Professional Documents

Culture Documents

High Efficiency DC-to-AC Power Inverter

Uploaded by

Divyabharathi JanakiramanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High Efficiency DC-to-AC Power Inverter

Uploaded by

Divyabharathi JanakiramanCopyright:

Available Formats

High Efficiency DC-to-AC Power Inverter

K. H. EDELMOSER

Institute of Electrical Drives and Machines

Technical University Vienna

Gusshausstr. 27-29, A-1040 Wien

AUSTRIA

Abstract: In case of medium voltage (several tenth up to hundred volts on DC-side) solar inverter applications a

DC-to-DC converter for voltage level adaptation is required in front of the DC-to-AC inverter. This leads to a

two-stage concept with accumulation of the losses. In our case a concept has to be chosen, where the efficiency

in each stage is maximized by usage of the best-fit topology. The given requirements force the application of a

non-isolated design to avoid additional transformer losses. In this paper a 60V-120V DC (input) to 230V AC

(output) / 1kW converter with minimal conversion losses is derived. A simple modification in the inverters

output section lead to a significant improvement of the losses in the inverter system. Only three additional

components (two diodes and one inductor) are necessary to optimize the inverters power stage. The topology

presented here shows a remarkable improvement of the switching losses and significantly reduced EMC. It is

well suited for solar power inverter applications.

Keywords: Inverter, Solar Power, PWM, efficiency

1. Introduction: storage elements and coupling filters) which leads

to an expensive design and increasing losses. Also

Switching mode PWM inverters are industrial the switching ripple in the output waveform due to

standard in the field of power conversion the limited switching frequency requires a complex

applications. The starting point of our EMC-filter.

investigations was a solar inverter with the goal of

very high efficiency operating on the European In conventional solutions mostly standard halve-

power grid (230V). Driving stages for high bridge switching legs where used [3]. The main

dynamic actuators and small motor drives are disadvantage in these topologies is the dedicated

another field of application. The proposed inverter current peak when the opposite power switch is

circuit can also be used as a high quality Class-D turned on. Due to the poor body diodes (even

amplifier for audio applications. In this paper a new modern power MOSFET’s imply a rather weak

concept is shown which increases the output signal diode compared to dedicated discrete components)

quality to meet high power quality, and reduces the the switching losses of the system will increase.

electromagnetic disturbance caused by the current Furthermore also the EMC will become more

peaks of the power switch diode reverse recovery. problematic. To overcome these topics normally

As a result the over all efficiency is major the switching speed of the power semiconductor

improved. has to be limited explicit resulting in a further

increase of the losses [4].

The main drawback of conventional PWM-

inverters (cf. Fig. 1) operating from a 350V DC- To overcome the known drawbacks a topology was

link is the wide dynamic range of the output chosen, where the inverters power stage discharged

voltage (0..320V in our case), and the required from switching current peaks. The separated

switching frequency (for minimizing the energy components (power switch and diode) are used to

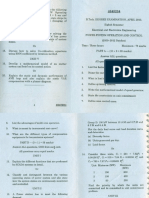

Fig. 1. Direct-coupled DC-to AC solar inverter with voltage DC-link

Fig. 2. Improved Power stage of the DC-to AC inverter

optimise the systems behaviour. So the switching

speed can be increased and the required EMC-filter

will be minimized. The optimised switching

structure introduced in this paper leads to a more

effective design. Furthermore a very simple control

scheme (similar to normal PWM operation) can be

used, while the efficiency is maximized.

Figure 2 depicts the converters topology. It consists

of two stages, a DC-to-DC converter (a) and a DC-

to-AC inverter (b).

The step-up / inverting DC-to-DC converter uses an

optimised structure for alternating operation.

