Professional Documents

Culture Documents

Buok Chapter 1

Uploaded by

Edmil Jhon Ariquez0 ratings0% found this document useful (0 votes)

14 views11 pageschapter 1

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentchapter 1

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views11 pagesBuok Chapter 1

Uploaded by

Edmil Jhon Ariquezchapter 1

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 11

CHAPTER I

1.0 PLANT LOAD CALCULATION

1.1 STATEMENT OF THE PROBLEM

Design of a 10.832 MW, 2708kW x 4 units of diesel power

plant on the daily load demand of town 5.

DAILY LOAD DEMAND

TIME, hr LOAD TIME, hr LOAD

12MN 4500 1:00 PM 6100

1:00 AM 3600 2:00 PM 5000

2:00 AM 3000 3:00 PM 6000

2:30 AM 3500 4:00 PM 7000

3:00 AM 3500 5:00 PM 7500

4:00 AM 4000 6:00 PM 8000

5:00 AM 4100 6:30 PM 8750

6:00 AM 4500 7:00 PM 8750

7:00 AM 5000 8:00 PM 9100

7:30 AM 5200 9:00 PM 9000

8:00 AM 5200 10:00 PM 7000

9:00 AM 6100 11:00 PM 5000

10:00 AM 6500 12 MN 4750

11:00 AM 7000

12 NN 7200

Generator Set used:

MAK M25C

2708 Kw each, 60 Hz,720 rpm

Installed Capacity: 2,708 kW x 4 units = 10,832 kW

Power Plant Engineering - Design of Diesel Power Plant 1

1.2 DAILY ENERGY PRODUCED

The daily energy produced is equal to the area under the curve

and is computed using the formula for area of trapezoid, rectangle

and triangle for this instance.

1

AT = (a+b)(h)

