Professional Documents

Culture Documents

14 Ricardo B Reterm 114 2005 PDF

Uploaded by

ricva_rjOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

14 Ricardo B Reterm 114 2005 PDF

Uploaded by

ricva_rjCopyright:

Available Formats

Tecnologia/Technology

DILUTE PHASE VERTICAL PNEUMATIC CONVEYING OF

CORK STOPPERS

R. Barbosaa, ABSTRACT

b

and C. Pinho The pneumatic conveying of cork stoppers is used in the cork processing

industries with equipments designed and built purely on an empirical basis.

a

DEMGI Experimental studies to characterize this type of pneumatic transportation

have been, so far, oriented towards the study of horizontal conveying

Escola Superior de Tecnologia de Viseu

processes, either for steady state transportation or for the acceleration zone.

Campus Politécnico de Repeses However studies were carried out on the determination of the pressure drop

3504-510, Viseu, Portugal on vertical transportation of cork stoppers. Here the experimental apparatus

and procedure are described, and the first experimental data that have been

rbarbosa@demgi.estv.ipv.pt

obtained are shown. In consequence a simple correlation for the pressure

b

CEFT-DEMEGI, FEUP drop in the steady state region of the conveying pipe is proposed. The

Universidade do Porto correlation is a function of dimensionless parameters used to characterize

the two phase flow under analysis. Three standard stoppers sizes and a

Rua Dr. Roberto Frias, s/n Engineering

single pipe diameter were used in the experiments, all carried out at ambient

4200-465 Porto, Portugal. temperature.

ctp@fe.up.pt

Corresponding author Keywords: Vertical pneumatic conveying, pressure drop, cork stoppers.

NOMENCLATURE

INTRODUCTION

a fitting parameter, Eq. (2)

b fitting parameter, Eq. (2) Pneumatic conveying is used in some steps of

c fitting parameter, Eq. (2) the production of cork stoppers, where particle

d fitting parameter, Eq. (2) damage through interparticle or particle and

ds diameter of the stopper, m confining walls impaction has a minor effect upon

deq equivalent diameter of a stopper, m the quality of the stoppers. The development of small

dp particle diameter, m distance transport systems for stoppers has been

D pipe diameter, m essentially an empirical process and only recently has

Fr Froude number, U f / g D been subjected of a systematic experimental

approach. The research work that has been carried

g acceleration of gravity, m s-2

out so far refers only to horizontal pneumatic

l length of the stopper, m conveying, either in steady state (Neto and Pinho,

L pipe length, m 1998), or during acceleration conditions (Pinho,

N number of experiments

1999; Pinho, 2001).

p pressure, N m-2 In the horizontal pneumatic conveying of cork

Re Reynolds number, ρ f U f D µ f stoppers, fine cork dust is released and acts as a

Uf intersiticial gas velocity, m s-1 lubricant reducing friction effects, Neto and Pinho

(1998). The deposition of this fine dust is still

Greek symbols enhanced by electrostatic generation, Smeltzer et al

(1982). The conveying air pressure drop is then

θ loading factor reduced, with the increase of the solids mass loading.

λt overall friction factor This situation has already been found on solid-liquid

µf fluid viscosity, N s m-2 systems; Lee et al (1974) studied polymeric solutions

ρf fluid density, kg/m3 containing suspended fibbers and Radin et al (1975)

ρp gas density, kg/m3 studied the drag reduction in several dilute solid-

liquid suspensions. Szikszay (1988) argued that, as

ψ sphericity of the stopper

the measured experimental data referred to both the

solids and the conveying air pressure drop, it was

Subscripts

unreasonable to separate them. Weber (1991) also

suggested that a single friction factor for the gas-

tcal total calculated

texp total experimental solid mixture should be used, instead of two separate

friction factors, one for the air and the other for the

solids. This question of drag reduction with the

36 Engenharia Térmica (Thermal Engineering), Vol. 5 • No 02 • December 2006 • p. 36-41

Tecnologia/Technology Barbosa and Pinho. Dilute phase vertical …

addition of particles into a flow stream has been section of 6.8 m length and the recovery circuit

recently reviewed in the book of Fan and Zhu (1998), composed by a small horizontal portion of 1.6 m and

who presented a phenomenological model to account a diagonal portion 5.9 m long. Figure 2 presents a

for the drag reduction. picture of the installation. The tube was a PVC pipe

For vertical pneumatic conveying the important with 125 mm nominal diameter pipe (121 mm

research points concern the acceleration region, the internal diameter, D). Cork stoppers, moving in

determination of correlations for the solids friction closed circuit, were introduced into the pneumatic

factor (Rautiainen et al, 1999) and the definition of conveying circuit through the feeding hopper,

flow choking conditions. Recent examples of studies installed in the horizontal portion of the duct. This

on the characterization of the acceleration region are hoper was also receiving the corks after their tour

the publications of Dzido et al (2002) and Namkung into the system.

