Professional Documents

Culture Documents

Formulation and Evaluation of Enteric Coated Pellets of Omeprazole PDF

Uploaded by

Yuppie RajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Formulation and Evaluation of Enteric Coated Pellets of Omeprazole PDF

Uploaded by

Yuppie RajCopyright:

Available Formats

International Journal of Drug Development & Research

| October-December 2012 | Vol. 4 | Issue 4 | ISSN 0975-9344 |

Available online http://www.ijddr.in

Covered in Official Product of Elsevier, The Netherlands

SJR Impact Value 0.03 & H index 2

©2012 IJDDR

Formulation and Evaluation of Enteric Coated Pellets of Omeprazole

Kammela K Chakravarthy 1, Mohammad Younus2*, Shahidulla Shaik1, Sai Venkata Vedavyas Pisipati3

1

Dr. Samuel George Institute of Pharmaceutical Sciences, Markapur, Prakasam Dist, Andhra Pradesh, India.

2

Chandra Labs, Kukatpally, Hyderabad, Andhra Pradesh, India

3

Donbosco College of Pharmacy Pulladigunta, Guntur Dist, Andhra Pradesh, India.

Covered in Index Copernicus with IC Value 4.68 for 2010

Abstract How to Cite this Paper:

The objective of the present study is to formulate Kammela K Chakravarthy , Mohammad

and evaluate delayed release pellets of Omeprazole Younus*, Shahidulla Shaik, Sai Venkata

comparable to the innovator product. The Vedavyas Pisipati “Formulation and Evaluation of

formulations of Omeprazole delayed release pellets Enteric Coated Pellets of Omeprazole” Int. J. Drug

of Omeprazole were developed by enteric film Dev. & Res., October-December 2012, 4(4): 257-264.

coating process varying the compositions of drug

Full Length Research Paper

loading, barrier coating and enteric coating. Copyright © 2012 IJDDR, Mohammad

Eudragit L 100 55 and HPMC Phthalate 55 S were Younus et al. This is an open access paper

used as enteric polymers. The process variables distributed under the copyright agreement with

were standardized and the different batches Serials Publication, which permits unrestricted use,

prepared were evaluated for assay/drug content, distribution, and reproduction in any medium,

water content, acid resistance and dissolution rate. provided the original work is properly cited.

The drug dissolution profiles of Omeprazole

Article History:------------------------

delayed release formulations developed were

Date of Submission: 21-09-2012

compared with that of innovators product. Based

Date of Acceptance: 05-10-2012

on the results formulation containing enteric

Conflict of Interest: NIL

coating polymer HPMC P 55 S (12%), and

Source of Support: NONE

plasticizers diethyl phthalate, cetyl alcohol has

been selected as the best formulation developed

INTRODUCTION

for Omeprazole delayed release pellets.

The primary aim of using delayed release products is

to protect the drug from gastric fluids, to reduce

gastric distress caused by drugs particularly irritating

*Corresponding author, Mailing address:

Mohammad Younus to the stomach or to facilitate gastrointestinal transit

E-mail: mdyounus1127@gmail.com for drugs that are better absorbed from intestine [1, 2].

Enteric polymers are becoming very popular due to

their property of intact in the stomach, but will

Key words: dissolve and release of the contents once it reaches

Omeprazole; Enteric Coating; Acid Resistance the small intestine, their prime intension is to delay

Int. J. Drug Dev. & Res., October-December 2012, 4 (4): 257-264

Covered in Scopus & Embase, Elsevier

257

Mohammad Younus et al: Formulation and Evaluation of Enteric Coated Pellets of Omeprazole

the release of drugs, which are inactivated by the Esophageal Reflux Disease (GERD) [4, 5]. It is highly

stomach contents or may cause bleeding or nausea by acid labile and presents many formulation challenges

the irritation of gastric mucosa [3]. Omeprazole is a and to protect it from acidic environment of the

proton pump inhibitor used for short-term treatment stomach an enteric coated pellets formulation was

of acid peptic disease, gastro esophageal reflux, tried in the present study.

gastric ulcer, duodenal ulcer, and Zollinger-Ellison

Covered in Index Copernicus with IC Value 4.68 for 2010

syndrome and for maintenance treatment of Gastro MATERIALS AND METHODS:

Chemicals/Excipients used

Chemical/Excipients Manufactures /Supplier Category

Anti – ulcerative Gastric proton –

Omeprazole Natco chemical division

pump inhibitor

Sugar spheres J.R.S. Pharma(mfg), forum product Pvt Ltd (supp) Seed pellets

PVP K30 Signet chemical corporation Film former

HPMC E5 Signet chemical corporation Film former

Full Length Research Paper

Di Basic Sodium Merck Ltd. (mfg), Vasco Scientifics (supp), Signet

Alkalizing Agent

Phosphate chemical corporation (supp)

Light Magnesium Merck Ltd. (mfg), Vasco Scientifics (supp), Signet

Alkalizing Agent

Carbonate chemical corporation (supp)

Merck Ltd. (mfg), Vasco Scientifics (supp), Signet

Sodium Lauryl Sulphate Solubilising Agent

chemical corporation (supp)

Roquette Ltd. (mfg) Signet chemical corporation

Mannitol Diluent

(Supp)

Eudragit L 100 55 Shin – Etsu (mfg) Enteric Polymer

Merck Ltd. (mfg), Vasco Scientifics (supp), Signet

HPMC P55 S Enteric Polymer

chemical corporation (supp)

Merck Ltd. (mfg), Vasco Scientifics (supp), Signet

PEG 4000 Plasticizer

chemical corporation (supp)