2

Thus, Daily kW – hrs Energy = Areas under the curve

Daily Energy Produced

4,500 3,600 kW 1hr 4,500 5,000kW 1 hr

A1 A8

2 2

A 4,050 kW hr A 4,750 kW hr

1 8

3,600 3,000 kW 1 hr 5,000 5,200 kW 0.5hr

A2 A9

2 2

A 3,300 kW hr A 2,550 .0kW hr

2 9

3,000 3,500 kW 0.5hr 5,200 5,200 kW 0.5 hr

A3 A10

2 2

A 1,625 kW hr A 2,600 kW hr

3 10

3,500 3,500 kW 0.5hr 5,200 6,100 kW 1 hr

A4 A11

2 2

A 1,750 kW hr A 5,650 kW hr

4 11

3,500 4,000 kW 1 hr 6,100 6,500 kW 1 hr

A5 A12

2 2

A 3,750 kW hr A 6 300 kW hr

5 12

4,000 4,100 kW 1 hr 6,500 7,000 kW 1 hr

A6 A13

2 2

A 4,050 kW hr A13 6,750 kW hr

6

4,100 4,500 kW 1 hr 7,000 7,200 kW 1 hr

A7 A14

2 2

A 4,300 kW hr A 7,100 kW hr

7 14

Power Plant Engineering - Design of Diesel Power Plant 2

7,200 6,100 kW 1 hr 9,000 7,000 kW 1 hr

A15 A 25

2 2

A 6,650 kW hr A 8,000 kW hr

15 25

6,100 5,000 kW 1 hr 7,000 5,000 kW 1 hr

A16 A 26

2 2

A 5,550 kW hr A 26 6,000 kW hr

16

5,000 6,000 kW 1 hr 5,000 4,7500 kW 1 hr

A17 A 27

2 2

A 5,500 kW hr A 27 4,875 kW hr

17

6,000 7,000 kW 1 hr

A18

2

A 6,500 kW hr

18

7,000 7,500 kW 1 hr

A19

2

A 7, 250 kW hr

19

7,500 8,000 kW 1 hr

A 20

2

A 7,750 kW hr

20

8,000 8,750 kW 0.5hr

A 21

2

A 4,187 .50 kW hr

21

8,750 8,750 kW 0.5hr

A 22

2

A 4,375 kW hr

22

8,750 9,100 kW 1 hr

A 23

2

A 8,925 kW hr

23

9,100 9,000 kW 1 hr

A 24

2

A 9,050 kW hr

24

Power Plant Engineering - Design of Diesel Power Plant 3

For daily energy produced, AT = A1 + A2 + A3 ... + An

= 143,137.50 kW- hr

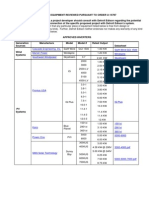

1.2 PLANT FACTOR CALCULATION

Design and Operating Conditions:

Engine Manufacturer MAK

Engine Model 9M25C Diesel engine

Generator Rating 2708 kW

1.3 Installed Capacity, IC

IC Diesel Genset Rating Number of Units Installed

IC 2,708 kW unit 4 units

IC 10,832 kW

1.4 Reserve Over Peak Load, ROPL

ROPL Installed Capacity Peak LOad

ROPL 10,832 9,100 kW

ROPL 1,732 kW

1.5 Average Load, AL

Daily Energy Produced

AL

Hours in Operation

143,137.50 kW hr

AL

24 hr

AL 5964.06 kW

1.6 Load Factor, LF

Power Plant Engineering - Design of Diesel Power Plant 4

Average Load

LF x 100%

Peak Load

5964.06kW

LF x 100%

9,100 kW

LF 65.54%

1.7 Plant Capacity Factor, PCF

Daily Energy Produced

PCF x 100%

Plant Capacity Hours in Operation

143,137.50 kW hr

PCF x 100%

10,832 kW 24 hr

PCF 55.06%

1.8 Use Factor of each Unit, UFU

DAILY ENERGY PRODUCED

The daily energy produced is equal to the area under the curve

and is computed using the formula for area of trapezoid, rectangle

and triangle for this instance.

1 1

AT = (a+b)(h) AR =(b)(h) ATria = (b)(h)

2 2

1.8.1 1Use Factor of Unit # 1, UFU #1

Unit #1 daily energy produced

UFU#1=

Unit #1 capacity x Unit #1 hrs. of operation

Unit #1 daily energy produced=(b)(h)

Unit #1 daily energy produced=(24hr)(2708kw)

Unit #1 daily energy produced=64992kW-hr

Unit #1 daily energy produced

UFU#1=

Unit #1 capacity x Unit #1 hrs. of operation

Where: no. of hours of operation of unit #1 = 24 hours

64,992kW-hr

UFU#1=

2708kw-hr x 24 hrs

UFU#1= 100%

Power Plant Engineering - Design of Diesel Power Plant 5

Use Factor of Unit # 2, UFU # 2

Unit #2 daily energy produced

UFU#2=

Unit #2 capacity x Unit #2 hrs. of operation

1.8.2 For Unit #2 daily energy produced:

1

A1 = (4,500 − 3,600) + [1 × (3,600 − 2,708)] kw − hr

2

A1 =1,342 kw − hr

1

A2 = (3,600 − 3,000) + (3000 − 2,708) kw − hr

2

A2 = 592 kw − hr

A3 = (0.5 × 500)kw − hr + (3,000 − 2,708)kw − hr

A3 = 271 kw − hr

A4 = 0.5(3,500-2,708) kw − hr

A4 = 396 kw − hr

1

A5 = (1ℎ × 500𝑘𝑤) + (3,000ℎ − 2,708𝑘𝑤)

2

1

A5 = 1042kw − hrA6 = [1ℎ × (4,100 − 4,000)𝑘𝑤] + [1ℎ × (4,000 − 2,708)𝑘𝑤]

2

A6 = 1,342 kw − hr

1

A7 = [1ℎ × (4,500 − 4,100)𝑘𝑤] + [1ℎ𝑟 × (4,100 − 2,708)𝑘𝑤]

