Professional Documents

Culture Documents

Do Not Operate Pyroprobe Until You Have Been Properly Trained by The Lab Safety Coordinator

Uploaded by

TPN0 ratings0% found this document useful (0 votes)

22 views3 pagesSOP

Original Title

GNBR1724-UNV

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSOP

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views3 pagesDo Not Operate Pyroprobe Until You Have Been Properly Trained by The Lab Safety Coordinator

Uploaded by

TPNSOP

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

STANDARD OPERATION PROCEDURE FOR Pyroprobe (C-110)

Date of the last revision: 02/15/2018

Last reviewed

by:__________________________________________Date:__________________________

SOP discussed

with:________________________________________Date:__________________________

Personal Protective Equipment (PPE) Required: Safety glasses, lab coat, and gloves.

(PPE may differ based on the samples and the hazards it possess).

Chemicals used (IUPAC Name, CAS Number, MSDS, Associated Risks

Nitrogen – Nitrogen, CAS Number: 8013-59-0, Contact with rapidly expanding gas may cause burns or

frostbite. Can act as a asphyxiant

Oxygen- Oxygen, CAS Number: 7782-44-7, Oxidiser, May cause or intensify fire. Keep away from

combustible materials. Keep valves and fittings free of oils and grease. Contains Gas is under pressure,

may explode if heated. Continuous inhalation of concentrations higher than 75% may cause nausea,

dizziness, respiratory difficulty, and convulsion.

Helium-Helium, CAS Number: 7440-59-7, Contact with rapidly expanding gas may cause burns or

frostbite. Can act as a asphyxiant

Hydrogen – Hydrogen, CAS Number: 4368-28-9, Flammable. Contact with rapidly expanding gas may

cause burns or frostbite. Can act as a asphyxiant. Acute or chronic respiratory conditions may be

aggravated by overexposure to this gas.

DO NOT OPERATE PYROPROBE UNTIL YOU HAVE BEEN

PROPERLY TRAINED BY THE LAB SAFETY COORDINATOR

1.- Reactor Ensure bypass valve is set to

Setup direct, not to bypass

Pack catalyst inbetween two

layers of quartz wool in a ¼’’

quartz tube

Ensure graphite ferrules spin

freely, replace ferrules that

bind

Attack quartz tube to exit

line first, then inlet line.

Change bypass valve to If pressure drops tighten

reactor and monitor ferrules further

pressure.

Gently place insulation at

furnace openings, do not

pack inside

Set reactor temperature and If reduction is needed place

flowing gas pulsing valve in the down

position with hydrogen flowing

for 30 minutes at 30% open

Check all heat tapes to

ensure lines are properly

heated

2.-pyroprobe Pack 1 mg of sample into

setup pyroprobe tubes, and place

in sample holder

Enable autosampler under

accessory window

3.-Software Open lab solutions, turn on

Setup transfer line to 300°

Go to batch processes, enter

names and labels for each

sample. Include a blank run

before and after samples

Open and check method file

for changes, load method file

into batch processing

If using autosampler copy file

names into autosampler

software

Under details on the right

side ingite the flame

Hit run If doing pulse reactions more

effort will be required with each

sample

Watch pyroprobe for

completion of each sample.

Next sample will need to be

manually started

When all runs are complete

turn off flame under details

window to stop gas flow

Hit stop and confirm stop

batch processing

Remove reactor bed and

dispose of all samples

You might also like

- Ammonia Systems: Testing, Charging and SafetyDocument3 pagesAmmonia Systems: Testing, Charging and SafetyCorrosion FactoryNo ratings yet

- Pe AaDocument5 pagesPe AanedalllNo ratings yet

- PCMPKDocument3 pagesPCMPKErickNo ratings yet

- 34C Manual 5172019Document18 pages34C Manual 5172019KUMARNo ratings yet

- 1 5-EnDocument14 pages1 5-EnThong Kin MunNo ratings yet

- VR8304 Intermittent Pilot Combination Gas Control: ApplicationDocument8 pagesVR8304 Intermittent Pilot Combination Gas Control: ApplicationGregorio Mata MartínezNo ratings yet

- Mi 2008 1 en TT 1Document3 pagesMi 2008 1 en TT 1john BustosNo ratings yet

- Troubleshooting Intermittent Ignition Systems For Gas Furnaces and BoilersDocument27 pagesTroubleshooting Intermittent Ignition Systems For Gas Furnaces and BoilerswarthogwillieNo ratings yet