Merck Ltd. (mfg), Vasco Scientifics (supp), Signet

Tri Ethyl Citrate Plasticizer

chemical corporation (supp)

Merck Ltd. (mfg), Vasco Scientifics (supp), Signet

Di Ethyl Phthalate Plasticizer

chemical corporation (supp)

Cetyl Alcohol VVF Ltd. (mfg) Sundeep Enterprises (Supp) Plasticizer

Luzenac Pharma Ltd. (mfg) =, Signet chemical

Talc Anti-Agglomerate

corporation (Supp)

Merck Ltd. (mfg), Vasco Scientifics (supp), Signet

Titanium Dioxide Opacifier

chemical corporation (supp)

Isopropyl Alcohol S.D Fine Chemical ltd. (mfg) Vasco Scientifics (Supp) Solvent

Equipments Used:

Instruments/ Equipment Model No & Manufacturer/ Supplier

Digital Shimadzu AX- 200, Japan

Electronic balance Oriental

HPLC Alliance 2695, Waters India limited

Disintegration apparatus (disintegration tester USP) ED2AL, electro lab

Dissolution test apparatus, USP XXII Electro lab, six jars

Karl fisher titrator Mettler Toledo DL50, Switzerland

Fluid bed dryer Umang pharmatech Pvt Ltd

Preparation of Omeprazole Enteric Coated Specified quantity of non-pareil seeds were

Pellets and Capsules: accurately weighed and dispensed. 500 ml of purified

Drug Loading water is taken in a beaker and kept for stirring under

a mechanical stirrer. Specified quantities of PVP K 30

Int. J. Drug Dev. & Res., October-December 2012, 4 (4): 257-264

Covered in Scopus & Embase, Elsevier

258

Mohammad Younus et al: Formulation and Evaluation of Enteric Coated Pellets of Omeprazole

or HPMC E 5, dibasic sodium phosphate or light Dried pellets were collected and coating efficiency

magnesium carbonate and Sodium Lauryl sulphate was calculated.

were added slowly to form a uniform suspension. Enteric Coating Stage:

Specified quantity of Omeprazole is added and 300 ml of Iso propyl and 900 ml of Acetone were

stirring is continued for 30 mins. Non pareil seeds taken in a beaker and kept for stirring under a

were coated with the prepared drug suspension using mechanical stirrer. Specified quantities of enteric

Covered in Index Copernicus with IC Value 4.68 for 2010

Fluidized Bed Coater (FBC). Dried pellets were coating polymer, plasticizers (Eudragit L 100 55, Tri

collected and coating efficiency was calculated. ethyl citrate, PEG 4000 or HPMC P 55 S, Di Ethyl

Barrier Coating Stage Phthalate Cetyl Alcohol), Titanium dioxide and Talc

500 ml of purified water is taken in a beaker and kept (previously passed through 200#) were added slowly

for stirring under a mechanical stirrer. Specified to form a uniform suspension. Stirring was continued

quantities of PVP K 30 or HPMC E 5, dibasic sodium for 30 mins. Barrier coated pellets were coated with

phosphate or light magnesium carbonate and the above suspension using Fluidized Bed Coater

Full Length Research Paper

mannitol were added slowly to form a uniform (FBC). Dried pellets were collected and coating

suspension. Drug loaded pellets were coated with the efficiency was calculated.

above suspension using Fluidized Bed Coater (FBC).

Ingredients F1 F2 F3 F4 F5 F6 F7 F8 F9 F10

Sugar spheres (18/20#) 460 460 460 460 460 460 460 460 460 460

DRUG LOADING

Omeprazole 115 115 115 115 115 115 115 115 115 115

PVP K-30 8 16 16 16 - 16 16 16 16 16

HPMC E-5 - - - - 16 - - - - -

Dibasic Sodium phosphate 10 10 10 - - - - - - -

Light Magnesium Carbonate - - - 10 10 10 10 10 10 10

Sodium Lauryl Sulphate 1.7 1.7 1.7 1.7 1.7 2.7 2.7 2.7 2.7 2.7

Water Q.S Q.S Q.S Q.S Q.S Q.S Q.S Q.S Q.S Q.S

BARRIER COATING

PVP k-30 30 30 30 30 - 30 30 30 30 30

HPMC e – 5 - - - - 30 - - - - -

Dibasic Sodium Phosphate 10 10 20 - - - - - - -

Light Magnesium Carbonate - - - 20 20 20 20. 20 20 20

Mannitol 218.3 210.3 200.3 200.3 200.3 199.3 179.3 219.3 199.3 179.3

Water Q.S Q.S Q.S Q.S Q.S Q.S Q.S Q.S Q.S Q.S

ENTERIC COATING

Eudragit L 100 55 120 120 120 120 120 120 140 - - -

PEG 4000 12 12 12 12 12 12 12 - - -

Tri Ethy1 Citrate 3 3 3 3 3 3 3 - - -

HPMC P 55 S - - - - - - - 100 120 140

Di Ethyl Phthalate - - - - - - - 12 12 12

Cetyl Alcohol - - - - - - - 3 3 3

Titanium Dioxide 4 4 4 4 4 4 4 4 4 4

Talc 8 8 8 8 8 8 8 8 8 8

Iso Propyl Alcohol Q.S Q.S Q.S Q.S Q.S Q.S Q.S Q.S Q.S Q.S

Acetone Q.S Q.S Q.S Q.S Q.S Q.S Q.S Q.S Q.S Q.S

Table No 1 Formula for preparation of pellets

Int. J. Drug Dev. & Res., October-December 2012, 4 (4): 257-264

Covered in Scopus & Embase, Elsevier

259

Mohammad Younus et al: Formulation and Evaluation of Enteric Coated Pellets of Omeprazole

Evaluation of Pellets sample, transfer quickly to the titration vessel, stir to

Angle of Repose: dissolve and titrate with Karl Fischer reagent to end

Angle of repose is used to determine the flow point.

properties of powders, pellets or granules. The Calculation:

method to find angle of repose is to pour the powder Moisture content = V X F X 100

on a conical heap on a level, flat surface and measure Weight of Sample in Mg

Covered in Index Copernicus with IC Value 4.68 for 2010

the included angle with the horizontal. Where,

Tan θ = h/r F= factor of Karl Fischer reagent.