2

A7 = 1592kw − hr

1

A8 = [1ℎ × (500)𝑘𝑤] + [1ℎ𝑟 × (4,500 − 2,708)𝑘𝑤]

2

A8 = 2042 kw − hr

1

A9 = [0.5ℎ × (5,200 − 5,000)𝑘𝑤] + [0.5ℎ𝑟 × (5,000 − 2,708)𝑘𝑤]

2

A9 = 1,196 kw − hr

1

A10 = [0.5ℎ × (5,200 − 2,708)𝑘𝑤]

2

A10 = 1,246kw − hr

1

A11 = [1ℎ × (5,416 − 2,708)𝑘𝑤] − [0.25ℎ𝑟 × (5,416 − 5,200)𝑘𝑤]

2

A11 = 2,681 kw − hr

1

A12 = [5ℎ × (5,416 − 2,708)𝑘𝑤] − [0.5ℎ𝑟 × (5,416 − 5,000)𝑘𝑤]

2

A12 = 13,436 kw − hr

Power Plant Engineering - Design of Diesel Power Plant 6

1

A13 = [9ℎ × (5,416 − 2,708)𝑘𝑤] − [0.25ℎ𝑟 × (5,416 − 5,000)𝑘𝑤]

2

1

− [0.25ℎ𝑟 × (5,416 − 5,000)𝑘𝑤]

2

A13 = 24,268 kw − hr

1

A14 = [0.5ℎ × (5,200 − 5,000)𝑘𝑤] + [0.5ℎ𝑟 × (5,000 − 2,708)𝑘𝑤]

2

A14 = 2,167 kw − hr

AT = 53,513 kw-hr (total energy produced of Unit #2)

Unit #2 daily energy produced

UFU#2=

Unit #2 capacity x Unit #2 hrs. of operation

Where: no. of hours of operation of unit #2 = 15.217 hours

53,513 kw-hr

UFU#2=

2,708kw-hr x 24 hrs

UFU#2= 82.34%

1.8.3 Use Factor of Unit # 3, UFU # 3

Unit #3 daily energy produced

UFU#3=

Unit #3 capacity x Unit #3 hrs. of operation

For Unit #3 daily energy produced:

A1 =0.75h(6,100-2,708)kw

A1 = 513 kw-hr

1

A2 = [1ℎ × (6,500 − 6,100)𝑘𝑤] + [1ℎ𝑟 × (6,100 − 5,416)𝑘𝑤]

2

A2 =884kw-hr

1

A3 = [1ℎ × (7,000 − 6,500)𝑘𝑤] + [1ℎ𝑟 × (6,500 − 5,416)𝑘𝑤]

2

A3 = 1,334 kw-hr

1

A4 = [1ℎ × (7,200 − 7,000)𝑘𝑤] + [1ℎ𝑟 × (7,000 − 5,416)𝑘𝑤]

2

A4 =1,684kw-hr

1

A5 = [1ℎ × (7,200 − 6,100)𝑘𝑤] + [1ℎ𝑟 × (6,100 − 5,416)𝑘𝑤]

2

A5 =1,234kw-hr

A6 =0.5h(6,100-5,416)kw

Power Plant Engineering - Design of Diesel Power Plant 2

A6 =342kw-hr

1

A7 = (0.25h)(6,000-5,416)kw

2

A7 =73kw-hr

1

A8 = [1ℎ × (7,000 − 6,000)𝑘𝑤] + [1ℎ𝑟 × (6,000 − 5,416)𝑘𝑤]

2

A8 =1,084kw-hr

1

A9 = [1ℎ × (7,500 − 7,000)𝑘𝑤] + [1ℎ𝑟 × (7,000 − 5,416)𝑘𝑤]

2

A9 =1,834kw-hr

1

A10 = [1ℎ × (8,000 − 7,500)𝑘𝑤] + [1ℎ𝑟 × (7,500 − 5,416)𝑘𝑤]