- Instructional Model of Basic Rankine Cycle: User'S ManualDocument4 pagesInstructional Model of Basic Rankine Cycle: User'S ManualJoseph DavidNo ratings yet

- D 2669Document5 pagesD 2669Asep TheaNo ratings yet

- Method of Statement Testing Commissioning With Sprinkler HeadsDocument5 pagesMethod of Statement Testing Commissioning With Sprinkler HeadskushiNo ratings yet

- ARO 2019 6661XX 1 1 2 Inch Non Metallic PRO SERIES Diaphragm Pump Manual Air Motor SectionDocument8 pagesARO 2019 6661XX 1 1 2 Inch Non Metallic PRO SERIES Diaphragm Pump Manual Air Motor Sectionboy tryadiNo ratings yet

- Astm D153Document5 pagesAstm D153EngrWasiAhmadNo ratings yet

- Pg-U Manual Im-T-113q 01 EngDocument4 pagesPg-U Manual Im-T-113q 01 EngRajitha ShehanNo ratings yet

- Clau Astm PDFDocument3 pagesClau Astm PDFLezlie Berenice Serrano GalindoNo ratings yet

- 6661ax XXX C enDocument8 pages6661ax XXX C enMauricio Cesar DalzochioNo ratings yet

- Exp 1Document9 pagesExp 1zackwanNo ratings yet

- Niosh 7903 SKCDocument1 pageNiosh 7903 SKCSilvina AmbrosolioNo ratings yet

- D 1817 - 01 - Rde4mtcDocument3 pagesD 1817 - 01 - Rde4mtcDr. Ahmed Abdel-HakimNo ratings yet

- D 4180Document3 pagesD 4180JGD123No ratings yet

- SOP of Oxide Mill RPDocument6 pagesSOP of Oxide Mill RPamisharatan202No ratings yet

- Qatar Petroleum Ngl-1 Operating Manual: 1. GeneralDocument49 pagesQatar Petroleum Ngl-1 Operating Manual: 1. Generalvaratharajan g rNo ratings yet

- FSMRDocument6 pagesFSMRlencer tumbagaNo ratings yet

- Draft Standard Operating Procedure - Tubular Reactor and CSTRDocument5 pagesDraft Standard Operating Procedure - Tubular Reactor and CSTRshivaNo ratings yet

- D 3279 - 97 - RdmynzktotcDocument3 pagesD 3279 - 97 - RdmynzktotcHans AbantoNo ratings yet

- GC-NPD - G - GC MaintenanceDocument4 pagesGC-NPD - G - GC MaintenanceContato - ChronionNo ratings yet

- Astm D3902Document3 pagesAstm D3902RodrigoArayaNo ratings yet

- EQ-17 StackDocument6 pagesEQ-17 StackSangam SharmaNo ratings yet

- 0.5 PULGADAS NO METÁLICA 670109 ManualDocument12 pages0.5 PULGADAS NO METÁLICA 670109 ManualRichard Rodriguez GarciaNo ratings yet

- TC600 Oxygen Lead 203-821-488Document2 pagesTC600 Oxygen Lead 203-821-488Sitec Industrial AutomationNo ratings yet

- LI6400 Preparation ChecklistDocument8 pagesLI6400 Preparation ChecklistArinal Haq Izzawati NurrahmaNo ratings yet

- Pacakage Aircon MaintenanceDocument15 pagesPacakage Aircon Maintenancerjv.premi74No ratings yet

- Automated Water Content Determination of Transformer Oils With Inmotion KFDocument7 pagesAutomated Water Content Determination of Transformer Oils With Inmotion KFKenny GavaNo ratings yet

- HoseDocument3 pagesHoseSangeetha RangarajanNo ratings yet

- 052tankfarm Fire ProteDocument6 pages052tankfarm Fire ProtesaikiranNo ratings yet

- On-Vehicle Inspection: - RadiatorDocument2 pagesOn-Vehicle Inspection: - RadiatorsalusfrankNo ratings yet

- Hydrogen in Petroleum Fractions: Standard Test Method ForDocument4 pagesHydrogen in Petroleum Fractions: Standard Test Method Forpbp2956No ratings yet

- No 49 Applications With Karl Fischer Oven AutosamplerDocument80 pagesNo 49 Applications With Karl Fischer Oven AutosamplerKeila ChavesNo ratings yet

- 360-0027-01rD AP20S ManualDocument16 pages360-0027-01rD AP20S ManualetchegarayfNo ratings yet

