Professional Documents

Culture Documents

Tecs HF 0251 1954 200910 GB PDF

Uploaded by

Leuce LaviniuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tecs HF 0251 1954 200910 GB PDF

Uploaded by

Leuce LaviniuCopyright:

Available Formats

Climaveneta Technical Bulletin

TECS_HF_0251_1954_200910_GB

TECS-HF

0251 - 1954 Water-cooled liquid chillers

241 - 1949 kW

(The photo of the unit is indicative and may change depending on the model)

< Unbeatable efficiency at part load

< Extremely silent operation

< Simplified logistics

< Low in rush current

TECS-HF

INDEX TECS-HF

0251 - 1954

Product presentation pg. n° III

Energetic indices IPLV and ESEER pg. n° IV

Tests pg. n° V

Unit description pg. n° 1

Versions pg. n° 2

Functions pg. n° 2

Accessories pg. n° 3

General technical data pg. n° 4

Cooling capacity performance pg. n° 7

Heat pump capacity performance pg. n° 15

Operating range pg. n° 20

Hydraulic data pg. n° 22

Electrical data pg. n° 24

Full load sound levels pg. n° 25

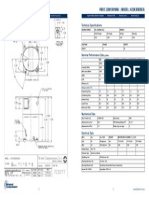

Dimensional drawings pg. n° A1

Legend of pipe connections pg. n° A5

Condensation control devices pg. n° B1

VPF systems pg. n° C1

This company partecipa- Eurovent certification ap-

tes in the Eurovent Certifi plied to units with cooling

cation Programme. The pro- capacity up to 1500 kW for

ducts are listed in the Directo- air cooled water chillers and

ry of certifi ed products. water cooled liquid chillers.

Company quality system

certifi ed to UNI EN ISO 9001

Liability disclaimer drawings and schemes. Climaveneta declines any liability deri-

This bulletin is not exhaustive about: installation, use, safety ved from the bulletin’s use. This bulletin is of exclusive property

precautions, handling and transport. Refer to “General Manual of Climaveneta, and all forms of copy are prohibited. The data

for Installation” for further informations. This bulletin refers to contained herein are subject to variation without notice.

standard executions, in particular for dimension, weight, elec-

tric, hydraulic, aeraulic and refrigerant connections (whereas

applicable). Contact Climaveneta Commercial Offi ce for further

II TECS-HF_0251_1954_200910_GB HFC R134a

TECS-HF

PRODUCT PRESENTATION

Very strict energy efficiency and sustainability require- Unbeatable efficiency at part load

ments

Reduced initial investment and running At partial load, TECS units are more

costs, compliance with increasingly strict efficient than traditional scroll/screw

energy consumption and environmental units, with ESEER values up to 60%

impact regulations, are becoming more higher. Running cost savings are evi-

and more crucial factors not only for real dent and consistent, especially when

estate valuation, but also in deciding if all year round operation is required.

the project should proceed.

Precise attention to comfort and noise emissions Extremely silent operation

To guarantee ideal temperature, hu- Thanks to the adoption of the cen-

midity and air quality goes together trifugal compressor with magnetic

with the need to reduce noise emis- levitation, and, in air source units, of

sions and vibrations. This is a decisi- fans with reduced noise emission,

ve aspect in order to ensure adequate TECS sound power and pressure

comfort, as well as to comply with noi- are the lowest on the market, without

se emission regulations. peaks in any of the sound frequency

spectrum. Vibrations are dramatical-

ly reduced as well, with considerable

advantages in terms of transmission

to the building.

Complex architecture and logistics Simplified logistics

The search for prestigious central lo- Turbocor compressors feature an ex-

cations together with regulations and tremely advantageous capacity/weight

incentives for requalification of urban reduction allows simplified site ope-

areas increase the building site logi- rations. Moreover, for water source

stical complexity and the challenge of units this goes together with reduced

moving the system’s components. dimensions, thus enabling also a re-

duction of plantroom space.

Infrastructure and technical space optimization Low in rush current

The real estate value, especially with A further benefit is the very low inrush

expensive, prestigious investment in current, obtained thanks to the cha-

urban environments may be determi- racteristics of the compressor and to

ned also by the qualiity of the electrical the “inverter” starting. This is a crucial

system installed. Hence, choices that factor, as it allows a more favourable

do not overload electric infrastructure selection of the protection devices to

are more and more desiderable. be placed on the power sullpy betwe-

en transformer and unit.

