Professional Documents

Culture Documents

Hydro Chlorination

Uploaded by

Iqbal Muhamad IrfanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydro Chlorination

Uploaded by

Iqbal Muhamad IrfanCopyright:

Available Formats

HYDROCHLORINATION OF METHANOL T O

METHYL CHLORIDE IN FIXED CATALYST BEDS

M. S. T H Y A G A R A J A N , R A J I N D E R K U M A R , A N D N. R. K U L O O R

Department of Chemical Engineering, Indian Institute of Science, Bangalore, India

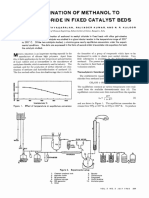

The vapor phase hydrochlorination of methanol to methyl chloride in fixed beds with silica gel-alumina

(88 to 12) and y-alumina catalysts was studied in a glass tubular reactor in the temperature range of 300"

to 390" C. Of the two catalysts studied, y-alumina gave nearly equilibrium conversions under the experi-

mental conditions. The data are expressed in the form of second-order irreversible rate equations for both

the catalysts studied.

METHYL CHLORIDE is an important starting material in the the formation of a group of compounds which have to be

manufacture of silicone high polymers. Apart from fractionated in order to obtain pure methyl chloride. Very

this, it finds applications in the low temperature polymerization little information is available on the hydrochlorination of

of butyl rubbers and as intermediate in the manufacture of methanol. The present investigation was undertaken to study

methylene chloride, which is extensively used in industry. The the reaction in fixed beds of silica gel-alumina (88 to 12) and

methods used for the production of methyl chloride are chlo- y-alumina catalysts.

rination of methane and hydrochlorination of methanol ( 3 ) .

The first method suffers from the disadvantage that it results in Thermodynamic Considerations

The stoichiometric equation for the preparation of methyl

chloride from methanol and hydrogen chloride is given as

CH3.OH + HC1 --t CH3.Cl + H20

The equilibrium constants a t various temperatures were eval-

uated from the available thermodynamic data (4). The

1

equilibrium conversions were then evaluated from the equation

0 ~ 8 1 - 11 I I 1 I 1

s ZOO 400 600 e00 1000

TBHPERATURE, *K and are shown in Figure 1. The equilibrium conversion de-

Figure 1. Effect of t'emperature on equilibrium conversion creases from 99% a t 300' K. to 85% a t 1000" K. T o produce

WATER

Figure 2. Experimental setup

1. Constant overhead tank 6. Reactor

2. Aspirator bottle 7. Thermocouple

3. Hg manometer 8. Condensers

4. Methanol storage 9. N a O H bubbler

40. HCI generator 10. Mariotte system

5. Mixer

VOL. 5 NO. 3 JULY 1966 209

methyl chloride in high conversions and in reasonably high

rates the temperature range of 600’ to 700’ K. is explored for

kinetic studies.

/ A I

Experimental

Equipment a n d Operation. A flow diagram of the appara-

tus is shown in Figure 2 . The reactor is a borosilicate glass

tube of 15-mm. i.d. and 700 mm. long. A thermowell is /m I

provided for inserting the calibrated iron-constantan thermo-

couple. Care is taken to keep the tip of the thermowell at the

center of the catalyst bed when the catalyst is packed inside

the reactor tube. The reactor is also packed with porcelain

beads which serve as the preheater for the reactant gases and

as a distributor. The reactor is provided with a radiation

heater and the energy input to the heater is controlled by a

Dimmerstat. Arrangements are made for the admission of the

reactants a t the bottom of the reactor and for withdrawal of the

products through a side tube a t the top.

