Professional Documents

Culture Documents

10-DP-D704.12 6 2

Uploaded by

Chechae ChaerikaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10-DP-D704.12 6 2

Uploaded by

Chechae ChaerikaCopyright:

Available Formats

TIG WELDING

PENGELASAN TIG

Document No. : 10-DP-D704.12

Revision : 6

Date of Issued : September 23, 2016

Status of Distribution : Controlled

Uncontrolled

COPY & PRINTED FOR INFORMATION ONLY

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 2 of 39

Rev.6

DISTRIBUTION LIST

DAFTAR DISTRIBUSI

This document is controlled and maintained as a confidential Document. The

controlled document is stamped “CONTROLLED COPY” in red color.

Dokumen ini dikontrol dan dipelihara sebagai Dokumen rahasia. Dokumen yang

dikontrol dicap "CONTROLLED COPY" dengan warna merah.

COPY

COPY HOLDER

NO.

01 Head of Div. Quality Assurance

02 Head of Div. Manufacturing Engineering

03 Manager of Quality Engineering - QA

04 Manager of Quality Inspection for DPM - QA

05 Manager of Metal Forming And Heat treatment - DM

06 Manager of CN235 - PP

07 Manager of C212 Program - PP

08 Manager of MK II Eurocopter Program - PP

09 Manager of Detail Part Manufacturing Planning - PE

10 Manager of Tooling Engineering - PE

11 Manager of Lean & Development - PE

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 3 of 39

Rev.6

APPROVAL & REVISION HISTORY LOG

PERSETUJUAN DAN REVISI DOKUMEN

Reason for

Effective Approved

No. Revision Revision/ Author

Date by

Change Request

Initial Release,

1 0 06/10/2011 supersedes OI 22- M Ramdhan A Yustiono DA

AE-03-049

Refer to DCR

2 1 11/08/2011 M Ramdhan A Yustiono DA

No.0121/PE6000/11

Refer to DCR

3 2 05/03/2013 Asep Harun Yustiono DA

No. 0028/AE0210/13

3 Refer to DCR M.Robiawan

4 01/17/2014 M. Adhitya

(Bilingual) No. 0021/QA1000/14 Nefota FL

4 June 5, Refer to DCR

5 M. Adhitya M.Robiawan

(Bilingual) 2015 No. 0064/PE6200/15

5 Mar. 31, Refer to DCR

6 M. Adhitya M.Robiawan

(Bilingual) 2016 No. 0046/QA1400/16

6 Sep. 23, Refer to DCR M.Robiawan

7 M. Adhitya

(Bilingual) 2016 No. 0158/PE6200/16

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 4 of 39

Rev.6

TABLE OF CONTENTS Page

DAFTAR ISI Halaman

APPROVAL SHEET / Lembaran Pengesahan 1

DISTRIBUTION LIST / Daftar Distribusi 2

APPROVAL & REVISION HISTORY LOG / Persetujuan & Riwayat 3

Perbaikan

TABLE OF CONTENTS / Daftar Isi 4

1. PURPOSE / Tujuan 5

2. SCOPE / Ruang Lingkup 5

3. REFERENCE / Referensi 5

4. DEFINITION & ACRONYM / Definisi & Singkatan 6

5. GENERAL / Umum 7

6. RESPONSIBILITIES / Tanggung Jawab 7

7. ATTACHMENTS / Lampiran 22

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 5 of 39

Rev.6

1. Purpose 1. Tujuan

Describes the procedure to perform Operating Instruction ini menjelaskan

welding using TIG welding machine, prosedur untuk pengelasan meng-

starting from preparation (checking the gunakan mesin las TIG manual mulai dari

machine, working document, material), persiapan (pemeriksaan fasilitas,

perform the task (loading, welding, dokumen kerja, alat bantu, material),

unloading) until the finished parts are pelaksanaan pekerjaan (loading, pe-

ready to be delivered to the next ngelasan, unloading), sampai benda kerja

operation. dikirim untuk operasi selanjutnya.

This operating instruction replaces the title Operating instruction ini menggantikan

“Operating TIG Welding Machine”. judul “Operating TIG Welding Machine”.

2. Scope 2. Ruang Lingkup

This work instruction is applicable to weld Operating instruction ini berlaku untuk

all material welded assembly. pengelasan semua jenis material.

Note 1: Catatan 1:

If required by AH engineering, Welding Apabila diperlukan oleh Engineering AH,

Procedure Specifications is required for Spesifikasi prosedur pengelasan diper-

welding inspection of level 1 and 2. lukan untuk pemeriksaan pengelasan

tingkat 1 dan 2.

Note 2: Catatan 2:

For welder qualification use WPS number Untuk kualifikasi welder gunakan WPS

as follow: nomor sbb:

a. WPS/FW-QUAL/AH/01 a. WPS/FW-QUAL/AH/01

b. WPS/FW-QUAL/AH/02 b. WPS/FW-QUAL/AH/02

c. WPS/FW-QUAL/AH/03 c. WPS/FW-QUAL/AH/03

d. WPS/FW-QUAL/AH/04 d. WPS/FW-QUAL/AH/04

e. WPS/FW-QUAL/AH/05 e. WPS/FW-QUAL/AH/05

f. WPS/FW-QUAL/AH/06 f. WPS/FW-QUAL/AH/06

Note 3: Catatan 3:

Welding parameters for parts production Parameter pengelasan untuk produksi

refer to table 7, table 8, table 9 and table part, mengacu ke table 7, 8 tabel 9 dan

10. table 10.

3. Reference 3. Referensi

I+D-P-181 : Fusion Welding of I+D-P-181 : Fusion Welding of

Metals Metals

27-P-2C-181 : SMPI (Standard 27-P-2C-181 : SMPI (Standard

Manufacturing Process Manufacturing Process

Inspection) Inspection)

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 6 of 39

Rev.6

IF-MA No. 853 : TIG Welding IF-MA No. 853 : TIG Welding

IGC04.62.165 : Steel Parts and IGC04.62.165 : Steel Parts and

Assemblies Fusion Assemblies Fusion

Welding Inspection Welding Inspection

IGC04.62.166 : Aluminium Alloy Parts IGC04.62.166 : Alumunium Alloy Parts

and Assemblies and Assemblies

Inspection of Fusion Inspection of Fusion

Welding Welding

4. Definition and Acronym 4. Definisi dan Singkatan

TIG : TIG :

Tungsten Inert Gas Welding is an electric Tungsten Inert Gas Welding adalah

arc welding. The necessary heat for Gas pengelasan dengan busur listrik. Panas

Tungsten Arc Welding (TIG) is produced yang diperlukan untuk Gas Tungsten Arc

by an electric arc maintained between a Welding (TIG) dihasilkan dari busur listrik

non consumable tungsten electrode and antara non consumable elektroda tungsten

the part to be welded. The heat-affected dan part yang akan dilas. Heat affected

zone, the molten metal, and the tungsten zone, metal yang cair, dan elektroda

electrode are all shielded from the tungsten semuanya dilindungi dari udara

atmosphere by a blanket of inert gas fed luar dengan gas mulia yang disalurkan

through the GTAW torch. melalui GTAW torch.

In-process correction : In-process correction :

Any correction of a weld made by the Setiap perbaikan pada lasan yang

welder before submitting the weldment for dilakukan oleh welder sebelum

acceptance inspection. menyerahkan lasan untuk diperiksa oleh

inspektor.

MEK : MEK :

Methyl Ethyl Keton, solvent cleaner to Methyl Ethyl Keton, solvent cleaner untuk

clean dirt, oil, grease etc. membersihkan kotoran, oli, stempet dll.

SAP : SAP :

System Application and Procedure System Application and Production

Welding procedure/ welding schedule/ Welding prosedur/ Welding schedul/

welding parameters : welding parameter:

Form that contains parameters for welding Form yang berisi parameter untuk

such as current, gas flow, voltage, pengelasan seperti arus, gas flow, voltase,

specification of filler metal, electrode, spesifikasi filler, tungsten elektroda, nozzle

nozzle etc. dll.

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 7 of 39

Rev.6

5. General 5. Umum

Operating and Maintenance/ Repair of the Pengoperasian dan perawatan/perbaikan

machine are only performed by designated fasilitas hanya boleh dilakukan oleh

/ authorized person, who has the personil yang ditunjuk/berwenang dan

qualification and experience. mempunyai kualifikasi dan pengalaman

yang memadai.

Manager of Metal Forming and Heat Personil yang mengoperasikan mesin

Treatment assign the person who ditunjuk/ditentukan oleh Manager Metal

operates the machine. Forming and Heat Treatment .

Welding machine, fixture, tooling and Mesin las,fixture,tool dan material tool

tooling material shall be suitable and harus sesuai dan menghasilkan lasan

capable of consistently producing yang konsisten dan dapat diterima.

acceptable weld.

Maintenance and repair of TIG welding Perawatan dan perbaikan fasilitas mesin

machine is only performed by designated TIG welding dilakukan oleh personil yang

person appointed by Manager of Facility ditunjuk/ditentukan oleh Facility

Maintenance. Maintanance .

Quality Assurance Management assigns Quality assurance management

personnel (see attachment-11) to perform menetapkan personil untuk melaksanakan

and control welding process. dan memeriksa proses welding (lampiran

11).

6. Responsibilities 6. Tanggung jawab

The function that has the responsibility to Fungsi yang bertanggung jawab dalam

perform this work instruction is the menjalankan instruksi kerja ini adalah

operator, leader and supervisor of TIG operator, leader, supervisor welding,

welding machine, inspector and related inspektor dan fungsi terkait.

function.

