Professional Documents

Culture Documents

P Number Soldadores (Welder)

Uploaded by

josel2130 ratings0% found this document useful (0 votes)

28 views1 pageP

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentP

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

28 views1 pageP Number Soldadores (Welder)

Uploaded by

josel213P

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Frs|uljkwhg#pdwhuldo#olfhqvhg#wr#Xqlyhuvlw|#ri#Wrurqwr#e|#Wkrpvrq#Vflhqwlilf/#Lqf1#+zzz1whfkvwuhhw1frp,1##Wklv#frs|#grzqordghg#rq#534803:046#3:=69=6:#03833#e|#dxwkrul}hg#xvhu#orjdq#dkovwurp1##Qr#ix

ASME BPVC.IX-2015

QW-423 ALTERNATE BASE MATERIALS FOR

Base Metal(s) Used for

WELDER QUALIFICATION Procedure Qualification

ð15Þ QW-423.1 Base metal used for welder qualification Coupon Base Metals Qualified

may be substituted for the metal specified in the WPS in One metal from a P‐Number to Any metals assigned that

accordance with the following table. When a base metal any metal from the same P‐Number

shown in the left column is used for welder qualification, P‐Number

One metal from a P‐Number to Any metal assigned the first

the welder is qualified to weld all combinations of base

any metal from any other P‐Number to any metal

metals shown in the right column, including unassigned P‐ Number assigned the second

metals of similar chemical composition to these metals. P‐Number

One metal from P‐No. 15E to Any P‐No. 15E or 5B metal to

Base Metals for Welder Qualified Production Base any metal from P‐No. 15E any metal assigned P‐No.

Qualification Metals 15E or 5B

P‐No. 1 through P‐No. 15F, P‐No. 1 through P‐No. 15F, One metal from P‐No. 15E to Any P‐No. 15E or 5B metal to

P‐No. 34, or P‐No. 41 P‐No. 34, and P‐No. 41 any metal from any other any metal assigned the

through P‐No. 49 through P‐No. 49 P‐Number second P‐Number

One metal from P‐No. 3 to any Any P‐No. 3 metal to any metal

P‐No. 21 through P‐No. 26 P‐No. 21 through P‐No. 26 metal from P‐No. 3 assigned P‐No. 3 or 1

One metal from P‐No. 4 to any Any P‐No. 4 metal to any metal

metal from P‐No. 4 assigned P‐No. 4, 3, or 1

P‐No. 51 through P‐No. 53 or P‐No. 51 through P‐No. 53 and

One metal from P‐No. 5A to Any P‐No. 5A metal to any

P‐No. 61 or P‐No. 62 P‐No. 61 and P‐No. 62

any metal from P‐No. 5A metal assigned P‐No. 5A, 4,

3, or 1

Any unassigned metal to the The unassigned metal to itself One metal from P‐No. 5A to a Any P‐No. 5A metal to any

same unassigned metal metal from P‐No. 4, or P‐No. metal assigned to P‐No. 4, 3,

3, or P‐No. 1 or 1

Any unassigned metal to any The unassigned metal to any One metal from P‐No. 4 to a Any P‐No. 4 metal to any metal

P-Number metal metal assigned to the same metal from P‐No. 3 or P‐No. assigned to P‐No. 3 or 1

P-Number as the qualified 1

metal Any unassigned metal to the The unassigned metal to itself

same unassigned metal

Any unassigned metal to any The unassigned metal to any

Any unassigned metal to any The first unassigned metal to

P‐Number metal metal assigned to the same

other unassigned metal the second unassigned

P‐Number as the qualified

metal

metal

Any unassigned metal to any The unassigned metal to any

metal from P‐No. 15E metal assigned P‐No. 15E or

5B

Any unassigned metal to any The first unassigned metal to

other unassigned metal the second unassigned

QW-423.2 Metals used for welder qualification con- metal

forming to national or international standards or specifi-

cations may be considered as having the same P‐Number QW-424.2 For welds joining base metals to weld me-

as an assigned metal provided it meets the mechanical tal buildup or corrosion-resistant weld metal overlay, the

and chemical requirements of the assigned metal. The buildup or overlay portion of the joint may be substituted

base metal specification and corresponding P‐Number in the test coupon by any P-Number base material that

shall be recorded on the qualification record. nominally matches the chemical analysis of the buildup

or overlay.

