Professional Documents

Culture Documents

High Pr. Pipe

Uploaded by

Haresh Jogani0 ratings0% found this document useful (0 votes)

22 views1 pagepipe

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentpipe

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views1 pageHigh Pr. Pipe

Uploaded by

Haresh Joganipipe

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 1

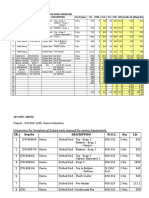

L&T-NIRO LIMITED.

DESIGN ENGINEERING DEPARTMENT

ORDER NO. : BANAS-II- LTN-030-1056 DATE : 09.03.00

EQUIPMENT : HIGH PRESSURE LINE PIPING REV. NO : R0

DESIGNER : GJJ TOTAL PAGES : 1

(I) Summery :

A. SIZE OF THE PIPE 40NB

B. DESIGN PRESSURE 400 Kg/cm2

C. DESIGN TEMPRATURE 90° Deg .c

D. MOC SA 312 TP 304

E. ALLOWABLE STRESS ### Kg/cm2

F. MINIMUM THICKNESS REQUIRED 6.94 mm

G. PIPE SCHEDULE Sch-160

H. PIPE THICKNESS 7.14 mm

I. THICKNESS WITH NEGATIVE TOLERANCE 6.25 mm

J. SINCE MINIMUM THICKNESS REQUIRED IS MORE THAN PIPE THICKNESS WITH NEGATIVE TOLERANCE, FINAL PIPE

SPECIFICATION TO BE FOLLOWED IS - "40NB x Sch-160 (Seamless) WITHOUT NEGATIVE TOLERANCE IN THE

THICKNESS".

(II) Detailed Calculations :

DESIGN CODE : ASME SEC. VIII , DIV-I ,1995

CALCULATION : STRENGTH CALCULATIONS FOR NOZZEL AS PER UG-32 & UG-33

MATERIAL OF CONSTRUCTION FOR NOZZLE PIPE : SA 312 TP 304 - SEAM LESS

SR DESCRIPTION UNIT SYB. VALUES

NO. FOR NOZZLE PIPE

1 NOZZLE MARK Feed Pipe

2 NOZZLE SIZE 40 NB

3 LOCATION AIR DISPERSER

4 M.O.C. OF NOZZLE PIPE SA312TP304

5 OUT SIDE DIAMETER OF NOZZLE cms Do 4.83

6 OUT SIDE RADIUS OF NOZZLE cms Ro 2.41

7 DESIGN PRESSURE(INTERNAL) Kg/cm2 Pi 407.88

8 DESIGN PRESSURE(EXTERNAL) Kg/cm2 Pe 0

9 DESIGN TEMPERATURE Deg .c T 90°

10 JOINT EFFICIENCY FOR NOZZLE En 1

11 ALLOWABLE STRESS FOR NOZZLE Kg/cm2 Sn 1255.71

12 MINIMUM REQUIRED THK. NOZZLE cms tmin 0.69

13 CORROSION ALLOWANCE mm C.A. 0.00

14 THICKNESS OF THE STD SCH PIPE mm t1 3.91

15 MIN. STD SCH PIPE THK. +C.A. mm t1 3.42

16 MIN. REQ. TK. OF NOZZ.+C.A. mm t 6.94

17 GREATER OF t & t1 mm t2 6.94

18 MINIMUM PIPE THICKNESS REQUIRED mm t2 6.94

19 MIN.SCH. TO BE PROVIDED (IF PIPE) Sch-160

20 NOMINAL PIPE THICKNESS PROVIDED mm 7.14

21 MINIMUM PIPE THICKNESS WITH -VE TOL. mm 6.25

MINIMUM PIPE THICKNESS REQUIRED FOR HIGH PRESSURE PIPE IS 40NB x Sch-160 WITHOUT

NEGATIVE TOLERANCE

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Damper DimnDocument1 pageDamper DimnHaresh JoganiNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Holding Tubes KMFDocument7 pagesHolding Tubes KMFHaresh JoganiNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Dished EndDocument3 pagesDished EndHaresh JoganiNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Catalogue 6 English 06.2012 Pacific HoseflexDocument24 pagesCatalogue 6 English 06.2012 Pacific HoseflexHaresh JoganiNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Indian Rolled Sections 756Document1 pageIndian Rolled Sections 756Haresh JoganiNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A B C Outside Dia D Inside Dia E Ang of Development F Remaining Angle G Dist-X H Dist-YDocument2 pagesA B C Outside Dia D Inside Dia E Ang of Development F Remaining Angle G Dist-X H Dist-YnileshNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- How To Make Pipe Specifiction PDFDocument9 pagesHow To Make Pipe Specifiction PDFHaresh JoganiNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Is 1364 1 2002Document20 pagesIs 1364 1 2002harikrishnanmveplNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Is-4263.1967 RF2002Document26 pagesIs-4263.1967 RF2002Haresh JoganiNo ratings yet

- WeldSymbolsProof PDFDocument1 pageWeldSymbolsProof PDFHaresh JoganiNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Seat MaterialDocument3 pagesSeat MaterialDeyci Yamile Peña SantosNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Goulds Pump Selection GuideDocument24 pagesGoulds Pump Selection GuidecladonellNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Bonney Forge BrochureDocument22 pagesBonney Forge BrochureAnonymous dvrhf5No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Piping Catalogues and Specifications Tm-1202Document253 pagesPiping Catalogues and Specifications Tm-1202Haresh Jogani67% (6)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- M22T AVEVA Plant - 12 Series - Создание каталогов элементов трубопроводов - Rev 0.6 -Document161 pagesM22T AVEVA Plant - 12 Series - Создание каталогов элементов трубопроводов - Rev 0.6 -Ionut Catoiu100% (1)