The steps that has to be performed to do Langkah langkah yang harus dilakukan

the work using TIG welding machine as untuk pengelasan sebagai berikut :

follows:

A. Implementation of Safety at Work A. Pelaksanaan Keselamatan Kerja

and House Keeping 5 S dan 5R

1. Keep clean the working area and 1. Jaga kebersihan area kerja dan

facility fasilitas kerja.

2. Place working document, tool and 2. Tempatkan dokumen kerja, alat

detail parts in the designated place. bantu dan material pada tempat

yang telah ditentukan.

3. Use personal protective equipment 3. Gunakan alat keselamatan kerja

in accordance with the regulation. sesuai dengan ketentuan.

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 8 of 39

Rev.6

B. Welding Procedure /Schedule B. Welding Procedure /Welding

Schedule

1. Welding procedure/schedule shall 1. Welding prosedur/schedule harus

be established for each production ditetapkan untuk setiap part jika

weld where qualification is required kualifikasi dipersyaratkan oleh

by the customer. pelanggan.

2. Welding procedure/schedule shall 2. Welding prosedur/schedule harus

be approved by customer if required di-approved oleh pelanggan jika

by customer. dipersyaratkan oleh pelanggan.

3. Welding parameter on Welding 3. Welding parameter pada Welding

procedure/schedule shall be prosedur/schedule harus dapat

traceable to qualification test report, ditelusuri dari laporan hasil test,

when required by customer. jika dipersyaratkan oleh pelanggan.

4. Use welding parameter (see 4. Gunakan welding parameter (lihat

attachment 1-6 for CASA Program, lampiran 1-6 untuk Program CASA,

I+D-P-181, attachment 7-10 for I+D-P-181, lampiran 7-10 untuk

EUROCOPTER Program, IF-MA Program EUROCOPTER, (IFMA

No. 853) if customer does not No. 853) jika pelanggan tidak

require Welding procedure / mempersyaratkan Welding

schedule, unless the drawing called prosedur/schedule, kecuali drawing

out REP or “Specific Process memanggil REP atau “Specific

Requirement”. Process Requirement”.

C. Filler material and Non consumable C. Material filler dan Elektroda tidak

Electrode (Tungsten) terumpan (Tungsten)

1. The filler material shall be stored in 1. Filler metal harus disimpan dalam

a clean, dry environment. lingkungan yang bersih dan

kering.

2. If filler material identification 2. Apabila tanda indentifikasi filler

markings are lost, missing, or metal hilang atau rusak maka filler

destroyed, the filler material shall metal tersebut harus di scrap.

be scrapped.

3. Only the authorized person 3. Hanya personil yang ditunjuk

(storage crib personnel) has (personil tool crib) yang

access to filler material storage mempunyai akses terhadap filler

and the storage crib shall be metal dan tool crib harus dikunci

locked if the authorized person left jika personil tersebut me-

the storage crib. ninggalkan tool crib.

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 9 of 39

Rev.6

4. Each filler material containers shall 4. Setiap container (box) filler metal

be marked/label with lot number or harus ditandai/label dengan lot

receiving voucher. number atau receiving voucher.

5. All types, specification, diameter of 5. Semua jenis, spesifikasi, diameter

filler metal release from the storage dari filler metal yang dikeluarkan

crib shall be in accordance with the dari tool crib harus sesuai dengan

process sheet and drawing, check process sheet dan drawing,

the identity of filler material and periksa identitas dari filler metal

record the receiving voucher dan catat nomor receiving voucher

number of the filler in the process dalam process sheet.

sheet.

6. Welders shall not be issued more 6. Welder jangan menggunakan

than one weld filler material at one lebih dari satu filler sekaligus.

time. However, when the Process Tetapi, jika process sheet

Sheet requires more than one memper-syaratkan lebih dari satu

welding process or weld filler proses pengelasan atau jenis filler

material type, weld filler metal for metal, filler metal untuk kedua

both processes may be issued at proses dapat diberikan sekaligus,

the same time, provided the welder dengan catatan bahwa welder

is qualified for both processes. sudah terkualifikasi untuk kedua

Quantities of weld filler material proses tersebut. Jumlah filler

shall be based on the amount metal harus berdasarkan jumlah

estimated for one part. estimasi untuk satu part.

7. The purchase order of Non 7. Order pengadaan untuk Non-

consumable electrode (Tungsten) consumable elektroda (Tungsten)

shall call out the AWS A5.12/ISO harus mencantumkan AWS

6848. A5.12/ISO 6848.

8. Non-consumable electrodes 8. Box non-consumable electrodes

(Tungsten) box shall be marked / (Tungsten) harus ada label/tanda

labeled with lot number or dengan lot nomber atau receiving

receiving voucher voucher.

9. Non-consumable electrodes 9. Non-consumable electrodes

(Tungsten) shall be stored in (Tungsten) harus disimpan

original box. didalam box yang asli.

10. Non-consumable electrodes 10. Non-consumable electrodes

(Tungsten) shall have identification (Tungsten) harus selalu ada

all the time (color code), if the color indentitas (kode warna), jika tidak

code identification is lost the non- ada indentitas harus di scraped

consumable electrodes shall be

scraped.

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 10 of 39

Rev.6

D. Checking of welding machine D. Pemeriksaan kondisi mesin las

condition

1. Make sure the power cable supply 1. Yakinkan bahwa kabel power

to the welding machine is in good supply untuk mesin las dalam

condition, no damage to the cable kondisi baik, tidak ada kerusakan

insulation. pada isolasi kabel.

2. Make sure the grounding is 2. Yakinkan bahwa grounding telah

installed. terpasang.

3. Make sure no leaks in the cooling 3. Yakinkan bahwa tidak ada

hose, in the shielding hose, and in kebocoran pada slang pendingin,

the reducer. shielding hose, dan pada reducer.

4. The nozzle shall be clean and in 4. Nozzle harus bersih dan dalam

good condition keadaan baik

5. Make sure the argon gas is 5. Pastikan bahwa gas argon diberi

labelled by QA, shall meet the label oleh QA, sesuai MIL-A-

standard MIL-A-18455 the purity is 18455C purity 99.995 % minimum

99.995 % minimum and O2 ≤ 10 dan O2 ≤ 10 ppm. Botol gas harus

ppm. The shielding gas bottle shall dalam kondisi baik.

be in good condition.

6. Foot control shall be in good 6. Foot control harus dalam kondisi

condition. baik.

7. Check the validity of the calibration 7. Periksa validasi kalibrasi dari alat

of measuring instruments on the ukur pada mesin las

machine

8. Make sure that the preventive 8. Pastikan bahwa preventive

maintenance has been done by maintenance telah dilakukan oleh

Facility Maintenance according to Facility Maintenance sesuai de-

10.DP-W602.02 “Preventive ngan 10-DP-W602.02 “Preventive

Maintenance” and the schedule. Maintenance” dan jadwal.

9. Check all machine facilities by 9. Periksa semua fasilitas mesin

starting the machine and make dengan menjalankan mesin las

sure that the machine performs dan yakinkan bahwa mesin

well. tersebut berfungsi baik.

10. All supporting tools used such 10. Semua alat bantu yang dipakai

hammer, file etc are ready for use. seperti palu, kikir dll harus dalam

All cleaning tools, such as brushes, keadaan siap pakai.Semua

flap wheels, abrading tools etc, peralatan untuk cleaning seperti

shall be labelled or engraved with sikat kawat,flap wheels,alat

the material type they are used on penghalus harus dipisahkan

in order to avoid cross penggunaannya untuk masing2

contamination. material dengan cara di beri label

atau di gravier untuk menghindari

kontaminasi.

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 11 of 39

Rev.6

11. Inspect the welding machine for 11. Periksa kebersihan mesin las dan

cleanliness and for obvious kerusakan yang terjadi pada

damage to the cabinet, power cabinet, power switch, lampu

switches, indicator lights and indikator dan control.

controls.

12. Stop to operate the machine if 12. Hentikan menjalankan mesin las

anything found that could damage jika terjadi sesuatu yang dapat

the process and report to membahayakan proses dan

supervisor. segera laporkan kepada

supervisor.

E. Checking of working document E. Pemeriksaan dokumen kerja

1. Make sure that the working 1. Yakinkan bahwa dokumen kerja

document including the process termasuk process sheet, drawing

sheet and drawing are complete. telah lengkap.

2. Make sure the previous operation 2. Pastikan bahwa operasi

has been performed and inspected. sebelumnya telah dilakukan dan

diinspeksi.

3. Check the detail parts to be welded 3. Periksa detail part yang akan dilas

according to the drawing and sesuai dengan drawing dan

process sheet. process sheet.

4. Check the document number 4. Periksa nomor dokumen (Jid. No.,

(Jid.No.; Drawing Number) are nomor drawing) telah sesuai.

correct.

5. Report any discrepancy to the 5. Laporkan setiap penyimpangan

leader/supervisor to be solved in kepada leader/supervisor untuk

accordance with the procedure. diperbaiki sesuai dengan prosedur

F. Checking tools condition, welding F. Pemeriksaan kondisi tool, welding

jig jig

1. Check the identity and legality of 1. Periksa indentitas dan legalitas

welding jig (number, tooling index, dari welding jig (nomor, tooling

inspection stamp) and periodic index, stamp inspeksi) dan

inspection that will be used periodic inspection yang akan

according to 10-DP-W713.04 “Tool digunakan sesuai dengan 10-DP-

Scheduled Routine Inspection” and W713.04 “Tool Scheduled Routine

make sure that they are in Inspection” dan pastikan telah

accordance with the requirements sesuai dengan persyaratan dalam

in the process sheet. process sheet.

2. Make sure that the welding jig 2. Pastikan bahwa welding jig

(stopper, pin), is in good condition (stopper, pin) dalam kondisi baik

and capable of consistently dan mampu menghasilkan lasan

producing acceptable welds. yang konsisten dan dapat

diterima.

