Professional Documents

Culture Documents

DIMP Basics PDF

Uploaded by

antonio0 ratings0% found this document useful (0 votes)

31 views2 pagesOriginal Title

DIMP_Basics.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

31 views2 pagesDIMP Basics PDF

Uploaded by

antonioCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

TO FURTHER SUPPORT THE REGULATIONS IDENTIFIED IN

THE PIPE LINE SAFETY ACT OF 2002, 49 CFR PART 192

SUBPART O WAS DEVELOPED WITH PROVISIONS TO Transmission Integrity Management Program

INCLUDE: IMPLEMENT INTEGRITY MANAGEMENT PLANS;

CONDUCT BASELINE ASSESSMENTS AND PERIODIC

REASSESSMENTS; REMEDIATE SIGNIFICANT DEFECTS;

TRIMP

CONTINUALLY MONITOR PROGRAM EFFECTIVENESS.

TRANSMISSION INTEGRITY PLAN DEFINED: “THE SET OF

DOCUMENTS AND PROCEDURES THAT SYSTEMATICALLY

DEFINE, CONTROL AND IMPLEMENT INTEGRITY

MANAGEMENT.”

TRANSMISSION INTEGRITY MANAGEMENT PROGRAM BASICS

basics

Pipeline Integrity is a mandated program focusing on Peoples Transmission and Storage pipelines. This program requires

systematic examination of these pipelines in High Consequence Areas to ensure the safety of the public, our employees,

and our system. In addition, Peoples monitors these lines and performs preventative and mitigative measures over and

above US Department of Transportation minimum standards to continually assess the safety of the system.

High Consequence Areas

Peoples maintains and operates pipelines in Identified Sites:

both populated and remote geographic areas. Outdoor Congregating Area. An

A High Consequence Area (HCA) is an area outside area or open structure

where a leak or other failure could have a occupied by 20 or more persons 50

serious effect on populations. There are two days in any 12 month period. (ex.

methods for determining an HCA. park)

Peoples uses the following method. Buildings for Public Assembly. A

building that is occupied by 20 or

An HCA is the area with a Potential Impact more persons at least 5 days a week

Circle (PIC) containing: for 10 weeks in any 12 month period.

an identified site, or (ex. gym, gas station)

20 or more Buildings Intended for Human Hard to Evacuate Facilities. A facility

Occupancy (BIHOs) occupied by persons who: are

confined, are of impaired mobility, or

would be difficult to evacuate. (ex.

PREVENTIVE AND

hospital, school) MITIGATIVE

MEASURES

PROTECTING & MONITORING OUR PIPELINES There are two categories of P&M

To protect and monitor our pipelines, Peoples chooses among the following measures: Measures.

monthly aerial surveys, bi-monthly line walking, operational and maintenance activities Prescriptive: Actions are

and surveillance reports completed by knowledgeable company employees familiar with mandated by the Federal

our service territory. Government.

Non-Prescriptive: Rule allows

PIPELINE 1. External Corrosion

2. Internal Corrosion

ASSESSMENT Peoples to decide what actions to

take.

INTEGRITY 3. Stress Corrosion METHODS Below are examples of P&M

Cracking Peoples employs three Measures used by Peoples.

THREATS: 4. Equipment Failure methods for assessing One Call Center Participation

5. Manufacturing Defects pipeline integrity. These Line Locating and Marking

Nine Categories 6. Construction Defects methods are: Monitored Excavations

(Welding/Fabrication In Line Inspection, Third Party Damage – monitoring

Related) Pressure Testing for excavation near Transmission

rd

7. 3 Party Integrity, and lines to prevent damage

Damage/Mechanical Line replacement and Damage Reporting

Damage pressure test. Pipeline Surveillance

8. Incorrect Operations

(Human Error)

9. Weather Related and Find more information on the Transmission Integrity Management

Outside Force Program at peoples-gas.com or call 1-866-863-6266.

