. It is designed

for high reliability and built ruggedly to withstand the engine

environment.

Simplicity of installation and adjustment was foremost in the

design. Non-interacting performance controls allow near op-

timum response to be easily obtained.

Other features include adjustable droop and idle operation,

inputs for accessories used in multi-engine or special appli-

cations, protection against reverse battery voltage, transient

voltages, accidental short circuit of the actuator and fail safe

design in the event of loss of speed sensor signal or battery

supply. with the speed adjust set point input. The speed range has

a ratio of 9:1 and is adjusted with by the 25-turn SPEED po-

DESCRIPTION tentiometer. The output from the summing circuit is the input

to the dynamic control section of the speed control unit. The

Engine speed information for the speed control unit is usu- dynamic control circuit, of which the GAIN and STABILITY

ally received from a magnetic speed sensor. Any other sig- adjustments are part of, has a control function that will pro-

nal-generating device may be used provided that the gener- vide isochronous and stable performance for most engine

ated frequency is proportional to engine speed and meets types and fuel systems.

the voltage input and frequency range specification. The

speed sensor is typically mounted in close proximity to an The ESD’s circuit is influenced by the GAIN and STABILITY

engine driven ferrous gear, usually the engine ring gear. As performance adjustments. The governor system sensitivity

the teeth of the gear pass the magnetic sensor, a signal is is increased with clockwise relation of the GAIN adjustment.

generated which is proportional to engine speed. The GAIN adjustment has a range of 33:1. The STABILITY

adjustment, when advanced clockwise, increases the time

Signal strength must be within the range of the input ampli- rate of response of the governor system to match the vari-

fier. An amplitude of 0.5 to 50 volts RMS is required to al- ous time constants of a wide variety of engines. The ESD is

low the unit to function within its design specifications. The a PID device, the “D”, derivative portion can be varied when

speed signal is applied to Terminals C and D on the ESD’s. required. (See instability section in PIB1000.)

Between these terminals there is an input impedance of over

33,000 Ω. Terminal D is internally connected to Terminal E, During the engine cranking cycle, the actuator becomes fully

battery negative. Only one end of the cable shield should be energized and moves to the maximum fuel position. The ac-

connected. tuator will remain in this state during engine cranking and

acceleration. While the engine is at steady load, the actuator

When a speed sensor signal is received by the ESD, the sig- will be energized with sufficient current to maintain the gov-

nal is amplified and shaped by an internal circuit to provide ernor speed set point.

an analog speed signal. If the speed sensor monitor does

not detect a speed sensor signal, the output circuit on the The output circuit provides switching current at a frequency

ESD will turn off all current to the actuator. of about 500 Hz. to drive the actuator. Since the switching

frequency is well beyond the natural frequency of the actua-

A summing circuit receives the speed sensor signal along tor, there is no visible motion of the actuator output shaft.

Governors America Corp., 720 Silver Street Agawam, MA 01001

phone: 413.786.5600 fax: 413.789.7736

www.governors-america.com ISO 9001

info@governors-america.com CERTIFIED

1

Switching the output transistors reduces its internal power of load are applied to the engine. Engine idle speed can be

dissipation for efficient power control. remotely selected and is adjustable.

The output circuit can provide current up to 10 Amps con- The ESD5100 Series can accept accessory inputs (i.e.,

tinuous at 25°C for 12 and 24 VDC battery systems. The ac- GAC’s Load Sharing Modules & Synchroners) to achieve

tuator responds to the average current to position the engine variable speed operation and multi-engine control. Protec-

fuel control lever. tion against reverse battery voltage and transient voltages is

provided. The design is fail safe in the event of loss of speed

In standard operation, the ESD’s performance is isochro- sensor signal or battery supply.

nous. Droop governing can be selected by connecting Ter-

minals K and L and the percent of droop governing can be The ESD5100 Series speed control unit is compatible with

varied with the DROOP adjustment control. Connecting Ter- GOVERNORS AMERICA CORP. proportional electric actua-

minals G and H can increase the droop range. The ESD has tors (except the 2001 Series) as well as those from other

several performance and protection features, which enhance manufacturers.

the governor system. A speed anticipation circuit minimizes

speed overshoot on engine startup or when large increments

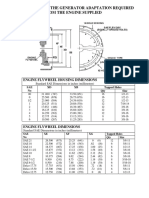

Diagram 1 System Wiring and Outline SeLECTION CHART

5.00

(127)

LEAD CIRCUIT

JUMPER

Model Characteristics

ESD5131, ESD5131H, ESD5111 Standard Unit

GA OVERNORS

MERICA and ESD5151 only

C ORP.