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 12 of 39

Rev.6

3. The jigs, fixtures and measuring 3. Jig, fixture dan alat ukur harus

devices shall be free of scale, bebas dari scale, grease,

grease, protective coatings, oxides, protective coating, oxida, debu, oli

dust, oil and other foreign matter dan benda asing lainnya yang

detrimental to the welding process. dapat merusak proses

pengelasan.

4. Report any discrepancy to the 4. Laporkan setiap penyimpangan

leader/supervisor to be solved in kepada leader/supervisor untuk

accordance with the procedure. diperbaiki sesuai dengan

prosedur.

G. Checking of material G. Pemeriksaan material

1. Type, specification, quantity and 1. Jenis, spesifikasi, jumlah dan

dimensions of the material shall be dimensi dari material harus sesuai

in accordance with the process dengan process sheet atau

sheet or drawing. drawing.

2. The component/part shall be free 2. Part/komponen harus bebas dari

from dirt, oil, grease etc. kotoran, oli, stempet dll.

3. Check the smoothness of part 3. Periksa kehalusan dari sisi part

edges to be welded yang akan dilas

4. Clean using stainless steel wire 4. Bersihkan dengan menggunakan

brush if necessary. sikat kawat stainless steel jika

diperlukan.

5. Report any discrepancy to the 5. Laporkan setiap penyimpangan

leader/supervisor to be solved in kepada leader/supervisor untuk

accordance with the procedure. diperbaiki sesuai dengan

prosedur.

H. Checking of filler material and Non- H. Pemeriksaan filler metal

consumable electrodes (Tungsten)

1. The filler metal shall be free from 1. Filler metal harus bebas dari

dirt (oil, grease, etc.). kotoran (oli, stempet, dll.).

2. Clean filler metal using MEK before 2. Bersihkan filler metal dengan

use menggunakan MEK sebelum

digunakan

3. Welder shall check the color code 3. Welder harus mengecek kode

of non-consumable electrodes warna dari non-consumable

(Tungsten) before welding electrodes (Tungsten) sesuai

operation according to persyaratan sebelum operasi

requirements. pengelasan.

4. Report any discrepancy to the 4. Laporkan setiap penyimpangan

leader/supervisor to be solved in kepada leader/supervisor untuk

accordance with the procedure. diperbaiki sesuai dengan

prosedur.

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 13 of 39

Rev.6

I. Setting the welding equipment I. Setting fasilitas pengelasan

1. Before performing welding, the 1. Sebelum melakukan pengelasan,

settings on the welding equipment setting pada fasilitas pengelasan

shall set to those listed in the harus disetel sesuai dengan yang

attachments including welding tercantum pada setting parameter

torch and electrode. (lampiran) termasuk welding torch

dan elektroda.

2. Inspector should be witnessed and 2. Inspector harus menyaksikan dan

recorded all setting parameter into mencatat semua setting para-

log book. meter dan dimasukan ke dalam

log book

3. Sharpen the tip of tungsten 3. Runcingkan ujung tungsten

electrode by grinding in longitudinal elektroda dengan menggerinda

direction and electrode sharpening dengan arah longitudinal dan

must be adapted to the amperage meruncingkan elektroda harus

and thicknesses to be welded (Fig. disesuaikan dengan ampere dan

below) ketebalan yang akan dilas

(Gambar di bawah).

4. Prepare try out material to test the 4. Persiapkan material percobaan

setting parameters. untuk menguji setting parameter.

5. Set the scale of AC balance 5. Posisikan skala dari AC balance

(balance wave at 3). (balance wave berada pada skala

3).

6. Star the welding machine and 6. Jalankan mesin las dan lakukan

perform welding on the try out pengelasan pada material

material percobaan.

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 14 of 39

Rev.6

J. Setting /Fitter of Part. J. Setting / Fitter pada part.

1. Prepare the detail parts to be 1. Persiapkan detail part yang akan

welded. di las

2. Check the edges of the part and 2. Periksa sisi part dan break sharp.

break sharp.

3. Clean by stainless steel wire 3. Bersihkan dengan sikat kawat

brushing or wipe with MEK if stainless steel atau digosok

necessary. dengan MEK jika diperlukan.

4. Position / set the part on the 4. Posisikan/atur part pada welding

welding jig to avoid any mismatch. jig untuk mencegah mismatch.

5. Clamp the detail parts. 5. Kelem detail part.

6. Check the position of the part in 6. Periksa posisi dari part sesuai

accordance with the dimensions in dengan dimensi pada drawing.

the drawing.

K. Cleaning and surface preparation. K. Cleaning dan persipan permukaan

sebelum pengelasan.

1. Make sure that detail part has 1. Yakinkan bahwa detail part telah

been cleaned and free from paint, dibersihkan dan bebas dari cat,

oil, oxidation, grease and any oli, oxida, stempet dan benda

other foreign materials that are asing lainnya yang dapat me-

detrimental to welding, according rusak pada pengelasan, sesuai

to process sheet, applicable PIC’s dengan proses sheet dan PIC

and for EC program use approved yang digunakan untuk program

PIC’s as follow: EC, gunakan PIC sebagai

berikut:

a) ST/EC/CBW-01 for aluminium a) ST/EC/CBW-01 untuk

parts aluminium part

b) ST/EC/CBW-02 for Steel parts b) ST/EC/CBW-02 untuk steel

c) ST/EC/CBW-03 for Stainless part

parts c) ST/EC/CBW-03 untuk

stainless part

2. The parts shall be adequately 2. Part harus diproteksi dengan

protected after cleaning use kraft benar sesudah cleaning gunakan

paper to prevent contamination kertas kraft untuk mencegah

and handled carefully, if kontaminasi dan ditangani secara

contamination occur, the parts hati-hati, jika terjadi kontaminasi

shall be re-cleaned. part harus cleaning ulang.

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 15 of 39

Rev.6

3. After cleaning all detail parts shall 3. Pengelasan detail part harus

be welded within specified time dilakukan dalam batasan waktu

limit (ADS program ;maximum cleaning yang ditentukan

delay time between cleaning and (Program ADS; maksimum delay

welding for aluminium alloys shall time antara proses cleaning dan

be 5 days, while for carbon steel pengelasan untuk aluminium

shall be immediately proceeded alloy harus 5 hari, sedangkan

once the parts are dry as per untuk carbon steel harus segera

I+D-P 181. EC program; maximum diproses welding segera setelah

delay time between cleaning and part kering sesuai I+D-P 181.

welding for critical and important Program EC; maksimum delay

parts shall be 48 hours, while for time antara proses cleaning dan

secondary class parts shall be 7 welding untuk critical parts harus

days as per IFMA 853). The 48 jam, sedangkan untuk part

welder and inspector shall make kelas sekunder harus 7 hari

sure that the cleaning time on the berdasarkan IFMA 853). Welder

process sheet until ready to weld dan inspector harus meyakinkan

not exceeds the limit. bahwa batasan waktu cleaning

belum terlewati.

L. Preheating L. Preheating

Preheating shall be performed for Preheating harus dilakukan untuk

aluminium thicker than 5 mm. The aluminium lebih tebal dari 5 mm,

interpass temperatures shall not Interpass temperatur harus tidak

exceed the maximum value specified melebihi nilai maksimun seperti yang

in the I+D-P-181 and shall be checked ditetapkan dalam I+D-P-181 dan

on the surface of the component using harus diperiksa pada permukaan

temperature indicating crayon. komponen dengan menggunakan

Temperature indicating crayon shall temperature indicating crayon.

not be used directly in the weld zone. Temperature indicating crayon tidak

boleh digunakan langsung pada area

pengelasan.

M. Tack welds M. Las titik / Tack weld

1. Tack weld should be done when 1. Tack weld dilakukan jika

their joint alignment of the welded kelurusan / kerataan dari

cannot be maintained sambungan tidak dapat terjaga

dengan baik.

2. The tack weld requirement should 2. Persyaratan tack weld harus

be in accordance with welding sesuai dengan persyaratan

requirement, number of tack welds pengelasan, jumlah tack weld

minimum 4 and if more than 4 minimal 4 titik dan jika lebih dari 4

distance between tack weld are 5 jarak antar tack weld 5 mm

mm to 20 mm. sampai 20 mm

3. If filler metal is used for tack 3. Filler metal yang digunakan untuk

welding, use the same filler metal tack weld, harus sama dengan

alloy as specified for the weld. material filler yang digunakan

untuk pengelasan.

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 16 of 39

Rev.6

4. Tack weld shall be of a size that 4. Ukuran tack weld harus masuk

can be contained within the fused dalam area yang akan meleleh

area of the completed weld and dari lasan dan tidak merusak

shall not jeopardize the quality of kualitas dari pengelasan

the subsequent weld. berikutnya.

5. Clean part after tack weld, wipe 5. Bersihkan part setelah dilakukan

with MEK or Stainless steel wire tack weld, dengan menggunakan

brushing if necessary MEK atau sikat kawat dari

stailess.

N. Weld start and run-off tabs N. Weld start dan run-off tabs

Run on and run-off tabs when used Run on dan run-off tabs jika digunakan

shall be composed of the same alloy harus menggunakan material yang

as the detail parts and shall be welded sama dengan detail part dan harus

with the filler metal specified on the dilas dengan material filler yang

engineering drawing. ditetapkan dalam engineering drawing.

O. Weld start and run-off tabs removal O. Menghilangkan Weld start dan run-

off tabs

Run on and run-off tabs removal shall Menghilangkan run on dan run-off tabs

be performed carefully to prevent harus dilakukan dengan hati-hati untuk

damage of the part. mencegah kerusakan part.