Where, h = height of the heap, V= volume in ml of Karl Fischer reagent consumed

r = Radius of the heap. for sample titration.

Bulk Density Scanning Electron Microscope (SEM

Bulk density of the coated pellets was determined by analysis):

pouring pellets into a graduated cylinder via a large SEM analysis is used to study the morphology of

Full Length Research Paper

funnel and measuring the volume and weight. prepared pellets by Hitachi (Model: S-3400 N,

Bulk density = weight of granules Japan).

Bulk volume of granules FTIR analysis

Tapped Density: FTIR spectra of drug and optimized formulation were

Tapped density was determined by placing a obtained. Sample about 5 mg was mixed thoroughly

graduated cylinder containing a known mass of with 100 mg potassium bromide IR powder and

granules and mechanical tapper apparatus, which compacted under vacuum at a pressure of about 12

was operated for a fixed number of taps until the Psi for 3 minutes. The resultant disc was mounted in

powder bed volume has reached a minimum volume. holder in IR spectrophotometer and the IR spectrum

Using the weight of the drug in the cylinder and this was recorded from 4000 cm-1 to 625 cm-1 in a scan

minimum volume, the taped density may be time of 12 minutes. The resultant spectra were

computed. compared for any spectral changes.

Tapped density = weight of granules Assay:

Tapped volume of granules Standard preparation:

Carr’s Index: Weigh accurately about 75 mg of omeprazole working

Carr’s index is measured using the values of bulk standard into 100 ml of volumetric flask add 50 ml of

density and tapped density. The following equation is Methanol sonicated and shake well and diluted to

used to find the Carr’s index. volume with Methanol, mixed well. Pipetted out 2 ml

CI = (TD-BD) x 100 of this solution in to 100 ml volumetric flask diluted

TD to volume with DM water and mix well.

Where, TD = Tapped density Sample Preparation:

BD = Bulk density Weigh accurately about 75 mg drug equivalent pellets

in a 100 ml volumetric flask, add 50 ml of Methanol,

Moisture Content (Or) Water by KF: sonicated for 10 minutes. Cool and dilute to volume

Take around 50ml of methanol in titration vessel of with Methanol. Filter the solution through what man

Karl Fischer titrator and titrate with Karl Fischer filter paper. Then take 2 ml of filtrate into 100 ml

reagent to end point. In a dry mortar grind the pellets volumetric flask. And dilute to volume with DM

to fine powder .Weigh accurately about 0.5 g of the water.

Int. J. Drug Dev. & Res., October-December 2012, 4 (4): 257-264

Covered in Scopus & Embase, Elsevier

260

Mohammad Younus et al: Formulation and Evaluation of Enteric Coated Pellets of Omeprazole

Procedure: Formulation Development

Scan the solution of both standard and sample In first trial (F1), improper coated sugar spheres were

preparation against Blank preparation between 200 observed during drug loading, and would have been

nm and 400 nm measure the absorbance for both due to insufficient amount of binder. Sufficient

standard and sample at 240 nm. amount of binder used in next trial. In trail 2 (F2),

Calculation: the binder concentration was increased in drug

Covered in Index Copernicus with IC Value 4.68 for 2010

AT WS 2 100 100 loading stage but the drug release was lesser than the

A = ------ × ------ × ------- × ---------- × --------- × P

AS 100 100 WT 2 innovator. So, to get better release, an attempt made

with increasing amount of alkalizing agent dibasic

AT =Absorbance of the sample preparation. sodium phosphate in barrier coating stage (F4). The

P = Purity of the standard drug release was observed to be lesser than the

AS = Absorbance of the standard preparation. innovator. To get better release, strong alkalizing

WS = Weight of the standard taken in mg agent i.e. light magnesium carbonate was used (F4).

Full Length Research Paper

WT = Weight of the sample taken in mg The drug release was increased when compared to

previous formulation but however the release was

In-vitro Dissolution: lower than the innovator. So, to get better release,

Apparatus: USP APPARATUS II another binder HPMC E 5 was used (F5). The release

Medium: 0.1N HCl up to 1st two hours, pH 1.2 was almost same but still it was lower than the

Phosphate buffer (pH 6.8 for) remaining hours innovator. Another attempt, made with previously

Sampling interval: 15, 30, 45 & 60 minutes. used binder i.e. PVP K 30 and also increased the

Rpm: 100 concentration of solubilizing agent i.e. sodium lauryl

Temperature : 37ºC± 0.5ºC sulphate (F6). The drug release was increased and

Procedure: Weigh and transfer the pellets did not match with the innovator, made another

equivalent to 100 mg of omeprazole individually in attempt with increased concentration of enteric

each of the 6 dissolution flasks, containing 900ml of polymer i.e. Eudragit L 100 55 (F7). The drug release

0.1N HCl. Previously adjust the temperature to37ºC± in buffer media was matched with the innovator but

0.5ºC. Collect the samples for first 2hrs and later in acidic media it did not match with the innovator.