Reactants. METHANOL, analytical reagent grade, is metered

through a calibrated all-glass rotameter and fed into the

preheater. A steady feed rate is obtained by the pressure of

air displaced by water from a constant-level tank. Catalyst: r-Alumlna

HYDROGEN CHLORIDE.An all-glass apparatus for the Ratio of rcrctants=l:l (HCI:CHaOH)

preparation of hydrogen chloride is a modified form of the

apparatus developed by Bhatnagar and Kuloor ( Z ) , so that

dry hydrogen chloride could be produced a t pressures slightly

higher than atmospheric. The gas is dried by passing it I 1 I I I I I 1 I

through a calcium chloride tube and is metered using a cali- 0.1 0.3 0.5 0.7 0.9 11 1.3 1.5

brated glass capillary flowmeter. The manometric liquid W/F, gm of crtalyrt/gm mole of fccdlhr

used in this flowmeter is concentrated sulfuric acid. Figure 3. Conversion vs. time factor at various tem-

Preparation of Catalysts. SILICAGEL-ALUMINA (88 to 12)

CATALYST.Aluminum foil is dissolved in potassium hy- peratures

droxide solution to yield potassium aluminate solution. Silica Catalyst. y-Alumina

gel (obtained from water glass) is then dispersed in potassium Ratio of reactants 1:l

aluminate solution. Carbon dioxide is passed into the solu-

tion until all the alumina is precipitated. Then a 15Oj, solu-

tion of ammonium chloride is added to maintain the required

pH. After some time the precipitate is washed free of chloride,

filtered, and then dried. The effect of the other variables- WJF and temperature-is

7-ALUMINACATALYST.y-Alumina is prepared by dis- dependent on the levels of each. To take these interactions

solving aluminum foil in a solution of potassium hydroxide into account, a complete factorial design approach was resorted

solution and bubbling carbon dioxide into the resulting potas- to. Thus, for each level of temperature, four levels of space

sium aluminate solution until all the alumina is precipitated.

T h e precipitate is washed and then dried. The alumina thus velocity were studied. The amount of catalyst was mqintained

obtained is then activated a t 400’ C. for about 16 hours and the same throughout the investigation, but was changed for a

then used as such. few runs in order to ascertain whether diffusion or chemical

Characteristics of Catalysts. SILICAGEL-ALUMINA. Par- reaction rate constitutes the rate-controlling mechanism.

ticle size, -28+ 48 Tyler mesh. Surface area, 775.0 sq. meters EFFECTOF TIMEFACTOR. The time factor ( W J F ) in the

per gram.

?-ALUMINA.Particle size, cylinders of 2.1 -mm. length, present case was varied by changing the feed rate while main-

1.0-mm. diameter. Surface area, 169.0 sq. meters per gram. taining the weight of the catalyst constant. The data obtained

Experimental Procedure. The preheaters, mixer, and by varying the time factor on both the catalysts a t temperatures

reactor are heated to the desired temperature. Methanol of 300°, 330°, 360°, and 390’ C. are shown in Figures 3 to 6.

and hydrogen chloride in predetermined proportions are then

fed into the reactor through the mixer by applying the constant The fact that the curves do not register fall or sudden rise in-

pressure device. When steady state of temperatures and feed dicates that the rates of side reaction are negligible.

rates is reached, the product coming out of the reactor is con- EFFECTOF TEMPERATURE. The manner in which the tem-

densed, scrubbed through sodium hydroxide solution, and perature increases the conversion is shown in Figure 7, where

finally collected over brine solution in a Mariotte system. the conversion has been plotted against temperature for various

Each run is conducted for 10 minutes and a sample of product

is analyzed immediately. WJFvalues as parameters. This increase is expected from the

Analysis. The methyl chloride content in the product gas Arrhenius equation, which gives the effect of temperature on

is determined by absorption in glacial acetic acid (7). homogeneous reactions. For catalytic reactions, the final

apparent effect of temperature is due to both the effect on

adsorption constants and specific reaction rate constants. I n

Results and Discussion

the present case, as the change in conversion with temperature

Influence of Variables on Conversion. The pressure of is high for both the catalysts, the effect of adsorption constants

operation was considered to be of negligible effect because the appears to be less.

number of moles of the reactants is equal to that of products. No fall in the activity of the catalyst was observed with rise in

Hence, all of the experiments during the present investigation temperature within the range of temperatures studied. Higher

were conducted at nearly atmospheric pressure. Separate temperatures, however, could not be employed because of the

design equations are developed for each of the two catalysts lowering of the equilibrium conversion and the higher prob-

studied-silica gel-alumina and y-alumina. The composition ability of formation of side products like ether.

of the feed was not very important and only a few experiments E ~ F E COF

T COMPOSITION OF REACTANTS.I t is seen (from

were conducted by changing the composition of the feed. Figures 4 and 5) that a t lower temperatures the effect of change

210 l&EC PROCESS DESIGN A N D DEVELOPMENT

E

30.3

U

-

-

a?