Depending on the load current polarity normally

only one direction has to be operated. During

positive load current shape the step-up structure,

formed by S2 & D2 is used (S1 turned on

continuously). At the opposite load current

direction the inverting structure formed by S1 & D1

is used (S2 turned on continuously) is used. The

improvement compared do standard solutions are

the omission of one inductor. Furthermore only one Fig. 3.a. & 3.b. Operation of the step up DC-to-DC

power switch is PWM-operated resulting in Converter

switching losses; the second one shows only The tow operating modes are used in conjunction

conduction losses. with the inverters output voltage polarity.

In the inverter stage (b) a modified halve bridge Depending on the output current direction the

structure is used. Simulation results shows, that the energy flow into the positive respectively negative

switching losses can be reduced by a factor of more DC-rail can be separated by an intelligent

then 10 compared to conventional hard switching controlling algorithm leading to a minimization of

halve bridge stages, when modern components are the switching cycles in the DC-to-DC converter.

used. The excessive current peaks in a switching

leg resulting from the hard switched opposite body-

diode of a power MOSFET in conventional halve-

bridge inverters can be avoided. The application of

modern diodes (SiC) can be used here for further

optimisation.

2. DC/DC Converter Operation

Figure 3 shows the four switching states of the

proposed inverter. In Figs. 3.a and 3.b the step-

down operation is clarified while Figs. 3.c and 3.d

Fig. 3.c. Operation of the inverting DC-to-DC

show the step-up operation.

Converter (driving phase)

Driving phase (S3 is turned on); duty cycle d, cycle

duration T: 0 < t < d * T:

U DCL

−UM

iL(t ) = iL(t =0) + 2 ⋅t

L

1.) Free-wheeling (current path through D3):

d*T<t<T

U DCL

−UM

iL(t ) = iL(t =tON ) − 2 ⋅t

L

Fig. 3.c. Operation of the inverting DC-to-DC This leads to

Converter (free-wheeling phase) U DCL

−UM

U − 2 ⋅U M 2

iL(t ) = iO + DCL ⋅ d ⋅T − .

Especially a weak DC-rail (high dynamic internal L L

resistance generated by the voltage regulator) can When the DC-link voltage and the mains voltage is

be used for further efficiency improvement. known (can be measured directly) the output

current of the inverter can therefore directly be

controlled by the duty-cycle of the switching stage.

3. DC-to-AC Inverter Operation:

The DC-to-AC inverter operation can also be

divided into four sections depending on output

polarity and switching state:

Fig. 4.a. Operation of the DC-to-AC Converter,

positive output voltage, driving phase

Fig. 4.c. & d. Operation of the DC-to-AC

Converter, negative output voltage

The Inverters section can handle both voltage and

both current directions and therefore especially

Fig. 4.b. Operation of the DC-to-AC Converter, well suited for local voltage generation (island

positive output voltage, freewheeling phase applications).

During positive output current (IM) flow the

switching leg formed by S3, D3 and Lc has to be 4. DC-to-DC Converter Simulation

used. Opposite to this state during the negative To determine the system behaviour o circuit level

output current shape the second switching leg (S3 based simulation (PSPICE) of the converter stage

D3 & Ld) has to be used. was performed. The results are depicted in Fig. 5

The output current of the step-down stages is (step up operation, ref. Fig’s 3.a. & 3.b.) and Fig. 6

formed by the control law (approximation) (inverting operation, ref. Fig’s 3.c. & 3.d.)

depending on the switching states: (converter start up).

20 5. DC-to-AC Converter Simulation

10

VG(S2)

In this section the combined inverter stage is

simulated and compared to a conventional hard

V(S2)[V]

-10

switched PWM stage operated at the same ambient

conditions. In this model a load power factor of 1 is

assumed, so that the polarity of the mains current

-20

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

-3

400

x 10

IM depend only on the polarity of the mains voltage

300

V(L1B)

shape. Figure 7 shows the simulation results of the

V(L1B),+UZK[V]

V(+UZK)

200 power stage. In the upper trace one can see the

100 reference current (standardized mains voltage),

0 below the resulting output current shape is shown.