2

A10 =2,334kw-hr

1

A11 = [5ℎ × (8,124 − 5,416)𝑘𝑤] − [ (0.5)ℎ𝑟 × (8,124 − 7,000)𝑘𝑤]

2

A11 =13,259kw-hr

1

A12 = [1ℎ × (7,000 − 5,416)𝑘𝑤]

2

A12 =792kw-hr

AT = 25,367 kw-hr (total energy produced of Unit #3)

Unit #3 daily energy produced

UFU#3=

Unit #3 capacity x Unit #3 hrs. of operation

Where: no. of hours of operation of unit #3 = 13.33 hours

25,367 kw-hr

UFU#3=

2708kw-hr x 13.33 hrs

UFU#3= 70.27%

1.8.4 Use Factor of Unit # 4, UFU # 4

Unit #4 daily energy produced

UFU#4=

Unit #4 capacity x Unit #4 hrs. of operation

For Unit #4 daily energy produced:

1

A1 = [0.5ℎ × (8,750 − 8,124)𝑘𝑤]

2

A1 =156.5kw-hr

A2 = [0.5ℎ × (8,750 − 8,124)𝑘𝑤]

A2 =313kw-hr

Power Plant Engineering - Design of Diesel Power Plant 3

1

A3 = [1ℎ × (9,100 − 8,750)𝑘𝑤] + [1ℎ𝑟 × (8,750 − 8,124)𝑘𝑤]

2

A3 =801kw-hr

1

A4 = [1ℎ × (9,100 − 9,000)𝑘𝑤] + [1ℎ𝑟 × (9,000 − 8,124)𝑘𝑤]

2

A4 =926kw-hr

1

A5 = [0.5ℎ × (9,000 − 8,124)𝑘𝑤]

2

A5 =219kw-hr

AT = 2415.50 kw-hr (total energy produced of Unit #4)

Unit #4 daily energy produced

UFU#4=

Unit #4 capacity x Unit #4 hrs. of operation

2415.50 kw − hr

UFU#4=

2,708 x 3.75hrs

UFU#4=29.73%

1.9 Plant Use Factor, PUF

Daily Energy Produced

PUF x 100%

Plant Capacity Hours in Operation

143,137.50 kW hr

PUF x 100%

10,832 kW 24 hr

PUF 55.06%

Power Plant Engineering - Design of Diesel Power Plant 4

SUMMARY OF PLANT FACTOR CALCULATION

Daily Energy Produced 143,137.50 kW-hr

Installed Capacity 10,832 kW

Reserve Over Peak Load 1,732 kW

Average Load 5,964.06kW

Load Factor 65.54 %

Plant Capacity Factor 55.06 %

Plant Use Factor 55.06 %

Use Factor of each Unit

Use Factor of Unit # 1 100%%

Use Factor of Unit # 2 82.34%%

Use Factor of Unit # 3 70.27%%

Use Factor of Unit # 4 29.73%

Power Plant Engineering - Design of Diesel Power Plant 5

Power Plant Engineering - Design of Diesel Power Plant 6

You might also like

- Harga Helicar Gear 2.1Document1 pageHarga Helicar Gear 2.1yuhuNo ratings yet

- Plant Load CalculationDocument4 pagesPlant Load CalculationRuby Jane LuchingNo ratings yet

- Gas Turbie Start Up MethodologyDocument22 pagesGas Turbie Start Up Methodologydirman dirmanNo ratings yet

- Genset Rent PriceDocument1 pageGenset Rent PriceNamer HajiNo ratings yet

- Fsel-Senvac-2.2 KW, 3.7 KW, 5.5 KW - CDocument9 pagesFsel-Senvac-2.2 KW, 3.7 KW, 5.5 KW - Ctechsupport techsupportNo ratings yet

- XVII Variable LoadDocument8 pagesXVII Variable LoadJerry B Cruz50% (2)

- CPA Electrical Valuation ReportDocument3 pagesCPA Electrical Valuation ReportSatyanarayanareddy AiluriNo ratings yet