III TECS-HF_0251_1954_200910_GB HFC R134a

TECS-HF

PRODUCT PRESENTATION

Energetic indices IPLV and ESEER EER values

The electrical power consumed by units is now being subjected

TECS-HF HC ESEER 100% 75% 50% 25%

to greater and greater attention. Indexes have been adopted that

now take into consideration even use under partial load condi- 30◦C 26◦C 22◦C 18◦C

tions, with external air ow lower than design project value and 0251 8,70 5,24 6,77 9,22 11,00

under partial load conditions in the chiller compressors installed.

0311 8,83 5,15 6,89 9,43 11,00

The valuation index adopted in the United States is called IPLV

(Integrated Part Load Value) and is defined in the regulations 0351 8,84 5,19 6,85 9,28 11,40

issued by ARI (American Refrigeration Institute): 0411 8,95 5,13 6,91 9,44 11,50

ARI standard 0512 9,08 5,24 7,08 9,21 12,20

(1) IPLV ARI = (1*EER100% + 42*EER75% + 45*EER50% + 12*EER25%) /100 0612 9,16 5,16 6,91 9,44 12,40

0712 9,04 5,14 6,79 9,20 12,50

where EER100%, EER75%, EER50%, EER25% are the effi ciencies

of the chiller in the various load conditions (100% - 75% - 50% 0812 9,21 5,14 6,92 9,44 12,60

and 25% respectively), calculated in the operating conditions 0913 9,13 5,15 6,90 9,44 12,30

shown below.

1053 8,96 5,15 6,82 9,21 12,10

T of evaporator outlet water 6,7 °C constant 1213 9,12 5,12 6,90 9,42 12,30

Delta T at full load 5°C

1414 9,16 5,23 6,91 9,32 12,60

Load 100% 75% 50% 25%

Cond. water inlet temp 29,4°C 23,9°C 18,3°C 18,3°C 1614 9,20 5,13 6,90 9,43 12,60

The multipliers 1, 42, 45 and 12 are the statistical coefficients

allocated to the cooling effi ciencies calculated at the various EER values

load conditions analytically calculated by ARI for different TECS-HF LC ESEER

100% 75% 50% 25%

typologies of buildings and operating conditions in 29 different

30◦C 26◦C 22◦C 18◦C

American cities.

0511 9,37 5,24 7,01 9,64 12,80

In Europe, the ESEER index proposed by EECCAC (Energy

0912 9,19 5,12 6,74 9,20 13,20

Effi ciency and Certifi cation of Central Air Conditioners) is

used in order to more closely interpret European airconditioning 1012 9,45 5,24 7,01 9,61 13,20

usage. ESEER (European Seasonal Energy Effi ciency Ratio) 1353 9,43 5,27 7,04 9,66 13,00

is defined as:

1453 9,41 5,22 6,99 9,60 13,10

Proposal EECCAC 1854 9,52 5,26 6,94 9,84 13,20

(2) ESEER = (3*EER100% + 33*EER75% + 41*EER50% + 23*EER25%) /100 1954 9,42 5,23 7,00 9,60 13,10

where

T of evaporator outlet water 7 °C costante

Delta T at full load 5 °C

Load 100% 75% 50% 25%

Cond. water inlet temp. 30°C 26°C 22°C 18°C

These indices can be used to estimate the total energy requi-

rement of the plant during the summer season. Calculations

using the ESEER index will therefore be more accurate than

those using just the EER.

(1) IPLV (Integrated Part Load Value) ARI Standard indices

(2) ESEER (European Seasonal Energy Efficiency Ratio) Indices for EECCAC proposal

IV TECS-HF_0251_1954_200910_GB HFC R134a

TECS-HF

Tests

Perfect functionality of Climaveneta units is guaranteed by ac- Performance tests are based on the measurement of electric

curate tests carried out along the productive process, and by data, water fl ow, working temperature, electric power absor-

nal test of every unit at the end of the work cycle, as imposed by bed, and capacity delivered. Measurements can be made at

ISO9001. Climaveneta also offers clients the chance to require one or three work points while varying the outlet temperatures

and witness additional performance and sound level tests be of the evaporator and condenser conditions. At the client’s di-

performed; highly skilled technical crew follow these operations scretion, performance tests can be conducted under full or part

in detail, to ensure maximum satisfaction of the customer. For load conditions for every operating mode possible for the unit.

units of the TECS series Climaveneta offers the possibility to

conduct visionati or presenziati tests. Full load tests conducted in one or three work points permit

two further personalized versions:

Running tests are standard tests similar to those normally • with a mixture of ethyl glycol water in the heat exchanger;

conducted at the productive unit that the client can observe wi- • up to the maximum working temperature of the heat exchan-

thout participation. ger on the source side.