-100

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 The lower trace depicts the PWM signals of each

t[s] -3

x 10 power switch (S3 respectively S4).

Fig. 5 DC-to-DC converter in Step-Up mode

20

IC

20

ISoll[A]

VG(S1) 0

10

V(S1)[V]

0 -20

0 0.002 0.004 0.006 0.008 0.01 0.012 0.014 0.016 0.018 0.02

-10 20

IM

IIst[A]

-20

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1 0

-3

x 10

200 -20

V(L1A) 0 0.002 0.004 0.006 0.008 0.01 0.012 0.014 0.016 0.018 0.02

V(L1A),-UZK[V]

V(-UZK) 20

0 VG(S3)

SW1,SW2

VG(S4)

0

-200

-20

-400 0 0.002 0.004 0.006 0.008 0.01 0.012 0.014 0.016 0.018 0.02

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

t[s]

t[s] -3

x 10

Fig. 6 DC-to-DC converter in inverting mode Fig. 7 switching behaviour of the improved inverter

stage

The simulation results are compared to a

To determine the quality of the mains current one

conventional Step-Up / Step-Down and an isolated

can see the output spectrum of the inverter in

(transformer coupled) PWM DC-to-DC converter

Figure 8. Here no additional filter is used. A simple

switching stage. Every case uses the same

mains coupling filter (which is always required in

component models so that simulation results can be

practical applications but not taken into

compared directly. The conclusion is given in

considerations here) will lead to a further

Table 1. As one can see the used topology can

improvement of the switching harmonics.

compare with a conventional Step-Up / -Down

solution. As an advantage here only one inductor is 2

required. The simulation based on the supply of the 10

DC-to-AC inverter stage as depicted in Fig. 4. 1

10

(alternating current flow with mains frequency,

power factor of one). The isolated topology deals 0

10

with the disadvantage of the two-step energy

conversion (DC-to-AC – PWM stage, transformer.

ISoll[A]

-1

10

AC-to-DC – rectifier, Filter).

-2

10

Pout New Top. - η UP/DN. - η Isolated- η

100W 92,4 % 92,4 % 85,5 % -3

10

200W 96,1 % 96,0 % 94,1 %

-4

500W 98,5 % 98,6 % 96,3 % 10

10

1

10

2

10

3

10

4

1kW 97,6 % 97,9 % 95,2 % t[s]

Fig. 8 Output Spectrum of the mains current,

Table 1 Efficiency of the DC-to-DC converter without Filter

The control is realizes by a simple bang-bang References:

controller and some additional logic for switching

[1] P.J. Wolfs, A current-sourced DC-DC

signal separation.

converter derived via the duality principle from

Table 2 compares the proposed switching stage the half-bridge converter, IEEE Transactions

with a conventional PWM inverter. The on Industrial Electronics, Volume 40, Issue 1,

improvement of the advanced topology can raise Feb. 1993, pp.: 139-144.

the efficiency by about 2%.

[2] V.J. Thottuvelil, G.C. Verghese, Analysis and

control design of paralleled DC/DC

Pout PWM - η New Top. - η

converters with current sharing, IEEE

100W 90,5 % 92,5 %

Transactions on Power Electronics, Volume:

200W 94,1 % 96,1 % 13 Issue: 4 , July 1998, pp.: 635-644.

500W 96,3 % 98,2 %

1kW 95,2 % 97,9 % [3] A.Tuladhar, H. Jin, T. Unger, K. Mauch and

Table 2 Efficiency conversion of the DC-to-AC Burnaby, B.C: "Control of Parallel Inverters

inverter in Distributed AC Power Supply with

Consideration of the Line Impedance Effect",

Applied Power Electronics Conference APEC

'98, pp. 321-329, Anaheim, California.