and Cho (2002), although the works of Yang and co-

authors are still a basic reference (Yang and Keairns,

1976). The mostly recommended correlations for the

calculation of the friction factor are the publications

of Yang, namely Yang (1973), Yang (1974) and

Yang (1978). For the definition of the choking

conditions, the work of Yang (1975) is again

frequently recommended in many recent

publications, like for example Raczek and Palica

(1997) and Xu et al (2001). These last authors

present a thorough analysis on the fundamentals of

suspension collapsing in vertical conveying.

However, in all these more recent publications,

whatever is the subject being treated, acceleration,

friction or choking conditions, the order of

magnitude of the size of the particles under

consideration is quite different from what is found in

the pneumatic transportation of cork stoppers, hence

the justification for the present study.

On the other end, although drag reduction was

detected in horizontal conveying of cork stoppers,

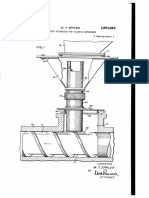

nothing was known as far as vertical conveying was Figure 1. Schematic diagram of the experimental

concerned, and one of the main aims of this work apparatus.

was to find out how important this could be.

For the short distances used in pneumatic Conveying air was introduced into the system

conveying of cork stoppers, the steady state transport through a centrifugal fan controlled by a ABB

conditions are difficultly reached and the acceleration frequency variator model ACS401000932, with a

regime becomes dominant. The theoretical resolution of 0.1 Hz/50 Hz. Air flow was measured

determination of the acceleration length is a difficult through an orifice plate flow meter, positioned

task and the Rose and Duckworth (1961) equation is upstream the feeding hopper, and equipped with a

still the reference for this matter. However, it is differential pressure transducer with an operating

becoming recognized that the acceleration length range of 0 to 1245 Pa. The orifice plate flow meter

does not change very much with the solids loading was previously calibrated by means of a Pitot tube,

factor and also that, such equation gives acceleration installed before the feeding hopper.

lengths below those measured for the transport of To carry on with the calibration process, the

large particles, Marcus et al (1985). The present conveying pipe had to be disconnected from the

experimental measurements will allow the entrance of the feeding hopper and through the Pitot

determination of the importance of this phenomenon tube an average conveying air velocity was obtained

in the vertical conveying, compared to what has been with the log-linear method applied to the

previously found under horizontal pneumatic measurement of the air velocity in six points along

conveying conditions, (Neto and Pinho 1998; Pinho, the pipe diameter. To reduced the air leakage through

1999; Pinho 2001). the feeding system of the corks, the hopper

connection with the conveying pipe was closely

EXPERIMENTS isolated with aluminium adhesive tape. With the

continuous reading of conveying air temperature,

The experimental system as schematically corrections in the air flow rate were made for the air

shown in Fig 1, was composed by a 6 m long temperature increase with attrition effects inside the

horizontal portion where the stoppers were transporting pipe, as well as to account for changes in

introduced into the conveying pipe, a vertical testing the ambient air temperature.

Engenharia Térmica (Thermal Engineering), Vol. 5 • No 02 • December 2006 • p. 36-41 37

Tecnologia/Technology Barbosa and Pinho. Dilute phase vertical …

Along the vertical testing section, pressure taps subsequent pressure taps, it was possible to get an

were fitted half a meter apart. The first pressure tap is overall idea of the evolution of the pressure drop, as

0.5 m away from the bend connecting the horizontal a function of particle entrance effects in the vertical

feeding section to the vertical testing section. For portion of the pipe and also of the particle

measurements of the pressure drop along the acceleration. Afterwards, by knowing the length of

conveying pipe, differential pressure transducers in the steady state conveying region, pressure drop data

the 0 to 490 Pa range were used. The transducers obtained in this portion of the vertical pipe were

were from Series T of Modus Instruments, Inc., and treated in order to obtain an empirical correlation.