1 OFF 1 2 ON 2

ESD5111H Hard Potted

SPEED CONTROL SPEED E7 E6 LEAD CIRCUIT

ON

SOFT COUPLING

OFF

UNIT

MODEL: ESD51xx GAIN 1 2

ESD5111T Temperature Compensated

S/N :

MADE IN AGAWAM, MA U.S.A. STABILITY

ESD5119 EFC Reverse Acting

CAUTION

E1 E2 E3

5.00

(127)

ENGINE SPEED CONTROL

COMPONENT. WHEN INSTALLING

DROOP ESD5120 EFC Forward Acting/Light Force

OR SERVICING REFER TO

PRODUCT PUBLICATION.

EFC Forward Action/Light Force/Temperature

PICK-UP - + IDLE ESD5120T

ACTUATOR BATTERY

DEAD TIME

COMPENSATION Compensated

AUX 10V JUMPER

A B C D E F GH J K L MN P ESD5131 Soft Coupling Option/Speed Detection Circuit

Ø0.27

(6,8)

ESD5131H Soft Coupling Option/Hard Potted

OPTIONAL ACTUATOR

ESD5150 4-20 mA Output

CABLE SHIELDING TO ACCESSORY POWER SUPPLY

MEET CE DIRECTIVE

ACCESSORY INPUT ESD5151 Soft Coupling Option/Expanded Range to 10.5K Hz

*

ADD JUMPER TO INCREASE

ACTUATOR DROOP RANGE

ESD5159 Expanded Adjustable Speed Range

CW GROUND REFERENCE

MAGNETIC

PICK-UP IDLE

ISOCHRONOUS

SPEED TRIM

DROOP

_ + S1

EXTERNAL SELECTOR

BATTERY FUSE SWITCH

15A MAX (NOT REQUIRED FOR SINGLE

SPEED ISOCHRONOUS OPERATION)

SEE SPECIFIC ACTUATOR PUBLICATION FOR PROPER

WIRING OF ACTUATOR BASED ON BATTERY VOLTAGE Specifications

Performance RELIABILITY

Isochronous Operation…................................................… ±0.25 % or better Vibration……………...............................................................1G, 20-100 Hz

Speed Range /Governor...........................................1K - 7.5K Hz Continuous Testing..................................................................100% Functionally Tested

Speed Drift with Temperature……....……...............................±0.5% Typical

Idle Adjust CW.......………….…...…Min. 1200 Hz. Below set speed Environmental

Idle Adjust CCW…………….…....…Min. 4100 Hz. Below set speed Ambient Operating Temperature Range......-40° to +185°F (-40° to +85°C)

Droop Range.....................................................................1 - 5% Regulation Relative Humidity……………………………………........…………up to 95%

Droop Adj. Max. (K-L Jumpered).................875 Hz., 75 Hz. per 1.0 A change All Surface Finishes.........................Fungus proof and corrosion resistance

Droop Adj. Min. (K-L Jumpered)...................15 Hz., 6 Hz. per 1.0 A change RoHS Regulation...........................................................................Compliant

Speed Trim Range...........................................................................±200 Hz.