6. Conclusion

This new solution will improve the disadvantage of [4] K. H. Edelmoser: DC-to-DC Solar Power

hard-switched PWM power stages in conventional Converter for Parallel String Operation in

inverters. Due to the separation of the current paths Multi Source Structures, Proceedings of the

each switching leg can be optimised. Furthermore international Power Conversion Conference

the problem of the weak body diode can be PCIM '02, May 12-16, 2002, Nuremberg /

overcome. The result is a stage with significant Germany, pp. 381-386.

lowered current peaks when modern (e.g. SiC) [5] K. H. Edelmoser, F. A. Himmelstoss: “DC-to-

diodes are used. DC Solar Battery Converter Optimized for

The presented inverter stage leads to an Parallel Operation in Multi-Source

improvement of about 2% in over all efficiency. Structures”, Proceedings of the International

This helps to simplify power inverters in the Conference of Power and Energy Systems

medium power range (several kilowatts). IASTED (Euro-PES 2002), June 25-28, 2002,

Another advantage is the scaleable output power. Crete, Greece, pp.: 406-409.

The stage is optimal appropriated for parallel

operation due to its current source characteristics.

No additional external control is required.

The simple control principle of the step-down

power stages can easily be implemented in a

modern microcontroller without additional logic

support for the pulse pattern generator. A simple

PWM stage fulfils all the requirements. Also the

maximum power point tracking for the solar cells

can be implemented simply by monitoring the

system signals (UDLC and iM). The main drawback

of the topology is the additional required for the

separated power stage.

The new control topology can also be used to build

up redundant multiphase systems. The inverter

presented in this paper is a simple and effective

solution for medium power applications. The

concept is well suited for wind-, solar- and

renewable energy as well as aerospace applications.

Because of the improved efficiency e.g. battery

lifetime can be increased without any quality

reduction.

You might also like

- High Efficiency DC-to-AC Power Inverter With Special DC InterfaceDocument6 pagesHigh Efficiency DC-to-AC Power Inverter With Special DC InterfacestrahinjaNo ratings yet

- A Single Phase, Single Stage Three Level Boost DC - DC ConverterDocument5 pagesA Single Phase, Single Stage Three Level Boost DC - DC Converterijsret100% (1)

- Art3 - (S1), Florian Ion, 17-22Document6 pagesArt3 - (S1), Florian Ion, 17-22camiloNo ratings yet

- Zeta Converter PDFDocument7 pagesZeta Converter PDFSreeram PanigrahiNo ratings yet

- Transformer Less DC - DC Converter With High Step Up Voltage Gain MethodDocument6 pagesTransformer Less DC - DC Converter With High Step Up Voltage Gain Methodsurendiran123No ratings yet

- Traiki2018 FormulaDocument6 pagesTraiki2018 FormulaTamilselvanNo ratings yet

- Non-Control Transformer Inrush Current: A LimiterDocument6 pagesNon-Control Transformer Inrush Current: A LimiterNohelia CruzNo ratings yet

- 018 Sheshidar - MP JESTEC PublnDocument14 pages018 Sheshidar - MP JESTEC Publnmprabhakar.ped1573No ratings yet

- PCM BuckboostDocument5 pagesPCM BuckboostDipanjan DasNo ratings yet

- Cuk For Power Factor CorrectionDocument4 pagesCuk For Power Factor CorrectionRichard MadandaNo ratings yet

- Sandy 123Document9 pagesSandy 123Sandy RonaldoNo ratings yet

- Three-Phase Rectifier Using A Sepic DC-DC Converter in Continuous Conduction Mode For Power Factor CorrectionDocument7 pagesThree-Phase Rectifier Using A Sepic DC-DC Converter in Continuous Conduction Mode For Power Factor CorrectionuakragunathanNo ratings yet

- International Journal of Engineering Research and Development (IJERD)Document7 pagesInternational Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- Cuk Converter State SpaceDocument5 pagesCuk Converter State SpaceEdu Daryl MacerenNo ratings yet