had output signals of 0-1 V dc. The transducers To calculate the mass flow rate of transported

outputs were checked towards U-type water cork stoppers, a basket was used as collection device

manometer readings. A data acquisition system for conveyed particles. The batch of collected

(DAS 1601 plus EXP 16 boards) installed on a stoppers during a finite time interval was weighted

personal computer received information from the and the solids mass flow rate could then be

differential pressure transducers on use (for the calculated. The measurement of the voidage fraction

orifice plate pressure drop and the conveying during pneumatic conveying was carried out through

pressure drop), as well as temperature readings of the the knowledge of the amount of cork stoppers that in

conveying air through a type T thermocouple. The a given instant remain inside the pipe. Having the

accuracy of differential pressure drop measurements experimental installation working in steady state

considering also the data acquisition process was of conditions, the feeding hopper was suddenly stopped

9.7 Pa for the 0 - 1245 Pa pressure transducer, and of and all the cork stoppers being conveyed were

7.9 Pa for the 0 - 490 Pa pressure transducer. immediately collected and weighted. This was, for

the stoppage instant, the amount of particles

remaining inside the conveying system. Comparisons

between the overall volume of the corks and the

inside volume of conveying pipe, gave the voidage

fractions under normal conveying conditions.

Table 1 presents the physical characteristics of

the tested cork stoppers, size, sphericity and density.

Table 1. Characteristics of cork stoppers.

Size (l×ds)

(mm×mm) 38 × 22 38 × 24 45 × 24

deq

0.0302 0.0320 0.0339

(m)

ψ 0.85 0.85 0.84

ρp

167 155 139

(kg/m3)

RESULTS AND DISCUSSION

The first approach towards the experiments was

to analyze the importance of the acceleration region

on the evolution of the pressure drop. As can be seen

from Fig. 3, where some typical results are presented

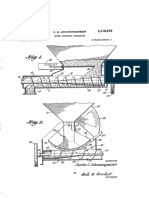

Figure 2. Experimental installation. In the first plan it for the differential pressure drop between the first

can be seen the orifice plate air flow meter and the pressure tap and the subsequent ones, after a sudden

corks feeding hopper. initial rise in the pressure drop due to the entrance

effects, the acceleration of the particles justifies the

For each tested situation characterized by a following strong reduction in the measured values.

definite air flow rate and solids loading factor Only after steady state transportation conditions

θ (ratio between the solids mass flow rate and the are reached, the evolution of the pressure drop

conveying air mass flow rate), pressure drop follows a smooth trend. This steady state situation

measurements were made throughout the straight arrives at around 3.5 to 4 meters beyond the entrance

vertical transporting pipe, using all the available of the stoppers. This order of magnitude of the

pressure taps. Through the adequate grouping of the entrance/acceleration length is similar to what was

pressure drop measurements, like for example the found for the horizontal conveying of cork stoppers

sequential combination between the first and (Pinho, 1999; Pinho 2001). On the other end,

38 Engenharia Térmica (Thermal Engineering), Vol. 5 • No 02 • December 2006 • p. 36-41

Tecnologia/Technology Barbosa and Pinho. Dilute phase vertical …

pressure drop data obtained with pressure taps close vertical pneumatic conveying such abnormal

to the end of the vertical conveying pipe were not situation does not happen, as the experiments have

plotted as the flow deceleration induces the increase shown, Fig. 4. Total, gas plus solids, pressure drop is

of the pressure drop, and again unsteady conveying higher than the pressure drop corresponding to the

conditions are obtained. From this figure it is evident sole flow of air, as the experimental points in Fig. 4

that, to get reliable pressure drop data for steady state stand, comparatively to the corresponding values

pneumatic conveying, values beyond 4 m should be obtained through the Blasius equation.

used for the determination of empirical correlations.

100

38x22,θ=0.228 38x22,θ=0.258 45x24,θ=0.276 45x24, θ= 0.226, Fr = 23.42

90 Blasius' equation

38x22,θ=0.186 38x22,θ=0.212 45x24,θ=0.226

38x22,θ=0.186 45x24,θ=0.226

38x22,θ=0.147 45x24,θ=0.182 80

100

[Pa/m]

70

90

60

80

∆p/L

50

70

[Pa/m]

40

60

30

∆p/L

50

20

0 1000 2000 3000 4000 5000

40

L [mm]

30

20 Figure 4. The overall, air plus solids, pressure drop

0 1000 2000 3000 4000 5000 and the corresponding values calculated through the

L [mm] Blasius equation.