U

-u

I

Catalyst: r-Alumina

Ratio of reactantr=l:2 (HCI:CH3OH)

I I

0 0.5 1.0 1.5

WIF, gm o f c a l s l y r l / g m mole of.feed/hr

Figure 4. Conversiori vs. time factor at various tem-

peratures

Catalyst. y-Alumina

Ratio of reactants 1 :2 I I I

1 2 3

W/F, grn of catalyrt/gm mole of fced/hr

Figure 6. Conversion vs. time factor at various tem-

peratures

Catalyst. Silica gel-alumina

Ratio of reactants 1 :1

0.5-

>

U

m

r

U

I 0.4-

0

-

u

: - 0.3

.-$- 0.2-

E Catalyst : r-Alumina

W/F, gm of catalyst/gm mole of feed/hr >

C

Figure 5. Conversion vs. time factor at various tem- 8 0.1 - Ratio of reactants=l:l (HCi: CH30t

peratures

Catalyst. y-Alumina 0,0

Ratio of reactants 1 :3 300 330 360 390 410

TemperatUrQ *C

Figure 7. Effect of temperature on conversion

in molal ratio is not considerable but a t higher temperatures it Catalyst. y-Alumina

is more significant. Thus, conversion can be increased mainly Ratio of reactants 1:l

by increasing the temperature.

Comparison of Catalysts. Comparison of Figure 4 with

Figure 7 shows that y-al.umina catalyst gives higher conversions higher surface area for the reaction, thereby making it possible

throughout the range of temperatures and time factors consid- to achieve higher conversions even if its activity is slightly less

ered. However, it s e e m unreasonable to compare the catalysts than the other. In the present case, the density of y-alumina

in the above fashion because their densities are not the same. is very low compared with that of silica gel-alumina, so much

As a result, the volume of the catalyst possessing a lower density so that the volume of 1.O gram of silica gel-alumina catalyst is

will be much greater than that of the other and the number of smaller than 0.5 gram of y-alumina. The bulk densities of

particles of this catalyst is greater than that of the other. Thus, silica gel-alumina and y-alumina are, respectively, 0.6302 and

for the same weight, the catalyst having lower density offers 0.2857 gram per cc.

VOL. 5 NO. 3 JULY 1966 211

Rate Equation Arrhenius plots were made for both y-alumina and silica

The method employed for expressing the results quantita- gel-alumina catalysts. The plot for y-alumina is presented in

tively is based on the order of reaction approach. Figure 8, and that for silica gel-alumina is presented in Figure

The design equation for a catalytic flow reactor can be put 9. The values of k employed in these graphs are averaged

in the form values which are considered to be more representative than

any arbitrary chosen value.

W/F' = [ dXA/T (2)

From the slopes and intercepts the values of E and A are cal-

culated for both the catalysts and are given below:

I n Equation 2 r is a function of x A because the concentrations y-Alumina

of unreacted materials vary with conversion. The second- E = 19,178 cal./gram mole

A = 1.816 X lo7

order rate equation for the reaction can be expressed as

Silica Gel-Alumina

r = k CA C B (3)

E = 18,860 cal./gram mole

By substituting this in Equation 2 and making substitution and A = 2.615 X l o 3

integration, the final equation obtained is Employing these values of E and A , the final integrated rate

equation is written by expressing k of Equations 4 and G in

W/F' = n$/k - 1

---

nAo - nBo

In 0

nAo

n.4

- XA

+ terms of E and A . Thus for 7-alumina, the final rate equations

are :

1 nBo Where the feed does not contain equimolal quantities of

In - (4)

nAo - nBo nBo - XA methanol and hydrogen chloride :

This equation applies only when the initial moles of the

reactants are not equal. For the special case when nAo = n B o ,

Equation 3 becomes

r = k CAz (5)

Substituting Equation 5 in Equation 2 and integrating we When feed contains equimolal quantities of methanol and

obtain hydrogen chloride:

pV/F' = D

k.nAo

n 2 ( ~

nAu - xA ) (6)

The known values of %A, nAo, n B o ) no, and p!'/F' are substituted Similarly for silica gel-alumina catalyst the final integrated

and the values of k calculated a t various conversion values.

rate equation is

T h e resulting values of k are given for y-alumina and silica

gel-alumina catalysts in Table I.