- Ab1e2282cb851c3 Ek ImportantDocument5 pagesAb1e2282cb851c3 Ek ImportantulaganathanNo ratings yet

- Closed Loop Control Design of Two Inductor Current-Fed Isolated DC-DC Converter For Fuel Cells To Utility Interface ApplicationDocument8 pagesClosed Loop Control Design of Two Inductor Current-Fed Isolated DC-DC Converter For Fuel Cells To Utility Interface ApplicationNagababuMutyalaNo ratings yet

- A Novel ZCS-PWM Flyback Converter With A Simple ZCS-PWM Commutation CellDocument9 pagesA Novel ZCS-PWM Flyback Converter With A Simple ZCS-PWM Commutation CellSHIVIKA BISARIANo ratings yet

- High-Step-Up DC-DC Converter Using Voltage Multiplier Cell With Ripple Free Input CurrentDocument6 pagesHigh-Step-Up DC-DC Converter Using Voltage Multiplier Cell With Ripple Free Input Currentkunalkundanam1046No ratings yet

- A New Single Switch Buck-Boost Type DC-DC ConverterDocument4 pagesA New Single Switch Buck-Boost Type DC-DC ConverterRaveendhra IitrNo ratings yet

- Analysis of Non-Isolated Bidirectional DC-DC Converter With ZVSDocument7 pagesAnalysis of Non-Isolated Bidirectional DC-DC Converter With ZVSAnuja VargheseNo ratings yet

- Bidirectional DC-DC Conversion in The Traction DriveDocument4 pagesBidirectional DC-DC Conversion in The Traction DrivegacalaNo ratings yet

- A Novel Buck Boost InverterDocument8 pagesA Novel Buck Boost InverterskrtamilNo ratings yet

- PPTPRITYDocument27 pagesPPTPRITYPrity kumariNo ratings yet

- Matlab Simulation of High Step-Up DC-DC ConverterDocument10 pagesMatlab Simulation of High Step-Up DC-DC ConverterANAMIKA DASNo ratings yet

- Analysis of Single Switch Step Up DC-DC Converter For Alternative Energy SystemsDocument6 pagesAnalysis of Single Switch Step Up DC-DC Converter For Alternative Energy SystemsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design of Transformer-Less DC To AC Converter Using PWM TechniqueDocument6 pagesDesign of Transformer-Less DC To AC Converter Using PWM TechniqueHariesh WaranNo ratings yet

- Implementation of High Step-Up Solar Power Optimizer For DC Micro Grid ApplicationDocument5 pagesImplementation of High Step-Up Solar Power Optimizer For DC Micro Grid ApplicationMeral MeralNo ratings yet

- 9 271Document11 pages9 271Алексей ЯмаNo ratings yet

- Analysis of Buck Converter and Simulating It For Different Switching Frequencies and Different Power DevicesDocument6 pagesAnalysis of Buck Converter and Simulating It For Different Switching Frequencies and Different Power DevicesPrema Vinod PatilNo ratings yet

- 고전압비와 낮은 전압 스트레스를 가진 단일 스위치와 전압 체배 회로를 이용한 새로운 비절연형 DC-DC 컨버터Document5 pages고전압비와 낮은 전압 스트레스를 가진 단일 스위치와 전압 체배 회로를 이용한 새로운 비절연형 DC-DC 컨버터Armandinho CaveroNo ratings yet

- Energies: Modular Battery Charger For Light Electric VehiclesDocument21 pagesEnergies: Modular Battery Charger For Light Electric VehiclesOsito de AguaNo ratings yet

- Transformerless DC-DC Converters With High Step-Up Voltage GainDocument9 pagesTransformerless DC-DC Converters With High Step-Up Voltage Gainr.ebrahimi1993No ratings yet

- Zeta DC-DCDocument8 pagesZeta DC-DCferdous sovonNo ratings yet

- Analysis of Notching in Marine Power Electronic DrivesDocument5 pagesAnalysis of Notching in Marine Power Electronic Drivespadmasiri1No ratings yet