Figure 3. Evolution of overall pressure drop along However, as a first approach to the treatment of

the conveying pipe. the experimental results, the adopted methodology

was again to consider a unique overall friction factor

The plot of pressure drop per unit length as a for the gas-solid mixture, as suggested by Weber

function of several parameters, to characterize the (1991). This is tempting, because the experimental

operation of a pneumatic conveying system, is a determination of pneumatic conveying pressure drop

typical procedure found in the technical literature is effectively the measurement of a combined (gas

(Marcus et al, 1990; Rhodes, 1998); in the situation plus solid) pressure drop, and consequently the total

of Fig. 3 it allows a quick definition of the pressure will then be given by,

acceleration region.

2

In classical models for pneumatic conveying, L Uf

∆p t = λ t ρf (1)

Barth (1960a; 1960b), Yang (1973; 1974; 1978) and D 2

Yang and Keairns (1973; 1976), the steady state

overall pressure drop is considered to be the addition where the global friction factor λ t , is written as a

of two individual contributions, the gas and the solids

simple function of dimensionless parameters,

pressure drop. More recently, Rhodes (1998)

Szikszay (1988),

continues to adopt, as a general approach, the

addition of individual pressure drop contributions. In e

these approaches, it is implicitly assumed that the dp

d

ρp

overall pressure drop for a pneumatic conveying λ t = a θ Fr b c

ρ

(2)

D f

situation should be higher than any individual

contribution. However, this is not always the real

situation and the application of any of such models, Knowing experimental data of ∆p t L , for

or others following the same philosophy, would different tested situations covering several stoppers

mean that some individual contributions should be diameters d p and densities ρ p , loading factors θ

negative, leading to a physically inaccurate

and air interstitial velocities Uf, λ t is calculated by

condition. For horizontal pneumatic conveying of

cork stoppers such is the situation, the overall, gas means of Eq. (1) and correlated with the

plus solid, pressure drop, is smaller than the pressure dimensionless numbers referred in Eq. (2), θ , Fr,

drop corresponding to the exclusive flow of air (Neto dp/D and ρp/ρf, through fitting parameters a, b, c, d

and Pinho, 1998; Pinho, 1999; Pinho, 2001). For the and e, obtained through the application of a

Engenharia Térmica (Thermal Engineering), Vol. 5 • No 02 • December 2006 • p. 36-41 39

Tecnologia/Technology Barbosa and Pinho. Dilute phase vertical …

commercial software for nonlinear regression this formula is of 17.4 % whereas the mean

analysis NLREG. The obtained values for those deviation, calculated through

parameters guarantee the best fit to the set of

provided experimental data obtained in the 2

λ tcal − λ t exp

experiments. Mean Deviation % = ∑ N × 100

λ t exp

0.03

(4)

0.025

as defined by Wen and Chen (1982), is 9.2 %.

Experimental and calculated λ t are compared in Fig.

5.

If an alternative and more elegant correlation is

texp

0.02

adopted through the use of rounded values for the

λ

fitting parameters a, b, c, d and e, the result is

Correlation

0.015 38x22

−4 / 5 4/ 5

38x24

45x24 d eq ρp

λ t = 2 × 10 θ−3 1/ 5

Fr

−4 / 5

ρ

0.01 D f

0.01 0.015 0.02 0.025 0.03

(5)

λ

tcal

In these circumstances the absolute deviation

Figure 5. Comparison between experimental and between experimental λ t exp and calculated data

calculated values for the overall friction factor.

λ tcal with Eq. (5) is of 17.5 %, while the mean

For the determination of steady state pressure deviation calculated again through Eq. (4) will be 9.4

drop in horizontal pneumatic conveying, as referred %.

in Tab. 1, three stoppers sizes were used, 38×22, These data were obtained through a set of about

38×24, 45×24 (mm×mm). Tested loading factors 40 experimental runs, for each run twenty results for

covered the range from 0.10 to 0.35, the air flow twelve pressure differentials were registered and each

Reynolds number ( Re = ρ f U f D µ f ) went from registered value corresponded to an average of a

1000 readings.

