Professional Documents

Culture Documents

Thickness Calucaltion 200 Bar - Is 7285

Uploaded by

vijaygalaxy0 ratings0% found this document useful (0 votes)

47 views1 pagethickness

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentthickness

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

47 views1 pageThickness Calucaltion 200 Bar - Is 7285

Uploaded by

vijaygalaxythickness

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

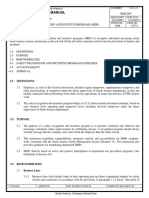

DESIGN CALCULATIONS 11.09.

2014

WALL THICKNESS CALCULATION AS PER IS 7285 (part 2 ): 2004

Drawing No. : 52284480

As per IS 7285 (Part 2) : 2004 - Clause 6.3 the wall thickness of cylindrical shell of the cylinder

is calculated using the following formula :

(Working Pressure at 15°C) = 204.00 Kgf/cm²

200.00 Bar

Ph (1.3 Do² + 0.4 Di²)

f = 100 (Do² - Di²)

PARAMETERS :

1 Outside Diameter of cylinder (Do) = 279.00 mm

Inside Diameter of cylinder (Di) = mm

3 Hydrostatic Stretch test Pressure (Ph) = 340.00 Kgf/cm²

4 Max. allowable wall stress at

Hydrostatic test pressure (5/6 Re) (f) = 66.68 Kgf/mm²

5 Min. value of Yield Strength (Re) = 80.0 Kgf/mm² 785.00 N/mm²

6 Min. value of Tensile Strength (Rg) = 94.6 Kgf/mm² 928.00 N/mm²

7 Yield / Tensile strength ratio (Min.) (Re / Rg) = 0.846

Re = 80.0 kgf/mm²

f= 5/6 x 80.0 = 66.68 kgf/mm²

Ph (1.3 Do² + 0.4 Di²)

f = 100 (Do² - Di²)

340.00 (1.3 Do² + 0.4 Di²)

66.68 = ------------------------------

100 (Do² - Di²)

66.68 Do² - 66.68 Di² = Do² x 4.42 + Di² x 1.36

( 66.68 -4.42 ) Do² =( 66.68 + 1.36 ) Di²

62.26

Di² = ------------ x ( 279.00 )²

68.04

Di² = 71228.76 = Di = 266.89 mm

(Do - Di) 279.00 - 266.89

t= ---------------- = --------------------------------- = 6.06 mm

2 2

As per clause 6.3.2, IS:7285 (Part 2):2004

t = 0.136 x \/(Do) = 0.136 x \/ 279.00

t = 2.27 mm

By substituting the value of Do as 279.00 in formula 0.136 \/ Do ,

we get the value of minimum wall thickness 2.27 mm which is less than

6.06 mm, the value obtained by using above formula in clause 6.3 of IS 7285 (Part 2) : 2004.

The wall thickness 6.06 mm. meets the requirement of IS : 7285 (Part 2) : 2004 clause no. 6.3.

However, based on the nearest minimum wall thickness available from the

tube manufacturer, the wall thickness selected is 6.30 mm.

Prepared By: Approved By:

You might also like

- Forhtml - Af Imt Form 1222 Boiler or Pressure Vessel Inspection Report PDFDocument2 pagesForhtml - Af Imt Form 1222 Boiler or Pressure Vessel Inspection Report PDFReama QumsanNo ratings yet

- 9 Forklift Pre-Operational ChecklistDocument2 pages9 Forklift Pre-Operational ChecklistandrewhwNo ratings yet

- FAT ProcedureDocument7 pagesFAT ProcedureOlek TybińskiNo ratings yet

- Boilers and Unfired Pressure VesselsDocument67 pagesBoilers and Unfired Pressure Vesselsviansh1974No ratings yet

- Dimensional Tolerance ChartDocument1 pageDimensional Tolerance Chartpushkar_k123No ratings yet

- Interview ASME SEC IX & General QUESTIONSDocument45 pagesInterview ASME SEC IX & General QUESTIONSabdo50% (2)

- Pick Carry Cranes Risk AssessmentDocument45 pagesPick Carry Cranes Risk Assessmentbilo1984No ratings yet