Witness tests are extra tests that the client can observe and Part load, tests can be conducted using two different load par-

during which can request clarifi cations upon modalities or work tialization methods: the fi rst one requires to reduce the active

conditions of the unit, receiving test reports at the end. Witness resources’ number, while second one requires to modulate load

tests can include sound level and performance tests. on each resource. At part load the unit can be tested just in one

working point.

Acoustical tests allow to verify levels of sound emissions of

the unit; tests are performed repeating measurements of sound The following two tests can always be requested during final

pressure in determined points, positioned on an ideal grid with testing:

walls 1 meter distance from the unit panels. For every measu- • Simulation of the most common alarm states

ring point a spectrum in octave band for sound pressure and • Measurement of pressure drop of exchanger on

the average value is supplied to the customer. Then the avera- hydraulic circuit side

ge global values for pressure at 1 meter, according to ISO3744,

and the average sound power, referred to the whole unit, are

counted.

V TECS-HF_0251_1954_200910_GB HFC R134a

TECS-HF

UNIT DESCRIPTION

Water-cooled liquid chillers outside the pipes. Only for the units in function /H (heat pump

Internal units for the production of cool water. Oil-free centri- reversible on hydraulic side), the steel shell is insulated with a

fugal compressors, designed for R134a refrigerant, shell and foamed polyethylene closed-cell mat of 10 mm thikness and

tubes condenser, shell and tubes flooded type evaporator and a thermal condcuctivity of 0,033 W/mK at 0°C to avoid con-

electronic regulation valve. Bed plate, structure and pannelling densation on its surface. The copper tubes are internally and

made from plyester-painted thick hot galvanised sheet steel. externally grooved to improve heat exchange. Heads can be

High efficiency unit; the accurate thermoregulation and the removed to inspect the tubes. Under request it’s possible to

use of a continuous speed variation compressor assure a con- have a 4-steps heat exchanger (water side) for application with

tinuous modulation of the unit, depending on load variations. low-medium temperature sources (for example underground

Unit supplied with refrigerant charge and factory tested. On-site water). The heat exchanger comply with PED standards, con-

installation therefore just involves making connections to the cerning to operating pressure.

mains power and water supplied.

Refrigerant circuit

STANDARD UNIT COMPOSITION Unit designed with a single refrigerant circuit in order to optimi-

Structure ze the heat exchange’s process, especially in part load mode,

Frame comprising supporting elements in polyester-painted without any risk in the proper management of oil which is, in

thick hot galvanised sheet steel. The self supporting frame is this series, completely absent. Standard components of the

designed to ensure maximum ease of access during servicing refrigerant circuits are, in addition to the previous one: electro-

and maintenance operations. nic expansion valve and dedicated sensor level on condenser

side, high and low pressure safety valve with visualization of

Compressors the pressure’s level and the rotational speed directly from the

Two stage, variable speed, centrifugal compressor with alu- controller’s interface, compressor’s discharge and suction shut-

minium impellers, designed requiring no oil for lubrification. off valve, liquid line shut-off valve, drier filter with replaceable

Compressor constructed with cast aluminium casing and high- cartridge, refrigerant line sight glass with humidity indicator,

strenght thermoplastic electronics enclosures. Compressor high pressure transducer.

provided with radial and axial magnetic bearings to levitate the

shaft thereby eliminating metal to metal contact, and thus eli- Electrical and control panel

minating friction and the need for oil. Each bearing position is Electrical and control panel built to EN60204-1 and EC204-1

sensed by position sensors to provide real-time repositioning standards, complete with: electronic controller, control circuit

of the rotor shaft, controlled by the on-board digital electronics. transformer, general door lock isolator, power circuit with bar

Compressor speed is reduced as condensing temperature and/ distribution system, EMC filter and reactor on the compressor’s

or heat load reduces, optimizing energy performance through power circuit, fuses for compressors, terminals for cumulative

the entire range. Continuous modulation is possibile thanks to alarm block, remote on/off terminals, spring-type control circuit

the integrated inverter. Signals from the compressor controller terminal board, remote signal 4-20 mA and control pumps rela-

determine the inverter output frequency, voltage and phase, ies both on plant side and heat source side.

thereby regulating the motor speed. In case of power failure,

the compressor is capable of allowing for a normal de-levita-

tion and shutdown. Inlet Guide Vanes is built-in to further trim

the compressor capacity in conjuction with the variable-speed

control, to optimize compressor performance at low loads. The

compressor is provided with a direct drive, high efficiency, per-

manent-magnet synchronous motor powered by pulse-width-

modulating (PWM) voltage supply. Motor cooling is by liquid

refrigerant injection. A non-return valve on the discharge port of

the compressor is installed to protect against backflow of refri-

gerant during coastdown; a thermal protection protects against

over-currents while a soft-charge device reduces in-rush star-

ting current under 2 amps.