1.3×105 to 2.6×105, while the Froude number

( Fr = U f / g D ) ranged from 15.3 to 30.7, all CONCLUSIONS

values typical for cork stoppers conveying systems.

In the definition of the Reynolds number, µ f is the From the preliminary results of a study on

vertical pneumatic conveying of cork stoppers, it was

dynamic viscosity of the conveying air. Small values realized that contrary to what was found for

for the loading factor are common in the pneumatic horizontal conveying, in the vertical transportation

conveying of stoppers, because of the combined regime the total pressure drop is higher than the

influence of having to transport large size particles pressure drop corresponding to the single flow of air.

with the use of centrifugal fans having flat working The order of magnitude of the acceleration

curves promoting flow blockage situations, Wirth length is identical to that of horizontal conveying,

and Molerus (1986). This affects minimum although a deeper analysis of the experimental results

conveying conditions and imposes restrictions on the is still under way.

maximum possible loading factor. At the same time, Finally, as a preliminary approach, a simple

the extreme fragility of stoppers imposes some empirical correlation for the overall (gas plus solid)

limitations on the maximum recommended transport pressure drop in the steady state conveying regime

velocity, reducing even further the range of working was proposed. By sacrificing a little of the accuracy

conditions. of the original correlation, a more elegant one can be

The obtained correlation was then, obtained through the use of rounded fitting

parameters.

−0.830 0.830

d eq ρp

λ t = 1.97 × 10 θ −3 1.70

Fr

−0.877

ρ

REFERENCES

D f

(3) Barth, W., 1960a, Physical and Economical

Aspects of Transportation of Solids in Fluids and

The maximum absolute deviation between Gases, (In German), CIT 32, No. 2, pp.164-171.

experimental λ t exp and calculated data λ tcal with

40 Engenharia Térmica (Thermal Engineering), Vol. 5 • No 02 • December 2006 • p. 36-41

Tecnologia/Technology Barbosa and Pinho. Dilute phase vertical …

Barth, W., 1960b, Technical Flow Problems in Szikszay, G., 1988, Friction Factor for Dilute

Conveying Dust and Gas Mixtures, (In German), Phase Pneumatic Conveying, Bulk Solids Handling,

Mitt. VGB., No. 79, pp.238-244. Vol. 8, No. 4, pp.395-399.

Dzido, G., Palica, M. and Raczek, J., 2002, Weber, M., 1991, Friction of the Air and the

Investigations of the acceleration region in the Air/Solid Mixture in Pneumatic Conveying, Bulk

vertical pneumatic conveying, Powder Technologt, Solids Handling, Vol. 11, No. 1, pp. 99-102.

Vol. 127, pp. 99-106. Wen, C.Y. and Chen, L.H., 1982, Fluidized Bed

Fan, L. S., and Zhu, C., 1998, Principles of Freeboard Phenomena: Entrainment and Elutriation,

Gas-Solid Flows, Cambridge University Press, AIChE J., vol. 28, No. 1, pp. 117-128.

Cambridge Series in Chemical Engineering, Wirth, K.-E. and Molerus, O., 1986, Solids and

Cambridge. Gas-Solid Flows, Encyclopedia of Fluids Mechanics,

Lee, W. K., Vaseleski, R. C. and Metzner, A. Vol. 4, Ch. 15, pp. 471-484 N. P. Cheremisinoffs

B., 1974, Turbulent Drag Reduction in Polymeric Editor, Gulf Publishing Company.

Solutions Containing Suspended Fibbers, A.I.Ch.E. Xu, G., Nomura, K., Gao, S. and Kato, K, 2001,

J., Vol. 20, No..1, pp. 128-133. More Fundamentals of Dilute Suspension Collapse

Marcus, R. D., Hilbert Jr., J. D, and Klinzing, and Choking for Vertical Conveying Systems,

G. E., 1985, Flow Through Bends and Acceleration AIChE J., Vol. 47, No. 10, pp. 2177- 2196.

Zones in Pneumatic Conveying Systems, Bulk Solids Yang, W. and Keairns, D.L., 1973, Estimating

Handling, Vol. 5, No. 4, pp. 121-126. the Solid Particle Velocity in Horizontal Pneumatic

Marcus, R. D., Leung, L. S, Klinzing, G. E. and Conveying Lines, The Canadian Journal of Chem.