- Nfpa 13 Chapter 1Document34 pagesNfpa 13 Chapter 1hmayordomo100% (1)

- Load Chart & Rigging Learning Guide: Mobile Hydraulic Crane 80 Tonnes & UnderDocument25 pagesLoad Chart & Rigging Learning Guide: Mobile Hydraulic Crane 80 Tonnes & UndersutarNo ratings yet

- 2Document11 pages2maheshNo ratings yet

- JSEA FOR DISMNTLING OF MACHINES (Central Work Shop)Document16 pagesJSEA FOR DISMNTLING OF MACHINES (Central Work Shop)B&R HSE BALCO SEP SiteNo ratings yet

- Stress Analysis and Design of Bolted Flange Connections UnderDocument11 pagesStress Analysis and Design of Bolted Flange Connections UndervijaygalaxyNo ratings yet

- Recip. Compressor TestingDocument10 pagesRecip. Compressor TestingS DasNo ratings yet

- 0005 - 007 SAFETY RECOGNITION AND INCENTIVE PROGRAMS (SRIPs)Document5 pages0005 - 007 SAFETY RECOGNITION AND INCENTIVE PROGRAMS (SRIPs)baseet gazaliNo ratings yet

- PTW Associated Certificates KEC - Final V3-TotalDocument9 pagesPTW Associated Certificates KEC - Final V3-TotalXiang JintaoNo ratings yet

- Quiz Questions EHSDocument3 pagesQuiz Questions EHSvijaygalaxy0% (1)

- Saep 1026Document23 pagesSaep 1026Aneesh JosephNo ratings yet

- CartridgeSelectionPoster English HRDocument1 pageCartridgeSelectionPoster English HRTg TarroNo ratings yet

- MME Chemical DistillationDocument42 pagesMME Chemical DistillationsaketNo ratings yet

- Quality Assurance Plan: MPL QAP No.Document13 pagesQuality Assurance Plan: MPL QAP No.Varun MalhotraNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitvarunstuffNo ratings yet

- 1926 Fall Protection ProgramDocument25 pages1926 Fall Protection ProgramDaDemonNo ratings yet

- Oisd RP 233 DraftDocument66 pagesOisd RP 233 DraftvijaygalaxyNo ratings yet

- Oisd RP 233 DraftDocument66 pagesOisd RP 233 DraftvijaygalaxyNo ratings yet

- Subcontractors Weekly HSE Statictic Report: Lagging Indicators - Up To DateDocument1 pageSubcontractors Weekly HSE Statictic Report: Lagging Indicators - Up To Dateindra setiawanNo ratings yet

- Noise MonitoringDocument1 pageNoise MonitoringSAMEER JAVEDNo ratings yet

- Quize Competition Question: Name: - Company Name: - DateDocument1 pageQuize Competition Question: Name: - Company Name: - DateSahabuddin AhmedNo ratings yet

- 02-2013 Kpi Safety PTPDMDocument34 pages02-2013 Kpi Safety PTPDMRobby DamanikNo ratings yet

- Work Management System - Atmospheric Test Record (Supplement)Document1 pageWork Management System - Atmospheric Test Record (Supplement)AndiWSutomoNo ratings yet

- Fault & Event Tree Analysis: BY Nitesh M. DongareDocument34 pagesFault & Event Tree Analysis: BY Nitesh M. DongareTahir AbbasNo ratings yet

- Confined Space TrainingDocument39 pagesConfined Space TrainingFahad Abdul HaqNo ratings yet

- IWkm 370d4 Ball Valve - IOM ManualDocument20 pagesIWkm 370d4 Ball Valve - IOM ManualAsemota Oghogho100% (1)

- Gwo BSTDocument186 pagesGwo BSTΠασχάλης ΖαφειριάδηςNo ratings yet

- Alsa Engineering and Construction Co. L.L.C: Hse Audit Closed Out ReportDocument2 pagesAlsa Engineering and Construction Co. L.L.C: Hse Audit Closed Out ReportHARSHALNo ratings yet