P. Welding P. Pengelasan

1. Use safety equipments. 1. Gunakan peralatan keselamatan

kerja

2. Make sure that the setting on the 2. Pastikan bahwa pengaturan pada

welding machine (amperage, mesin las (ampere, diameter

tungsten diameter, nozzle size, tungste , ukuran nozzle, laju

flow rate etc.) are correct and aliran, dll) sudah benar dan

according to the table of welding sesuai dengan tabel parameter

parameter, when setting the penge-lasan, ketika mengatur

amperage, consider the gaps ampere, pertimbangkan gap

between amperage set and antara penga-turan ampere

amperage reached according to dengan ampere yang telah

the calibration report attached on tercapai menurut laporan

the machine (Dynasty 200 DX) kalibrasi yang terpasang pada

mesin (Dynasty 200 DX)

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 17 of 39

Rev.6

Note: Catatan:

For AH program perform untuk program AH lakukan

calibration of amperage and kalibrasi ampere dan voltase

voltage of welding machine mesin welding setiap bulan

monthly to check if there are any untuk memeriksa jika terjadi

gap deviates (periodicity penyimpangan gap (periodik

calibration might be increased or kalibrasi mungkin ditambah atau

reduced according to the dikurangi sesuai dengan hasil

calibration results after several kalibrasi setelah beberapa

calibrations) kalibrasi)

3. Ensure cleanliness of inner part, 3. Yakinkan kebersihan part bagian

tools, welding fixture, table and dalam, tools, welding fixture, dan

clean wipe by MEK or stainless meja kerja,jika kurang bersih

steel wire brushing if necessary bersihkan menggunakan MEK

atau stailess steel wire brushing

4. Check and pay attention to the 4. Periksa dan perhatikan pada

weld (weld bead, cleanliness, lasan (kampuh las, kebersihan,

penetration). penetrasi).

5. Clean part due to tungsten 5. Bersihkan part menggunakan

contaminated, by MEK or stainless MEK atau stailess steel wire

steel wire brushing, clean part if brushing bersihkan apabila part

the part has cooled, cut filler metal sudah dingin, potong filler metal

when the welding was stopped yang teroksidasi pada saat

and restarted. pengelasan berhenti .

6. At all times through point of 6. Penggunaan filler metal dalam

consumption, bare wire in straight bentuk batang / rod harus

lengths shall retain the mempunyai tanda seperti ben-

manufacturer’s flag tag or dera atau identifikasi dari

identification. manufacturer.

7. Waste ends, stubs, shim etc. shall 7. Sisa-sisa material, shim dll.

be discarded by the welder in a Harus dibuang dengan benar

non-retrievable scrap or trash bin oleh welder kedalam tempat

khusus.

8. Non used filler material shall be 8. Sisa filler metal harus

returned to the store and record by dikembalikan ke gudang dan

stored keeper in the log book harus dicatat dan direcord ke

dalam log book oleh penjaga

gudang.

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 18 of 39

Rev.6

9. In-process corrections shall be 9. Perbaikan selama proses penge-

performed in accordance with lasan (“In Process Correction”)

customer specification dilakukan sesuai dengan per-

requirements. The surface syaratan spesifikasi pelanggan.

imperfections detected by the Cacat yang terjadi dipermukaan

operator during the welding, such harus diperiksa oleh operator

as bites, shrinking and undersized selama proses pengelasan ber-

beads, can be repaired giving langsung seperti Bite, Shrinking

another bead, without any need of dan kontaminasi pada lasan

removing material. harus dibersihkan sebelum me-

lakukan pengelasan berikunya.

dan undersized bead dapat di-

perbaiki dengan menambahkan

bead, tanpa harus membuang

bead lasan.

10. The welder shall perform inter- 10. Untuk pengelasan multi pass,

pass cleaning and visually welder harus melakukan

examines the previous pass for pemeriksaan dan cleaning pada

contamination and defects prior to lapisan pengelasan sebelumnya.

the deposition of each pass in

multiple pass welds.

11. Any defects and contaminants 11. Setiap cacat dan kontaminan

shall be removed prior to harus dibersihkan sebelum me-

deposition of subsequent passes. lakukan pengelasan berikutnya.

Q. Rework and Repair. Q. Rework dan Repair

1. Rework is “in process correction” 1. Rework adalah “in process

in any correction of weld made by correction (perbaikan saat proses

the welder before submitting the pengelasan berlangsung)” ada-

weldment for acceptance lah perbaikan pengelasan pada

inspection, the correction such as, saat welder mengerjakan pe-

undercut, under fill, or crater ngelasan sebelum diperiksa oleh

(without crack) and corrected by inspector yaitu perbaikan cacat

depositing filler material, an undercut, under fill, atau crater

overlap, weld reinforcement, or (tanpa crack), dan juga perbaikan

protruding indication may be dengan cara menam-bahkan filler

removed by metal removal metal seperti,pada cacat overlap,

method. weld reinforcement, atau peng-

hilangan kelebihan bead lasan

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 19 of 39

Rev.6

2. Allowed number of “in process 2. Jumlah in process correction

correction” attempts one is allowed yang diusahakan adalah satu kali

in each individual flow location. untuk setiap lokasi yang

When the “in process correction” diperbaiki. Apabila in process

require more than one attempt at correction dilakukan lebih dari

same flow location the satu kakali pada lokasi yang

combination of corrections shall be sama maka gabungan dari

qualified as original weld or perbaikan tersebut harus

approved by the appropriate diajukan untuk disetujui oleh

Material Review Board (MRB). Material Review Board (MRB).

3. Repair is any corrective action on 3. Repair adalah tindakan perbaikan

part by Material Review Board pada part yang harus disetujui

(MRB), repairs made to repair terlebih dahulu oleh Material

discrepancies in welds or to Review Board (MRB), repair

correct other defect. dilakukan apabila terjadi ketidak

sesuaian pada lasan atau

perbaikan pada cacat lasan.

4. Allowed numbers of repair are, 4. Jumlah repair yang diijinkan

depend on the class of welding adalah bergantung pada kelas

and accordance to applicable pengelasan dan spesifikasi yang

specification. digunakan.

5. Inspector should be recorded 5. Inspektor harus mencatatkan

rework and repair into F- pelaksanaan rework dan repair

AE704.08.02 document kedalam dokumen no F-

AE704.08.02.

R. Unloading R. Unloading

1. Stop the welding machine; release 1. Hentikan mesin las, buka kelem

the clamping on the part. pada part.

2. Remove the part from welding jig 2. Lepaskan part dari welding jig

carefully, if it used. dengan hati-hati, jika digunakan.

S. Visual inspection S. Inspeksi visual

The criteria to be met for weld classes Kriteria yang harus dipenuhi untuk las

1 and 2 are those defined in kelas 1 dan 2 adalah yang dijelaskan

attachment 12 and 13. di dalam lampiran 12 dan 13.

Visual inspection held on as welded Inspeksi visual dilaksanakan

condition. sebagai persyaratan las

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 20 of 39

Rev.6

Visual inspection of the weld bead with Inspeksi visual terhadap “weld bead”

the naked eye and x2 to x5 magnifying dengan mata telanjang dan kaca

glasses. The Cracks are never pembesar hingga 2 x sampai 5 x

permissible in weld zone and HAZ as pembesaran. Keretakan di zona las

well as in the bead terminations. The dan HAZ serta dalam penghentian

acceptance criteria of the other manik tidak diperbolehkan. Jika tidak

imperfections detected by visual ada spesifikasi khusus, kriteria

inspection. Special to butt welds, ketidaksempurnaan yang dapat

when there is no special specification, diterima oleh inspeksi visual, dapat

can be adapted to the attachment 12. disesuaikan dengan lampiran 12.

Welding inspection in accordance with Pemeriksaan pengelasan sesuai

the following: ketentuan berikut:

1. All welds shall be inspected by 1. Semua lasan harus diperiksa oleh

qualified visual inspector; welding inspekstor yang ter-

qualification is according to 10-DP- kualifikasi sesuai dengan 10-DP-

P601 “Training” and 10-DP- P601 “Training” dan 10-DP-

D804.03 “Qualification D804.03 “Qualification

Requirement for QA personnel”. Requirement for QA personnel”.

2. Check all dimensions according to 2. Periksa semua ukuran sesuai

the drawing, and applicable dengan gambar dan spesifikasi

specification as follow: sebagai berikut :

a) I+D-P-181 (fusion welding of a) Untuk program Airbus military

metals),for Airbus Military I+D-P-181

Program

b) IGC04.62.165 (steel parts and b) Untuk program Eurocopter

assemblies fusion welding IGC04.62.165 (steel parts

inspection) for Eurocopter and assemblies fusion

program welding inspection).

c) IGC04.62.166 (aluminium c) Untuk program Eurocopter

alloys parts and assemblies IGC04.62.166 (aluminium

inspection of fusion welding) alloys parts and assemblies

for Eurocopter program inspection of fusion welding)

d) The inspector shall open d) Inspektor harus membuat

rejection tag if any rejection tag jika diketemukan

discrepancy found and shall ketidak sesuaian dan harus

be processed in accordance diproses sesuai dengan 10-

with 10-DP-P805. DP-P805.

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 21 of 39

Rev.6

e) When deterioration of welding e) Apabila terjadi penurunan

is encountered, an kualitas hasil pengelasan,

investigation shall be harus dilakukan investigasi

conducted to assign the cause terhadap penyebab dan

and implement corrective menentukan langkah

action. Quality inspection perbaikannya. Inspektor

function shall review harus memeriksa kembali

inspection results and hasil pemeriksaannya dan

investigate the deterioration menginvestigasi data

data to assign the cause and penurunan kualitas untuk

implement corrective action menentukan penyebab dan

with related function such as langkah perbaikannya

Quality Planning, Quality bersama fungsi yang terkait

Engineering, Production, yaitu Quality Planning, Quality

Welding Engineering and Engineering, Produksi,

Manufacturing Engineering. Welding Engineer dan

Manufacturing Engineering.