- CUK ConverterDocument4 pagesCUK Converterranjitheee1292No ratings yet

- Power Converter Selection For Electric VehiclesDocument7 pagesPower Converter Selection For Electric VehiclesVarun TalwalkarNo ratings yet

- Design and Simulation of Pulse-Width Modulated ZETA Converter With Power Factor CorrectionDocument7 pagesDesign and Simulation of Pulse-Width Modulated ZETA Converter With Power Factor CorrectionRama KrishnaNo ratings yet

- Design of Isolated Interleaved Boost DC-DC Converter Based On Sic Power Devices For Microinverter ApplicationsDocument6 pagesDesign of Isolated Interleaved Boost DC-DC Converter Based On Sic Power Devices For Microinverter Applicationsgrasia77No ratings yet

- Soft Switched High Step-Up DC-DC Converter For Automotive ApplicationDocument4 pagesSoft Switched High Step-Up DC-DC Converter For Automotive Applicationkarthi.r.tNo ratings yet

- Single Stage Inverter Topology For Renewable Resources: Jeena Mary Abraham, M.S.P. Subathra, Senraj. RDocument5 pagesSingle Stage Inverter Topology For Renewable Resources: Jeena Mary Abraham, M.S.P. Subathra, Senraj. RskrtamilNo ratings yet

- Generalized Average Modeling of Dual ActiveDocument7 pagesGeneralized Average Modeling of Dual ActiveHarsh ChittoraNo ratings yet

- Research Article: Embedded Controlled Isolated Bidirectional Full-Bridge DC-DC Converter With Flyback SnubberDocument11 pagesResearch Article: Embedded Controlled Isolated Bidirectional Full-Bridge DC-DC Converter With Flyback SnubberBalaji Narayanan NNo ratings yet

- Voltage-Lift-Type Cu K Converters: Topology and Analysis: M. Zhu F.L. LuoDocument14 pagesVoltage-Lift-Type Cu K Converters: Topology and Analysis: M. Zhu F.L. LuomenguemengueNo ratings yet

- Power Electronics Exam 2017 SolutionsDocument13 pagesPower Electronics Exam 2017 SolutionsBakri BugaNo ratings yet

- High voltage gain DC/DC converter with cascaded structureDocument6 pagesHigh voltage gain DC/DC converter with cascaded structureNiharika DeshpandeNo ratings yet

- High Gain PaperDocument5 pagesHigh Gain PaperYuvaraj GopalNo ratings yet

- Improved Step Down Conversion in Interleaved Buck Converter and Low Switching LossesDocument10 pagesImproved Step Down Conversion in Interleaved Buck Converter and Low Switching LossesinventyNo ratings yet

- Non Isolated Bidirectional DC DC ConverterDocument6 pagesNon Isolated Bidirectional DC DC ConverterAnuja VargheseNo ratings yet

- High-Frequency Soft-Switching DC-DC Converters For Voltage and Current DC Power SourcesDocument18 pagesHigh-Frequency Soft-Switching DC-DC Converters For Voltage and Current DC Power SourcesFaraz AhmadNo ratings yet

- Switched Inductor Z-Source Matrix Converter Operation and AnalysisDocument9 pagesSwitched Inductor Z-Source Matrix Converter Operation and AnalysisA'Platinum EngNo ratings yet

- ZVZCS ConverterDocument7 pagesZVZCS ConverterefremofeNo ratings yet

- Bee4223:Power Electronics and Drive SystemsDocument7 pagesBee4223:Power Electronics and Drive SystemsChiam Tat MingNo ratings yet

- Current Mirror 1Document5 pagesCurrent Mirror 1Shaheer DurraniNo ratings yet

- Switching Converters With Wide DC Conversion Range: Dragan Maksimovic, and Slobodan CukDocument7 pagesSwitching Converters With Wide DC Conversion Range: Dragan Maksimovic, and Slobodan CukB DivyaNo ratings yet