DIMP IS A FEDERALLY MANDATED PROGRAM

Distribution Integrity Management Program

REQUIRED BY DOT REGULATIONS.

THE DISTRIBUTION INTEGRITY MANAGEMENT

PROGRAM IMPACTS EVERYDAY FIELD OPERATIONS

ACROSS THE ENTIRE PEOPLES DISTRIBUTION SYSTEM.

DIMP

basics

DISTRIBUTION INTEGRITY MANAGEMENT PROGRAM BASICS

DIMP’s purpose is to insure public safety by reducing

the number of incidents on gas distribution lines through

continued system improvement.

Safety is the number one priority of Peoples. The goal of DIMP is to maintain

up to date and accurate records of our distribution system to identify possible

threats and to mitigate risks.

PROGRAM ELEMENTS

These are the required elements of the DIMP.

KNOWLEDGE OF OUR PIPELINE SYSTEM

We are required to record the location and materials in our distribution system, as well as track the steps we take to maintain

and operate the pipelines. Building proximity, population density, and leak history is also tracked. We use this information to

calculate the level of any potential risk a segment of pipe may have.

THREAT IDENTIFICATION IMPLEMENT MEASURES TO

We continuously survey the system to identify threats. REDUCE RISK

We have established programs to address risks once they are

DETERMINE THE RISK ON ALL identified. Preventative and Mitagative (P&M) measures are

DISTRIBUTION PIPELINES. then implemented to address identified risks.

Excavation Damage: Digging near our pipe causes the

highest threat to our distribution system. REPORTING PERFORMANCE RESULTS

Bare Steel and Cast Iron Pipe: Have a higher risk due Metrics are reported to the Federal Government annually.

to the threat of corrosion. Peoples is embarking on an Hazardous leaks eliminated or repaired,

aggressive pipeline replacement program to mitigate Number of excavation damages,

the risk. Number of excavation notifications received,

Total number of leaks eliminated or repaired,

Number of hazardous leaks either eliminated or repaired by

MEASURE PERFORMANCE pipeline material type.

We maintain records pertaining to the Distribution

System for a minimum of 10 years. The records are PROGRAM EVALUATION

used to determine the company’s performance in our Peoples periodically reviews and analyzes records to determine

efforts to continually improve the Distribution System. program effectiveness to minimize risk.

Find more information on the Distribution Integrity Management

Program at peoples-gas.com or call 1-866-863-6266.

You might also like

- PlasmaDocument47 pagesPlasmasushaantb400No ratings yet

- 01 PDFDocument51 pages01 PDFantonioNo ratings yet

- Knowing KnowledgeDocument176 pagesKnowing Knowledgestarmania831No ratings yet

- Complete Phrasal Verbs ListDocument137 pagesComplete Phrasal Verbs ListHermes®No ratings yet

- t2 PDFDocument1 paget2 PDFantonioNo ratings yet

- Calefon Junkers 25.4 KWDocument2 pagesCalefon Junkers 25.4 KWantonioNo ratings yet

- t2 PDFDocument1 paget2 PDFantonioNo ratings yet

- Viper-Skin Technical Binder (KR - 7.6.10)Document47 pagesViper-Skin Technical Binder (KR - 7.6.10)antonioNo ratings yet

- Phrasal Verbs List PDFDocument20 pagesPhrasal Verbs List PDFNelly Vicky CruzNo ratings yet

- Units For Magnetic Properties: Quantity Symbol Gaussian & Cgs Emu Conversion Factor, C Si & Rationalized MksDocument1 pageUnits For Magnetic Properties: Quantity Symbol Gaussian & Cgs Emu Conversion Factor, C Si & Rationalized MksantonioNo ratings yet

- Review of Gas Transmission Pipeline Repair MethodsDocument2 pagesReview of Gas Transmission Pipeline Repair MethodsantonioNo ratings yet

- Subsea Pipeline RepairsDocument12 pagesSubsea Pipeline RepairsBhavesh1993100% (3)