Table I shows that a t 300' C. the values of k are nearly equal

for feeds of various molal ratios. Similar is the case with

values of k a t 330" and 360' C. These observations confirm

that the reaction is definitely of first order with respect to each

of the reactants, methanol and hydrogen chloride.

Reaction velocity constants for silica gel-alumina catalyst

a t various temperatures are also presented in Table I.

Effect of Temperature on Reaction Velocity Constants. 1.0 -

The reaction velocity constant is related to the reaction tem-

perature, in accordance with the Arrhenius equation, as 0.8 -

follows :

k =A ,--E/RT

(7) -

0.6

or .x

In k = In A - E/RT (8) 01

0 0.4-

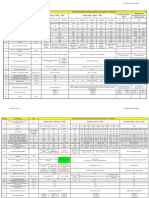

Table 1. Reaction Velocity Constants at Various Ternpera- 0.2 -

tures

Mole

Ratio of 0.0 -

Reactants

Aaerage Value of k

NO.

( HCl :

CHaOH) 300'C. 33'0'C. 36OOC. 390'C. 7,s -

?-Alumina Catalyst 1 1

0.15

1

0-16 0-17

I 1

0.18

1 1:l 1.034 2.202 3.404 7.714

2 1:2 1.032 2.198 3.403 ... +*lo2

3 1:3 1.036 2.206 *.. ... Figure 8. Effect of temperature on reaction velocity con-

Silica Gel-Alumina Catalyst stants

1 1:l 0,2573 0,6415 1.4010 2.8180 Catalyst. y-Alumina

Ratio of reactants 1 :1

212 I&EC PROCESS D E S I G N A N D DEVELOPMENT

Table II. Validity of Rate Equations

Catalyst. ?-Alumina

Ratio of reactants. 1 : 1 (CHaOH:HC1)

Conversion Temlberature 300" C. Temperature 330" C. Temperature 360' C. Temperature 390" C.

X W/F' calcd. W/F' exptl. W/F' calcd. W/F' exptl. W/F' calcd. W/F' exptl. W/F' calcd. W/F' exptl.

0.05 0.2546 0.2220 0.1101 0.1170 0.5160 0.7600 0.0260 0.0280

0.075 0.4044 0.3510

0.10 0.5729 0.5000 0.2477 0.2520 0 .'1.162 0 .'l620 0 0582 0,0660

0.15 0.9820 0.9050 0.4245 0.4120 0.1988 0.2660 0.0997 0.1330

0.20 ... ... 0.6603 0.6270 0.3092 0.3950 0.1551 0.1780

0.30 ... ... 1.4853 1.2740 0.6956 0.8250 0.3488 0,3900

0.35 ... ... ... ... 1.0816 1.1600 0.5425 0.5950

0.40 ... I . . ... ... *.. ... 0.9293 0.9230

silica gel-alumina catalyst showed that Equation 11 expresses

the data well.

Acknowledgment

0.50- The authors thank the authorities of the Council of Scientific

and Industrial Research, New Delhi, for the award of a Junior

Research Fellowship to one of them (M.S.T.).

0.30 -

Nomenclature

JL

0.10 - A = frequency factor, gram moles/hr. (atm.*) (gram

cn

0

cat.)

CB = concentration of species A and B

?so - CA,

E = activation energy, cal./gram mole

F = feed rate, gram moles/hr.

F' = feed rate, gram/hr.

7-70 - k = reaction velocity constant, gram moles/(hr.)

(atrn.2) (gram cat.)

K = equilibrium constant

T.50 - nAo, nBo = number of moles of species A and B initially

present, gram moles per unit mass of feed

-1.30 - 2

=

=

total moles of feed per unit mass of feed

universal gas cmstant

r = rate of reaction, gram moles/(hr.) (gram cat.)