QW-424 BASE METALS USED FOR PROCEDURE

QUALIFICATION

QW-430 F-NUMBERS

QW-424.1 Base metals are assigned P‐Numbers in

Table QW/QB-422; metals that do not appear in Table QW-431 GENERAL

QW/QB-422 are considered to be unassigned metals ex- The following F‐Number grouping of electrodes and

cept as otherwise defined for base metals having the same welding rods in Table QW-432 is based essentially on

UNS numbers. Unassigned metals shall be identified in the their usability characteristics, which fundamentally de-

WPS and on the PQR by specification, type and grade, or termine the ability of welders to make satisfactory welds

by chemical analysis and mechanical properties. The with a given filler metal. This grouping is made to reduce

minimum tensile strength shall be defined by the organi- the number of welding procedure and performance qua-

zation that specified the unassigned metal if the tensile lifications, where this can logically be done. The grouping

strength of that metal is not defined by the material does not imply that base metals or filler metals within a

specification. group may be indiscriminately substituted for a metal

161

You might also like

- Common Material and Welding CodesDocument1 pageCommon Material and Welding CodesLuttpiNo ratings yet

- 8.9 Basic Maths For Well PlanningDocument9 pages8.9 Basic Maths For Well PlanningKhanh Pham MinhNo ratings yet

- Acceptance Criteria For Weld of All Code and Standard Prepared by SadamDocument30 pagesAcceptance Criteria For Weld of All Code and Standard Prepared by Sadamananth rajanNo ratings yet

- b25d b30d Mkiii HydraulicsDocument28 pagesb25d b30d Mkiii HydraulicsErmias100% (3)

- Poster Welding Positions Asme Vs enDocument1 pagePoster Welding Positions Asme Vs enalan100% (1)

- Piping MaterialDocument8 pagesPiping Materialnitin_birNo ratings yet

- This documentDocument44 pagesThis documentTran Thanh HaoNo ratings yet

- ASME Sec-IX interpretation on qualification of dissimilar base metal groupsDocument2 pagesASME Sec-IX interpretation on qualification of dissimilar base metal groupsManivannanMudhaliarNo ratings yet

- ASME IX (2023) - Range Qualification WPS & WelderDocument10 pagesASME IX (2023) - Range Qualification WPS & WelderMOHAMMAD RAMZAN100% (1)

- RMC Case StudyDocument2 pagesRMC Case StudyAmer RahmahNo ratings yet

- Thermal Efficiency and Arc Energy FEM ModelDocument5 pagesThermal Efficiency and Arc Energy FEM ModelWilly Villa SalsavilcaNo ratings yet

- Toolbox Meeting Or, TBT (Toolbox TalkDocument10 pagesToolbox Meeting Or, TBT (Toolbox TalkHarold PonceNo ratings yet

- QW-424 Asme Ix 2023Document1 pageQW-424 Asme Ix 2023CARLOS OLIVEROSNo ratings yet

- ASME P-Numbers: A Guide to Material GroupingsDocument6 pagesASME P-Numbers: A Guide to Material GroupingsAbdul KharisNo ratings yet

- STAINLESS Filler Selector Guide PDFDocument1 pageSTAINLESS Filler Selector Guide PDFArul Edwin VijayNo ratings yet

- ASME B16.48-2010 Line BlanksDocument56 pagesASME B16.48-2010 Line Blanksjosel213No ratings yet

- Lab Testing Report - RoHSDocument16 pagesLab Testing Report - RoHSajayNo ratings yet

- WPSDocument42 pagesWPSjoehodoh100% (1)

- ASME P and F Material Numbers ExplainedDocument17 pagesASME P and F Material Numbers ExplainedArfanAliNo ratings yet

- Guidlines Norms For Grant of Permission For Construction of Acce001Document6 pagesGuidlines Norms For Grant of Permission For Construction of Acce001Abhi Corleone BallackNo ratings yet