Remote Variable Speed Range....................500 - 3.7 kHz. or any part thereof Input POWER

Terminal Sensitivity DC Supply...........................................12 or 24 ± 20% VDC Battery Systems

J..........................................-115 Hz., ±15 Hz/Volt @ 5 K Impedance (Transient and Reverse Voltage Protected)

L........................................-735 Hz., ±60 Hz/Volt @ 65 K Impedance Polarity......................................................Negative Ground (case isolated)

N........................................-148 Hz., ±10 Hz/Volt @ 1 M Impedance Power Consumption......................................100 mA (No actuator current)

P.........................................................10 VDC Supply @ 20 ma Max. Speed Signal Range..................................................................0.5 – 50 VAC

Actuator Current Range @ 77°F (25°C)........................10 Amps continuous

Physical

Dimensions…………...…....................................................See DIAGRAM 1 COMPLIANCE / STANDARDS

Weight………………………………………………...….........1.2 lb. (0.545 kg) Agency…...........................................................................CE Requirements

Mounting.........................……………………Any Position, vertical preferred

This document is subject to change without notice.

Caution: None of GAC products are flight certified controls including this item.

PTI1000 C

2

You might also like

- sx460 Conversion ChartDocument1 pagesx460 Conversion ChartBrianHaze100% (3)

- Gac Governör Esd5500e PDFDocument2 pagesGac Governör Esd5500e PDFDr.HlaNo ratings yet

- 2.041 Woodward - EasyGen O&M PDFDocument69 pages2.041 Woodward - EasyGen O&M PDFJoséNo ratings yet

- Réseau International: Avrs For Shunt ExcitationDocument6 pagesRéseau International: Avrs For Shunt Excitationlpolo12100% (1)

- User'S Manual: Surf-Amf Auto Start - Surf-Auto EnhancedDocument48 pagesUser'S Manual: Surf-Amf Auto Start - Surf-Auto EnhancedBelghennou Hadj AliNo ratings yet

- PMG PDFDocument6 pagesPMG PDFrajan_2002eeeNo ratings yet

- Guangzhou Electway Technology Co.,LtdDocument21 pagesGuangzhou Electway Technology Co.,Ltdabdelhamed mahmoudNo ratings yet

- ESD-5100 Series Speed Control Unit ManualDocument14 pagesESD-5100 Series Speed Control Unit ManualreckyNo ratings yet

- Determining The Generator Adaptation Required From The Engine SuppliedDocument2 pagesDetermining The Generator Adaptation Required From The Engine SuppliedolumideNo ratings yet

- MX-321Document6 pagesMX-321Akun BackupNo ratings yet

- Dead Bus ParelingGLPT 6174 enDocument8 pagesDead Bus ParelingGLPT 6174 enAndré Alfacinha0% (1)

- Universal 16 Amp Self Excited Automatic Voltage Regulator ManualDocument9 pagesUniversal 16 Amp Self Excited Automatic Voltage Regulator ManualJuan José Tovar Pérez100% (1)

- Instruction Sheet C622 Instructions For Spacer Replacement in Contact Blocks Used On 40/70/125 Amp OT III and OTPC Transfer Switches (Kit 541-0766)Document3 pagesInstruction Sheet C622 Instructions For Spacer Replacement in Contact Blocks Used On 40/70/125 Amp OT III and OTPC Transfer Switches (Kit 541-0766)Quang Pham100% (1)

- DSE8680 Operators ManualDocument51 pagesDSE8680 Operators ManualSon DoNo ratings yet

- Avr Conversion InstructionsDocument2 pagesAvr Conversion InstructionsJose PirulliNo ratings yet

- EST To Flash A PowerWizardDocument2 pagesEST To Flash A PowerWizardmahmoud khtaNo ratings yet

- Automatic Voltage Regulator-R438Document2 pagesAutomatic Voltage Regulator-R438Wilman33No ratings yet

- Sync Step Speed Adj Motor For UG Govs 03027 - BDocument8 pagesSync Step Speed Adj Motor For UG Govs 03027 - Bcrazycanuck100% (1)

- Genset Inst Manual Feb 08Document16 pagesGenset Inst Manual Feb 08Saad ZiaNo ratings yet

- Excel ApodysDocument4 pagesExcel ApodysjeremiahNo ratings yet

- Wiring Diagrams: VR6 Voltage RegulatorDocument21 pagesWiring Diagrams: VR6 Voltage Regulatorgeorgi15685No ratings yet