T. Job Data Entry on SAP System T. Entry Job Data pada Sistem SAP

and Welder Activity & Performance dan Aktifitas & Performa Welder

on Log-Book pada Log-Book

1. Report the activity that will be 1. Laporkan kegiatan yang akan dan

performed and that has been telah dilakukan dengan

performed by entering on SAP memasukkan data pada sistem

System (entry start for begin and SAP (masukkan start pada waktu

entry stop for finish). mulai dan masukkan stop setelah

selesai).

2. Submit the process sheet to the 2. Kirimkan process sheet untuk

next operation after stamped by operasi selanjutnya setelah

the operator. distamp oleh operator

3. Welding Shop Management / 3. Supervisor Shop Welding harus

Supervisor should monitor the memonitor kinerja atau kom-

performance or competency of petensi dari Welder yg ditugaskan

qualified welder who be signed to untuk mengelas part produksi A/C

weld the A/C parts production by dengan mencatat kegiatan dan

recording their welding activities performa pengelasan mereka

and performance on F-DP704.08- pada form F-DP704.08-03 untuk

03 to maintain, guarantee or memaintain, jaminan atau untuk

extending their license validity memperpanjang validitas lisensi

according to 10-DP-P711 Para. mereka berdasarkan 10-DP-P711

5.2.10. Para. 5.2.10

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 22 of 39

Rev.6

U. Improvement U. Improvement

The Welding Shop Supervisor shall Supervisor bengkel welding harus

assemble a cross functional team for membentuk team untuk melakukan

improvement. The team shall consist of pelaksanaan improvement. Team

production, QA, Manufacturing harus terdiri dari bagian Produksi, QA,

Engineering and related function. Manufacturing Engineering, dan fungsi

lain yang terkait.

The topics of improvement could be Topik dari improvement harus

process performance such as rejection mengenai kemampuan proses seperti

etc. The welding supervisor shall plan masalah rejection dll. Supervisor

and monitor the activity. bengkel welding harus membuat

rencana dan harus selalu memonitor

aktivitasnya.

7. Attachments/ Lampiran

Attachment 1 : Welding Parameter for Aluminium and Aluminium Alloys (Ref. I+D-P-181)

Attachment 2 : Filler Metals For Aluminium And Aluminium Alloys Depending On The

Material To Be Welded (Ref. I+D-P-181)

Attachment 3 : Welding Parameter for Stainless Steel (Ref. I+D-P-181)

Attachment 4 : Filler Metals for Stainless Steel and Refractory Steels and Complex

Nickel and Cobalt Alloys (Ref. I+D-P-181)

Attachment 5 : Welding Parameter for Carbon and Alloyed Steel (Ref. I+D-P-181)

Attachment 6 : Filler Metals for Carbon and Alloyed Steel (Ref. I+D-P-181)

Attachment 7 : Filler Metal Table Tig Welding (Ref. IF-MA No. 853)

Attachment 8 : Welding Low or High Alloy Steel (Ref. IF-MA No. 853)

Attachment 9 : Welding Stainless Steel (Ref. IF-MA No. 853)

Attachment 10 : Welding Light Alloys (Ref. IF-MA No. 853)

Attachment 11 : List of Approved Welding Group

Attachment 12 : Acceptance Criteria For Geometry And External Defects For Butt Joint

Welded (Ref. IF-MA No. 853)

Attachment 13 : Acceptance Criteria For Internal Defects (linear and volume)

(Ref. IF-MA No. 853)

Attachment 14 : WELDING PROCEDURE SPECIFICATION (WPS) TIG Welding

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 23 of 39

Rev.6

Attachment 1 / Lampiran 1

Welding Parameter For Aluminium and Aluminium Alloys (Ref. I+D-P-181)

Base Material : Aluminium and aluminium alloys

Joint type : Fillet / Butt weld

Filler material : See attachment

Type of current : AC

Type of tungsten : Zirconium EW Zr / EWP

Balance : Balanced

Shielding gas (Purity) : Argon (minimum 99,995%)

Number of tack weld : Minimum 4

Filler material for tack

: As for welded

weld

TABLE OF WELDING PARAMETER

Diameter

Base material Tungsten Nozzle Shielding

of Filler Welding current

thickness diameter diameter gas

material [Amps]

[mm] [mm] [mm] [l/m]

[mm]

1.0 1.0 1.0 - 1.6 6.4 - 9.5 5 -7 20 - 50

1.6 1.6 1.6 6.4 - 9.5 5 -7 40 - 80

3.2 2.4 2.4 8.0 - 9.5 6-8 80 - 140

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 24 of 39

Rev.6

Attachment 2 / Lampiran 2

Filler Metals For Aluminium and Aluminium Alloys Depending On The Material To Be

Welded (Ref. I+D-P-181)

L2571(355.0)

L3420(6061)

WELDABLE L3002(1100) L3191 L3321 L3322 L3360 L3390 L0334 L2561(356.0)

L3441(6063)

ALLOYS L3810(3003) (2219) (5083) (5086) (5052) (5754) (5456) L2652(A356.0)

(4)

L265(A357.0)

L3002(1100) L0360(1160) L0368 L0368 L0363 L0368 L0363 L0363

- -

L3810(3003) (2) (5356) (5356) (4043) (5356) (4043) (4043)

L0362

L3191(2219) - - - - - - - -

(2319)

L0368 L0368 L0368

L3321(5083) - - (5183) - - (5183)

(5356) (5356) (5356)

L0368 L0368 L0363 L0363

L3322(5086) - - - - -

(5356) (5356) (4043) (4043)

L0368 L0368 L0363 L0368 L0363 L0363

L3360(5052) - -

(5356) (5356) (4043) (5356) (4043) (4043)

L0368

L3390(5754) - - - - - - - -

(5356)

L0369 L0368 L0368

L0334(5456) - - - - - -

(5556) (5356) (5356)

L3420(6061) L0363

L3441(6063) - - - - - - - (4043) L0364(4013)

(4) (3), (4)

L2571(355.0)

L2561(356.0) L0363(4043)

- - - - - - - -

L2652(A356.0) L0365(4047)

L265(A357.0)

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 25 of 39

Rev.6

Attachment 3 / Lampiran 3

Welding Parameter For Stainless Steel (Ref. I+D-P-181)

Base Material : Stainless Steel

Joint type : Fillet / Butt weld

Filler material : See attachment

Type of current : DC

Type of tungsten : Thorium EWTh

Balance :

Shielding gas (Purity) : Argon (minimum 99,995%)

Number of tack weld : Minimum 4

Filler material for tack

: As for welded

weld

TABLE OF WELDING PARAMETER

Diameter

Tungsten Nozzle Shielding Welding

Base material of Filler

diameter diameter gas current

thickness [mm] material

[mm] [mm] [l/m] [Amps]

[mm]

1.0 1.0 1.0 - 1.6 6.4 3-4 20 - 50

1.6 1.6 1.6 6.4 - 8.0 3-5 70 -120

3.2 2.4 2.4 8.0 - 9.5 4-6 110 - 160

Note:

Use backing gas with flow rate 2 - 10 l/min depend on volume of the part, if more flow

rate needed use additional trailing gas with flow rate 2 - 10 l/min.

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 26 of 39

Rev.6

Attachment 4 / Lampiran 4

Filler Metals For Stainless And Refractory Steels And Complex Nickel And Cobalt Alloys

(Ref. I+D-P-181)

FILLER METALS

METALS REMARKS

TO BE DESIGNATION SPECIFICATION

WELDED (I+D-M-30) Wire (*) COATED ELECTRODE

F-3401 F-0284 AMS 5776 or AMS 5821 AMS 5777

MIL-E-22200/2 (MIL-308L-

MIL-R-5301 (Classes 5A, 15

F-3503 F-0291 15/-16 or MIL-347-15/-16) or

or 16) or AMS 5680

AMS 5681

F-0287 MIL-R-5301 (Classes 1 or MIL-E-22200/2 (MIL-308-15/-

F-3504

F-0291 5A) 16).

F-3507

MIL-R-8031 (Classes 1 or - MIL-E-22200/2 (MIL-308-15/-

F-3517 F-0287

16) 16 or MIL-308L-15/-16)

F-0356

F-3523 MIL-R-5301 (Classes 5A or MIL-E-22200/2 (MIL-347-15/-

F-0291

F-3524 6) AMS 5680 or AMS 5690 16), AMS 5681or AMS 5691

MIL-E-22200/2 (MIL-316L-

F-3533 F-0288 MIL-R-5301 (Class 17)

15/-16)

(*) Weld by

MIL-E-22200/2 (MIL-316-15/- electric arc

F-3534 F-0288 MIL-R-5301 (Class 4)

16) protected with

AMS 5680 or MIL-R-5031 inert gas and

F-0355 F-0291 AMS5681 or AMS 5691

(Class 5A) refractory

AMS 5794 or MIL-R-5031 MIL-E-22200/3 (3N1N) or electrode. Do not

F-0361 F-0295 use these filler

(Class 9) AMS 5795

wires in OA or

F-0381 MIG welding,

F-0289 AMS 5825 AMS 5827

F-0384 unless indicated

F-0382 F-0292 AMS 5824 ------ by the drawing.