- P-Number For Welding MaterialDocument14 pagesP-Number For Welding MaterialTâm NgôNo ratings yet

- WPS, PQR & WPQTDocument14 pagesWPS, PQR & WPQTSky RNo ratings yet

- Audi A3 Injeção DiretaDocument109 pagesAudi A3 Injeção Diretawesley candido100% (1)

- Part 01 - Review of EN ISO 9606-1Document26 pagesPart 01 - Review of EN ISO 9606-1Turbo Snail RNo ratings yet

- DIN 17007-4-1963, Material Type NumberDocument9 pagesDIN 17007-4-1963, Material Type NumberLloyd R. PonceNo ratings yet

- Carbon Structural Steel: Standardspecification ForDocument4 pagesCarbon Structural Steel: Standardspecification ForlinaNo ratings yet

- 8602 BookDocument240 pages8602 BookSohail100% (2)

- ISO 10816 - Severidad en Vibracion PDFDocument2 pagesISO 10816 - Severidad en Vibracion PDFJuan Carlos Bonifacio BricenoNo ratings yet

- ASME Definitions, Welding Positions, Materials GuideDocument9 pagesASME Definitions, Welding Positions, Materials GuideSankar KrishnanNo ratings yet

- TableQW-461.9 Performance Qualification-Position and Diameter LimitationsDocument1 pageTableQW-461.9 Performance Qualification-Position and Diameter LimitationsMadidj_2014No ratings yet

- TableQW-461.9 Performance Qualification-Position and Diameter LimitationsDocument1 pageTableQW-461.9 Performance Qualification-Position and Diameter LimitationsMadidj_2014No ratings yet

- Poster Weldingpositions enDocument1 pagePoster Weldingpositions enEsin DenizNo ratings yet

- Proposed To Revision To QW-423.1: QW-423 Alternate Base Materials For Welder Qualification QW-423.1Document4 pagesProposed To Revision To QW-423.1: QW-423 Alternate Base Materials For Welder Qualification QW-423.1Marcio Jr.No ratings yet

- P No QaDocument11 pagesP No QadhasdjNo ratings yet

- Welding Base MetalsDocument9 pagesWelding Base MetalsBaluNo ratings yet

- A LTM at Welder QualDocument13 pagesA LTM at Welder QualMidhun K Chandrabose100% (1)

- The Methodology of The Number System of The Welding WorldDocument9 pagesThe Methodology of The Number System of The Welding WorldHenry RojasNo ratings yet

- QW 423.1 InterpretationDocument1 pageQW 423.1 InterpretationZaheed ManooNo ratings yet

- Complete List of Welding Processes and Their Corresponding Tables For Variables (As Per ASME Section IX)Document16 pagesComplete List of Welding Processes and Their Corresponding Tables For Variables (As Per ASME Section IX)Deb MajiNo ratings yet

- iNTERVIEW QUESTIONSDocument20 pagesiNTERVIEW QUESTIONSBalasahebNo ratings yet

- RESISTANCE WELDING ELECTRODES AND PROPERTIES GUIDEDocument48 pagesRESISTANCE WELDING ELECTRODES AND PROPERTIES GUIDESebastian MolinaNo ratings yet

- P-Number F-Number and A-Number in Welding PDFDocument3 pagesP-Number F-Number and A-Number in Welding PDFAkansha SharmaNo ratings yet

- Book 1Document1 pageBook 1Mian Aamir SaddiqNo ratings yet

- Classwork 1 Rehab MS-1Document1 pageClasswork 1 Rehab MS-1halahossam8899No ratings yet

- Drawing Bohr ModelsDocument6 pagesDrawing Bohr ModelsNOVA LESLIE AGAPAYNo ratings yet

- JIS B2316 Steel Socket Welding Pipe Fittings2Document17 pagesJIS B2316 Steel Socket Welding Pipe Fittings2nse mcxNo ratings yet

- 4 Asme Sec Ix Wps PQR Slide 36 To 70Document35 pages4 Asme Sec Ix Wps PQR Slide 36 To 70qazi12No ratings yet

