Professional Documents

Culture Documents

Andrew's CV - September 2018

Uploaded by

Andrew CogerCopyright

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Andrew's CV - September 2018

Uploaded by

Andrew CogerCopyright:

Andrew Coger

Oxford, UK • (+44) 7380 432332 • ACoger25@gmail.com • www.AndrewCoger.co.uk

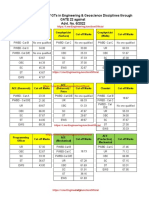

Engineering Synopsis

• Two Degrees: BSc in Materials Science and MSc in Mechanical Design

Engineering

• Head of Composites at Oxford Brookes Racing – Led composite design and

manufacturing processes for motorsport components

• Hands on experience – Full-cycle design and production involvement with

complex automotive assemblies

Education

Oxford Brookes University – MSc in Mechanical Engineering

Oxford, England - Sept. 2017 – Sept. 2018

• Distinction (expected)

• Dissertation Topic: Tyre Wake Management and Optimisation on Formula

Student Race Car (CFD)

• Relevant Courses: Advanced Mechanical Engineering Design I & II, Advanced

Expertise Materials and Strength of Components, CAD/CAM

Composite Layup

★★★★★ Michigan State University – BSc in Materials Science and Engineering

SEM, EDS, XRD, FTIR

East Lansing, Michigan - Aug. 2014 – May 2017

★★★★☆

Metallography

• 3.6 GPA (2:1)

★★★★★ • Undertook independent study investigating the effects of Omega Phase

StarCCM+ formation in Titanium and its alloys.

★★★★☆ • Relevant Courses: Advanced Composites, Microstructural Design, Mechanics,

CATIA V5 Synthesis and Processing of Material Systems

★★★★☆

SolidWorks

★★★★★ Extra-Curricular Activity

MATLAB Oxford Brookes Racing - Formula Student

★★★★☆ Sept. 2017 – Sept. 2018

Head of Composites, Aerodynamicist

• Worked in collaboration with design and manufacturing departments to derive

functional components with manufacturing practicality considered.

Interests • Introduced and implemented resin infusion composite manufacturing

techniques.

• Fostered partnership between OBR and carbon fibre suppliers to develop highly

optimized carbon fibre components.

• Lead the full-cycle design and production process for aerodynamic

Formula 1 College Football components featured on the 2018 race car.

• Assisted in the surface and mechanical design of various components using a

combination of CATIA V5 and Solidworks CAD software packages.

Michigan State University – Department of Mechanical Engineering

Happy Hour Cycling

Dec. 2016 – June 2017

Undergraduate Research Assistant

• Modelled and simulated water treatment technologies using Solidworks 2016

and ANSYS Workbench.

• Conducted multi-phase turbulent flow simulations using ANSYS Fluent.

• Utilized Michigan State University’s High-Performance Computing Center for

Aerospace Travelling various CFD simulations.

Michigan State University – Department of Materials Science and

Engineering

Jan. 2017 – June 2017

Undergraduate Research Assistant

• Assisted in the characterization of various metallic alloys using

techniques such as Scanning Electron Microscopy, Energy-dispersive X-ray

Spectroscopy, and X-Ray Photoelectron Microscopy.

• Received hands-on training with Scanning Electron Microscope, and X-

Ray Diffractometer.

Employment Record

Department of Environmental Quality - State of Michigan

East Lansing, Michigan - Jan. 2016 – Aug. 2017

Water Quality Lab Assistant

• Conducted the extraction and analysis of drinking water samples from

municipal sources around the state of Michigan.

• Worked directly with public samples using a variety of different extraction

techniques such as liquid-liquid and solid-phase extractions.

Accumed: Biomedical Systems

Ann Arbor, Michigan - Aug. 2012 – Aug. 2014

Assembler/Production Manager

• Responsible for managing inventory, assembling, cleaning, and packaging

medical devices.

Figure 1: SEM image taken during failure

• Worked directly with management to assist in the logistics sending and

analysis of ceramic plate.

receiving manufactured parts.

Societies & Clubs

Michigan State University Materials Science Engineers Society

• Led student-run help sessions for coursework related to materials science on a

weekly basis.

• Organized presentations from guest-speakers working in various industries such

as Automotive and Industrial Manufacturing.

Michigan State University Engineers for a Sustainable World

• Engaged in a student led team to design and build an environmentally conscious

botanical structure.

