Professional Documents

Culture Documents

Motion Control On An Fpso Rev 2

Uploaded by

donyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Motion Control On An Fpso Rev 2

Uploaded by

donyaCopyright:

Available Formats

consultancy Computational Fluid Dynamics (CFD)

www. zeta-pdm.com

Motion Control on an FPSO

Motion studies allow performance issues on FPSOs to be resolved and help to ensure that production

can continue in adverse weather conditions. To this end, CFD is used to inform the choice of the baffle

systems inside the vessel, subject to the operational conditions, the arrangement of the separator vessel

and its internals. This ensures that the effects of sloshing on the production processes can be minimized.

The Goal

To design a baffle arrangement that

controls sloshing, allowing separation

to continue by:-

• Minimizing disturbances to the

phase interfaces.

• Reducing liquid carry-over into the

gas stream.

• Reducing gas carry-under through

the liquid outlets.

• Preventing the movement of water

over the weir plate into the oil stream.

Above: The graphic shows the gas / liquid interface in a primary horizontal 3-phase separator. Parts

shown in pale blue are solid plates, parts coloured dark blue are porous baffles and the gas / liquid

interface is shown in red.

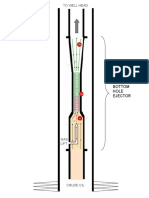

Right: The graphic shows sloshing in a gas

scrubber contained by the vertical porous baffle

and a containment ring. The motion control in

the gas scrubber has to prevent gas carry under

and liquid re-entrainment back into the gas

stream.

Zeta-pdm Ltd

Sales Office

phone +31 (0) 26 389 4240

email sales@zeta-pdm.com

Head office and production

20 Barry Way

Newport, Isle of Wight

PO30 5GY

UK

phone +44 (0) 1983 528 142

fax +44 (0) 1983 223 344

email info@zeta-pdm.com

Zeta-pdm Ltd is a member of the Zeta Group ®

Certified by NQA to

A NEW PHASE IN SEPARATION

BS EN ISO 9001: 2008

Copyright © Zeta-pdm Ltd. 2010. All rights reserved. Motion Control on an FPSO Rev 2 Page 1/1

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ejector Modeling in HYSYS PDFDocument5 pagesEjector Modeling in HYSYS PDFdonyaNo ratings yet

- Huawei Core Roadmap TRM10 Dec 14 2011 FinalDocument70 pagesHuawei Core Roadmap TRM10 Dec 14 2011 Finalfirasibraheem100% (1)

- A Winning Formula: Debrief For The Asda Case (Chapter 14, Shaping Implementation Strategies) The Asda CaseDocument6 pagesA Winning Formula: Debrief For The Asda Case (Chapter 14, Shaping Implementation Strategies) The Asda CaseSpend ThriftNo ratings yet

- Czech Republic GAAPDocument25 pagesCzech Republic GAAPFin Cassie Lazy100% (1)

- Crawler Base DX500/DX600/DX680/ DX700/DX780/DX800: Original InstructionsDocument46 pagesCrawler Base DX500/DX600/DX680/ DX700/DX780/DX800: Original InstructionsdefiunikasungtiNo ratings yet

- Option Selection Program: Select Your Reason For Using This ProgramDocument2 pagesOption Selection Program: Select Your Reason For Using This ProgramdonyaNo ratings yet

- BOTTOMHOLEEJECTORDocument1 pageBOTTOMHOLEEJECTORdonyaNo ratings yet

- Questionnaire For: Liquid Jet Vacuum Ejectors For Continuous OperationDocument2 pagesQuestionnaire For: Liquid Jet Vacuum Ejectors For Continuous OperationdonyaNo ratings yet

- Distillation Trays That Operate Beyond The Limits of Gravity by Using Centrifugal SeparationDocument6 pagesDistillation Trays That Operate Beyond The Limits of Gravity by Using Centrifugal SeparationdonyaNo ratings yet

- Chemical Engineering CommunicationsDocument15 pagesChemical Engineering CommunicationsdonyaNo ratings yet

- FF - Mar-Apr - 2018 - Zero Waste Urea Production - ONLINEDocument3 pagesFF - Mar-Apr - 2018 - Zero Waste Urea Production - ONLINEdonyaNo ratings yet

- Pressure Drop Measurements in Distillatio ColumnsDocument5 pagesPressure Drop Measurements in Distillatio Columnsdonya100% (1)

- Inventions 04 00016Document54 pagesInventions 04 00016donyaNo ratings yet

- Theresa Renee Anthony: All Rights ReservedDocument53 pagesTheresa Renee Anthony: All Rights ReserveddonyaNo ratings yet

- (Paperhub Ir) 10 1021@ie950674wDocument14 pages(Paperhub Ir) 10 1021@ie950674wdonyaNo ratings yet

- Size Distributions in Strongly Coalescing Agitated Liquid-Liquid SystemsDocument4 pagesSize Distributions in Strongly Coalescing Agitated Liquid-Liquid SystemsdonyaNo ratings yet

- Objectlistview Python Edition StableDocument77 pagesObjectlistview Python Edition StabledonyaNo ratings yet