- Pages From BPVC - IX-2021Document2 pagesPages From BPVC - IX-2021Ramona CrangasNo ratings yet

- Registration for Metals SupplierDocument4 pagesRegistration for Metals SupplierMohammad Kalim Kazi MumbaiNo ratings yet

- Metal Introduction PDFDocument4 pagesMetal Introduction PDFMohammad Kalim Kazi MumbaiNo ratings yet

- ASME A-Number Guide for Weld MetalsDocument3 pagesASME A-Number Guide for Weld MetalsAbdul KharisNo ratings yet

- Selection of Filler Metal For WeldingDocument21 pagesSelection of Filler Metal For WeldingRegu vlogsNo ratings yet

- Electrode With Material Grades Rev.00Document1 pageElectrode With Material Grades Rev.00Muhammad NozarNo ratings yet

- Asme Ix QW MTDocument57 pagesAsme Ix QW MTharabiNo ratings yet

- Table 4 Shows The Information of Three Chemical CellsDocument2 pagesTable 4 Shows The Information of Three Chemical CellsIzz KhawarizmiNo ratings yet

- Classwork 3 MS RehabDocument1 pageClasswork 3 MS Rehabhalahossam8899No ratings yet

- P number in welding reduces procedure qualificationsDocument4 pagesP number in welding reduces procedure qualificationsAlok SinghNo ratings yet

- Corrosion Control Materials: Exothermic-WeldingDocument2 pagesCorrosion Control Materials: Exothermic-WeldingElambarithi KalyanakumarNo ratings yet

- DocumentDocument5 pagesDocumentmohammed siddiqNo ratings yet

- Welding Base Metal GroupingDocument5 pagesWelding Base Metal GroupingBN JadhavNo ratings yet

- Variable E SE NE Description of Variable As in Code 2011a QW SMAW Welding Variables For WPS - ASME Sec IX 2011aDocument7 pagesVariable E SE NE Description of Variable As in Code 2011a QW SMAW Welding Variables For WPS - ASME Sec IX 2011aSaut Maruli Tua SamosirNo ratings yet

- ASME P Material Numbers ExplainedDocument6 pagesASME P Material Numbers Explainedsagar1503100% (1)

- PVWC Listing For CliftonDocument55 pagesPVWC Listing For CliftonDavid WebbNo ratings yet

- Catalog: Consumable Welding ProductsDocument76 pagesCatalog: Consumable Welding ProductsNicole S. TeodoroNo ratings yet

- Re: Difference Between P-No and S-No in ASME IX: Pietro RandelliDocument1 pageRe: Difference Between P-No and S-No in ASME IX: Pietro Randellitaselvakumar4229No ratings yet

- Steel Designation SystemDocument3 pagesSteel Designation SystemvalamaghamNo ratings yet

- Earn A College Degree Online. Financial Aid Available. Call 24/7Document4 pagesEarn A College Degree Online. Financial Aid Available. Call 24/79885869251No ratings yet

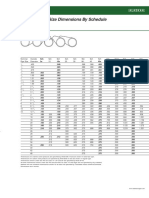

- Nominal Pipe Size DimensionsDocument1 pageNominal Pipe Size Dimensionsjosel213No ratings yet

- F Number ER70S 6Document1 pageF Number ER70S 6josel213No ratings yet

- F Number ER70S 6Document1 pageF Number ER70S 6josel213No ratings yet

- Welding StainlessSteel LincolnDocument40 pagesWelding StainlessSteel Lincolnjosel213No ratings yet

- Test TensileDocument31 pagesTest Tensilejosel213No ratings yet

- Concept Shot BlastingDocument16 pagesConcept Shot Blastingjosel213No ratings yet

- Al Flhakj Halhfakg Lkahf LKJHG Agas GaDocument1 pageAl Flhakj Halhfakg Lkahf LKJHG Agas Gaabidaliabid1No ratings yet

- 1169 2014-BOK Rev-071014Document9 pages1169 2014-BOK Rev-071014Siva KumarNo ratings yet