- Pressure Proced TestDocument6 pagesPressure Proced Testjamaljamal20No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Introduction - Metallic Expansion Joint PDFDocument16 pagesIntroduction - Metallic Expansion Joint PDFsdmel100% (2)

- Pdms PMLDocument31 pagesPdms PMLHaresh JoganiNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hydro TestDocument3 pagesHydro TestjkahamedNo ratings yet

- AutoDRAFT User GuideDocument68 pagesAutoDRAFT User GuidesimplekelechiNo ratings yet

- Rubber Lining Application Manual Revision Date: September 1, 2009 Section 10: Pipe Lining Procedures Page: 10 - 1Document15 pagesRubber Lining Application Manual Revision Date: September 1, 2009 Section 10: Pipe Lining Procedures Page: 10 - 1Haresh JoganiNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- FVC Nozzle 2Document14 pagesFVC Nozzle 2Haresh JoganiNo ratings yet

- OpenSteel User GuideDocument112 pagesOpenSteel User GuideHaresh JoganiNo ratings yet

- Overall Layout ModelDocument1 pageOverall Layout ModelHaresh JoganiNo ratings yet

- Valves HandbookDocument51 pagesValves Handbookedhy_0367% (3)

- Corporate Compliance Broschüre Englisch FinalDocument14 pagesCorporate Compliance Broschüre Englisch FinalHaresh JoganiNo ratings yet

- Doc. No: Client: Project: S. NO. Eq. No. Description RemarksDocument2 pagesDoc. No: Client: Project: S. NO. Eq. No. Description RemarksHaresh JoganiNo ratings yet

- StairDocument2 pagesStairHaresh JoganiNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Asme B16.5Document11 pagesAsme B16.5jacquesmayol100% (1)

- Fluid DynamicsDocument2 pagesFluid DynamicsBilal AhmadNo ratings yet

- Technical SpecificationsDocument62 pagesTechnical SpecificationsRamu Nallathambi100% (1)

- HDF120-180 User ManualDocument4 pagesHDF120-180 User ManualVijay Pawar Innovative TechnologiesNo ratings yet

- Trouble Shooting Chart For Centrifugal PumpDocument1 pageTrouble Shooting Chart For Centrifugal PumpMohamed RefaatNo ratings yet

- Technical Standards Committee Local Water Utilities Administration Accredited Manufacturers January 2017 To December 2017Document4 pagesTechnical Standards Committee Local Water Utilities Administration Accredited Manufacturers January 2017 To December 2017Abegael PenaredondoNo ratings yet

- 1246 SP 4 Emm 24003 B2Document132 pages1246 SP 4 Emm 24003 B2Arash Aghagol100% (1)

- Water Flow in Open ChannelsDocument83 pagesWater Flow in Open ChannelsShashank ShawNo ratings yet

- PK'G No. Description Q'Ty Unit Weight PK'G#1-1 300KGS: M/T Claxton Bay (Hmd-2138)Document8 pagesPK'G No. Description Q'Ty Unit Weight PK'G#1-1 300KGS: M/T Claxton Bay (Hmd-2138)cmc261185No ratings yet

- Pipe Reference DataDocument7 pagesPipe Reference Datatomeu_vanrellNo ratings yet

- BulHY14 2000 B8Document1 pageBulHY14 2000 B8مصطفي جودهNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Valves Barendsen PDFDocument63 pagesValves Barendsen PDFidontlikeebooksNo ratings yet

- ABV ValvesDocument1 pageABV ValvesJamesTorresPalmaNo ratings yet

- 5 Gas Lift Vision 2010Document37 pages5 Gas Lift Vision 2010DanteNo ratings yet

- Centrifugal Compressors For CPI Plants PDFDocument4 pagesCentrifugal Compressors For CPI Plants PDFAmanda Aracely Herreria SalazarNo ratings yet

- PumpsDocument133 pagesPumpssuave_artistNo ratings yet

- BFP-PPT March 20Document16 pagesBFP-PPT March 20Abhishek Diwanji100% (1)

- Gardner Denver Air Compressor Parts CatalogDocument113 pagesGardner Denver Air Compressor Parts CatalogJR AguilarNo ratings yet

- External FlowDocument64 pagesExternal FlowHardik RadadiyaNo ratings yet

- Function of A Centrifugal PumpDocument4 pagesFunction of A Centrifugal Pumphutsonianp50% (2)

- PSV, CV and Fe Data ListDocument35 pagesPSV, CV and Fe Data ListGear VideoNo ratings yet

- Pipe Chart - Steel & TubeDocument18 pagesPipe Chart - Steel & Tubezinha_alNo ratings yet

- Physics Project Class 11Document18 pagesPhysics Project Class 11Aarya Rajesh71% (55)

- Piping Training CourseDocument446 pagesPiping Training CourseJose Luis Roca CordovaNo ratings yet

- Directional Control ValveDocument12 pagesDirectional Control ValveManojkumar ThilagamNo ratings yet

- N Diagnostic PDFDocument13 pagesN Diagnostic PDFZahir KhiraNo ratings yet

- Axial Flow CompressorsDocument16 pagesAxial Flow CompressorsPrasad ChamarajanagarNo ratings yet

- Pneumatic Control ValvesDocument28 pagesPneumatic Control ValvesKartik UpadhyayNo ratings yet

- Valves and Their SymbolsDocument35 pagesValves and Their SymbolsVel MuruganNo ratings yet

- Sullair ES-8 Air Compressor Operation, Maintenance, TroubleshootingDocument74 pagesSullair ES-8 Air Compressor Operation, Maintenance, TroubleshootingElvis100% (4)

- Funs of AeroDocument99 pagesFuns of AeroAntriksha VishwakarmaNo ratings yet