replace the medium with phosphate buffer 6.8 and Another attempt made by changing the enteric

collect the samples for remaining 20hrs from a zone polymer (F8). The drug release was not match with

midway between the surface of the medium and the the innovator. The reason may be of enteric polymer,

top of the rotating blade and not less than 1cm from increased concentration of enteric polymer (F9). The

the vessel wall and filter through 0.45µ membrane drug release was as that of the innovator. This batch

filter by discarding the first 5ml.The absorbance is considered as an optimized batch however an

measured at 271nm by using UV-spectrophotometer. attempt was made to know whether there is any

Stability Studies: change on increasing the enteric polymer

Selected formulation is subjected to stability studies concentration (F10). The drug release did not match

as per ICH guidelines at 30°C/ 65 % RH and 40°C / with the innovator. It may be due to high

75% RH for 6 months. Sample are taken and concentration of enteric polymer. So the previous

analyzed at time interval. formulation was considered as an optimized

formulation.

RESULTS AND DISCUSSION Evaluation Parameters

Int. J. Drug Dev. & Res., October-December 2012, 4 (4): 257-264

Covered in Scopus & Embase, Elsevier

261

Mohammad Younus et al: Formulation and Evaluation of Enteric Coated Pellets of Omeprazole

Result of angle of repose of powder showed the poor Omeprazole was carried out using UV

flow properties. Angle of repose of the different spectrophotemeter and it was found to be with in

formulations were compared with bulk drug, limits. The weight variation test for capsules was

omeprazole, which shows that after pellets done results were in the prescribed limits. Results

formulation flow properties were excellent. Assay of were shown in table no 2.

Covered in Index Copernicus with IC Value 4.68 for 2010

Parameters Omeprazole F1 F2 F3 F4 F5 F6 F7 F8 F9 F10

Angle of repose 38.23 24.21 24.48 25.06 25.04 24.37 25.06 26.23 24.23 23.52 25.12

Bulk Density 0.4065 0.923 0.937 0.921 0.934 0.915 0.952 0.947 0.928 0.938 0.921

Tapped density 0.5813 0.989 1.004 0.988 0.991 1.032 1.012 0.996 1.031 1.037 0.989

Hausner’s ration 1.43 1.07 1.07 1.07 1.06 1.04 1.04 1.08 1.06 1.04 1.05

Carr’s Index 5.47 5.71 4.38 4.96 5.21 5.47 5.39 5.01 5.11 4.96

Moister content 0.19 1.88 1.86 1.89 1.92 1.89 1.91 1.91 1.95 1.86 1.94

Assay 99.91 98.12 98.23 98.87 99.23 99.12 98.56 98.39 99.12 99.85 99.12

Full Length Research Paper

Table No 2 Results of evaluation parameters

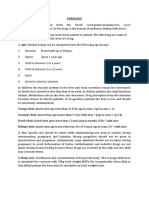

In vitro dissolutions studies

In vitro dissolution studies for first two hours in

acidic medium had revealed the acid resistance

capacity of pellets. Followed by dissolution behavior

of pellets in basic medium (phosphate pH 7.4)

revealed the in vitro drug release characteristics, F9

has shown the similar release characteristics as

innovator. Result shown in fig no 1 and table no 3

Fig No 1 dissolution behavior of different

formulations

% Drug Released

Innovator F1 F2 F3 F4 F5 F6 F7 F8 F9 F10

Acid Stage 0.1 NHCL,100 rpm, Paddle, (As per U.S.P)

120 Min 5.3 - 3.2 3.1 3.6 3.4 1.6 7.8 3.8 2.1 5.3

Buffer Stage pH 6.8 Phosphate Buffer, 900 ml, rpm-100, Paddle (As per U.S.P)

15 Min 89.6 61.3 72.7 76.7 75.9 76.9 83.2 80.0 94.0 90.3

30 Min 95.0 - 69.4 82. 0 86.1 85.0 89.2 92.8 89.0 94.3 93.2

45 Min 93.0 - 72.0 83.9 87.8 86.0 91.6 94.3 91.0 96.0 95.0

60 Min 92.0 - 70.1 85.4 89.0 89.0 93.5 96.0 93.1 98.6 97.0

Table No 3 Results of dissolution studies

Scanning Electronic Microscopy pellets was compact, continuous and uniform and is

Microscopy figures of optimized formulation (F9), porous in nature. SEM demonstrated the spherical

the coated pellets appeared to exist as spherical nature of the pellets. The average size of the pellets

discrete units whilst the surface morphology of the was found to be 1085±5 µm.

Int. J. Drug Dev. & Res., October-December 2012, 4 (4): 257-264

Covered in Scopus & Embase, Elsevier

262

Mohammad Younus et al: Formulation and Evaluation of Enteric Coated Pellets of Omeprazole

Covered in Index Copernicus with IC Value 4.68 for 2010

Fig No 2 Scanning Electron Microscopy figures of

optimized formulation

Fig No 4 FTIR spectra of F9 formulation

FTIR

The FT-IR spectrum of the formulation showed the Stability Studies

presence of the drug in its active form without There were no changes in appearances and

Full Length Research Paper

alteration of its chemical structure. percentage drug content of pellets stored at different

temperature for drug remaining vs. time at

25°C/60% RH, 30°C/65% RH and 40°C/75% RH. All

the parameters were within the limit after 90 days.

Result were shown in table no.

Fig No 3 FTIR spectra of Omeprazole

S.