- 12 20 86Document9 pages12 20 86antonioNo ratings yet

- Fracturamiento de Rocas Mediante Tecnolo PDFDocument16 pagesFracturamiento de Rocas Mediante Tecnolo PDFantonioNo ratings yet

- Concentrative Properties of Aqueous Solutions: Density, Refractive Index, Freezing Point Depression, and ViscosityDocument26 pagesConcentrative Properties of Aqueous Solutions: Density, Refractive Index, Freezing Point Depression, and ViscosityantonioNo ratings yet

- 12 01 91Document4 pages12 01 91antonioNo ratings yet

- Common Spurious Signals Observed in Mass Spectrometers ReferenceDocument1 pageCommon Spurious Signals Observed in Mass Spectrometers ReferenceantonioNo ratings yet

- Enthalpy of Dilution of Acids: H, The Negative of TheDocument1 pageEnthalpy of Dilution of Acids: H, The Negative of TheantonioNo ratings yet

- CARBOHYDRATE NAMES AND SYMBOLS TABLEDocument2 pagesCARBOHYDRATE NAMES AND SYMBOLS TABLEnelaojNo ratings yet

- Melting, Boiling, Triple, and Critical Points of The ElementsDocument3 pagesMelting, Boiling, Triple, and Critical Points of The ElementsantonioNo ratings yet

- Index Of Refraction Of Air: N = Λ P (1 + P (60 .1 - 0 .972T) × 10Document1 pageIndex Of Refraction Of Air: N = Λ P (1 + P (60 .1 - 0 .972T) × 10antonioNo ratings yet

- Properties of Amino Acids: M T, PK, PKDocument2 pagesProperties of Amino Acids: M T, PK, PKantonioNo ratings yet

- Practical PH Measurements On Natural Waters: A. K. Covington and W. DavisonDocument2 pagesPractical PH Measurements On Natural Waters: A. K. Covington and W. DavisonantonioNo ratings yet

- Solubility of Hydrocarbons in Seawater: S/PPM (Mass) 10 MDocument2 pagesSolubility of Hydrocarbons in Seawater: S/PPM (Mass) 10 MantonioNo ratings yet

- Percentage Points, Student'S T-Distribution: Normal Probability FunctionDocument1 pagePercentage Points, Student'S T-Distribution: Normal Probability FunctionantonioNo ratings yet

- Electron Stopping Powers: Cedric J. PowellDocument2 pagesElectron Stopping Powers: Cedric J. PowellantonioNo ratings yet

- 08 60 93Document8 pages08 60 93antonioNo ratings yet

- 19 63Document5 pages19 63antonioNo ratings yet

- Electrical Conductivity Of Water Reference: Conductivity In Μs/Cm At The Indicated PressureDocument1 pageElectrical Conductivity Of Water Reference: Conductivity In Μs/Cm At The Indicated PressureantonioNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- TESCO - The Customer Relationship Management ChampionDocument8 pagesTESCO - The Customer Relationship Management ChampionBulbul JainNo ratings yet

- Is Generation Y Addicted? How Social Media Affects RelationshipsDocument10 pagesIs Generation Y Addicted? How Social Media Affects RelationshipsYamuna GovindarajNo ratings yet

- Review of Related LiteratureDocument16 pagesReview of Related Literaturema.sharine valerie PablicoNo ratings yet

- Allwords WithdigitsDocument9,785 pagesAllwords WithdigitsAnthony ANTONIO TONY LABRON ADAMS0% (1)

- Student Handbook Lesson PlanDocument3 pagesStudent Handbook Lesson Planapi-312544851100% (1)

- Forecast of Pressure and Working Conditions in Rock Tunnels ROCK TUNNELING WITH STEEL SUPPORT CHAPTER 5Document13 pagesForecast of Pressure and Working Conditions in Rock Tunnels ROCK TUNNELING WITH STEEL SUPPORT CHAPTER 5Johana JaramilloNo ratings yet

- Tell Me About YourselfDocument3 pagesTell Me About YourselfSandra GuadarramaNo ratings yet