F-0383 F-0293 SMS 5812 or AMS 5813 ------ The filler metals

MIL-R-5031,

F-0294 MIL-R-5301 (Class 12), AMS MIL-E-22200/3 (4N1N) or Classes 5, 7 and

F-0385

V-0614 5804 or AMS 5805 AMS 5787 8, are indicated to

F-0387 F-0299 AMS 5780 AMS 5781 be used only in

the OA welding,

MIL-R-5301 (Class 8A), or MIL-E-22200/3 (3N12

V-0411 V-0615 and those of the

AMS 5679 Inconel 132) or AMS 5684

Classes 5A, 8A,

V-0413 V-0610 MIL-R-5301 (Class 14) AMS 5779 14,15, 16 and 12,

V-0423 V-0611 AMS 5832 ------ to be used only in

V-0424 V-0618 MIL-R-5301 (Class 11) ------ inert atmosphere.

V-0426 V-0612 AMS 5793 AMS5799

V-0442 AMS5676 or MIL-R-5301

V-0616 AMS 5677

V-0445 (Class 7)

V-0456 V-0613 AMS 5828 ------

MIL-R-5301 (Class 12), or

V-0470 V-0614 ------

AMS 5786

V-0471 V-0617 MIL-R-5301 (Class 10) ------

V-0481 F-0290 AMS 5340 MIL-E-22200/3 (9N10)

MIL-R-5301 (Class 13), or MIL-E-22200/3 (3N1L) or

V-0514 V-0630

AMS 5796 AMS 5797

MIL-R-5301 (Class 12), or

V-0421 V-0614 AMS 5787

AMS 5786

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 27 of 39

Rev.6

Attachment 5 / Lampiran 5

Welding Parameter Carbon and Alloyed Steels (Ref. I+D-P 181)

Base Material : Carbon and Alloyed Steel

Joint type : Fillet / Butt weld

Filler material : See attachment

Type of current : DC

Type of tungsten : Thorium EWTh

Balance :

Shielding gas (Purity) : Argon (minimum 99,995%)

Number of tack weld : Minimum 4

Filler material for tack weld : As for welded

TABLE OF WELDING PARAMETER

Diameter

Tungsten Nozzle Shielding Welding

Base material of Filler

diameter diameter gas current

thickness [mm] material

[mm] [mm] [l/m] [Amps]

[mm]

1.0 1.0 1.0 - 1.6 6.4 3-4 20 - 50

1.6 1.6 1.6 6.4 - 8.0 3-5 70 -120

3.2 2.4 2.4 8.0 - 9.5 4-6 110 - 160

Note:

Use backing gas with flow rate 2 - 10 l/min depend on volume of the part, if more flow

rate needed use additional trailing gas with flow rate 2 - 10 l/min.

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 28 of 39

Rev.6

Attachment 6 / Lampiran 6

Filler Metals for Carbon and Alloyed Steel (Ref. I+D-P-181)

(2) FILLER METALS REMARKS

METALS TO BE

WELDED DESIGNATIO SPECIFICATION

(1) N COATED ELECTRODE

(I+D-M-30) Wire

(3)

Low carbon Mil -R-5632(type1,IV,or MIL –E-6843(E-10013 The magnetic alloys shall

C% 0,25

contents VII) or E-10020),AMS welded using as filler metal

Carbon including

steel(F-0270to MIL-E-23765/1(705) 6464,QQ-E-450 flanges or rods cut of the

Steel magnetic

F-0273)F-0283 MIL-E23765/2 (6012,6013) and AMS same sheet used for the

alloys

and F-0279 (1005,1105 or 1205) 5031 manufacturing of the part

AIR 9114(E343R or

F-0221 F-0282 AIR 9114/A(A50)

E3458)

AIR 9114/A Should two steels of

AIR 9114/A(25CD4) different composition be

Special (AIR85,E445B or E-

F-0222 F-0283 MIL-R-5632(type1),LW- welded or other filler metals

steels 534B) MIL-E-8697(HT-

1.7214 be used, the welding shall

for 4130)

be performed with the prior

welding

AIR approval of the quality

F-0286 9114/A(15CDV6).LW-1- AIR 9114/A(AIR 100 or assurance laboratory

F-0225 7734 E543B) MIL-E-6343

(E10013).

F-0274 AIR 9114/A(8CD12)

F-1250,

F-1251, F-0238,F-

MIL-R-5632 (Types I,IV MIL-E-8697(HT-4130

F-1255, 0279,

or VII) class 1)

F-1256, And F-0280

F-0138 The steels with an

equivalent carbon contents

(CE) of more than 0,44%

Alloyed F-1252 shall be welded under

MIL-E-8697(HT-4130

steels and F-0278 MIL-R-5632 (type II) authorization of the quality

class 2)

F-1272 assurance laboratory.

CE=C+Mn/6+Mo/4+Cr/5+(Ni

+Cu)/15+ P/3

F-0120

MIL-E-8697(HT-4130

And F-0297 MIL-R-5632 (type III)

class 3)

F-1272

i. The steels requiring hardness values over 30 RC (100kg/mm) shall be heat treated after being welded.

ii. The detailed utilization instruction and specific limitations for each filler metal are established in its

corresponding national specifications.

iii. The UNE 14003 standard establishes the denomination of coated electrodes for manual arc welding of the

normal strength carbon steels and low alloy steels with strength comprised between 500and 600 Mpa.

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 29 of 39

Rev.6

Attachment 7 / Lampiran 7

Filler Metal Table Tig Welding (Ref. IF-MA No. 853)

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 30 of 39

Rev.6

Attachment 8 / Lampiran 8

Welding Low or High Alloy Steel (Ref. IF-MA No. 853)

Note:

Used Electrode 1). Trioxide tungsten - gold ends (La2O3/Y2O3/ZrO2 or

La2O3/CeO2/Y2O3).

2). 2% cerium - grey ends.

Used DC current for welding steel and stainless steel part.

Use backing gas with flow rate 2 - 10 l/min depend on volume of the part, if more flow

rate needed use additional trailing gas with flow rate 2 - 10 l/min.

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 31 of 39

Rev.6

Attachment 9 / Lampiran 9

Welding Stainless Steel (Ref. IF-MA No. 853)

Note:

Used Electrode 1). Trioxide tungsten - gold ends (La2O3/Y2O3/ZrO2 or

La2O3/CeO2/Y2O3).

2). 2% cerium - grey ends.

Used DC current for welding steel and stainless steel part.

Use backing gas with flow rate 2 - 10 l/min depend on volume of the part, if more flow

rate needed use additional trailing gas with flow rate 2 - 10 l/min.

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 32 of 39

Rev.6

Attachment 10 / Lampiran 10

Welding Light Alloys (Ref. IF-MA No. 853)

Note:

Used Electrode 1). Pure tungsten - green ends.

2). Trioxide tungsten - gold ends (La2O3/Y2O3/ZrO2 or

La2O3/CeO2/Y2O3).

3) 2% cerium - grey ends

Used AC current for welding light alloy part

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 33 of 39

Rev.6

Attachment 11 / Lampiran 11

List of Approved Welding Group

(Personnel Responsible For Welding Process)

No: SPRINT/179/AE0100/PTD/05/2012

Function Responsibility Name / ID

Review customer requirement, including

Memet Ahmad / 117027

specifications, tool, process, facilities, etc.

Budhi Rochman / 099062

Engineering Review facilities needed by production.

Yulianto

Prepare and approve welding schedule and

WPS if required by customer

Sutarno / 851141

Manufacturing Prepare and plan of welding assembly using

Yayat Supriatna / 147301

Planning in sequence process sheet

Yusup Mahmud / 821646

Prepare (WIP) Fusion Welding Inspection

Quality Plan (F-DP704.08-01) Dodi Mulyawan / 820620

Engineering Prepare and qualify welder and welding Agus Irianto / 831078

operator

Review, verify and validate the process sheet A Raedi / 820867

Quality Planning

before released to production Joko Wiyoto / 832254

Patar Pakpahan / 832270

Manufacture welding assembly according to Tatang / 822088

Fabrication the work package (process sheet, drawing Aripin / 832705

etc) E. Kustarman / 812653

Setiyo Saparyanto / 822555

Inspect welding assembly according to Achwan / 830596

Inspection

customer requirements, and record WIP M. Irsyad Junaedi / 119105

Iyus R / 117099

Perform NDT on welding assembly according

NDT Hendi Rehendi / 810461

to process sheet

Bana Sobana / 109010

Perform mechanical test and metallographic

test and metallographic inspection of

Laboratory Jajat Mujijat / 87089

specimens for welder qualification/ welding

schedule

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 34 of 39

Rev.6

Attachment 12 / Lampiran 12

ACCEPTANCE CRITERIA FOR GEOMETRY AND EXTERNAL DEFECTS (Ref. IF-MA No. 853)

Applicable for butt joint welded (Dimension in millimetres)

Aluminum, Steel ; nickel

Titanium and

Bead Characteristics magnesium and cobalt

titanium alloys

and their alloys alloys

e ≤ 3: L ≤ 2 e + 4

Forward face e ≤ 3: L ≤ 2 e + 6

L ≤ 1.8 e + 5 e > 3: L ≤ 0.75 e

width: L e > 3: L ≤ e + 9

+ 9 with bevel

e ≤ 3: 0.4 L ≤

e ≤ 3: 0.4L ≤ λ ≤

e ≤ 6: 0.5 L ≤ λ ≤ L λ≤L

Reverse face L

e > 6: 0.4 L ≤ λ < L e > 3: 0.4 L ≤

width: λ e > 3: 0.4 L ≤ λ <

with bevel λ < L with

L with bevel

bevel

Max.

consistency

variation

L max., L min.