T = absolute temperature, O K.

w = weight of catalyst, grams

XA = moles of hydrogen chloride converted per unit

Figure 9. Effect of temperature on reaction velocity mass of feed

constants X = moles of methyl chloride formed per mole of total

Catalyst. Silica gel-alumina

feed

Ratio of reactants 1:l

literature Cited

(I) Allison, V.C., Meighan, M. H., J. Znd. Eng. Chem. 7, 943

Reliability of Equsrtion. T o verify that the equations (1919).

derived represent the data adequately, calculations were (2) Bhatnagar, R. K., Kuloor, N. R., J . Sci. Znd. Res. (India)

12A, No. 11, 520 (1953).

made for W/F' values Iby putting various values of conversions (3) Kirk, E. R., Othmer, D. F., "Encyclopedia of Chemical

x A in the equations. A. set of values calculated through Equa- Technology," Vol. 3, p. 741, Interscience Encyclopedia Inc.,

New York, 1949.

tion 10 as well as experimentally determined values is given in (4) Kobe, K. A,, Crawford, H. R., Petrol. Rejner 37 (7), 125

Table I1 for y-alumina catalyst. (1958).

Table I1 shows that the calculated values agree well with RECEIVED

for review January 18, 1965

the experimental ones. Similar calculations conducted for ACCEPTEDJanuary 24, 1966

VOL. 5 NO. 3 JULY 1966 213

You might also like

- Ernest Guenther - Essential Oils Vol II PDFDocument878 pagesErnest Guenther - Essential Oils Vol II PDFMeiti PratiwiNo ratings yet

- Control Systems Engineering NotesDocument233 pagesControl Systems Engineering NotesPreetam PolakiNo ratings yet

- Technical Data Sheet for Emulsified Bituminous PrimerDocument2 pagesTechnical Data Sheet for Emulsified Bituminous Primerhandhammer qatarNo ratings yet

- Renewable Energy Sources and Engery Conservation PDFDocument6 pagesRenewable Energy Sources and Engery Conservation PDFYugalNo ratings yet

- ChE-433 Reaction Engineering Lab ManualDocument25 pagesChE-433 Reaction Engineering Lab ManualHasan AkhuamariNo ratings yet

- Oal Ed Ethahne: Prof. P. K. SinghDocument67 pagesOal Ed Ethahne: Prof. P. K. SinghViplove RajurkarNo ratings yet

- Blown Film ProblemsDocument33 pagesBlown Film Problemsjroyal69297467% (3)

- Lecture Notes - Chem 16 LE3Document8 pagesLecture Notes - Chem 16 LE3Alexander Gordon InesNo ratings yet

- Hydrogen Production From The Low-TemperatureDocument8 pagesHydrogen Production From The Low-TemperatureAndres Acosta100% (1)

- Lecture7 PDFDocument5 pagesLecture7 PDFrashidNo ratings yet

- Case Study On Production of Bio-Diesel and Evaluation of Its Properties and Its Use in Diesel Engine Based Power PlantDocument5 pagesCase Study On Production of Bio-Diesel and Evaluation of Its Properties and Its Use in Diesel Engine Based Power PlantSr2152No ratings yet

- Experimental Investigation of Photovoltaic Panel Cooling Using Passive InsertsDocument7 pagesExperimental Investigation of Photovoltaic Panel Cooling Using Passive InsertsInternational Journal of Innovative Science and Research Technology100% (1)

- Fluid Mechanics: The Gate CoachDocument18 pagesFluid Mechanics: The Gate CoachSandeep CharanNo ratings yet

- Unit IIIDocument62 pagesUnit IIIRavichandran SekarNo ratings yet

- CRE 1 Gavhane PDFDocument501 pagesCRE 1 Gavhane PDFrajneeshNo ratings yet

- Non Conventional Energy Sources GD RaiDocument382 pagesNon Conventional Energy Sources GD Rairavi khanna17% (6)

- CamScanner Document ScansDocument59 pagesCamScanner Document ScansYASH PAREKHNo ratings yet

- Unit 1 Non Conventional Energy ResourcesDocument22 pagesUnit 1 Non Conventional Energy ResourcesShubham Srivastava80% (5)

- Mass Transfer Part 1 by GaMa Sir PDFDocument153 pagesMass Transfer Part 1 by GaMa Sir PDFchandrakiran100% (3)