Test Result

No

Storage condition

Initial Analysis 40 0 C/75% RH 30 0 C/65% RH 250 C/60% RH

1st Month 2nd Month 3rd Month 3rd Month 3rd Month

2 Assay 99.85% 99.82% 99.76% 99.75% 99.83% 99.80%

Acid stage : Acid stage:2.2% Acid stage:2.3% Acid stage:2.3% Acid stage :2.3% Acid stage :2.3%

3 Dissolution 2.1% Buffer Buffer stage Buffer Buffer Buffer Stage Buffer stage :

stage :98.6% :98.5% stage:98.1% stage:98.2% :98.5% 98.5%

Water

3 1.86 %w/w 1.90%w/w 1.93%w/w 1.98%w/w 1.92%w/w 1.96%w/w

content

Table No 4 Results of stability studies

CONCLUSION coating and enteric coating using Eudragit L 100 55

The objective of the present study was to formulate and HPMC Phthalate 55 S as enteric polymers. The

and evaluate delayed release capsules comparable to formulation F9 has shown similar drug release

the innovator product. The formulations of characteristics as innovator, it was selected as the

Omeprazole delayed release capsules of Omeprazole optimized formulation and accelerated stability

were developed by enteric film coating process studies were done, formulation was stable for 3

varying the compositions of drug loading, barrier months under accelerated conditions.

Int. J. Drug Dev. & Res., October-December 2012, 4 (4): 257-264

Covered in Scopus & Embase, Elsevier

263

Mohammad Younus et al: Formulation and Evaluation of Enteric Coated Pellets of Omeprazole

REFERENCES

1) Bauer K. H., Lehman K., Osterwald H. P.,

Rothgang. Coated Pharmaceutical Dosage forms,

Medpharm Scientiphic Publishers, Stuttgart 1998

2) Sk. Zakir Hussain, S. Bhama, R. Senthil Selvi and L.

Srujan. Duloxetine Hydrochloride Delayed Release

Pellets Prepared by Suspension Layer Method.

Covered in Index Copernicus with IC Value 4.68 for 2010

International Journal of Pharmacy and

Pharmaceutical Sciences 2011; 2(10): 2741-2745

3) Anjaneyulu Vinukonda, P.Srinivasababu,

K.N.Jayaveera, S.Mounika, S.Jyothi. Formulation

and Evaluation of Rabeprazole Enteric Coated

Tablets. Pharmazie 2012; 1 (1): 1-9.

4) Wilde MI, McTavish D. Omeprazole. An update of

Full Length Research Paper

its pharmacology and therapeutic use in acid-

related disorders. Drugs. 1994;48(1):91-132.

5) McTavish D, Buckley MM, Heel RC. Omeprazole.

An updated review of its pharmacology and

therapeutic use in acid-related disorders. Drugs

1991;42(1):138-70.

Int. J. Drug Dev. & Res., October-December 2012, 4 (4): 257-264

Covered in Scopus & Embase, Elsevier

264

You might also like

- Formulation and Evaluation of Floating Tablets of Ondansetron Hydrochloride PDFDocument10 pagesFormulation and Evaluation of Floating Tablets of Ondansetron Hydrochloride PDFDeswita indahNo ratings yet

- Formulation and Evaluation of Floating Tablets of Ondansetron Hydrochloride PDFDocument10 pagesFormulation and Evaluation of Floating Tablets of Ondansetron Hydrochloride PDFHely PatelNo ratings yet

- Vol. 4 - Issue 2 - ISSN 0975-9344 - : - April-June 2012Document10 pagesVol. 4 - Issue 2 - ISSN 0975-9344 - : - April-June 2012permatalannyNo ratings yet

- Formulation, Development and Evaluation of Delayed Release Capsules of Duloxetine Hydrochloride Made of Different Enteric PolymersDocument13 pagesFormulation, Development and Evaluation of Delayed Release Capsules of Duloxetine Hydrochloride Made of Different Enteric PolymersamanaeryNo ratings yet

- FDF 1Document15 pagesFDF 1Ega TrikuntiantiNo ratings yet

- FDF 3Document10 pagesFDF 3Ega TrikuntiantiNo ratings yet

- Jurnal RekristalisasiDocument15 pagesJurnal RekristalisasiSquish DrawsNo ratings yet

- Preparation and Evaluation of Mouth Dissolving Films For The Delivery of AlmotriptanDocument9 pagesPreparation and Evaluation of Mouth Dissolving Films For The Delivery of AlmotriptanKhoa DuyNo ratings yet

- Hydrotropy A Promising Tool For Solubility Enhancementa Review PDFDocument8 pagesHydrotropy A Promising Tool For Solubility Enhancementa Review PDFCandra Septia HadiNo ratings yet

- Formulation Development Characterization of Microemulsiondrug Delivery Systems Containing Antiulcer DrugDocument9 pagesFormulation Development Characterization of Microemulsiondrug Delivery Systems Containing Antiulcer DrugRenan PioliNo ratings yet

- JurnalDocument11 pagesJurnalYanuar Ahsan OfficialNo ratings yet

- Full TextDocument7 pagesFull TexttuayuNo ratings yet

- ShubhamresearcharticleDocument14 pagesShubhamresearcharticleLina WinartiNo ratings yet

- Formulation and In-Vitro Characterisation of Sustained Releasemetronidazole Cocoa Butter SuppositoriesDocument7 pagesFormulation and In-Vitro Characterisation of Sustained Releasemetronidazole Cocoa Butter SuppositoriesRowaidaNo ratings yet

- 1654 3867 1 PBDocument7 pages1654 3867 1 PBLina WinartiNo ratings yet

- Spectrophotometry UV-VIS Validation 3 (2) CurcuminaDocument7 pagesSpectrophotometry UV-VIS Validation 3 (2) CurcuminaKelly FernandesNo ratings yet