Heat exchanger on plant side

Heat exchanger, with a function of evaporator, shell and tubes,

flooded type, with water flowing inside and refrigerant flowing

outside the pipes. The steel shell is insulated with a foamed

polyethylene closed-cell mat of 10 mm thikness and a thermal

condcuctivity of 0,033 W/mK at 0°C to avoid condensation on

its surface. The copper tubes are internally and externally groo-

ved to improve heat exchange. A drop’s separator is integrated

in the evaporator to protect the compressor against the possi-

bility of liquid’s suction. A differential pressure switch is already

fitted in order to monitor the waterflow while the unit is working,

avoiding the risk of ice generation. The heat exchanger comply

with PED standards, concerning to operating pressure.

Heat exchanger on heat source side

Heat exchanger, with a function of condenser, shell and tubes,

flooded type, with water flowign inside and refrigerant flowing

1 TECS-HF_0251_1954_200910_GB HFC R134a

TECS-HF

W3000SE Large controller

Keypad generously sized with full operating status display, 8 FUNCTIONS

lines display with plaintext messages, multi-level menu, multi-

profile access, all of them with password, 6 languages (italian, /B - Base

english, french, spanish, german and swedish). The controls Standard unit for production of chilled water

and detailed LCD make access to machine settings easy and

safe. Temperature regulation features the continuous modula- /H - Heat pump reversible on hydraulic side

tion of the capacity, based on both leaving- and return- water Heat pump reversible on hydraulic side. The unit has, as stan-

temperatures, combining the proportional- and integral logics dard, an additional temperature probe on condenser and an ex-

with the specific technological solutions adopted. The diagnosti- tra insulating material on it. The controller is setted to manage

cs includes full management of alarms with black-box functions the unit on a double set-point, depending on the commutation:

and alarm record for better analysis of unit performance. Su- summer or winter mode.

pervision is easy through Climaveneta devices or with various

options for interfacing to ModBus, Bacnet, Echelon LonTalk

protocols. Compatibility with remote keyboard (management

up to 10 units). Clock available with programming of operation

(standard 4 days and 10 time bands).

Unit’s test

Tests carried out along the all productive process as imposed

by ISO9001. Possibility to have performance and acoustical

witness tests, with the support of qualified technical operators.

Performance tests give the possibility to measure electric data,

waterflows, operating temperature, absorbed and given power,

both at full load and partial load condition. It’s even possible to

have a simulation of the most common alarm states and the

pressure drops (water side) measurements. The acoustical

tests allow to verify level of sound emissions of the unit; tests

are performed repeating measurements of sound pressure in

determined points, positioned on an ideal grid with walls 1 me-

ter distance from the unit panels. For every measuring point a

sèectrum in octave band for sound pressure and the average

value are reported to the costumer. The average global values

for pressure at 1 meter, according to ISO3744, and the average

sound power referred to the whole unit, are counted.

Certifications

EUROVENT - certification programme

CE – Product quality certificate for the European Union

GOST – Product quality certificate for Russian Federation

SAFETY QUALITY LICENCE – Product quality certificate for

Popular Republic of China

Machine Directive

Pressure Equipment Directive PED

Low voltage Directive

Electromagnetic compatibility Directive

Gas machine Directive

VERSIONS

HC - High Condensing

Maximum condenser leaving water temperature is 50°C. For

application in which the unit is supposed to work at high con-

densing levels, as for example in some critical dry-cooler in-

stallations or in all the situation in which the reversibility in heat

pump mode is requested.

LC - Low Condensing

Maximum condenser leaving water temperature is 40°C. For

applications in which the water cooled unit is coupled with me-

dium temperature external source, typically like underground or

superficial water or cooling towers.