- Linz GeneratorDocument7 pagesLinz GeneratorMohammad HazbehzadNo ratings yet

- CT365 CT400S (QSG12 50Hz)Document3 pagesCT365 CT400S (QSG12 50Hz)Md ShNo ratings yet

- Governor Controller (GAC ESD5111) - DatasheetDocument5 pagesGovernor Controller (GAC ESD5111) - Datasheetazhan77No ratings yet

- EA16 Generator Automatic Voltage Regulator Operation ManualDocument6 pagesEA16 Generator Automatic Voltage Regulator Operation Manualabuzer1981No ratings yet

- Stamford PI734FDocument8 pagesStamford PI734FTaz UddinNo ratings yet

- DetCon2 InstalacionDocument14 pagesDetCon2 InstalacionMaia Naiara BarrientosNo ratings yet

- Maintenance of A.C GeneratorsDocument26 pagesMaintenance of A.C GeneratorsMohamed HamdallahNo ratings yet

- Heinzmann TrainingDocument10 pagesHeinzmann Trainingvo phong100% (1)

- Corte Al Aire - Hyundai - Serie UAN 2014.12 PDFDocument128 pagesCorte Al Aire - Hyundai - Serie UAN 2014.12 PDFAlexis Rodrigo Tapia Estrella100% (1)

- AVC63 7 ManualDocument4 pagesAVC63 7 ManualLuciano PereiraNo ratings yet

- Inteligen NTCDocument141 pagesInteligen NTCMohamed AbdelmalekNo ratings yet

- UPS - Especificaciones TécnicasDocument4 pagesUPS - Especificaciones TécnicasDanny SánchezNo ratings yet

- DC 6 Digital Gov Data Sheet PDFDocument4 pagesDC 6 Digital Gov Data Sheet PDFCarlos MajanoNo ratings yet

- Stamford AVR SX460 PDFDocument4 pagesStamford AVR SX460 PDFNasredine AlainNo ratings yet

- Parts/Components of Manual Transmission 1. Clutch 2. Clutch Pedal 3. Gearbox 4. Shift Fork 5. Shift Rod 6. Hydraulic SystemDocument7 pagesParts/Components of Manual Transmission 1. Clutch 2. Clutch Pedal 3. Gearbox 4. Shift Fork 5. Shift Rod 6. Hydraulic SystemVJ CarbonellNo ratings yet

- Woodward Easygen Configuration Manual PDFDocument201 pagesWoodward Easygen Configuration Manual PDFTayyeb HassanNo ratings yet

- Mixture Preperation in Ci Engines: Common-Rail System (Truck Engine)Document6 pagesMixture Preperation in Ci Engines: Common-Rail System (Truck Engine)Nuno PiresNo ratings yet

- Agn093 BDocument13 pagesAgn093 BariwibowoNo ratings yet

- Woodward GovernorDocument5 pagesWoodward Governorveer_s100% (2)

- SelcoDocument7 pagesSelcoSalman ArifNo ratings yet

- ANSI Code 87 Type RMC-131D Differential Current RelayDocument2 pagesANSI Code 87 Type RMC-131D Differential Current RelayshyamamolNo ratings yet

- Paralleling PCC 2100 in Droop Mode Using Aux101 ModuleDocument2 pagesParalleling PCC 2100 in Droop Mode Using Aux101 ModuleGeneral Projects and Electric, C.A GEPECANo ratings yet

- 6GA2490 0A ManualDocument5 pages6GA2490 0A Manualhosein0% (1)

- 9907 173 Load Sharing Module Installation ManualDocument36 pages9907 173 Load Sharing Module Installation ManualLuis Antonio Garcia EsparzaNo ratings yet

- Perkins 4012 46TAG2A PDFDocument5 pagesPerkins 4012 46TAG2A PDFAdriawan AnnesNo ratings yet

- FDMDocument4 pagesFDMKrishna PardeshiNo ratings yet

- 3516B, 1600 kW-2000 kVA PDFDocument6 pages3516B, 1600 kW-2000 kVA PDFbambangNo ratings yet

- Voltage Regulators - AVR 04-2017Document4 pagesVoltage Regulators - AVR 04-2017S G BavishkumarNo ratings yet