Rizk, F., 1990, Pneumatic Conveying of Solids, Eng., Vol. 51, pp. 779-781.

Chapman and Hall, London. Yang, W., 1973, Estimating the Solid Particle

Namkung, W. and Cho, M., 2002, Pressure Velocity in Vertical Pneumatic Conveying Lines,

Drop in a Vertical Pneumatic Conveying of Iron Ore, Ind. Eng. Chem. Fundam., Vol. 12, No. 3, pp. 349-

Ind. Eng. Chem. Res.,Vol. 41, pp. 5316-5320. 352.

Neto, P. and Pinho, C., 1998, Dilute Phase Yang, W., 1974, A Correlation for Solid

Horizontal Pneumatic Conveying of Cork Stoppers: Friction Factor in Vertical and Horizontal Pneumatic

A Preliminary Experimental Study, Proceedings of Conveying, AIChE J., Vol. 20, No. 3, pp. 605-607.

the Symposium on Thermal and Fluids Engineering, Yang, W., 1975, A Mathematical Definition of

CSME Forum SCGM, 19th-22nd May, Toronto, Vol. Choking Phenomenon and a Mathematical Model for

1, pp. 360-367. Predicting Choking Velocity and Choking Voidage,

Pinho, C., 1999, Acceleration of Cork Stoppers AIChE J., Vol. 21, No. 5, pp. 1013-1015.

in Pneumatic Conveying, 15th Brazilian Congress of Yang, W. and Keairns, D.L., 1976, Estimating

Mechanical Engineering, 22nd-26th November, Águas the Acceleration Pressure Drop and Particle

de Lindóia, São Paulo, SP, Brazil. Acceleration Length in Vertical and Horizontal

Pinho, C., 2001, Horizontal Pneumatic Pneumatic Transport Lines, Pneumotransport 3.

Conveying of Cork Stoppers, Proceedings of Cobem Third International Conference on the Pneumatic

2001, Fluid Mechanics, Vol. 8, pp 21-29, 26th to 30th Transport of Solids in Pipes, 7th - 9th April, pp. D7-89

November 2001, Uberlândia, MG, Brazil. - D7-98.

Raczek, J. and Palica, M., 1997, Selection of Yang, W., 1978, A Correlation for Solid

the gas working velocity in vertical pneumatic Friction Factor in Vertical Pneumatic Conveying

conveying systems for binary mixtures, Chemical Lines, AIChE J., Vol. 24, No. 3, pp. 548-552.

Engineering and Processing, No. 36, pp. 167-170.

Radin, I., Zakin, J.L. and Patterson, G.K., 1975,

Drag Reduction in Solid-Fluid Systems, A.I.Ch.E. J.,

Vol. 21, No..2, pp. 358-371.

Rautiainen, A., Stewart, G., Poikolainen, V. and

Sarkomaa, P., 1999, An experimental study of

vertical pneumatic conveying, Powder Technology,

Vol. 104, pp 139-150.

Rhodes, M., 1998, Introduction to Particle

Technology, John Wiley and Sons, Chichester.

Rose, H.E. and Duckworth, R. A., 1961,

Transport of Solids Particles in Liquids and Gases,

The Engineer, No. 14, 21st and 28th March.

Smeltzer, E. E., Weaver, M. L. and Klinzing, G.

E., 1982, Pressure Drop Losses due to Electrostatic

Generation in Pneumatic Transport, Ind. Eng. Chem.

Process Des. Dev., Vol. 21, No. 3, pp. 390-394.

Engenharia Térmica (Thermal Engineering), Vol. 5 • No 02 • December 2006 • p. 36-41 41

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Fundamentals of Air System Design I-P, 2nd Ed.Document378 pagesFundamentals of Air System Design I-P, 2nd Ed.Mahmoud Gwaily100% (16)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Transport Phenomena and Unit OperationsDocument457 pagesTransport Phenomena and Unit OperationsJazL2809100% (7)

- Glosario de Terminos en ExtrusionDocument21 pagesGlosario de Terminos en ExtrusionMiguel Angel Perez EsparzaNo ratings yet