- Minoxidil-Loaded Nano Lipid Carriers Effective Alopecia TreatmentDocument8 pagesMinoxidil-Loaded Nano Lipid Carriers Effective Alopecia TreatmentDeajeng Febby AyuNo ratings yet

- IndianJDentSci12268-3597318 095933Document5 pagesIndianJDentSci12268-3597318 095933TriptiLath DentalNo ratings yet

- Vol. 4 - Issue 4 - ISSN 0975-9344 - : - October-December 2012Document6 pagesVol. 4 - Issue 4 - ISSN 0975-9344 - : - October-December 2012Mayuri PadoleNo ratings yet

- NanoparticlesDocument12 pagesNanoparticlesAndrianna NastasyaNo ratings yet

- Formulation Development and Evaluation of New AlbeDocument12 pagesFormulation Development and Evaluation of New AlbeDương TrungNo ratings yet

- Design, Optimization and Pharmacodynamic Comparison of Dorzolamide Hydrochloride Soluble Ocular Drug Insert Prepared by Using 32 Factorial DesignDocument10 pagesDesign, Optimization and Pharmacodynamic Comparison of Dorzolamide Hydrochloride Soluble Ocular Drug Insert Prepared by Using 32 Factorial DesignANo ratings yet

- 131 138 PDFDocument8 pages131 138 PDFRizQi FatmiyahNo ratings yet

- The Concept of Ocular Inserts As Drug Delivery Systems: An OverviewDocument10 pagesThe Concept of Ocular Inserts As Drug Delivery Systems: An OverviewRifky FauzanNo ratings yet

- 2013 Pharm - Dev.TechnolDocument10 pages2013 Pharm - Dev.TechnolFilipNo ratings yet

- Mayonnaise 2Document5 pagesMayonnaise 2LaDii SepulveDaNo ratings yet

- Cocrystals of Efavirenz Improve SolubilityDocument8 pagesCocrystals of Efavirenz Improve SolubilityjokonudiNo ratings yet

- Bhalerao 2010Document7 pagesBhalerao 2010Héctor González ColónNo ratings yet

- Comparative Studies On Povidone-Iodine Ointment and GelDocument8 pagesComparative Studies On Povidone-Iodine Ointment and GelMini Bekti NingsihNo ratings yet

- Detection of Hydroxyl and Perhydroxyl Radical Generation From Bleaching Agents With Nuclear Magnetic Resonance SpectrosDocument10 pagesDetection of Hydroxyl and Perhydroxyl Radical Generation From Bleaching Agents With Nuclear Magnetic Resonance SpectrosDivya SharmaNo ratings yet

- Polymorphism of Paracetamol: A Comparative Study On Commercial Paracetamol SamplesDocument6 pagesPolymorphism of Paracetamol: A Comparative Study On Commercial Paracetamol SamplesDevina LirunganNo ratings yet

- Ocular Inserts - Advancement in Therapy of Eye DiseasesDocument8 pagesOcular Inserts - Advancement in Therapy of Eye DiseasesCristina Maria FranziniNo ratings yet

- IJDDRDocument9 pagesIJDDRShiv SMSNo ratings yet

- Vol. 3 - Issue 4 - ISSN 0975-9344 - : - October-December 2011Document20 pagesVol. 3 - Issue 4 - ISSN 0975-9344 - : - October-December 2011Yusti sriwulandariNo ratings yet

- yokAcikBilim 10185403Document71 pagesyokAcikBilim 10185403gozdebstnciNo ratings yet

- Development of Dimple-Shaped Chitosan Carrier for Dry Powder Inhaler Delivery of Tuberculosis DrugDocument11 pagesDevelopment of Dimple-Shaped Chitosan Carrier for Dry Powder Inhaler Delivery of Tuberculosis Drugqassim universityNo ratings yet

- Synthesis and Antimicrobial Activity of Some QuinazolinonesderivativesDocument4 pagesSynthesis and Antimicrobial Activity of Some QuinazolinonesderivativesYoga AmandaNo ratings yet

- Introduction of Artificial Inhaler A Novel Concept For The Management of Covid 19Document4 pagesIntroduction of Artificial Inhaler A Novel Concept For The Management of Covid 19Editor IJTSRDNo ratings yet

- IntJPedodRehabil2260-4247839 114758Document6 pagesIntJPedodRehabil2260-4247839 114758anna handayaniNo ratings yet

- IJISRT21 MAY192 KuldeepDocument11 pagesIJISRT21 MAY192 KuldeepKuldeep VinchurkarNo ratings yet

- Development of New Visible Spectrophotometric Methods For Quantitativedetermination of Almotriptan Malate As An Active Pharmaceutical Ingredient InformulationsDocument6 pagesDevelopment of New Visible Spectrophotometric Methods For Quantitativedetermination of Almotriptan Malate As An Active Pharmaceutical Ingredient InformulationsAmiraNo ratings yet

- Effect of polymers on orally disintegrating filmsDocument10 pagesEffect of polymers on orally disintegrating filmsKhoa DuyNo ratings yet

- Panda2020 Article FormulationAndDevelopmentOfFlo PDFDocument9 pagesPanda2020 Article FormulationAndDevelopmentOfFlo PDFYuppie RajNo ratings yet

- 5154-Article Text-15276-1-10-20220107Document7 pages5154-Article Text-15276-1-10-20220107jimi jamalNo ratings yet

- Heliyon: Emmanuel Kimaro, Prosper Tibalinda, Raphael Shedafa, Mary Temu, Eliangiringa KaaleDocument8 pagesHeliyon: Emmanuel Kimaro, Prosper Tibalinda, Raphael Shedafa, Mary Temu, Eliangiringa KaaleDương TrungNo ratings yet