- One-Quadrant Switched-Mode Power Converters: R. PetrocelliDocument26 pagesOne-Quadrant Switched-Mode Power Converters: R. PetrocelliClaudiu UdrescuNo ratings yet

- Buck Inverter Generates AC WaveformDocument5 pagesBuck Inverter Generates AC WaveformRexy RamadhanNo ratings yet

- DC Transformers 77Document15 pagesDC Transformers 77Keshavamurthy MurthyNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- HVDC Transmission May.2016Document2 pagesHVDC Transmission May.2016Divyabharathi JanakiramanNo ratings yet

- Leave Form PDFDocument4 pagesLeave Form PDFDivyabharathi JanakiramanNo ratings yet

- Power System Operation and Control Apr-May '17Document2 pagesPower System Operation and Control Apr-May '17Divyabharathi JanakiramanNo ratings yet

- Embedded Project ListDocument14 pagesEmbedded Project ListDivyabharathi JanakiramanNo ratings yet

- L6 Nces Unit 6Document1 pageL6 Nces Unit 6Divyabharathi JanakiramanNo ratings yet

- Design and Construction of Vertical Axis Wind TurbineDocument6 pagesDesign and Construction of Vertical Axis Wind TurbineDivyabharathi JanakiramanNo ratings yet

- MPPTDocument49 pagesMPPTwangha650% (2)

- Soon Ching ChunDocument45 pagesSoon Ching ChunDivyabharathi Janakiraman100% (1)

- Indusrtial Management - May.2016Document2 pagesIndusrtial Management - May.2016Divyabharathi JanakiramanNo ratings yet

- Btech New Syllabus PDFDocument119 pagesBtech New Syllabus PDFDivyabharathi Janakiraman100% (1)

- PLC Agri PDFDocument4 pagesPLC Agri PDFDivyabharathi JanakiramanNo ratings yet

- SET-90. UPS Battery Monitoring System Over GSM For High Availability SystemsDocument4 pagesSET-90. UPS Battery Monitoring System Over GSM For High Availability Systemssai raparthiNo ratings yet

- Design and Construction of Vertical Axis Wind Turbine PDFDocument8 pagesDesign and Construction of Vertical Axis Wind Turbine PDFJafarShojaNo ratings yet

- Automotive Electrical SystemsDocument101 pagesAutomotive Electrical SystemsMos CraciunNo ratings yet

- p1 PDFDocument4 pagesp1 PDFDivyabharathi JanakiramanNo ratings yet

- PV PDFDocument237 pagesPV PDFfaizNo ratings yet

- Mitsubishi Electric HD Technicians GuideDocument52 pagesMitsubishi Electric HD Technicians Guideadi22-22100% (1)

- High Efficiency DC-to-AC Power Inverter With Special DC InterfaceDocument6 pagesHigh Efficiency DC-to-AC Power Inverter With Special DC InterfaceDivyabharathi JanakiramanNo ratings yet

- DS1104 R&D Controller Board: Cost-Effective System For Controller DevelopmentDocument6 pagesDS1104 R&D Controller Board: Cost-Effective System For Controller DevelopmentMhmoud Al-TamimiNo ratings yet

- DT03 FinalDocument67 pagesDT03 FinalMuhamad Rizal Ibnu AbdulahNo ratings yet

- New ProjectDocument13 pagesNew Projectkaran gargNo ratings yet

- ED1000Document4 pagesED1000Mohamed TahounNo ratings yet

- Powerflex 6000 Medium Voltage Variable Frequency Drive Communications SpecificationsDocument29 pagesPowerflex 6000 Medium Voltage Variable Frequency Drive Communications SpecificationsJOSENo ratings yet