- Load ComputationDocument2 pagesLoad ComputationBenjie PescadorNo ratings yet

- 23.268 Cu.m. ÷ 0.50 Cu.m. Per Hour (Reinforced Conc.)Document6 pages23.268 Cu.m. ÷ 0.50 Cu.m. Per Hour (Reinforced Conc.)nathanieldagsaNo ratings yet

- S/N Name Registration Number Sign: Group 2 MembersDocument3 pagesS/N Name Registration Number Sign: Group 2 MembersAkankwasa RonaldNo ratings yet

- 4/6 POLE MOTOR (1500/1000 RPM) - III/50HzDocument1 page4/6 POLE MOTOR (1500/1000 RPM) - III/50HzabdulNo ratings yet

- Abc Ta2Document6 pagesAbc Ta2Diana Idrogo CarranzaNo ratings yet

- Generated Through CPM (New Then Crashing)Document14 pagesGenerated Through CPM (New Then Crashing)Aiman BaigNo ratings yet

- Quote For 18m X 8m X 2m TugboatDocument4 pagesQuote For 18m X 8m X 2m TugboatTerryNo ratings yet

- Amir Sab 8.2 KW and 5HPDocument3 pagesAmir Sab 8.2 KW and 5HPch.ahmad90000000No ratings yet

- Annexure 12 - Tool For Economic Size of Pumping MainDocument6 pagesAnnexure 12 - Tool For Economic Size of Pumping MainnarendraNo ratings yet

- No Investasi Rincian Investasi Harga (RP) JumlahDocument12 pagesNo Investasi Rincian Investasi Harga (RP) JumlahMuhammad NazarudinNo ratings yet

- OPCC Load Calculation - New ConfigurationDocument2 pagesOPCC Load Calculation - New ConfigurationWendi HaryadiNo ratings yet

- HM 1 Drilling Engineering PMRE 6004Document3 pagesHM 1 Drilling Engineering PMRE 6004MD Redwan IslamNo ratings yet

- Brosur Harga 2021Document6 pagesBrosur Harga 2021Michael TressaNo ratings yet

- Project Cost EstimateDocument4 pagesProject Cost EstimateVinay MalpaniNo ratings yet

- Incoming 2022Document1 pageIncoming 2022Amira AdlinNo ratings yet

- SB Quot 002-16-16 For Generators Spare PartsDocument2 pagesSB Quot 002-16-16 For Generators Spare PartsMohammad Khalid BarakzaiNo ratings yet

- Kawasaki Gas Turbine PDFDocument45 pagesKawasaki Gas Turbine PDF13421301508100% (1)

- 2.3 Main Busbar, HorizontalDocument1 page2.3 Main Busbar, Horizontalashraf atefNo ratings yet

- 5.list Harga Bengkel Tasya MotorDocument1 page5.list Harga Bengkel Tasya MotorTio 27No ratings yet

- 2 Propulsive PowerDocument19 pages2 Propulsive PowerKumar AnshNo ratings yet

- LV Motors Price List LP MOT 199 1-12-18 BDocument36 pagesLV Motors Price List LP MOT 199 1-12-18 BVenkateshwar DevendlaNo ratings yet

- SHPC Solar Product Pricelist 2022 Q4Document4 pagesSHPC Solar Product Pricelist 2022 Q4EcosenseTechnologies GreenenergyNo ratings yet

- G120C Protective Device Prod Info 0618Document14 pagesG120C Protective Device Prod Info 0618AlexandreNo ratings yet

- G120C Protective Device Prod Info 0618Document14 pagesG120C Protective Device Prod Info 0618AlexandreNo ratings yet

- LF PLN 20 KV OFFDocument5 pagesLF PLN 20 KV OFFradintan18No ratings yet

- Smoke Heat Exhaust Fans SystemAirDocument12 pagesSmoke Heat Exhaust Fans SystemAirronaldsmar8500No ratings yet

- LF PLN Off (Overall)Document1 pageLF PLN Off (Overall)radintan18No ratings yet

- 10 Kawan Laam GeneratorDocument15 pages10 Kawan Laam GeneratorharisNo ratings yet