- Scanned Docs by CamScanner AppDocument7 pagesScanned Docs by CamScanner AppAkshay Iyer100% (2)

- Mass Transfer 2 by KA GavhaneDocument554 pagesMass Transfer 2 by KA Gavhaneacharyarameswar1No ratings yet

- Non-Conventional Energy Sources - G. D. RaiDocument41 pagesNon-Conventional Energy Sources - G. D. RaiHari Kishan10% (10)

- 11-9-Brain Maps-Thermal Properties of Matter, Thermodynamics and Kinetic Theory of GasDocument1 page11-9-Brain Maps-Thermal Properties of Matter, Thermodynamics and Kinetic Theory of GasFredrickNo ratings yet

- (N.P Bali) Engineering Mathematics-IIDocument498 pages(N.P Bali) Engineering Mathematics-IIAryan jhaNo ratings yet

- Scanned Document Text RecognitionDocument87 pagesScanned Document Text RecognitionAnurag SrivastavaNo ratings yet

- Waste To Energy Conversion Technology Course Code: 4350502: Page 1 of 8Document8 pagesWaste To Energy Conversion Technology Course Code: 4350502: Page 1 of 8Cliches in0% (1)

- TTW - MCQ'sDocument9 pagesTTW - MCQ'sRajesh KumarNo ratings yet

- Fill in the blanks document answers chemical engineering questionsDocument5 pagesFill in the blanks document answers chemical engineering questionsKuldeep BhattNo ratings yet

- Blake Jaw CrusherDocument16 pagesBlake Jaw Crusher19-806 SreyaNo ratings yet

- Demo PDF Purchase Remove WatermarkDocument6 pagesDemo PDF Purchase Remove WatermarkMNButtNo ratings yet

- Catalytic Reactor Design and Kinetics QuestionsDocument37 pagesCatalytic Reactor Design and Kinetics QuestionsyaseenNo ratings yet

- CamScanner Scanned DocumentDocument253 pagesCamScanner Scanned DocumentIct Pfa Club50% (2)

- Engineering Physics SASTRA Semester Question PapersDocument7 pagesEngineering Physics SASTRA Semester Question PapersstarNo ratings yet

- Dr. M. Chidambaram PDFDocument70 pagesDr. M. Chidambaram PDFM.ThirunavukkarasuNo ratings yet

- rr320802 Chemical Reaction Engineering IDocument8 pagesrr320802 Chemical Reaction Engineering ISRINIVASA RAO GANTANo ratings yet

- Fundamentals of Gas Dynamics (NOC16 - ME05) Assignment - 3: SolutionsDocument4 pagesFundamentals of Gas Dynamics (NOC16 - ME05) Assignment - 3: SolutionsOyewole EmmanuelNo ratings yet

- Vlsi DocumentDocument100 pagesVlsi Documentbaburao_kodavatiNo ratings yet

- Controlling Renewable Energy SystemsDocument1 pageControlling Renewable Energy Systemskiran panditNo ratings yet

- Control Systems by Nagoor KaniDocument56 pagesControl Systems by Nagoor KaniVIGNESH T A100% (1)

- Unit 2. Structure of Solids and Characterization of Materials PDFDocument83 pagesUnit 2. Structure of Solids and Characterization of Materials PDFShail RajNo ratings yet

- Modern Speed Control Technologies of AC MotorsDocument3 pagesModern Speed Control Technologies of AC MotorsmadhumithaaNo ratings yet

- Lab Manuals 2CH403 IPC Jan 2020 PDFDocument47 pagesLab Manuals 2CH403 IPC Jan 2020 PDFSamriddha Das GuptaNo ratings yet

- CamScanner Scanned Document CollectionDocument222 pagesCamScanner Scanned Document CollectionRizual RanaNo ratings yet

- IIT-KGP Lecture Notes by GaMaSirDocument34 pagesIIT-KGP Lecture Notes by GaMaSirSaurabh Sharma100% (2)

- B K Dutta Mass Transfer PDFDocument2 pagesB K Dutta Mass Transfer PDFFvffghgNo ratings yet