- D08 049 PDFDocument10 pagesD08 049 PDFRashminda AttanayakeNo ratings yet

- 291-Questionnaire-Jet and Venturi scrubbers-EN-161202-STDocument2 pages291-Questionnaire-Jet and Venturi scrubbers-EN-161202-STdonyaNo ratings yet

- Experimental Investigation of An Ejector: Received 6 September 1985 Revised 16 September 1985Document3 pagesExperimental Investigation of An Ejector: Received 6 September 1985 Revised 16 September 1985donyaNo ratings yet

- 1975163Document2 pages1975163donyaNo ratings yet

- Questionnaire For: Liquid Jet Liquid EjectorsDocument2 pagesQuestionnaire For: Liquid Jet Liquid EjectorsdonyaNo ratings yet

- Modelling Gas Liquid Flow in Venturi SCR PDFDocument7 pagesModelling Gas Liquid Flow in Venturi SCR PDFdonyaNo ratings yet

- Data Sheet Ejector PDFDocument1 pageData Sheet Ejector PDFdonyaNo ratings yet

- Welcome To The Interactive Help Feature PDFDocument85 pagesWelcome To The Interactive Help Feature PDFdonyaNo ratings yet

- Dmta 20043 01en Omniscan SX UserDocument90 pagesDmta 20043 01en Omniscan SX UserwenhuaNo ratings yet

- Dr. Najeebuddin Ahmed: 969 Canterbury Road, Lakemba, Sydney, NSW, Australia, 2195Document2 pagesDr. Najeebuddin Ahmed: 969 Canterbury Road, Lakemba, Sydney, NSW, Australia, 2195Najeebuddin AhmedNo ratings yet

- An Over View of Andhra Pradesh Water Sector Improvement Project (APWSIP)Document18 pagesAn Over View of Andhra Pradesh Water Sector Improvement Project (APWSIP)gurumurthy38No ratings yet

- Types of MemoryDocument3 pagesTypes of MemoryVenkatareddy Mula0% (1)

- Is.14785.2000 - Coast Down Test PDFDocument12 pagesIs.14785.2000 - Coast Down Test PDFVenkata NarayanaNo ratings yet

- Icom IC F5021 F6021 ManualDocument24 pagesIcom IC F5021 F6021 ManualAyam ZebossNo ratings yet

- Hosts 1568558667823Document5 pagesHosts 1568558667823Vũ Minh TiếnNo ratings yet

- Hitt PPT 12e ch08-SMDocument32 pagesHitt PPT 12e ch08-SMHananie NanieNo ratings yet

- Frigidaire Parts and Accessories CatalogDocument56 pagesFrigidaire Parts and Accessories CatalogPedro RuizNo ratings yet

- Income Tax Calculator 2023Document50 pagesIncome Tax Calculator 2023TARUN PRASADNo ratings yet

- Understanding Consumer and Business Buyer BehaviorDocument47 pagesUnderstanding Consumer and Business Buyer BehaviorJia LeNo ratings yet

- MEMORANDUMDocument8 pagesMEMORANDUMAdee JocsonNo ratings yet

- Possession: I. A. Definition and Concept Civil Code Art. 523-530 CasesDocument7 pagesPossession: I. A. Definition and Concept Civil Code Art. 523-530 CasesPierrePrincipeNo ratings yet

- Numerical Transformer Differential RelayDocument2 pagesNumerical Transformer Differential RelayTariq Mohammed OmarNo ratings yet

- Belimo Fire & Smoke Damper ActuatorsDocument16 pagesBelimo Fire & Smoke Damper ActuatorsSrikanth TagoreNo ratings yet

- Danh Sach Khach Hang VIP Diamond PlazaDocument9 pagesDanh Sach Khach Hang VIP Diamond PlazaHiệu chuẩn Hiệu chuẩnNo ratings yet

- Between:-Mr. Pedro Jose de Vasconcelos, of Address 14 CrombieDocument2 pagesBetween:-Mr. Pedro Jose de Vasconcelos, of Address 14 Crombiednd offiNo ratings yet

- Mpi Model QuestionsDocument4 pagesMpi Model QuestionshemanthnagNo ratings yet

- A Comparison of Pharmaceutical Promotional Tactics Between HK & ChinaDocument10 pagesA Comparison of Pharmaceutical Promotional Tactics Between HK & ChinaAlfred LeungNo ratings yet

- August 2015Document96 pagesAugust 2015Cleaner MagazineNo ratings yet

- Scope of Internet As A ICTDocument10 pagesScope of Internet As A ICTJohnNo ratings yet

- A Survey On Multicarrier Communications Prototype PDFDocument28 pagesA Survey On Multicarrier Communications Prototype PDFDrAbdallah NasserNo ratings yet

- Sangeetahealingtemples Com Tarot Card Reading Course in UsaDocument3 pagesSangeetahealingtemples Com Tarot Card Reading Course in UsaSangeetahealing templesNo ratings yet

- Unit 5 Andhra Pradesh.Document18 pagesUnit 5 Andhra Pradesh.Charu ModiNo ratings yet

- Engagement Letter TrustDocument4 pagesEngagement Letter Trustxetay24207No ratings yet

- Sign Language To Speech ConversionDocument6 pagesSign Language To Speech ConversionGokul RajaNo ratings yet