Michigan State University Racing Club

• Assisted in the organization of the MSU Racing Club Car Show with over 1500

attendees. Figure 2: Brake duct design featured on

OBR18

Recent Projects

OBR 18 Brake Duct Design

• Designed surface and mechanical model, tooling mould,

and additional rapid prototype flap.

• Utilised unique carbon fibre placement techniques to

improve weight, strength, and manufacturability.

• Minimised the effects of in-wash and tyre squirt.

• 28% increase in mass flow rate to underbody.

Opposed-Piston Opposed-Cylinder Engine Design

• Designed full kinematic assembly featuring over 30 bespoke

components designed from the ground up in CATIA V5.

• Generated technical drawings adhering to BS8888 standards.

• Fully parameterised design enabled rapid adjustment

of features such as bore, stoke, and cam timing.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Science Technology Society 2010 Gaillard 271 307Document38 pagesScience Technology Society 2010 Gaillard 271 307Joe MichaelsNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Understanding The Self: BACANI, Rochelle BALLO, Rizzle Marevic BANGAO, Samantha JuanetteDocument5 pagesUnderstanding The Self: BACANI, Rochelle BALLO, Rizzle Marevic BANGAO, Samantha JuanetteCharlene BalageoNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- EriksonDocument9 pagesEriksonGemma Rose EscañoNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- RPH Masa Peksa BIDocument3 pagesRPH Masa Peksa BISiti SafuraNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- COC2 Conduct DemoDocument9 pagesCOC2 Conduct DemonickNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 10 Minutes Check in Conversation GuideDocument3 pages10 Minutes Check in Conversation GuideAjisafe Jerry T-moneyNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Daftar PustakaDocument6 pagesDaftar PustakaSuci nstNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Language Used in Academic Texts From Various DisciplinesDocument29 pagesLanguage Used in Academic Texts From Various DisciplinesZarah Joyce SegoviaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- ONGC GATE 2022 Cut Off MarksDocument3 pagesONGC GATE 2022 Cut Off MarksSachin BhadanaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- A Level Math 13 Nov2011Document4 pagesA Level Math 13 Nov2011romNo ratings yet

- HR CompetenciesDocument17 pagesHR CompetenciesSoumyajit PradhanNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- No1 Answer: D: Soal Try Out Pemprov Paket BDocument14 pagesNo1 Answer: D: Soal Try Out Pemprov Paket BArul Hidayat0% (1)

- Jessica Brooks - Resume Nurs 419 1Document1 pageJessica Brooks - Resume Nurs 419 1api-469609100No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ldm2 (Lac # 15-001-03) - Amistouso, Darwin B.Document56 pagesLdm2 (Lac # 15-001-03) - Amistouso, Darwin B.Janna DatahanNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Ancient Mali Unit OverviewDocument38 pagesAncient Mali Unit Overviewapi-336329266No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- DLL - DressmakingDocument3 pagesDLL - DressmakingCatherine SantistebanNo ratings yet

- Unit Outline MIS 205Document4 pagesUnit Outline MIS 205Wasim HassanNo ratings yet

- Digitally Connected HarvardDocument130 pagesDigitally Connected HarvardWilliam HenryNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- National Policy On Education (NPE 1986)Document11 pagesNational Policy On Education (NPE 1986)deepak kumarNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- CBM IndexDocument8 pagesCBM IndexSaili SarmalkarNo ratings yet

- M2Me Ivb 24Document6 pagesM2Me Ivb 24ZOSIMA ONIANo ratings yet

- Cvsu HistoryDocument19 pagesCvsu HistoryDolly ApolinarioNo ratings yet

- ENG Prescribed Literature Gr7 12Document32 pagesENG Prescribed Literature Gr7 12LiShengNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Mug IlandsfsDocument4 pagesMug IlandsfsSurendran CoolstarNo ratings yet

- 4.2 Probability Diagrams - Tree & Venn Diagrams: Question PaperDocument7 pages4.2 Probability Diagrams - Tree & Venn Diagrams: Question PaperharshalsachdevNo ratings yet

- 0510 s18 QP 21 PDFDocument16 pages0510 s18 QP 21 PDFChernYangEeNo ratings yet

- Semantics: The Basic NotionsDocument71 pagesSemantics: The Basic NotionsAhmad YusufNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- KKU-Scholar II (Letter of Recommendation) 2021Document3 pagesKKU-Scholar II (Letter of Recommendation) 2021Fearless BaekhyunNo ratings yet

- CPHL214 SyllabusDocument3 pagesCPHL214 SyllabusAnnNo ratings yet

- Bhavika Therani CVDocument2 pagesBhavika Therani CVBhavika TheraniNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)