- Heat Transfer Semester Exam QPsDocument61 pagesHeat Transfer Semester Exam QPsGoutham R100% (1)

- Chemical Kinetics Question Bank Class 12 CBSEDocument8 pagesChemical Kinetics Question Bank Class 12 CBSERahgul M.S.No ratings yet

- Acid, Base & SaltDocument2 pagesAcid, Base & SaltShreyansh DuggarNo ratings yet

- Bxe Notes Unit 1Document51 pagesBxe Notes Unit 1Ruchinu13099192No ratings yet

- Adama Science and Technology University School of Applied Natural Science Department of Applied MathematicsDocument9 pagesAdama Science and Technology University School of Applied Natural Science Department of Applied MathematicsALEMAYEHUNo ratings yet

- Non-Conventional Energy Sources - G. D. Rai PDFDocument41 pagesNon-Conventional Energy Sources - G. D. Rai PDFSuryakanta SwainNo ratings yet

- SASTRA University Basic Civil Engineering Question Papers First YearDocument16 pagesSASTRA University Basic Civil Engineering Question Papers First YearstarNo ratings yet

- Wetted Wall ColumnDocument4 pagesWetted Wall ColumnDeepak SharmaNo ratings yet

- Dynamic Characteristics of Power SemiconductorsDocument25 pagesDynamic Characteristics of Power SemiconductorsNANDINI SINHANo ratings yet

- CamScanner Document ScansDocument71 pagesCamScanner Document ScansBragadeeshNo ratings yet

- Ansys Fluent Simulation ReportDocument9 pagesAnsys Fluent Simulation ReportME 26 PRADEEP KUMARNo ratings yet

- CRE-2 (Mahima) PDFDocument114 pagesCRE-2 (Mahima) PDFammar sange100% (1)

- Heat Transfer Lab: Me8512-Thermal Engineering LabDocument55 pagesHeat Transfer Lab: Me8512-Thermal Engineering LabVinoNo ratings yet

- RAC - Short Questions PDFDocument3 pagesRAC - Short Questions PDFSachin MohalNo ratings yet

- S6 EEE BMI MODULE 5 Careeryuga NotesDocument32 pagesS6 EEE BMI MODULE 5 Careeryuga NotesArun JerardNo ratings yet

- CamScanner Scans PDF DocsDocument9 pagesCamScanner Scans PDF Docsspidy willxmen100% (1)

- Pmso - Question BankDocument4 pagesPmso - Question BankdarshanNo ratings yet

- Root Locus and Closed Loop Transfer Function CalculationDocument8 pagesRoot Locus and Closed Loop Transfer Function CalculationAkashNo ratings yet

- Santa Cesaria 1981Document10 pagesSanta Cesaria 1981Jorge LondoñoNo ratings yet

- Bercic-1993-Catalytic Dehydration of MethanolDocument7 pagesBercic-1993-Catalytic Dehydration of MethanolIonut BanuNo ratings yet

- MSDS Methyl Chloride (BOC)Document15 pagesMSDS Methyl Chloride (BOC)Iqbal Muhamad IrfanNo ratings yet

- AssassinsDocument1 pageAssassinsIqbal Muhamad Irfan100% (1)

- Dapus EditDocument1 pageDapus EditEdwin WidiatamajaNo ratings yet

- Us MelamineDocument3 pagesUs MelamineIqbal Muhamad IrfanNo ratings yet

- Hydro ChlorinationDocument5 pagesHydro ChlorinationIqbal Muhamad IrfanNo ratings yet

- Least Square Methyl ChlorideDocument11 pagesLeast Square Methyl ChlorideIqbal Muhamad IrfanNo ratings yet

- Polyethylene and Polypropylene Manufacturing: Technical Guidance Package For Chemical SourcesDocument26 pagesPolyethylene and Polypropylene Manufacturing: Technical Guidance Package For Chemical SourcesbaneNo ratings yet

- 07-PT11Centrifugal Compressors (Compatibility Mode)Document41 pages07-PT11Centrifugal Compressors (Compatibility Mode)moxlinde100% (1)

- Iqbal Muhamad Irfan BTP D3 Batch 4 Quality Control Department A Project PresentationDocument17 pagesIqbal Muhamad Irfan BTP D3 Batch 4 Quality Control Department A Project PresentationIqbal Muhamad IrfanNo ratings yet