- Special Instruction: Installation and Initial Start-Up Procedure For G3500 A3 EnginesDocument36 pagesSpecial Instruction: Installation and Initial Start-Up Procedure For G3500 A3 EnginesDjebali MouradNo ratings yet

- Pti1000 Esd5100 SeriesDocument2 pagesPti1000 Esd5100 SeriesRamon Thales DomeniconiNo ratings yet

- ESD-5500E Series: Analogue Speed GovernorsDocument4 pagesESD-5500E Series: Analogue Speed GovernorsVasil Stoianov100% (1)

- Manual Regulador de Velocidade Gac Esd 5111Document2 pagesManual Regulador de Velocidade Gac Esd 5111Paulo Alves100% (2)

- Esd5500E Series Speed Control Unit: Product Technical Information PTI 1002EDocument7 pagesEsd5500E Series Speed Control Unit: Product Technical Information PTI 1002EalstomNo ratings yet

- Speed Control GAC ESD5500Document8 pagesSpeed Control GAC ESD5500Manuel Otero80% (5)

- Electronic Governor CatalogDocument26 pagesElectronic Governor CatalogAung Mh100% (1)

- I Pues D 1000 Series Data SheetDocument3 pagesI Pues D 1000 Series Data Sheetkhaled kamelNo ratings yet

- Esd-5200 DS en 03.2011 V1.0Document4 pagesEsd-5200 DS en 03.2011 V1.0BryanLeonardoOspinoReinaNo ratings yet

- Esd5111 enDocument4 pagesEsd5111 enRicardo MonteroNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- 45pwrlog PDFDocument74 pages45pwrlog PDFGugui68No ratings yet

- Voice Recognition Module vr3 ManualDocument38 pagesVoice Recognition Module vr3 ManualMuni Sankar MatamNo ratings yet

- 20x4 LCD Brief DataDocument7 pages20x4 LCD Brief Datavigneshwaranj87100% (1)

- Amazon RallyDocument15 pagesAmazon RallyGugui68No ratings yet

- A Comprehensive Review of The Impact of Dust On The Use of Solar EnergyDocument36 pagesA Comprehensive Review of The Impact of Dust On The Use of Solar EnergyGugui68No ratings yet

- Working Paper GCPJU1502 ODK TutorialDocument25 pagesWorking Paper GCPJU1502 ODK TutorialHermenegildo LuisNo ratings yet

- H CellBrochureDocument7 pagesH CellBrochureGugui68No ratings yet

- Solar Air Conditioning SystemsDocument150 pagesSolar Air Conditioning SystemsAli AbdoNo ratings yet

- Ultrasonic System For Solar Panel CleaningDocument5 pagesUltrasonic System For Solar Panel CleaningGugui68No ratings yet

- Build RoboArmDocument82 pagesBuild RoboArmGugui68No ratings yet

- Constructopedia 2.1 15 Minute Building ProjectsDocument12 pagesConstructopedia 2.1 15 Minute Building ProjectsGugui68No ratings yet

- Robot LocomotionDocument25 pagesRobot LocomotionChaitanya Raghav SharmaNo ratings yet

- JBL GTO 2000 Amplifier ManualDocument8 pagesJBL GTO 2000 Amplifier ManualGopiNo ratings yet

- Cours Et Contenus Du DPT D'electricite Et ElectroniqueDocument28 pagesCours Et Contenus Du DPT D'electricite Et ElectroniqueBanzemwaboNo ratings yet

- Serie 7100 Manual 9000-0447Document50 pagesSerie 7100 Manual 9000-0447Diego CortesNo ratings yet

- Ballast CatalogDocument68 pagesBallast CatalogBinti Masyruroh100% (1)

- SJ-20101210110401-001-ZXSDR R8860E GU858 (HV2.0) Outdoor GSM&UMTS Dual Mode Macro RRU User Manual - 1STversionDocument103 pagesSJ-20101210110401-001-ZXSDR R8860E GU858 (HV2.0) Outdoor GSM&UMTS Dual Mode Macro RRU User Manual - 1STversionsaulhalcorNo ratings yet