- ROOM NO. 001, 103, 201, 202, 203, 204, 205, & 206.: Faculty CabinsDocument3 pagesROOM NO. 001, 103, 201, 202, 203, 204, 205, & 206.: Faculty CabinsrohitNo ratings yet

- Speed R/min Frequency HZ Eng. KW Gen. KW Eng. KW Gen. KW 6L32/44CR 7L32/44CR 8L32/44CR 9L32/44CR 10L32/44CRDocument1 pageSpeed R/min Frequency HZ Eng. KW Gen. KW Eng. KW Gen. KW 6L32/44CR 7L32/44CR 8L32/44CR 9L32/44CR 10L32/44CRghostt123No ratings yet

- MitsubishiDocument8 pagesMitsubishiRaheem_ka67% (3)

- Appliances Prices List 090722 20220709191818Document2 pagesAppliances Prices List 090722 20220709191818Karan RajputNo ratings yet

- Energy Savings Measurement Guide BC - HydroDocument96 pagesEnergy Savings Measurement Guide BC - HydroJose Rafael Leon JacoboNo ratings yet

- Lithos High Voltage Brochure-Spec SheetDocument1 pageLithos High Voltage Brochure-Spec SheetHarris CohnNo ratings yet

- Technical Report FinalDocument16 pagesTechnical Report FinalKenneth Dwight BojaNo ratings yet

- Magnetic Amplifier1Document20 pagesMagnetic Amplifier1Aryan BatraNo ratings yet

- Recip Overview Brochure HSR OnlyDocument11 pagesRecip Overview Brochure HSR OnlyMuhammad ImranNo ratings yet

- Simulasi: No. Keterangan Vol Sat Harga Satuan Jumlah Harga SatDocument13 pagesSimulasi: No. Keterangan Vol Sat Harga Satuan Jumlah Harga SatagungNo ratings yet

- Baudouin PowerKit Brochure PDFDocument8 pagesBaudouin PowerKit Brochure PDFanto starlinNo ratings yet

- Steam Power Plant DesignDocument20 pagesSteam Power Plant DesignAlvin LoocNo ratings yet

- Cost of Rooftop Solar System (On-Grid, Off-Grid, Hybrid) in India - AlienSolarDocument2 pagesCost of Rooftop Solar System (On-Grid, Off-Grid, Hybrid) in India - AlienSolarManishDikshitNo ratings yet

- GOG Hydrology Report - AnjunemDocument61 pagesGOG Hydrology Report - AnjunemNeil AgshikarNo ratings yet

- 442SRDocument5 pages442SRLuis MansillaNo ratings yet

- Chapter 1 Load CalculationDocument11 pagesChapter 1 Load CalculationAlvin LoocNo ratings yet

- Cascade Engineering, Inc. Swift Wind GCI 1500 Mariah Power Windspire Southwest Windpower SkystreamDocument4 pagesCascade Engineering, Inc. Swift Wind GCI 1500 Mariah Power Windspire Southwest Windpower SkystreamGLCIINo ratings yet

- 6014 Guascor Energy Gas Engines Fuel Flexibility enDocument4 pages6014 Guascor Energy Gas Engines Fuel Flexibility enMuhammad SyaqirinNo ratings yet

- Gas Turbine PerformancexlsDocument15 pagesGas Turbine PerformancexlsMahmood ElnagarNo ratings yet

- Docs 80 SolarDocument7 pagesDocs 80 Solarsanthosh.hNo ratings yet

- 05 Energyefficientmotor2004Document31 pages05 Energyefficientmotor2004nageswara_mutyalaNo ratings yet

- Brochure o e w34dfDocument2 pagesBrochure o e w34dfalex.lenagroNo ratings yet

- Air Conditioner Brands Window Type Specs FinalDocument12 pagesAir Conditioner Brands Window Type Specs FinalRogelioB.AlobIINo ratings yet