- Agenda Item: 650-2024: Coating Prior To Hydrostatic TestingDocument4 pagesAgenda Item: 650-2024: Coating Prior To Hydrostatic Testinggigiphi1No ratings yet

- Total USD Value: Unrealized USD Gain: Total BTC Value: Unrealized BTC GainDocument15 pagesTotal USD Value: Unrealized USD Gain: Total BTC Value: Unrealized BTC GainRodolfo Castro Jr.No ratings yet

- Saes A 005Document32 pagesSaes A 005hyderabad100% (1)

- Hydrotest Procedure For PipingDocument4 pagesHydrotest Procedure For Pipingsuria qaqcNo ratings yet

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex IDocument3 pagesPro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex IMohammed Hamza100% (1)

- Sis Book 6Document120 pagesSis Book 6Hamza AlamNo ratings yet

- Sabp L 002 PDFDocument27 pagesSabp L 002 PDFshyamNo ratings yet

- Material Handling Equipment. HTTPWWW - Ise.ncsu - Edukaymaterial Handling Equipment PDFDocument67 pagesMaterial Handling Equipment. HTTPWWW - Ise.ncsu - Edukaymaterial Handling Equipment PDFAan D'yantoNo ratings yet

- Quiz-Training Programme: Fire SafetyDocument8 pagesQuiz-Training Programme: Fire SafetyFarhat SetharNo ratings yet

- Did You Know There'S A Lot More To Ladder Safety Than Safely Climbing ItDocument1 pageDid You Know There'S A Lot More To Ladder Safety Than Safely Climbing ItBalaji ThiaguNo ratings yet

- Garware Polyester Limited-Electrical Films EM6, Thickness, Unit, Yield, DensityDocument2 pagesGarware Polyester Limited-Electrical Films EM6, Thickness, Unit, Yield, Densitybenghoe77100% (2)

- Air Receiver Tank Hazard ChecklistDocument2 pagesAir Receiver Tank Hazard ChecklistJade JavierNo ratings yet

- Confined SpacesDocument25 pagesConfined Spaceshi2lathaNo ratings yet

- QP MEP Q0202 Office AssistantDocument44 pagesQP MEP Q0202 Office Assistantjaveeed0401No ratings yet

- Drill Floor Safety - ArabicDocument22 pagesDrill Floor Safety - ArabicEslam IsmaeelNo ratings yet

- MtE325-Assignment 3Document3 pagesMtE325-Assignment 3Hacker YousafzaiNo ratings yet

- Luxathane 5160Document2 pagesLuxathane 5160shameelNo ratings yet

- Health and Safety & TOPdesk: A Safe CombinationDocument2 pagesHealth and Safety & TOPdesk: A Safe CombinationTOPdeskNo ratings yet

- ARaymond EDS Catalog 2018 WebDocument124 pagesARaymond EDS Catalog 2018 WebFidrian Eko Wahyudi100% (1)

- 1 45Document3 pages1 45nsadnan0% (1)

- Contractor Induction TrainingDocument3 pagesContractor Induction TrainingSanjeev KumarNo ratings yet

- Automobile Air Condition System Using Exahust GasDocument19 pagesAutomobile Air Condition System Using Exahust GasEr. Ramji TripathiNo ratings yet

- Benefit Cost Ratio Analysis and Payback PeriodDocument20 pagesBenefit Cost Ratio Analysis and Payback Periodfadhillah ivanNo ratings yet

- Interview Questions For EHS EngineerDocument6 pagesInterview Questions For EHS EngineerWasifNo ratings yet

- Jollyfix: Technical Data SheetDocument3 pagesJollyfix: Technical Data Sheetمحمد عزتNo ratings yet

- Resin R3X1080 - Material Safety Data Sheet - Part BDocument5 pagesResin R3X1080 - Material Safety Data Sheet - Part BRavie OuditNo ratings yet

- Attachment 7 Scaffolding PermitDocument2 pagesAttachment 7 Scaffolding PermitAviects Avie JaroNo ratings yet

- MSDS Caustic SodaDocument4 pagesMSDS Caustic Sodaoscarlopez12345No ratings yet

- SMPV ProformasNewDocument20 pagesSMPV ProformasNewSanjeet Kumar SinghNo ratings yet

