Professional Documents

Culture Documents

Manual de Servicio T45

Uploaded by

Arturo suzan arvizu100%(1)100% found this document useful (1 vote)

633 views25 pagesMANUAL DE TALLER MALACATE T45

Original Title

MANUAL DE SERVICIO T45

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMANUAL DE TALLER MALACATE T45

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

633 views25 pagesManual de Servicio T45

Uploaded by

Arturo suzan arvizuMANUAL DE TALLER MALACATE T45

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 25

Tae MAINTENANCE aes

AFIS Ts

\ U ass

ARMCO National Supply Division

Steel Corporation

a INTRODUCTION

The NATIONAL T-45 Drawworks is manufactured at the Torrance, California

‘of the NATIONAL SUPPLY DIVISION, Armco Steel Corporation. .A serial mu

is assigned 40 each drawworks and any inquiries concerning the drawworks in

possession must inclide reference to this serial number. This serial number apj

‘on the neme end instruction plate located on the drillers side of the drawworks

the cathead.

Information“on installation, operation, and maintenance has been fully covered ir

manual. Long trouble-free sorvico can bo achioved only by diligent care and pr

operation. Constant effort to improve our product makes it impossible for this

lication to be exact in every respect to the drawworks in your possession. The

‘operation and maintenance will, however, remain the same.

‘Always order teplacement parts from the Illustrated Parts List for the T-45 0

works. I+ contai

manual was written.

any modifications which may have been incorporated after

NATIONAL SUPPLY DIVISION

Armeo Stool Corporation

Copies of this manual have been furnished with each drawworks at time

of shipment on « "No Charge" basis. A charge of $5.00 per manual will

be assessed on all requests for additional or replacement copies.

TABLE OF CONTENTS

"Section r RIG-UP

LUBRICATION

ie CONTROLS-OPERATION

D AIR CLUTCHES

BRAKES

SHAFT DISASSEMBLY and OVERHAUL

SPECIFICATIONS

E PRESERVATION OF MACHINERY

SERVICE MANUAL

MAIN DRUM BRAKES

A supply of water is introduced at the drillers end of

the drunshaft, circulated through the brake ‘ims, and

Talus to be decharged at the drils end. Operator

51 nig.up must provide © valve ot dillrs position to

cinttcl the’ weter suppl. The soppy line to ond from

{his valve and connecting lines are, also furnished. by the

‘operator. The vater supply should be abcut 25 \galons

per minute ot 55 psi

MAIN DRUM AND SAND-REEL BRAKES

Periodic checking of brake rims is required. Check for

tnoven or excessive weer, Rim grooving i» caused by -

hard foreign particles embedded in the lining. Grind

NATIONAL

Type T-45

Drawworks

surface of the liting Yo remove evibodded particles.

Keep lising {ree of all confamina'ss, such as of, grease,

Inu. ok Thay yodice brating liziony.

Esch ling block ¥s secured with

may looten as the lining seats itsel

ur bolts, These bolts

ith service. Retighten

When replacing lining, check, onc! straighten bends if

vary, Lining blacks mist malo proper fit with the

fond. Under load the lining is keot in place on the band

by friction between the back of the Tning and

|. Without proper friction botween the band and

ing the bolts will be shecred and the lining wil

‘Off. Therefore, the contact aroa betwoon band and

9 should be freo from ofl, grease, mud, or soft paint.

The ase of brake rins worn beyond the minimum diameter

shown on Fig, 7 ig not recommended.

‘ALLOWABLE WEAR OF MAIN DRUM BRAKE RIMS

You might also like

- Instructivo de Operación Arranque de PCR y Equipos de GeneraciónDocument69 pagesInstructivo de Operación Arranque de PCR y Equipos de GeneraciónArturo suzan arvizu100% (1)

- Top Drive VFDDocument95 pagesTop Drive VFDArturo suzan arvizuNo ratings yet

- Manual Detroit Diesel Serie 60Document183 pagesManual Detroit Diesel Serie 60alexmaldonadohdz91% (200)

- Manual Detroit Diesel Serie 60Document183 pagesManual Detroit Diesel Serie 60alexmaldonadohdz91% (200)

- English - SpanishDocument109 pagesEnglish - SpanishjequirogNo ratings yet

- Manual de Operacion AMPHION PDFDocument295 pagesManual de Operacion AMPHION PDFteresita acopa85% (27)

- Presentacion Auditorias EfectivasDocument15 pagesPresentacion Auditorias EfectivasArturo suzan arvizuNo ratings yet

- Catalogo de Acoples FalkDocument7 pagesCatalogo de Acoples FalkAbimael Ochoa78% (9)

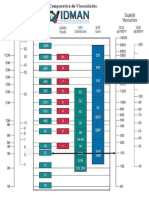

- Tabla de ViscocidadesDocument1 pageTabla de ViscocidadesArturo suzan arvizuNo ratings yet

- MALACATE Skytop Brewster n42-n46Document65 pagesMALACATE Skytop Brewster n42-n46Arturo suzan arvizuNo ratings yet

- Manual Del Usuario Base Line 1.0 ESPAÑOLDocument90 pagesManual Del Usuario Base Line 1.0 ESPAÑOLArturo suzan arvizu100% (1)

- Manual de Balsas Salvavidas ELLIOT PDFDocument10 pagesManual de Balsas Salvavidas ELLIOT PDFArturo suzan arvizuNo ratings yet

- Contaminación Por Residuos SolidoDocument6 pagesContaminación Por Residuos SolidoArturo suzan arvizuNo ratings yet

- Compresor 2Document1 pageCompresor 2Arturo suzan arvizuNo ratings yet

- Desarrollo de Competencias en El Proceso de Instruccion PDFDocument252 pagesDesarrollo de Competencias en El Proceso de Instruccion PDFArturo suzan arvizu88% (17)

- Malacate National 110 UeDocument62 pagesMalacate National 110 UeArturo suzan arvizuNo ratings yet

- Actualizado y Modificado Manual NovDocument63 pagesActualizado y Modificado Manual NovArturo suzan arvizu100% (1)

- Manual KISS 800 Español PDFDocument91 pagesManual KISS 800 Español PDFArturo suzan arvizuNo ratings yet

- Manual de Operacion y ManttoDocument44 pagesManual de Operacion y ManttoArturo suzan arvizuNo ratings yet

- Caracteristicas de TuberiaDocument1 pageCaracteristicas de TuberiaArturo suzan arvizuNo ratings yet

- Viscosidad RDMCDocument29 pagesViscosidad RDMCAdrian OmañaNo ratings yet

- Agitadores para Lodos Taza PDFDocument11 pagesAgitadores para Lodos Taza PDFArturo suzan arvizuNo ratings yet

- Caterpillar Contenido, Informacion General e IndiceDocument26 pagesCaterpillar Contenido, Informacion General e IndiceArturo suzan arvizuNo ratings yet

- Bomba Triplex Lodo Manual 12T1600 DrillmecDocument114 pagesBomba Triplex Lodo Manual 12T1600 DrillmecArturo suzan arvizu75% (4)