- Us 2604659Document5 pagesUs 2604659ricva_rjNo ratings yet

- High-Capacity Closed Circuit Separator: FHS03-HUS1260-9e 12.05.2009 15:40 Uhr Seite 1Document2 pagesHigh-Capacity Closed Circuit Separator: FHS03-HUS1260-9e 12.05.2009 15:40 Uhr Seite 1ricva_rjNo ratings yet

- Cimbria DELTA Pre Cleaner 159 Data SheetDocument1 pageCimbria DELTA Pre Cleaner 159 Data Sheetricva_rjNo ratings yet

- The Pollution and Its Consequences: Durán José RicardoDocument30 pagesThe Pollution and Its Consequences: Durán José Ricardoricva_rjNo ratings yet

- Radiator (Engine Cooling)Document7 pagesRadiator (Engine Cooling)ricva_rjNo ratings yet

- Creo Que Tenemos Que CharlasDocument4 pagesCreo Que Tenemos Que Charlasricva_rjNo ratings yet

- Screw conveyor apparatus with tapered core for improved material flow controlDocument10 pagesScrew conveyor apparatus with tapered core for improved material flow controlricva_rjNo ratings yet

- CN 201183312 yDocument7 pagesCN 201183312 yricva_rjNo ratings yet

- Jan. 1, 1963 W. E. Kaskel 3,071.498: 77oawaDocument8 pagesJan. 1, 1963 W. E. Kaskel 3,071.498: 77oawaricva_rjNo ratings yet

- Common Mistakes PDFDocument5 pagesCommon Mistakes PDFVladimir B. ZavaletaNo ratings yet

- Extrusion die forms uniform plastic beads for moldingDocument8 pagesExtrusion die forms uniform plastic beads for moldingricva_rjNo ratings yet

- Comprehensive Comparison of AXi, AX, HXi and HX Power Supply ModelsDocument9 pagesComprehensive Comparison of AXi, AX, HXi and HX Power Supply ModelsagustinbaezNo ratings yet

- 2,418,540 April 8, 1947.: R. E. BresslerDocument5 pages2,418,540 April 8, 1947.: R. E. Bresslerricva_rjNo ratings yet

- Design and Fabrication Ofscrew ConveyorDocument15 pagesDesign and Fabrication Ofscrew ConveyorhbookNo ratings yet

- WD Blue 3D Nand SSDDocument2 pagesWD Blue 3D Nand SSDMihaiNo ratings yet

- High-Capacity Closed Circuit Separator: FHS03-HUS1260-9e 12.05.2009 15:40 Uhr Seite 1Document2 pagesHigh-Capacity Closed Circuit Separator: FHS03-HUS1260-9e 12.05.2009 15:40 Uhr Seite 1ricva_rjNo ratings yet

- Pet GLDocument1 pagePet GLricva_rjNo ratings yet

- PET-H Material Properties and ApplicationsDocument1 pagePET-H Material Properties and Applicationsricva_rjNo ratings yet

- Li NNOTAMDocument1 pageLi NNOTAMricva_rjNo ratings yet

- LiNNOTAMHiPERFORMANCE 612Document1 pageLiNNOTAMHiPERFORMANCE 612ricva_rjNo ratings yet

- CAPSEngineersGuide August2017Document16 pagesCAPSEngineersGuide August2017ricva_rjNo ratings yet

- Peek XDocument1 pagePeek Xricva_rjNo ratings yet

- Linnotamhiperformance AstDocument1 pageLinnotamhiperformance Astricva_rjNo ratings yet

- Linnotamhiperformance AstDocument1 pageLinnotamhiperformance Astricva_rjNo ratings yet

- Feynman ParametrizationDocument3 pagesFeynman Parametrizationricva_rjNo ratings yet

- Parametrización de SchwingerDocument1 pageParametrización de Schwingerricva_rjNo ratings yet

- Natural Gas Generator Set QSK60 Series EngineDocument4 pagesNatural Gas Generator Set QSK60 Series Enginericva_rjNo ratings yet

- Generator Set Data Sheet 2000 KW ContinousDocument4 pagesGenerator Set Data Sheet 2000 KW Continousricva_rjNo ratings yet

- My PartDocument7 pagesMy Partricva_rjNo ratings yet

- 7 SizingDocument82 pages7 Sizingandersson benito herreraNo ratings yet

- Advances in Modeling of Fluid DynamicsDocument316 pagesAdvances in Modeling of Fluid DynamicsskilmagNo ratings yet