- EETD Course Plan (Probability and Statistics)Document6 pagesEETD Course Plan (Probability and Statistics)Raja ahmerNo ratings yet

- Factor Influencing Investment DecisionDocument19 pagesFactor Influencing Investment Decisiondashora8No ratings yet

- UntitledDocument37 pagesUntitledJanna AlisacaNo ratings yet

- Adapted StudyDocument14 pagesAdapted StudySunga ErikaNo ratings yet

- Tourist LoyaltyDocument19 pagesTourist LoyaltyAditya HendraNo ratings yet

- Abhishek DwivediDocument61 pagesAbhishek Dwivedishrikrishna computerNo ratings yet

- Establishing A Territory in The Introductions of Engineering Research Articles Using A Problem-Solution PatternsDocument18 pagesEstablishing A Territory in The Introductions of Engineering Research Articles Using A Problem-Solution PatternsAlexandre KennedyNo ratings yet

- Different Blog Writing Formats and How You Can Use Them To Engage Your AudienceDocument13 pagesDifferent Blog Writing Formats and How You Can Use Them To Engage Your AudienceNarrato SocialNo ratings yet

- Understanding Audiences Through Reception AnalysisDocument7 pagesUnderstanding Audiences Through Reception AnalysisLia KurniawatiNo ratings yet

- Lesson Plan 1 SoundDocument5 pagesLesson Plan 1 SoundMadison AnneNo ratings yet

- Kidanemariam AssgidDocument61 pagesKidanemariam AssgidLamesa GudetaNo ratings yet

- Thesis (From Curriculum Reform To Classroom Practice) 2Document448 pagesThesis (From Curriculum Reform To Classroom Practice) 2poiu100% (1)

- Jurnal JP - Peran Masa Kerja Dan Gaya Komunikasi Terhadap Kinerja Karyawan Dengan Motivasi Karyawan Sebagai Mediator Pada PT Gajah Tunggal TBKDocument13 pagesJurnal JP - Peran Masa Kerja Dan Gaya Komunikasi Terhadap Kinerja Karyawan Dengan Motivasi Karyawan Sebagai Mediator Pada PT Gajah Tunggal TBKAulia RachmanNo ratings yet

- Educ 601 Module 1Document18 pagesEduc 601 Module 1Joseph Brian Racho KierulfNo ratings yet

- Reflective Journals As A Research Tool The Case of Student Teachers Development of TeamworkDocument16 pagesReflective Journals As A Research Tool The Case of Student Teachers Development of TeamworkSahar SYSNo ratings yet

- Bowyer-Crane and Snowling 2005Document14 pagesBowyer-Crane and Snowling 2005Mara SimonNo ratings yet

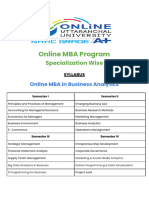

- Uu Online Mba SyllabusDocument3 pagesUu Online Mba SyllabusVimalesh YadavNo ratings yet

- Lesson 10 Estimating Population MeansDocument5 pagesLesson 10 Estimating Population MeansSamleedigiprintsNo ratings yet

- Research Paper - Blue Moon Group PDFDocument62 pagesResearch Paper - Blue Moon Group PDFNguyễn Võ Hoàng AnNo ratings yet

- Geophysical methods reveal Finland's kaolin and ilmenite depositsDocument8 pagesGeophysical methods reveal Finland's kaolin and ilmenite depositsFraztya HebbyNo ratings yet

- SWOT AnalysisDocument12 pagesSWOT AnalysisEka DarmadiNo ratings yet

- Effects of The Breakup On Children, School Performance and Peer RelationsDocument13 pagesEffects of The Breakup On Children, School Performance and Peer Relationszubiii aslamNo ratings yet

- Subjective Visual Vertical in Vestibular Disorders Measured With The Bucket TestDocument9 pagesSubjective Visual Vertical in Vestibular Disorders Measured With The Bucket Testcamila hernandezNo ratings yet