- Cooker Hood Hotte Dunstabzugshaube Dampkap Cappa Campana ExaustorDocument5 pagesCooker Hood Hotte Dunstabzugshaube Dampkap Cappa Campana ExaustorAleksander RzeczyckiNo ratings yet

- C 424 - 93 R99 QzqynaDocument2 pagesC 424 - 93 R99 QzqynaMarceloNo ratings yet

- 46-89 Sears LGS 66812 Coldspot Refrigerator PDFDocument21 pages46-89 Sears LGS 66812 Coldspot Refrigerator PDFdrt1200No ratings yet

- Needle Flame TesterDocument9 pagesNeedle Flame TesterGregorio ToroNo ratings yet

- Directions For Use Standard Filter Cartridges and Mini CartridgesDocument38 pagesDirections For Use Standard Filter Cartridges and Mini CartridgesTit fuckerNo ratings yet

- Manual SA 232 PDFDocument16 pagesManual SA 232 PDFAnonymous CSnweOx100% (9)

- Deep AASDocument6 pagesDeep AASAgniNo ratings yet

- Technical Study: ProductDocument15 pagesTechnical Study: ProductayomiNo ratings yet

- D 4051 - 99 - RdqwntetotkDocument4 pagesD 4051 - 99 - RdqwntetotkLea CoriaNo ratings yet

- Stopped-Flow Calorimeter For Biochemical Applications: ReagentsDocument6 pagesStopped-Flow Calorimeter For Biochemical Applications: ReagentsShajahan ShagulNo ratings yet

- Manual AW Remote KecilDocument32 pagesManual AW Remote KecilBambang PriyambodoNo ratings yet

- Halogen Moisture Analyzer User Manual DSHDocument9 pagesHalogen Moisture Analyzer User Manual DSHerwin surantaNo ratings yet

- Engineering and Maintenance Manual - SD660 Double Door - Steam GeneratorDocument89 pagesEngineering and Maintenance Manual - SD660 Double Door - Steam GeneratorPhuc Truong100% (1)

- TSP-1 RevC 04-15Document8 pagesTSP-1 RevC 04-15boulacharNo ratings yet

- UOP971Document8 pagesUOP971Do Duc ThanhNo ratings yet

- Lessons From The Field: Vacuum System Performance Surveys: Issue 5Document4 pagesLessons From The Field: Vacuum System Performance Surveys: Issue 5siva kumarNo ratings yet

- Scanboilerr TextDocument7 pagesScanboilerr TextAntonio AvilesNo ratings yet

- Operation Operation Manual Manual: SA-232 & SA-202 SA-232 & SA-202Document16 pagesOperation Operation Manual Manual: SA-232 & SA-202 SA-232 & SA-202tvmNo ratings yet

- 5-4842 - SOP Oxyfuel Burner & Pressure VesselDocument14 pages5-4842 - SOP Oxyfuel Burner & Pressure VesselMohamad Abou DaherNo ratings yet

- Double Effect Evaporator OperationDocument6 pagesDouble Effect Evaporator Operationpaulhill222No ratings yet

- Batch and Semi-batch Reactors: Practical Guides in Chemical EngineeringFrom EverandBatch and Semi-batch Reactors: Practical Guides in Chemical EngineeringNo ratings yet

- CBSE CHEMISTRY Class 10 - Chapter1. Chemical Reactions and EquationsDocument11 pagesCBSE CHEMISTRY Class 10 - Chapter1. Chemical Reactions and EquationsSandeep Kumar VRNo ratings yet

- Catalogue of IRO WaterDocument90 pagesCatalogue of IRO WatershoyebNo ratings yet

- Qualitative Tests For LipidsDocument6 pagesQualitative Tests For LipidsCorine RepatoNo ratings yet

- Advanced Chemistry For You Answers PDFDocument50 pagesAdvanced Chemistry For You Answers PDFpauljkt1No ratings yet

- Artigo 15 - Synthesis of High-Quality Zeolite LTA From Alum Sludge Generated in Drinking Water Treatment PlantsDocument12 pagesArtigo 15 - Synthesis of High-Quality Zeolite LTA From Alum Sludge Generated in Drinking Water Treatment PlantsJuscimara RodriguesNo ratings yet

- Calcium Stearate - Mittal Dhatu Rashayan Udyog, Kota-LubimaxDocument2 pagesCalcium Stearate - Mittal Dhatu Rashayan Udyog, Kota-LubimaxMomar Talla DiawNo ratings yet