Weld

misalignment

with respect to

joint surfaces

Applicable for end to end welds (Dimension in millimetres)

Aluminum, Steel ; nickel

Titanium and

Bead Characteristics magnesium and cobalt

titanium alloys

and their alloys alloys

Crack and

microcrak Not permitted Not permitted Not permitted

(4)

Over thickness

on forward face: R ≤ 1.5 + 0.1 L R ≤ 1 + 0.1 L R ≤ 1 + 0.1 L

R

Over thickness

on reverse face: r ≤ 3 + 0.1 λ r ≤ 1 + 0.1 λ r ≤ 1 + 0.1 λ

r

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 35 of 39

Rev.6

Not permitted for

Undercutting on C ≤ 0.1 e class 1 parts

C ≤ 0.1 e

forward face: C with a C ≤ 0.1 e for other

with a maximum of

(radius at base maximum of classes

0.5

of indication) 0.5 with a maximum

of 0.3

r ≤ 0.1 e

r ≤ 0.1 e

Undercutting on with a

with a maximum of Not permitted

reverse face: c maximum of

0.5

0.5

f ≤ 10 mm

Maximum f ≤ 10 mm

f ≤ 10 mm Interval

length of an Interval between

Interval between between two

isolated defect: two defects >

two defects > 2 f defects >

f (3) 2f

Σ f ≤ k/20 2f

for undercutting Σ f ≤ k/20

Σ f ≤ k/20

Lack of

Not permitted Not permitted Not permitted

thickness: – R

Aluminum, Steel ; nickel

Titanium and

Bead Characteristics magnesium and cobalt

titanium alloys

and their alloys alloys

Not permitted

Not permitted for for parts

Hollow

parts subjected to subjected to

penetration

fatigue, fatigue,

and/or root

otherwise r ≤ 0.1 e otherwise r ≤ Not permitted

shrinkage

with a maximum of 0.1 e

porosity:

0.5 with a

–r

maximum of

0.5

d ≤ 0.1 e + 0.2

d ≤ 0.1 e + 0.3 d ≤ 0.1 e + 0.2

Difference in with a

with a maximum of with a maximum

level at edges: d maximum of

0.5 of 0.3

0.5

Length of lack

of penetration:

m Not permitted Not permitted Not permitted

K: total length

of welding bead

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 36 of 39

Rev.6

Arc strike mark

(sharp edge at

Not permitted Not permitted Not permitted

bottom of

indication)

Aluminum, Steel ; nickel

Titanium and

Bead Characteristics magnesium and cobalt

titanium alloys

and their alloys alloys

Shrinkage

opening out on Not permitted Not permitted Not permitted

surface

Not permitted Not permitted

Not permitted

If part subjected to If part subjected

Pitting If part subjected to

fatigue, in to fatigue, in

Air cavity fatigue, in

accordance with accordance with

opening out on accordance with

designer designer

welding surface designer Static

Static diameter ≤ Static diameter

diameter ≤ 0.2 e

0.2 e ≤ 0.2 e

Tungsten

Not permitted Not permitted Not permitted

splashing

Arc strikes Not permitted Not permitted Not permitted

Welding

obtained by

assembly of

P ≥ 0.7 x

sheets on edge P ≥ 0.7 x minimum P ≥ 0.7 x

minimum

with straight thickness minimum thickness

thickness

edges

at joint surfaces

a

Exterior corner

welds with full

e ≤ P ≤ 1.2 x e e ≤ P ≤ 1.2 x e e ≤ P ≤ 1.2 x e

penetration

P: penetration

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 37 of 39

Rev.6

a ≥ 0.7 × e

a ≥ 0.7 × e a ≥ 0.7 × e

(not applicable to

(not applicable (not applicable to

Bead groove: a sealing

to sealing bead sealing bead

bead adjacent to

adjacent to adjacent to

structure

structure bead) structure bead)

bead)

(3) An alignment of slight defects is considered as a continuous and isolated defect if the interval separating

them is less than 3 times the length of

the smallest adjacent defect (if h < 3 × d2, then continuous defect f = d1 + h + d2).

(4) Defect detected with magnification not exceeding x50.

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 38 of 39

Rev.6

Attachment 13

ACCEPTANCE CRITERIA FOR INTERNAL DEFECTS (LINEAR AND VOLUME)

Applicable for steel (as per IGC04 62 165)

DEFECT DIMENSIONS MAXIMUM TOLERANCES

f: length of an isolated defect (1) f < 5 + (e / 4)

g: length of isolated defect g < 2 + (e / 5)

If k > 200 mm:

T: total length of defects over the total length k of

T ≤ 20 mm over 200 mm of assembly

the welding bead

If k ≤ 200 mm: T ≤ (k / 10)

(1) An alignment of slight defects is considered as a continuous and isolated defect if the interval

separating them is less than 3 times the length of the smallest adjacent defect.

Cracks are not permitted and must be repaired.

The conditions specified above must be met separately.

Specific case of steel parts with thickness e < 3 mm assembled by TIG welding

- Defects transversal to bead axis:

f < 2.5 + (e / 4) g < (e / 5)

- Bead end defects:

f < 1.5 + (e / 4) g < (e / 2)

- Angle of offset to bead axis > 45°

Applicable for Aluminium and magnesium (as per IGC04 62 166)

DEFECT DIMENSIONS MAXIMUM TOLERANCES

e ≤ 1 mm: f ≤ 0.5 mm

Length of isolated defect (1)

e > 1 mm: f ≤ (e / 2) (max. 5 mm)

If k > 200 mm:

T: Total length of defects over the total length k of

T ≤ 20 mm over 200 mm of assembly

the welding bead

If k ≤ 200 mm: T ≤ (k / 10)

(1) An alignment of slight defects is considered as a continuous and isolated defect if the interval

separating them is less than 3 times the length of the smallest adjacent defect.

Note: Cracks, lack of fusion (bonding) and lack of penetration are not permitted.

The conditions specified above must be met separately.

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

10-DP-D704.12 Page 39 of 39

Rev.6

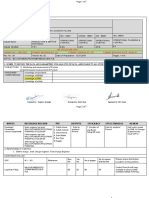

Attachment 14

WELDING PROCEDURE SPECIFICATION (WPS) TIG Welding

WPS No. :

WELDING PROCEDURE SPECIFICATION (WPS)

Issue :

TIG Welding Date :

Page :

Welding Process : Manual Automatic

Base material spec :: Tube diameter/ thickness :: to :

Sheet thickness : to

Joint Type : Fillet Butt

Cleaning Preparation : Chemical : Manual :

Welding Class : I II III

Filler Metals Specification :

Size of Filler Metals [diameter] :

Type of Current/Polarity : AC DCEN DCEP

Amperage [A] ranges :

Voltage [V] ranges :

Balance [%] :

Tungsten Electrode Type : Thorium Cerium Zirconium

Tungsten Electrode Size [diameter] :

Electrode Wire Speed :

Nozzle Diameter [mm] :

Shielding Gas : Argon Purity % : Flowrate [l/min] ranges :

Backing Gas : Argon Purity % : Flowrate [l/min] ranges :

Trailing Gas : Purity % : Flowrate [l/min] ranges :

Filler material for Tack Weld :

Number of Tack Weld : as necessary

Preheat Temp. Min. [ °C] : Not Applicable

Interpass Temp. Max. [ °C] : Not Applicable

Postweld Heat Treatment : Temper

Stress relieving

Not Applicable

Note:

Manufacturing Engineering Quality Engineering

Name : Name :

Signature : Signature :

Dated : Dated :

VERIFY THAT THIS IS THE CORRECT REVISION BEFORE USE

COPY & PRINTED FOR INFORMATION ONLY

You might also like

- ASTM A686 T72301 W1A 9.5 Steel GuideDocument2 pagesASTM A686 T72301 W1A 9.5 Steel GuideBernice JohnsonNo ratings yet

- Asme Section III Div 1 Nca Int Vol 60 - 2010Document36 pagesAsme Section III Div 1 Nca Int Vol 60 - 2010Mario Andres Jimenez AnguloNo ratings yet

- 17-7 Material PDFDocument5 pages17-7 Material PDFJothi ManiNo ratings yet

- Master Document MRB Index Rev SDocument10 pagesMaster Document MRB Index Rev SSalmanNo ratings yet

- Key Changes to ASME BPVC-2013Document5 pagesKey Changes to ASME BPVC-2013rtrajan_mech5408No ratings yet

- Asme B18.2.6 2003Document11 pagesAsme B18.2.6 2003Jesse ChenNo ratings yet

- 19013 MTC【CY】 PDFDocument1 page19013 MTC【CY】 PDFConstruction ProjectsNo ratings yet

- Summary of Changes - ASME 2015Document17 pagesSummary of Changes - ASME 2015mbc_enggNo ratings yet

- Competitive Solutions For Joining TechnologyDocument19 pagesCompetitive Solutions For Joining Technologyjy12bhuNo ratings yet

- DIN 3015 Clamp Technical OverviewDocument17 pagesDIN 3015 Clamp Technical OverviewBalderas Rosas WilibaldoNo ratings yet

- Stainless Steel Bars and Shapes: Standard Specification ForDocument7 pagesStainless Steel Bars and Shapes: Standard Specification ForMarcelo Santos100% (1)

- Grades of Steel ChartDocument3 pagesGrades of Steel ChartKimNo ratings yet

- ASTM A262, CorrosietestenDocument2 pagesASTM A262, CorrosietestenSales HBS Solutions100% (1)

- Training For Handling Hazardous MaterialsDocument24 pagesTraining For Handling Hazardous Materialssyreiljude100% (3)

- Joining Copper-Nickel Alloys GuideDocument9 pagesJoining Copper-Nickel Alloys GuidehboodhaiNo ratings yet