- Reynolds Number Calculator & Pipe Flow Formula SheetDocument22 pagesReynolds Number Calculator & Pipe Flow Formula SheetWAHID HUSAINNo ratings yet

- Basics in Process Design - 2006 PDFDocument30 pagesBasics in Process Design - 2006 PDFSamuel OnyewuenyiNo ratings yet

- Class Notes: Fluid Flow in Closed ConduitDocument5 pagesClass Notes: Fluid Flow in Closed ConduitRam Krishna Singh100% (1)

- Orifice Plate Sizing PDFDocument18 pagesOrifice Plate Sizing PDFalexmuchmure2158No ratings yet

- Control Valve SizingDocument4 pagesControl Valve SizingAmolNo ratings yet

- Flow in Water PipingDocument9 pagesFlow in Water PipingJanNo ratings yet

- NACA-RM-A52B13-The Effect of Bluntness On The Drag of Spherical-Tipped Truncated Cones of Fineness Ratio 3 at Mach Numbers 1.2 To 7.4Document20 pagesNACA-RM-A52B13-The Effect of Bluntness On The Drag of Spherical-Tipped Truncated Cones of Fineness Ratio 3 at Mach Numbers 1.2 To 7.4dalfeNo ratings yet

- CE-UG-2018 Spring FEB-JUN 2020Document50 pagesCE-UG-2018 Spring FEB-JUN 2020SalmanNo ratings yet

- Experimental Study On The Heat Transfer Performance of Nanofluid Mnfe O - Ethylene Glycol/Water On Double-Pipe Heat ExchangerDocument11 pagesExperimental Study On The Heat Transfer Performance of Nanofluid Mnfe O - Ethylene Glycol/Water On Double-Pipe Heat ExchangerAklilu BahetaNo ratings yet

- Modelling Turbulent Flow (1) : - Why Not Solve The Navier-Stokes Equations?Document18 pagesModelling Turbulent Flow (1) : - Why Not Solve The Navier-Stokes Equations?havaNo ratings yet

- Forced ConvectionDocument16 pagesForced ConvectionAleem AhmedNo ratings yet

- R&AC Lecture 24Document39 pagesR&AC Lecture 24Sachin S KumarNo ratings yet

- Comparing Circular and Rectangular Pipes in HTDocument5 pagesComparing Circular and Rectangular Pipes in HTshakil ahmadNo ratings yet

- Falco UAV Low Reynolds Airfoil Design Testing GalileoDocument25 pagesFalco UAV Low Reynolds Airfoil Design Testing Galileotomay777100% (1)

- Non Circular FlowDocument150 pagesNon Circular FlowAlexander VovaNo ratings yet

- High Power Density Air-Cooled Microchannel Heat ExchangerDocument8 pagesHigh Power Density Air-Cooled Microchannel Heat ExchangerAnkit LonareNo ratings yet

- Design and Control of Pig Operations Through PipelinesDocument9 pagesDesign and Control of Pig Operations Through PipelinespedriimNo ratings yet

- Nazla Alwan - FinalDocument72 pagesNazla Alwan - FinalNazla AlwanNo ratings yet

- 2d VIV PDFDocument11 pages2d VIV PDFRaghavNo ratings yet

- ME2134 NUS PipeflowDocument47 pagesME2134 NUS PipeflowMohammad TahaNo ratings yet

- Dennis Gertenbach, and Brian L. Cooper: Solid - Liquid Separations in Pilot-And Commercial - Scale OperationsDocument25 pagesDennis Gertenbach, and Brian L. Cooper: Solid - Liquid Separations in Pilot-And Commercial - Scale Operationssushant_jhawerNo ratings yet

- Topic 4 Fundamental of Fluids Flows - NEWDocument59 pagesTopic 4 Fundamental of Fluids Flows - NEWMuhammad AzarulNo ratings yet

- Heat Exchange in Subsea Flowline PDFDocument34 pagesHeat Exchange in Subsea Flowline PDFPrasanna KumariNo ratings yet

- Fanning DiagramDocument1 pageFanning DiagramPauline Cahyani SandyNo ratings yet

- CFDCompanion PDFDocument154 pagesCFDCompanion PDFYogitha Sarah BabyNo ratings yet