- Enpi (Old) Production: Month Unit Jan Feb Mar Apr MayDocument3 pagesEnpi (Old) Production: Month Unit Jan Feb Mar Apr MayDuy Phong PhanNo ratings yet

- A Simple Method To Solve Quartic Equations: June 2012Document7 pagesA Simple Method To Solve Quartic Equations: June 2012Edmil Jhon AriquezNo ratings yet

- Edmil Jhon B. Ariques, ME: MembershipDocument3 pagesEdmil Jhon B. Ariques, ME: MembershipEdmil Jhon AriquezNo ratings yet

- Edmil Jhon B. Ariques, ME: MembershipDocument2 pagesEdmil Jhon B. Ariques, ME: MembershipEdmil Jhon AriquezNo ratings yet

- Curriculum VitaeDocument2 pagesCurriculum VitaeEdmil Jhon AriquezNo ratings yet

- Edmil Jhon B. Ariques, ME: MembershipDocument2 pagesEdmil Jhon B. Ariques, ME: MembershipEdmil Jhon AriquezNo ratings yet

- Edmil Jhon B. Ariques, ME: MembershipDocument2 pagesEdmil Jhon B. Ariques, ME: MembershipEdmil Jhon AriquezNo ratings yet

- Fil7 PDFDocument1 pageFil7 PDFEdmil Jhon AriquezNo ratings yet

- 8.list of Tables PDFDocument1 page8.list of Tables PDFEdmil Jhon AriquezNo ratings yet

- ResumeDocument2 pagesResumeEdmil Jhon AriquezNo ratings yet

- Resistance and Ohm's Law: I (Constant) X VDocument3 pagesResistance and Ohm's Law: I (Constant) X VEdmil Jhon AriquezNo ratings yet

- Introduction To Plastics Processing.Document55 pagesIntroduction To Plastics Processing.Edmil Jhon AriquezNo ratings yet

- Electric Force and ColoumbDocument1 pageElectric Force and ColoumbEdmil Jhon AriquezNo ratings yet

- Remittance Advice - Emily Bano AriquezDocument1 pageRemittance Advice - Emily Bano AriquezEdmil Jhon AriquezNo ratings yet

- ReviewerDocument84 pagesReviewerEdmil Jhon Ariquez100% (6)

- Ta 700022623 Ari QuesDocument1 pageTa 700022623 Ari QuesEdmil Jhon AriquezNo ratings yet

- Terminal 1Document2 pagesTerminal 1Edmil Jhon AriquezNo ratings yet

- Ta 700022832 Jagu I oDocument1 pageTa 700022832 Jagu I oEdmil Jhon AriquezNo ratings yet

- 20 CasesDocument10 pages20 CasesEdmil Jhon AriquezNo ratings yet

- Storage Tank Day Tank: From Daihatsu Diesel Genset CatalogueDocument34 pagesStorage Tank Day Tank: From Daihatsu Diesel Genset CatalogueEdmil Jhon Ariquez100% (1)

- Engineering Research JournalDocument3 pagesEngineering Research JournalEdmil Jhon AriquezNo ratings yet

- Algebra 4Document65 pagesAlgebra 4Michael Damian100% (1)

- Mix Seating Arrangement Quiz PDFDocument97 pagesMix Seating Arrangement Quiz PDFneethurj9No ratings yet

- 2014 Bebras Solution GuideDocument80 pages2014 Bebras Solution GuideNicoleta MarinescuNo ratings yet

- Battery Sizing NicdDocument4 pagesBattery Sizing NicdMandip Pokharel0% (1)

- Solving Polynomial SystemsDocument164 pagesSolving Polynomial SystemsChristophe LauwerysNo ratings yet

- 21 AlgorithmsDocument25 pages21 AlgorithmsLasierdo Maria Sol KristineNo ratings yet