- Gengard Technology: For Open Recirculating Cooling SystemsDocument2 pagesGengard Technology: For Open Recirculating Cooling SystemsLucasBartzNo ratings yet

- Aluminum Waste Cans Recycling in Lagos State, Nigeria: Analysis of Soil and Water BenefitsDocument11 pagesAluminum Waste Cans Recycling in Lagos State, Nigeria: Analysis of Soil and Water BenefitsIJAR JOURNALNo ratings yet

- Molybdovanadic ReagentDocument2 pagesMolybdovanadic ReagentCeyhun Babac CetinNo ratings yet

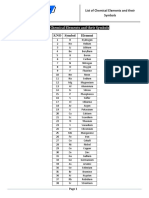

- List of Chemical Elements and Their Symbols: S.NO Symbol ElementDocument3 pagesList of Chemical Elements and Their Symbols: S.NO Symbol ElementKarthikeyan VickyNo ratings yet

- Calcium Compounds: - Animal Shells (Snails, Cockles) - Bones & Teeth - Corals - Egg Shells - Stalactites & StalagmitesDocument3 pagesCalcium Compounds: - Animal Shells (Snails, Cockles) - Bones & Teeth - Corals - Egg Shells - Stalactites & StalagmitesnyshahidaNo ratings yet

- Pharmaceutical Chemistry of Inorganic MedicalsDocument21 pagesPharmaceutical Chemistry of Inorganic MedicalsJuliane Caniele Indiongco0% (2)

- AbstractDocument13 pagesAbstractDell LiNo ratings yet

- 3-Effect of Seawater As Mixing Water On The Hydration Behaviour of Tricalcium AluminateDocument11 pages3-Effect of Seawater As Mixing Water On The Hydration Behaviour of Tricalcium AluminatequyNo ratings yet

- PDF Ce Report 61 e 12 2017Document28 pagesPDF Ce Report 61 e 12 2017RAUL FERNANDO VELOZ GUERRA100% (1)

- Chem - Rev-WS-01Document4 pagesChem - Rev-WS-01DhivegaNo ratings yet

- Dictionary of Chemical FormulasDocument44 pagesDictionary of Chemical Formulashendrayana1555100% (1)

- Quiz 1 Group 2 MCQDocument2 pagesQuiz 1 Group 2 MCQTee Xin RuiNo ratings yet

- Determine The QualityDocument7 pagesDetermine The QualityRohanSethiNo ratings yet

- NSS Chemistry Part 2 The Microscopic World HKCEE Past Paper Question The Microscopic World I Ns - Multiple Choice QuestionsDocument32 pagesNSS Chemistry Part 2 The Microscopic World HKCEE Past Paper Question The Microscopic World I Ns - Multiple Choice QuestionsミーチェルNo ratings yet

- Production of Acetylene and Acetylene-Based Chemicals From CoalDocument18 pagesProduction of Acetylene and Acetylene-Based Chemicals From CoalS.P.No ratings yet

- Activity Series Simulation 2022 PDFDocument3 pagesActivity Series Simulation 2022 PDFkateNo ratings yet

- The Owner' S Manual For The Human Body by Dr. Saul Pressman, DCHDocument75 pagesThe Owner' S Manual For The Human Body by Dr. Saul Pressman, DCHlighteagles131100% (2)

- Food Research International: A A A B ADocument10 pagesFood Research International: A A A B ANikolett NagyNo ratings yet

- Fertigation and Irrigation Management Systems of Vertical Gardens and Green RoofsDocument21 pagesFertigation and Irrigation Management Systems of Vertical Gardens and Green RoofsAhmed NabilNo ratings yet

- Influence of Lime ...Document7 pagesInfluence of Lime ...Luna EléctricaNo ratings yet

- Novartis Osteoporosis Slide KitDocument42 pagesNovartis Osteoporosis Slide KitShravanti SatyanandNo ratings yet

- Flash TypsDocument26 pagesFlash TypsohbabyohbabyNo ratings yet

- Codex General Standard For Process (Ed) Cheese Preparations (Process (Ed) Cheese Food and Process (Ed) Cheese Spread)Document3 pagesCodex General Standard For Process (Ed) Cheese Preparations (Process (Ed) Cheese Food and Process (Ed) Cheese Spread)lox agencyNo ratings yet

- Kimia T4 2023 - DLPDocument10 pagesKimia T4 2023 - DLPbrendan chee junNo ratings yet