- Figure UCS-66 Impact Test Exemption Curves (Cont'd) : ASME BPVC - VIII.1-2019 UCS-66Document2 pagesFigure UCS-66 Impact Test Exemption Curves (Cont'd) : ASME BPVC - VIII.1-2019 UCS-66MechanicalNo ratings yet

- Cooling Gel Safety ReportDocument15 pagesCooling Gel Safety ReportJacek Stanislawski100% (1)

- Uf FloatingDocument20 pagesUf Floatingmhidayat108100% (1)

- NASA Process Specification For The Heat Treatment of Steel AlloysDocument9 pagesNASA Process Specification For The Heat Treatment of Steel AlloysisraelkkNo ratings yet

- Top 1000Document21 pagesTop 1000Pradeep ChandarNo ratings yet

- Api600 Valve Trim ChartDocument2 pagesApi600 Valve Trim ChartBoankNo ratings yet

- ISO 898 Grade 10.9Document2 pagesISO 898 Grade 10.9Mihaela NastaseNo ratings yet

- PED 2014-68-EU Guidelines EN v4Document235 pagesPED 2014-68-EU Guidelines EN v4Nav TalukdarNo ratings yet

- Stainless Steel SAE J405Document14 pagesStainless Steel SAE J405Radu BurloiuNo ratings yet

- Comparison of Flange Face Finish As Per B16-5Document1 pageComparison of Flange Face Finish As Per B16-5Vivi OktaviantiNo ratings yet

- General Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessDocument9 pagesGeneral Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessCarlos Ramirez BaltazarNo ratings yet

- Flange - Long Weld Neck, ANSI Class 600, ASME B16.5, 1 - 16 - Raised Face (In)Document2 pagesFlange - Long Weld Neck, ANSI Class 600, ASME B16.5, 1 - 16 - Raised Face (In)Magin Idelfonso TorreblancaNo ratings yet

- Heavy Hex Nuts, Grade 2H: TechnicalDocument1 pageHeavy Hex Nuts, Grade 2H: TechnicalJohn MuellerNo ratings yet

- Corrosion Resistance TablesDocument9 pagesCorrosion Resistance TablesManoj BNo ratings yet

- 4 MM Plate - MTC - SS-304Document1 page4 MM Plate - MTC - SS-304Mohammad AdilNo ratings yet

- QCF312 WPQRDocument2 pagesQCF312 WPQRminhnnNo ratings yet

- Astm A192 Asme Sa192 PDFDocument4 pagesAstm A192 Asme Sa192 PDFWil Vasquez C100% (1)

- Dynamic Balancing MachineDocument4 pagesDynamic Balancing Machine.x100% (1)

- C43Document1 pageC43rudramansingh123No ratings yet

- Mechanical Properties Min. 0,2 % Yield Strength Values at Increased TemperaturesDocument4 pagesMechanical Properties Min. 0,2 % Yield Strength Values at Increased TemperaturesJarek CieslakNo ratings yet

- Laminated Shim Stock SpecificationDocument11 pagesLaminated Shim Stock SpecificationAsker Ali TPNo ratings yet

- Mil F 18240DDocument19 pagesMil F 18240DrjbelgauNo ratings yet

- Stainless Steel - Grade 321 (UNS S32100)Document4 pagesStainless Steel - Grade 321 (UNS S32100)mp87_ingNo ratings yet

- ML 1015998765Document42 pagesML 1015998765ডঃ শুভম চ্যাটার্জীNo ratings yet

- B16 Case 12Document2 pagesB16 Case 12InaamNo ratings yet

- 6-15-0001 Rev 2 Gen Spec For Heat Exchanger PDFDocument20 pages6-15-0001 Rev 2 Gen Spec For Heat Exchanger PDFsumit kumarNo ratings yet

- An818 Rev-20 2Document5 pagesAn818 Rev-20 2Senthil KumarNo ratings yet

- Astm A194Document11 pagesAstm A194Jarek CieslakNo ratings yet

- AISI 1045 Medium Carbon Steel - AZoMDocument4 pagesAISI 1045 Medium Carbon Steel - AZoMLuis NunesNo ratings yet

- A723A723M-18a 1.05 PDFDocument5 pagesA723A723M-18a 1.05 PDFist93993No ratings yet

- Mil DTL 18240Document24 pagesMil DTL 18240Андрей ПятыгинNo ratings yet

- Din 10140Document3 pagesDin 10140Diego CamargoNo ratings yet

- Bomba SihiDocument24 pagesBomba SihiCristian PovedaNo ratings yet

- Federal Specification Chains GuideDocument64 pagesFederal Specification Chains Guiderfuentes73No ratings yet

- MAN Truck & Bus Works Standard Bent Tubes DocumentationDocument17 pagesMAN Truck & Bus Works Standard Bent Tubes DocumentationAkmal NizametdinovNo ratings yet

- Asme Section Ii A-2 Sa-592 Sa-592m PDFDocument4 pagesAsme Section Ii A-2 Sa-592 Sa-592m PDFAnonymous GhPzn1xNo ratings yet

- Aerospace Material Specification: Tolerances Corrosion and Heat-Resistant Steel TubingDocument3 pagesAerospace Material Specification: Tolerances Corrosion and Heat-Resistant Steel TubingTetianaNo ratings yet

- Fabory Fasteners ASTM StudboltDocument13 pagesFabory Fasteners ASTM StudboltJohan ConradieNo ratings yet

- Highlights On ASME Essential VariablesDocument8 pagesHighlights On ASME Essential VariableschowhkNo ratings yet

- Titanium FormingDocument5 pagesTitanium FormingSiavash IraniNo ratings yet

- AN818 Rev-20 PDFDocument5 pagesAN818 Rev-20 PDFaldiNo ratings yet

- Welding Rod For c5 & f5 - Er 80s-b6Document1 pageWelding Rod For c5 & f5 - Er 80s-b6SatyamEngNo ratings yet

- ISO 630-Fe430-CDocument1 pageISO 630-Fe430-CS.Hasan MirasadiNo ratings yet

- Asme b18!8!4m Pin Materials and HardnessDocument2 pagesAsme b18!8!4m Pin Materials and Hardnessjaskaran singhNo ratings yet

- Astm A240 Uns S32205Document3 pagesAstm A240 Uns S32205Mintone Sajayah BekabekaNo ratings yet

- Astm A659-18Document3 pagesAstm A659-18Ryan ZhangNo ratings yet

- Draft LPG Hose Certification Manual CommentsDocument19 pagesDraft LPG Hose Certification Manual Commentsmodak cables (India)No ratings yet

- 37 Log Book Filling SOPDocument7 pages37 Log Book Filling SOPSiddhant SatpathyNo ratings yet

- Ormco-Catalog 2013 121013Document208 pagesOrmco-Catalog 2013 121013Ningombam Robinson SinghNo ratings yet

- 9Document6 pages9Chechae ChaerikaNo ratings yet

- BAB I Lapsus RadioDocument2 pagesBAB I Lapsus RadioChechae ChaerikaNo ratings yet

- Daftar PustakaDocument1 pageDaftar PustakaChechae ChaerikaNo ratings yet

- Squamous Cell Carcinoma of The TongueDocument6 pagesSquamous Cell Carcinoma of The TongueCitra Wulandari SofyanNo ratings yet

- Jadwal Puasa Sunnah 2012Document2 pagesJadwal Puasa Sunnah 2012Chechae ChaerikaNo ratings yet

- Penilaia If bkhkjk2011 FixDocument9 pagesPenilaia If bkhkjk2011 FixChechae ChaerikaNo ratings yet

- Jadwal Puasa Sunnah 2012Document2 pagesJadwal Puasa Sunnah 2012Chechae ChaerikaNo ratings yet

- LWAASHJSPLANGULDocument5 pagesLWAASHJSPLANGULAmiy SrivastavaNo ratings yet

- Samanea Saman 8Document7 pagesSamanea Saman 8Jesus Llorente mendozaNo ratings yet

- NJ DEP Guidance on Process Hazard Analysis and Risk AssessmentDocument17 pagesNJ DEP Guidance on Process Hazard Analysis and Risk AssessmentaakashtrivediNo ratings yet

- Organic Extraction Separates Acid, Bromophenol, and BiphenylDocument4 pagesOrganic Extraction Separates Acid, Bromophenol, and BiphenylMareline MendietaNo ratings yet

- Use of Phosphates in Meat ProductsDocument9 pagesUse of Phosphates in Meat ProductsNabil SouissiNo ratings yet

- CLS 7, Atomic Structure, WSDocument2 pagesCLS 7, Atomic Structure, WSEmerooNo ratings yet

- Diffuser AugmentedDocument8 pagesDiffuser Augmentedanthony100% (1)

- CKRD-MS-03 (2020)Document51 pagesCKRD-MS-03 (2020)Shakoor MalikNo ratings yet

- Ylang Ylang Oil PDFDocument1 pageYlang Ylang Oil PDFKaren Marra RostNo ratings yet

- Biopharm Tubing: For Every Part of Your ProcessDocument24 pagesBiopharm Tubing: For Every Part of Your ProcessFer PabNo ratings yet

- PMTC Guidance on Cleaning Validation PracticeDocument15 pagesPMTC Guidance on Cleaning Validation PracticehhNo ratings yet

- Marble and Granite Study ReportDocument15 pagesMarble and Granite Study Reportp156426 Ahmad KhanzadaNo ratings yet

- Kerasiev Ceramic Membrane Techinical Brochure 2018 (0.5MB)Document4 pagesKerasiev Ceramic Membrane Techinical Brochure 2018 (0.5MB)Suresh DNo ratings yet

- 247 0 Coating Brochure Web-EnDocument36 pages247 0 Coating Brochure Web-EnjorgeNo ratings yet