- SK Assoicates Authorized DealerDocument1 pageSK Assoicates Authorized DealerKamalesh KumarNo ratings yet

- Msds-Fluidsol 40Document8 pagesMsds-Fluidsol 40Yaseen Mohd KhanNo ratings yet

- Genie-Making Sense of MEWPSDocument11 pagesGenie-Making Sense of MEWPSd. donlonNo ratings yet

- Life Saving RulesDocument78 pagesLife Saving RulesmuratNo ratings yet

- Shift Changeover ChecklistDocument4 pagesShift Changeover ChecklistjohncoolaliNo ratings yet

- Plant LayoutDocument68 pagesPlant LayoutMadhu VigneshNo ratings yet

- GE PTW Confined SpacesDocument2 pagesGE PTW Confined SpacesKural MurugesanNo ratings yet

- Integrated Management System Awareness: Switch Off Mobile PhonesDocument39 pagesIntegrated Management System Awareness: Switch Off Mobile PhonesajoshpkNo ratings yet

- Crash Schedule Normal Schedule Activity Time Cost Time Cost: ST ND RDDocument2 pagesCrash Schedule Normal Schedule Activity Time Cost Time Cost: ST ND RDAkhilAgrawalNo ratings yet

- Chevron SOP 45 Scaffolding PDFDocument40 pagesChevron SOP 45 Scaffolding PDFmohammedkaustNo ratings yet

- Fundamentals of Heat and Mass Transfer 7Th Edition Incropera Solutions Manual Full Chapter PDFDocument68 pagesFundamentals of Heat and Mass Transfer 7Th Edition Incropera Solutions Manual Full Chapter PDFbrainykabassoullw100% (10)

- Flat Slab DesignDocument26 pagesFlat Slab Designbsreenu393No ratings yet

- Calculate The Weight Loss in Steel Sample Due To Erosion Corrosion in 3.5% NaCl Solution With 10% Silica Sand Particles As Per ASTM G-184.Document11 pagesCalculate The Weight Loss in Steel Sample Due To Erosion Corrosion in 3.5% NaCl Solution With 10% Silica Sand Particles As Per ASTM G-184.Farwa NaeemNo ratings yet

- 2 Ethyl 2520hexanol Design 2520of 2520equipmentsDocument49 pages2 Ethyl 2520hexanol Design 2520of 2520equipmentsapi-3714811100% (3)

- Жалюзийная насадка импортная PDFDocument4 pagesЖалюзийная насадка импортная PDFВалентин СелищевNo ratings yet

- Elastomeric BRG1Document7 pagesElastomeric BRG1vivekNo ratings yet

- Self Supporting Chimney Problem1Document17 pagesSelf Supporting Chimney Problem1GOVINDARAJU SNo ratings yet

- 9485 & 926 Transfer Tapes: Product Data SheetDocument3 pages9485 & 926 Transfer Tapes: Product Data SheetvijaygalaxyNo ratings yet

- Raghavendra Hegde: ND STDocument5 pagesRaghavendra Hegde: ND STvijaygalaxyNo ratings yet

- Full Page PhotoDocument48 pagesFull Page PhotovijaygalaxyNo ratings yet

- Fraction Conversion ChartDocument1 pageFraction Conversion ChartMichael RusynyakNo ratings yet

- Hypoxic Air Venting SystemDocument13 pagesHypoxic Air Venting SystemvijaygalaxyNo ratings yet

- Drill Size - Inch Go and No GoDocument1 pageDrill Size - Inch Go and No GovijaygalaxyNo ratings yet

- Tchart PDFDocument3 pagesTchart PDFferdyak1No ratings yet

- FEDEX PKG Testing Over150LbsDocument7 pagesFEDEX PKG Testing Over150LbsvijaygalaxyNo ratings yet

- Introduction To Windchill Pdmlink 10.2 For Light UsersDocument7 pagesIntroduction To Windchill Pdmlink 10.2 For Light UsersvijaygalaxyNo ratings yet

- Full Time Postgraduate ProgramDocument1 pageFull Time Postgraduate ProgramvijaygalaxyNo ratings yet