- A36 23793-1 PDFDocument1 pageA36 23793-1 PDFjosel213No ratings yet

- A572 15056-1Document1 pageA572 15056-1josel213No ratings yet

- Naxtra-Xabo 2010 GBDocument6 pagesNaxtra-Xabo 2010 GBjosel213No ratings yet

- b31.4 Contenido PDFDocument6 pagesb31.4 Contenido PDFEliezerlunaNo ratings yet

- Test TensileDocument31 pagesTest Tensilejosel213No ratings yet

- A36 23793-1 PDFDocument1 pageA36 23793-1 PDFjosel213No ratings yet

- XAR 400 (WB 703) EnglischDocument3 pagesXAR 400 (WB 703) Englischgheoda8926No ratings yet

- M1 121 221 2011Document1 pageM1 121 221 2011josel213No ratings yet

- CanReg5 InstructionsDocument150 pagesCanReg5 InstructionsdiyafersanNo ratings yet

- Food Conformity BA 550-13Document9 pagesFood Conformity BA 550-13puipuiesperaNo ratings yet

- CH - 1Document4 pagesCH - 1Phantom GamingNo ratings yet

- MCCB SchneiderDocument2 pagesMCCB SchneiderkumontholNo ratings yet

- Hardware Devices Used in Virtual Reality TechnologiesDocument6 pagesHardware Devices Used in Virtual Reality TechnologiesTheMoon LightNo ratings yet

- Sigmund Freud and His Main TheoriesDocument5 pagesSigmund Freud and His Main TheoriesNguyen HarryNo ratings yet

- Physical Layer:: SwitchingDocument27 pagesPhysical Layer:: SwitchingPKSachanNo ratings yet

- Check List of MossesDocument319 pagesCheck List of MossesAshen NirodyaNo ratings yet

- Mini-Com Cat6E - ®TX6 ™ PLUS UTP Coupler ModulesDocument2 pagesMini-Com Cat6E - ®TX6 ™ PLUS UTP Coupler Moduleslejlas77No ratings yet

- Active-Passive VoiceDocument18 pagesActive-Passive VoiceDivya JainNo ratings yet

- Ayurveda Signs of LifeDocument15 pagesAyurveda Signs of LifeSanjeethNo ratings yet

- Kompres Panas Dingin Dapat Mengurangi Nyeri Kala I Persalinan Di Rumah Sakit Pertamina Bintang AminDocument9 pagesKompres Panas Dingin Dapat Mengurangi Nyeri Kala I Persalinan Di Rumah Sakit Pertamina Bintang AminHendrayana RamdanNo ratings yet

- 13 Nilufer-CaliskanDocument7 pages13 Nilufer-Caliskanab theproNo ratings yet

- Upvc Project ReportDocument39 pagesUpvc Project ReportRohit KumarNo ratings yet

- Anie Altamirano Learning For Life HandoutDocument4 pagesAnie Altamirano Learning For Life HandoutAnnapurna VNo ratings yet

- Mascot LD series hydraulic motor specsDocument6 pagesMascot LD series hydraulic motor specsM S GokulNo ratings yet

- Facts & Figures of Nepalese HydroDocument11 pagesFacts & Figures of Nepalese Hydromark bingNo ratings yet

- Instruction Manual Series 854 XTG Level GaugeDocument60 pagesInstruction Manual Series 854 XTG Level GaugeJandri JacobNo ratings yet

- Marketing Assignment (Cool Air India)Document10 pagesMarketing Assignment (Cool Air India)Mandira PantNo ratings yet

- Journal of Travel & Tourism MarketingDocument19 pagesJournal of Travel & Tourism MarketingSilky GaurNo ratings yet

- Mobile Phone: Service ManualDocument129 pagesMobile Phone: Service ManualAlexNo ratings yet

- IC-V80 V80E ManualDocument64 pagesIC-V80 V80E Manualrzkyln100% (1)

- The historical evolution of organizational behavior and how it shaped modern managementDocument3 pagesThe historical evolution of organizational behavior and how it shaped modern managementSaravanan Swagger100% (1)