- Tyco SwitchsDocument326 pagesTyco SwitchshammondelecNo ratings yet

- Synthesis, Characterization and Evaluation of Antimicrobial Profile of 4-Thiazolidinone DerivativesDocument7 pagesSynthesis, Characterization and Evaluation of Antimicrobial Profile of 4-Thiazolidinone DerivativesPharma Research LibraryNo ratings yet

- Image Clustering: Prof. Dr. Rafiqul Islam Department of CSEDocument26 pagesImage Clustering: Prof. Dr. Rafiqul Islam Department of CSEMainul IslamNo ratings yet

- Ioqm 1 23Document5 pagesIoqm 1 23Shakir MommandNo ratings yet

- ECE 4610 Outline Fall 2014 UManitobaDocument3 pagesECE 4610 Outline Fall 2014 UManitobanathaliaNo ratings yet

- Entire Solutions ManualDocument475 pagesEntire Solutions ManualGregory Puckett89% (18)

- ScrewMax Piston PumpDocument19 pagesScrewMax Piston PumpMaximus Maxis100% (7)

- Applied Sciences: Hesitant Fuzzy Linguistic Term and TOPSIS To Assess Lean PerformanceDocument13 pagesApplied Sciences: Hesitant Fuzzy Linguistic Term and TOPSIS To Assess Lean PerformancejvanandhNo ratings yet

- Portfolio in MathDocument8 pagesPortfolio in MathKeith Danae SuquibNo ratings yet

- Memorex Disney DVD2000-CSM DVD2000-9 PDFDocument45 pagesMemorex Disney DVD2000-CSM DVD2000-9 PDFIleana RuvalcabaNo ratings yet

- ISO27001 Mapping To IASME v1.1Document3 pagesISO27001 Mapping To IASME v1.1Bobby SharonNo ratings yet

- BMW m43Document38 pagesBMW m43ZakariaKalomar100% (2)

- Pilot Operated Pressure Relief Valve - Series Vr4VDocument10 pagesPilot Operated Pressure Relief Valve - Series Vr4VajaydevbNo ratings yet

- K Means Clustering Numerical Example PDF - Gate VidyalayDocument19 pagesK Means Clustering Numerical Example PDF - Gate Vidyalaypriyanshidubey2008No ratings yet

- Algorithms: CS 202 Epp Section ??? Aaron BloomfieldDocument25 pagesAlgorithms: CS 202 Epp Section ??? Aaron BloomfieldJosephNo ratings yet

- AGMA 2015 915-1-A02 Accuracy Classification System - Tangential Measurement Tolerance Tables ForDocument108 pagesAGMA 2015 915-1-A02 Accuracy Classification System - Tangential Measurement Tolerance Tables ForLeonardo PestanaNo ratings yet

- Modification of The Surface Chemistry of Activated CarbonsDocument11 pagesModification of The Surface Chemistry of Activated CarbonsVictor HugoNo ratings yet

- Colic BabyDocument109 pagesColic BabyVivek AryaNo ratings yet

- FL-2 - Book B - Online - PDocument28 pagesFL-2 - Book B - Online - PBijay Krishna DasNo ratings yet

- Tutorial Exercises Clustering - K-Means, Nearest Neighbor and HierarchicalDocument7 pagesTutorial Exercises Clustering - K-Means, Nearest Neighbor and HierarchicalAbdulKalamNo ratings yet

- ST95040 ST95020, ST95010: 4K/2K/1K Serial SPI EEPROM With Positive Clock StrobeDocument19 pagesST95040 ST95020, ST95010: 4K/2K/1K Serial SPI EEPROM With Positive Clock StrobeCristian Esteban TamashiroNo ratings yet

- Montant de Total Pour Demarer Un Projet de Trois Vaches LaitiereDocument11 pagesMontant de Total Pour Demarer Un Projet de Trois Vaches LaitiereAmoud MimouneNo ratings yet

- Totachi Filter CatalogueDocument1,065 pagesTotachi Filter CatalogueEslam MakhlofNo ratings yet

- CAN Mode 6Document12 pagesCAN Mode 6Abdulbaset Selwy100% (1)