- 0409Document108 pages0409Iqbal Muhamad IrfanNo ratings yet

- 30 Days of Cardio BlastDocument32 pages30 Days of Cardio Blastlebink312No ratings yet

- Pamphlet 001 Chlorine BasicsDocument61 pagesPamphlet 001 Chlorine Basicsthorem100% (1)

- Technical Data Sheet:: Polybutadiene Adducted With Maleic AnhydrideDocument1 pageTechnical Data Sheet:: Polybutadiene Adducted With Maleic AnhydrideRobert ThomasNo ratings yet

- 9h47.02 CD Emerald LyseDocument9 pages9h47.02 CD Emerald LyseanggitasaputriNo ratings yet

- Forming Processes (MP Module 3)Document77 pagesForming Processes (MP Module 3)Kailas Sree ChandranNo ratings yet

- Weco African Energy FlyerDocument7 pagesWeco African Energy FlyerNasiru BelloNo ratings yet

- Origins of Rheology: A Brief Look at the Evolution of the Study of Material FlowDocument9 pagesOrigins of Rheology: A Brief Look at the Evolution of the Study of Material FlowAmlan PalNo ratings yet

- MIL-STD-202G Compliance DeadlineDocument191 pagesMIL-STD-202G Compliance DeadlinealfonsoNo ratings yet

- MasterSeal P 698 MSDS - EN-23.11.2022-Rev1.2Document11 pagesMasterSeal P 698 MSDS - EN-23.11.2022-Rev1.2recep kablanNo ratings yet

- Manufacturing porcelain figures using binder jetting 3D printingDocument8 pagesManufacturing porcelain figures using binder jetting 3D printingcesarNo ratings yet

- Eutronic - Arc - Spray 4HFDocument4 pagesEutronic - Arc - Spray 4HFMuhammad irfanNo ratings yet

- CE2155 - 01 Mechanic of Materials (Part 3)Document18 pagesCE2155 - 01 Mechanic of Materials (Part 3)Julia100% (1)

- United States: Patent OfficeDocument4 pagesUnited States: Patent OfficesherlybonitaNo ratings yet

- PhysioEx Exercise 1 Activity 4Document3 pagesPhysioEx Exercise 1 Activity 4Дмитро МарчукNo ratings yet

- Bio Process Problem 1Document1 pageBio Process Problem 1AshenafiNo ratings yet

- Aqa Bya1 Sms Jun09Document7 pagesAqa Bya1 Sms Jun09atbtbtbNo ratings yet

- Ethanol Absolute Lomb 201208XXDocument11 pagesEthanol Absolute Lomb 201208XXMarvvvNo ratings yet

- Satriana Et Al 2019 - European Journal of Lipid Science and TechnologyDocument1 pageSatriana Et Al 2019 - European Journal of Lipid Science and TechnologyMuhammad Dani SupardanNo ratings yet

- Stoichiometry Questions & AnswersDocument2 pagesStoichiometry Questions & Answersnosirat aladeNo ratings yet

- David Yu Zhang - Dynamic DNA Strand Displacement CircuitsDocument290 pagesDavid Yu Zhang - Dynamic DNA Strand Displacement CircuitsCogsmsNo ratings yet

- Lenox Catalogue PDFDocument40 pagesLenox Catalogue PDFInvotexNo ratings yet

- HS Analysis of AminesDocument10 pagesHS Analysis of AminesВиталий ШариповNo ratings yet

- PV Module IonDocument4 pagesPV Module IonrmalewarNo ratings yet

- Carbonyl CompoundsDocument34 pagesCarbonyl CompoundsprinceNo ratings yet

- Silva Et Al., 2013 Coffee FerDocument13 pagesSilva Et Al., 2013 Coffee FerYon SadisticNo ratings yet

- Khaled El Deeb Aquence 866 Process - ManualDocument39 pagesKhaled El Deeb Aquence 866 Process - ManualNew Wrld100% (1)

- Admixtures and Shotcrete DurabilityDocument7 pagesAdmixtures and Shotcrete DurabilityMulyawan WIdiasmanNo ratings yet