- Product Description: 7.9 - 11.0 GHZ 15 W Gan Power AmplifierDocument26 pagesProduct Description: 7.9 - 11.0 GHZ 15 W Gan Power AmplifierBabak SaranNo ratings yet

- MOSFET Amplifier Large Signal AnalysisDocument21 pagesMOSFET Amplifier Large Signal AnalysisRaghav100% (1)

- Libro Semi PDFDocument462 pagesLibro Semi PDFOmar AlejandroNo ratings yet

- MMP - Intro To ElectronicDocument12 pagesMMP - Intro To ElectronicAye Chan OoNo ratings yet

- Experiment No 6Document13 pagesExperiment No 6Gregern Paul Borja EstebanNo ratings yet

- MR-E Super: User-Friendly Servo With Easy OperationDocument32 pagesMR-E Super: User-Friendly Servo With Easy OperationDivNo ratings yet

- Study of Recent Charge Pump Circuits in Phase Locked Loop: Umakantananda, Jyotirmayee Sarangi, Prakash Kumar RoutDocument7 pagesStudy of Recent Charge Pump Circuits in Phase Locked Loop: Umakantananda, Jyotirmayee Sarangi, Prakash Kumar RoutgezahegnNo ratings yet

- A 1.5V 1.5GHz CMOS LNADocument16 pagesA 1.5V 1.5GHz CMOS LNAptt3iNo ratings yet

- Clarion PN 2445m A Manual de UsuarioDocument16 pagesClarion PN 2445m A Manual de UsuarioDavid DeyNo ratings yet

- Fja 5150 Bias ModDocument5 pagesFja 5150 Bias ModffuhnnadNo ratings yet

- TLE6368 DS Rev2.2Document59 pagesTLE6368 DS Rev2.2Yael AlcaNo ratings yet

- Amplifier Repair: Troubleshooting Guide (Electrical Parts)Document15 pagesAmplifier Repair: Troubleshooting Guide (Electrical Parts)Dada AlbertNo ratings yet

- EMQ ICA HM317 - v1.0Document12 pagesEMQ ICA HM317 - v1.0Mahmoud AhmedNo ratings yet

- Cairo University Electronics Course Chapter on Operational AmplifiersDocument16 pagesCairo University Electronics Course Chapter on Operational AmplifiersMerna AtefNo ratings yet

- Fanuc AC Spindle Alarm CodesDocument8 pagesFanuc AC Spindle Alarm Codesviernes06No ratings yet

- BTS GT-1 OwersManual ParameterGuide E01 WDocument57 pagesBTS GT-1 OwersManual ParameterGuide E01 WlucasvcardosoNo ratings yet

- 9226X01Document56 pages9226X01buntha_MNo ratings yet

- MICROCONTROLLER-BASED TACHOMETER - Kits 'N' Spares PDFDocument4 pagesMICROCONTROLLER-BASED TACHOMETER - Kits 'N' Spares PDFsafe cityNo ratings yet

- OscilloPhone Use Your Smartphone As An Oscilloscop PDFDocument22 pagesOscilloPhone Use Your Smartphone As An Oscilloscop PDFRodolfoPerezEscalonaNo ratings yet

- Opamp PPT For Engineering First Year StudentsDocument33 pagesOpamp PPT For Engineering First Year Studentsdarshankumar999No ratings yet

- Eca Ii Lab Manual Final PDFDocument65 pagesEca Ii Lab Manual Final PDFkapil chander100% (1)

- 70000635a PDFDocument33 pages70000635a PDFAnonymous iYKTkmhpZNo ratings yet

- Report On Simple Mic Audio Amplifier Project: (Midterm Project) Course: Circuit Analysis Instructor: Sir Abdul RabDocument6 pagesReport On Simple Mic Audio Amplifier Project: (Midterm Project) Course: Circuit Analysis Instructor: Sir Abdul RabsamiNo ratings yet

- PWM Inverter Circuit Based On SG3524 - 12V Input, 220V Output, 250WDocument2 pagesPWM Inverter Circuit Based On SG3524 - 12V Input, 220V Output, 250WPankaj D Patel100% (2)