- Zerone: Safety Drone With Blade-Free Propulsion: Wataru Yamada Hiroyuki Manabe Daizo IkedaDocument8 pagesZerone: Safety Drone With Blade-Free Propulsion: Wataru Yamada Hiroyuki Manabe Daizo IkedaНикола ЈовановићNo ratings yet

- (Dust Suppression SystemDocument4 pages(Dust Suppression SystemJhonny ManjarrezNo ratings yet

- Course Plan-Power ElectronicsDocument5 pagesCourse Plan-Power ElectronicsNarasimman DonNo ratings yet

- Calibration Procedure For Pulse Function Arbitrary Noise Generator, Agilent Model 81150a - Tb-9-6625-2402-24Document35 pagesCalibration Procedure For Pulse Function Arbitrary Noise Generator, Agilent Model 81150a - Tb-9-6625-2402-24luroguita100% (2)

- MP3389 r1.04Document16 pagesMP3389 r1.04Kevin Yang YangNo ratings yet

- DatasheetDocument40 pagesDatasheetjisa technologyNo ratings yet

- DC-DC Converter Guide: Chopper Circuits ExplainedDocument70 pagesDC-DC Converter Guide: Chopper Circuits ExplainedSri T. Suneel Assistant Professor, EEE DepartmentNo ratings yet

- DC to AC Inverter GuideDocument33 pagesDC to AC Inverter Guideबृजभूषणशर्माNo ratings yet

- Calculator SamebikeDocument8 pagesCalculator SamebikeRobert BaltatuNo ratings yet

- MG20B602Document110 pagesMG20B602Diego Alejandro Gallardo IbarraNo ratings yet

- Space Vector Pulse Width Modulation PDFDocument5 pagesSpace Vector Pulse Width Modulation PDFnarendra kumarNo ratings yet

- Mechanical RF Phase - ShifterDocument33 pagesMechanical RF Phase - ShifterutammarryNo ratings yet

- ST Digital Motion Engine DriversDocument75 pagesST Digital Motion Engine DriversminitecoNo ratings yet

- Variable Frequency DriveDocument9 pagesVariable Frequency DriveOsama SalemNo ratings yet

- UntitledDocument50 pagesUntitledYoussef JahidNo ratings yet

- Wireless Control of A DC Motor....Document31 pagesWireless Control of A DC Motor....NelarapuMaheshNo ratings yet

- Standard Microcircuit Drawing: Microcircuit, Linear, High Speed Differential Line Driver, Monolithic SiliconDocument15 pagesStandard Microcircuit Drawing: Microcircuit, Linear, High Speed Differential Line Driver, Monolithic SiliconmandameloaNo ratings yet

- A History of Sampling (Hugh Davies)Document9 pagesA History of Sampling (Hugh Davies)Dale GarlandNo ratings yet

- Ci Uc2526n (Illig, Fonte)Document11 pagesCi Uc2526n (Illig, Fonte)Jonathas Carioca FernandesNo ratings yet

- Re95203 2007-11 PDFDocument20 pagesRe95203 2007-11 PDFrenatNo ratings yet

- Harmonic Elimination in Three-Phase Voltage SourceDocument9 pagesHarmonic Elimination in Three-Phase Voltage SourceDaniloNo ratings yet

- Power Electronics Media Tensión PDFDocument88 pagesPower Electronics Media Tensión PDFPato LlumiNo ratings yet

- Resume for Electrical EngineerDocument2 pagesResume for Electrical EngineerAKRJN4uorhjnfIUhwj983edilkmw3IJKMNo ratings yet

- Design and Implementations of Control System Quadruped Robot Driver Application Based On Windows PlatformDocument8 pagesDesign and Implementations of Control System Quadruped Robot Driver Application Based On Windows Platformpuskesmas III denpasar utaraNo ratings yet

- AVC FAN Catalog 10 2017Document78 pagesAVC FAN Catalog 10 2017FRANCISCO JAVIER RODRIGUEZ LEAL0% (1)