- Fraction Conversion ChartDocument1 pageFraction Conversion ChartMichael RusynyakNo ratings yet

- GCR 2016 62-63Document2 pagesGCR 2016 62-63vijaygalaxyNo ratings yet

- WorkCover NSW Fees Schedule - From July 2015 - WorkCoverDocument4 pagesWorkCover NSW Fees Schedule - From July 2015 - WorkCovervijaygalaxyNo ratings yet

- Hypoxic Air Venting SystemDocument13 pagesHypoxic Air Venting SystemvijaygalaxyNo ratings yet

- MSDS 3MDocument8 pagesMSDS 3MvijaygalaxyNo ratings yet

- EPF PensionDocument3 pagesEPF Pensionsrikrishnanp825No ratings yet

- Charge HR Sizing GuideDocument1 pageCharge HR Sizing GuidevijaygalaxyNo ratings yet

- Flexi Online Term PlanDocument19 pagesFlexi Online Term PlanvijaygalaxyNo ratings yet

- School of Postgraduate Studies: Nettur Technical Training FoundationDocument1 pageSchool of Postgraduate Studies: Nettur Technical Training FoundationvijaygalaxyNo ratings yet

- Step by Step Guide To Reset Epson L200 Ink CounterDocument7 pagesStep by Step Guide To Reset Epson L200 Ink CountervijaygalaxyNo ratings yet

- 3.125 11ns THread SpecificationDocument4 pages3.125 11ns THread SpecificationvijaygalaxyNo ratings yet

- Concept Design - CapDocument1 pageConcept Design - CapvijaygalaxyNo ratings yet

- 123Document2 pages123vijaygalaxyNo ratings yet

- 32-Samss-036. Small Pressure VesselDocument33 pages32-Samss-036. Small Pressure VesseledwinNo ratings yet

- TCT Question Bank PDFDocument26 pagesTCT Question Bank PDFMahesh MeenaNo ratings yet

- A 1012 - 00 Qtewmtitukve PDFDocument6 pagesA 1012 - 00 Qtewmtitukve PDFfekihassanNo ratings yet

- Cross Country PipelinesDocument20 pagesCross Country PipelinesAnoop PrajapatiNo ratings yet

- Katalog 2020 ENG Stand 2020 01 25 Optimierte ZeichnungenDocument289 pagesKatalog 2020 ENG Stand 2020 01 25 Optimierte ZeichnungenFábio GamaNo ratings yet

- 26 Hydrostatic Testing Specification eDocument2 pages26 Hydrostatic Testing Specification eMuhammad Azlan Ahmad100% (1)

- Chevron Corrective Action OrderDocument8 pagesChevron Corrective Action OrderThe Salt Lake TribuneNo ratings yet

- Engineering Manual: Concrete Pressure PipeDocument176 pagesEngineering Manual: Concrete Pressure Pipeahmad elnggarNo ratings yet

- Sample UdsDocument8 pagesSample UdsPrince SharmaNo ratings yet

- Saudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechDocument3 pagesSaudi Aramco Inspection Checklist: Field Hydrostatic Testing of Isolation Valves SAIC-L-2042 25-May-05 MechHamidNo ratings yet

- Method Statement and Risk Assessment GeneralDocument16 pagesMethod Statement and Risk Assessment GeneralDwi Windi AjiNo ratings yet

- Procedimiento de Test & Pruebas Hidrostaticas M40339-Ppu-R10 HCL / Dosing Pumps Rev.0Document13 pagesProcedimiento de Test & Pruebas Hidrostaticas M40339-Ppu-R10 HCL / Dosing Pumps Rev.0José Angel TorrealbaNo ratings yet

- Pages From 053096-2Document1 pagePages From 053096-2Dgh TeriNo ratings yet

- Final - Draft Specificaion - P.C.C.P1Document22 pagesFinal - Draft Specificaion - P.C.C.P1Chief Engineer Hydro Project & Quality ControlNo ratings yet

- api 510 اسئلة متنوعة لكل الكورسDocument42 pagesapi 510 اسئلة متنوعة لكل الكورسhussam ghiathNo ratings yet