- Formulation & Evaluation of Sustained Release Microsphere of PropanololDocument11 pagesFormulation & Evaluation of Sustained Release Microsphere of PropanololAlfitaRahmawatiNo ratings yet

- Design and Evaluation of Topical Hydrogel Formulation of Diclofenac Sodium For Improved TherapyDocument8 pagesDesign and Evaluation of Topical Hydrogel Formulation of Diclofenac Sodium For Improved TherapyVeaux NouNo ratings yet

- Eudragit Expert OpinionDocument19 pagesEudragit Expert OpinionHarish GundaNo ratings yet

- 23.ravi Gour PaperDocument7 pages23.ravi Gour PaperMind PowerNo ratings yet

- Ameyapaperjournal PDFDocument16 pagesAmeyapaperjournal PDFKharisah AfifahNo ratings yet

- Formulation and Evaluation of Enteric CoatedDocument13 pagesFormulation and Evaluation of Enteric Coatedvanvu buiNo ratings yet

- Invitro Dissolution Studies of Lansoprazole EC Pellets 12% W/W - A Comparative Dissolution Profile With Reference SampleDocument7 pagesInvitro Dissolution Studies of Lansoprazole EC Pellets 12% W/W - A Comparative Dissolution Profile With Reference SampleUmair MazharNo ratings yet

- Ameya Paper JournalDocument16 pagesAmeya Paper Journalkilari pavaniNo ratings yet

- Formulation and Evaluation of Tablets Containing Poorly Water Soluble Drug by MADG MethodDocument16 pagesFormulation and Evaluation of Tablets Containing Poorly Water Soluble Drug by MADG MethodGudi OjhaNo ratings yet

- Formulation and Evaluation of New Long Acting Metoprolol Tartrate Ophthalmic GelsDocument9 pagesFormulation and Evaluation of New Long Acting Metoprolol Tartrate Ophthalmic GelsmelyNo ratings yet

- Article BIOCOMPATIBILITYDocument5 pagesArticle BIOCOMPATIBILITYGauri AroraNo ratings yet

- Rsearch WorkDocument35 pagesRsearch WorkNidhi SinghNo ratings yet

- 1 PDFDocument8 pages1 PDFDrNiladri RoyNo ratings yet

- 41 RJPT 14 6 2021Document6 pages41 RJPT 14 6 2021Rizki Uhud NasofiNo ratings yet

- Encapsulated CatalystsFrom EverandEncapsulated CatalystsSamahe SadjadiNo ratings yet

- Posology Notes Yuppie's GaloreDocument6 pagesPosology Notes Yuppie's GaloreYuppie RajNo ratings yet

- Ideal Solubility ParametersDocument14 pagesIdeal Solubility ParametersYuppie Raj100% (2)

- Posology 151223081101Document24 pagesPosology 151223081101eswarNo ratings yet

- Pharma. D Regulations 2008Document97 pagesPharma. D Regulations 2008Latest Laws TeamNo ratings yet

- Liquid Solubility GuideDocument33 pagesLiquid Solubility GuideYuppie Raj67% (3)

- Diffusion Principles in Biological SystemsDocument18 pagesDiffusion Principles in Biological SystemsYuppie Raj100% (2)

- Partially Miscible LiquidsDocument16 pagesPartially Miscible LiquidsYuppie Raj86% (7)

- Diffusion Principles in Biological SystemsDocument18 pagesDiffusion Principles in Biological SystemsYuppie Raj100% (2)

- PCI B Pharm Syllabus PDFDocument189 pagesPCI B Pharm Syllabus PDFDrGajanan Vaishnav100% (1)

- Solvation, Association and DissociationDocument14 pagesSolvation, Association and DissociationYuppie RajNo ratings yet

- Solubility of Liquids in LiquidsDocument12 pagesSolubility of Liquids in LiquidsYuppie RajNo ratings yet

- Quantitative Approach To Factors Affecting Solubility of DrugsDocument18 pagesQuantitative Approach To Factors Affecting Solubility of DrugsYuppie Raj100% (3)

- Multiple-Dosing Regimens (Repetitive Dosing)Document4 pagesMultiple-Dosing Regimens (Repetitive Dosing)Yuppie RajNo ratings yet

- Ideal Solubility ParametersDocument14 pagesIdeal Solubility ParametersYuppie Raj100% (2)

- Solubility ExpressionsDocument7 pagesSolubility ExpressionsYuppie RajNo ratings yet

- DEGRADATIONPATHWAY B. Pharm 2-2Document22 pagesDEGRADATIONPATHWAY B. Pharm 2-2Yuppie RajNo ratings yet

- Quantitative Approach To Factors Affecting Solubility of DrugsDocument18 pagesQuantitative Approach To Factors Affecting Solubility of DrugsYuppie Raj100% (3)

- Solubility Notes SummaryDocument9 pagesSolubility Notes SummaryYuppie RajNo ratings yet

- Solute Solvent Interactions PPI BPII - IDocument32 pagesSolute Solvent Interactions PPI BPII - IYuppie Raj100% (2)

- Solubility ExpressionsDocument7 pagesSolubility ExpressionsYuppie RajNo ratings yet

- Analysis and Design of Pharmacokinetic ModelsDocument77 pagesAnalysis and Design of Pharmacokinetic ModelsYuppie RajNo ratings yet

- Revised BiopharmaceuticsDocument34 pagesRevised BiopharmaceuticsYuppie RajNo ratings yet

- Formulation and Evaluation of Lansoprazole Sublingual TabletDocument13 pagesFormulation and Evaluation of Lansoprazole Sublingual TabletYuppie RajNo ratings yet

- Panda2020 Article FormulationAndDevelopmentOfFlo PDFDocument9 pagesPanda2020 Article FormulationAndDevelopmentOfFlo PDFYuppie RajNo ratings yet

- s43094 019 0010 0 PDFDocument11 pagess43094 019 0010 0 PDFYuppie RajNo ratings yet

- Drug Dosing in Obese Patients: A Dilemma: International Journal of Advances in PharmaceuticsDocument7 pagesDrug Dosing in Obese Patients: A Dilemma: International Journal of Advances in PharmaceuticsYuppie RajNo ratings yet

- bcp0057 0006Document9 pagesbcp0057 0006Hayder PharmacistNo ratings yet

- Panda2020 Article FormulationAndDevelopmentOfFlo PDFDocument9 pagesPanda2020 Article FormulationAndDevelopmentOfFlo PDFYuppie RajNo ratings yet

- Design of Dosage Regimens:: 1. Introduction To Clinical PharmacokineticsDocument1 pageDesign of Dosage Regimens:: 1. Introduction To Clinical PharmacokineticsYuppie RajNo ratings yet

- 78Document21 pages78RajasekharNo ratings yet

- Worksheet A: Teacher's Notes: Level 2 (Upper Intermediate - Advanced)Document9 pagesWorksheet A: Teacher's Notes: Level 2 (Upper Intermediate - Advanced)Elena SinisiNo ratings yet

- 3D MapsDocument1,128 pages3D MapsjoangopanNo ratings yet

- Educ 210Document2 pagesEduc 210Julie Ann CruzNo ratings yet

- Our Solar System Lesson PlanDocument20 pagesOur Solar System Lesson PlanDean EqualNo ratings yet

- Understanding BlockingDocument21 pagesUnderstanding BlockingganeshNo ratings yet

- BMM Cements LTD., Bharat Mines & Minerals, Gudipadu Cement Plant, GudipaduDocument2 pagesBMM Cements LTD., Bharat Mines & Minerals, Gudipadu Cement Plant, GudipaduDeepak Kumar PalNo ratings yet

- Explosion Proof ClassificationsDocument2 pagesExplosion Proof Classificationsneurolepsia3790No ratings yet

- Performance Analysis of A Dual Cycle Engine With Considerations of Pressure Ratio and Cut-Off RatioDocument6 pagesPerformance Analysis of A Dual Cycle Engine With Considerations of Pressure Ratio and Cut-Off RatioRajanish BiswasNo ratings yet

- Surfer 8 GuideDocument664 pagesSurfer 8 GuideYuliana DomínguezNo ratings yet

- Baro HR & Marketing BasicsDocument23 pagesBaro HR & Marketing Basicsedex73No ratings yet

- A10 Thunder Series and AX Series: ACOS 2.7.2-P7-SP3 22 December 2015Document360 pagesA10 Thunder Series and AX Series: ACOS 2.7.2-P7-SP3 22 December 2015huonz mrNo ratings yet

- Reaction PaperDocument3 pagesReaction PaperCamilla Reyes100% (1)

- Carbon Monoxide Poisoning - Wikipedia, The Free EncyclopediaDocument19 pagesCarbon Monoxide Poisoning - Wikipedia, The Free EncyclopediaSundar SugumarNo ratings yet

- InstructionsDocument1 pageInstructionssavinaumarNo ratings yet

- TerraPower Case PDFDocument7 pagesTerraPower Case PDFKaustav DeyNo ratings yet

- Semi-Log Analysis: Well Test Interpretation MethodologyDocument31 pagesSemi-Log Analysis: Well Test Interpretation MethodologyAshraf SeragNo ratings yet

- Oracle Hyperion Financial Management: Lightstream Analytics Pte LTDDocument63 pagesOracle Hyperion Financial Management: Lightstream Analytics Pte LTDJunnei LiuspitaNo ratings yet

- Users Manual of Rdlc320 Control SystemDocument36 pagesUsers Manual of Rdlc320 Control SystemriderbeeNo ratings yet

- Network File SystemDocument29 pagesNetwork File SystemYosef TayeNo ratings yet

- CASR PART 43 Amdt. 1 PDFDocument21 pagesCASR PART 43 Amdt. 1 PDFarbypratamax66100% (1)

- ACEE 7: Logic Circuits and Switching Theory: Logic Circuit Design On NI MultisimDocument7 pagesACEE 7: Logic Circuits and Switching Theory: Logic Circuit Design On NI MultisimJaypee100% (1)

- Thesis Document1Document51 pagesThesis Document1ericson acebedoNo ratings yet

- Lesson 1 Evolution & Definitions of QualityDocument39 pagesLesson 1 Evolution & Definitions of Qualitymillie jeonNo ratings yet

- Grade 2 math lesson plan compares mass in grams & kilogramsDocument3 pagesGrade 2 math lesson plan compares mass in grams & kilogramskristine arnaiz80% (10)

- VVBVBVBBDocument19 pagesVVBVBVBBnasimakhtarNo ratings yet

- Service Manual: NSX-SZ80 NSX-SZ83 NSX-AJ80 NSX-SZ80EDocument47 pagesService Manual: NSX-SZ80 NSX-SZ83 NSX-AJ80 NSX-SZ80EDjalma MotaNo ratings yet

- Problem For Ledger and Trial BalanceDocument39 pagesProblem For Ledger and Trial BalanceSumita MathiasNo ratings yet

- Kanban Card Creator v1.1Document30 pagesKanban Card Creator v1.1bukdownload04No ratings yet

- Software Verification: AISC 360-16 SFD Example 001Document7 pagesSoftware Verification: AISC 360-16 SFD Example 001Dompu MengajiNo ratings yet