2 TECS-HF_0251_1954_200910_GB HFC R134a

TECS-HF

ACCESSORIES Other accessories:

- Integral acoustical enclosure basic - Demand limit

Enclosure realized with peraluman panels lined with an acou- - Flanges on heat exchanger

stic insulation made by polyester fiber of thickness 30 mm. - 2 way-valve for the condensing pressure control (see dedica-

The sound power level reduction achieved with this accessory te section)

is 14 dB(A). - Flowswitches on heat exchangers

- Integral acoustical enclosure plus - Automatic circuit breakers for compressors

Enclosure realized with peraluman panels lined with a special - Compressors’ power factor correction (cos(phi) to 0,95)

acoustic insulation composed by 5 alternating layers of polyu- - Rubber type antivibration device

rethane and gaiter of total thickness 50 mm. The sound power - Groups of unit control devices (sequencer, Manager3000,

level reduction achieved with this accessory is 18 dB(A). Manager3000V, FWS3000)

- CuNi condensers - Numbered wiring on electrical board

Shell and tube heat exchanger recommended for applications - Remote keyboard

with water with an high corrosion potential. Headers, shell,

baffles and refrigerant connection in carbon steel. Available

tubes in CuNi 90/10 all, or CuNi 70/30; the last option is re-

commended for marine water applications.

- Pressostatic valve for the condensation control

Pressostatic valve with grey cast iron body. It’s used for re-

gulating the flow of water as a function of the condensing

pressure, maintaining it constant during operation. When the

refrigeration plant is stopped, the cooling water flow is shut off

automatically. The valve is selected for a thermic drop of 10°C

and tested by Climaveneta during the unit’s test. Recommen-

ded for applications with low temperature water, for example

groundwater, where it’s request the condensation pressure’s

control and it’s possible to work with variable flow on the rejec-

tion circuit (Separately supplied, not mounted)

- 3 way-valve for the condensing pressure control

3 way modulating valve in grey cast iron with diverting fun-

ction. The valve is selected for a thermic drop of 5°C and

tested by Climaveneta during the unit’s test. Recommended

for geo-thermal applications, in which constant waterflow is

necessary. (Separately supplied, not mounted)

- 0-10 V signal for the condensation’s control

0-10 V signal on terminal board for the condensation control.

For dry-cooler or cooling tower applications, it permits to mo-

dulate the fans’ speed in order to maintain the condensing

pressure in a pre-defined range. Max transmission lenght 30

m. Shielded cable is recommended.

- VPF system (see dedicate section)

Predisposition for the variable flow pumps’ control on the pri-

mary circuit. The system comprise: extensions on the con-

troller to read the system’s pressure transducer signals (4-20

mA) and the consequent management of pumps and bypass

valve (0-10 V signal), additional pressure transducer as extra

safety device. [Pressure transducer, pumps and bypass valve

at client responsability]

- Leak detector

Leak detection system available to comply with F-gas legi-

slation. The dedicated sensor has to be fitted close to the

unit,and will raise an alarm on detection of refrigerant gas.

Reccomended to be installed in closed spaces.

3 TECS-HF_0251_1954_200910_GB HFC R134a

TECS-HF

GENERAL TECHNICAL DATA

HC

SIZE 0251 0311 0351 0411 0512 0612 0712

TECS-HF

COOLING (1)

Cooling capacity kW 241 293 359 405 497 588 716

Total power input (unit) kW 46,0 57,0 69,2 78,9 94,8 114 139

EER 5,24 5,15 5,19 5,13 5,24 5,16 5,14

ESEER 8,70 8,83 8,84 8,95 9,08 9,16 9,04

Heat exchanger water flow m³/h 41,5 50,5 61,8 69,7 85,6 101 123

Heat exchanger pressure drop kPa 32,0 29,1 25,1 22,6 28,6 30,3 21,0

TECS-HF/HC/H

HEATING (2)

Heating capacity kW 273 334 419 478 563 668 835

Total power input (unit) kW 57,2 69,8 89,3 102 118 140 179

COP 4,77 4,77 4,69 4,66 4,79 4,78 4,66

Heat exchanger water flow m³/h 47,5 58,0 72,8 83,0 97,8 116 145

Heat exchanger pressure drop kPa 23,8 38,5 47,5 40,6 20,7 39,4 21,5

COMPRESSORS

Number N°. 1 1 1 1 2 2 2

Number of circuits N°. 1 1 1 1 1 1 1

Type of regulation STEPLESS STEPLESS STEPLESS STEPLESS STEPLESS STEPLESS STEPLESS

Type of refrigerant R134a R134a R134a R134a R134a R134a R134a

Refrigerant charge kg. 100 110 140 150 190 200 420

NOISE LEVELS (3)

Total sound power dB(A) 91 93 92 94 94 95 94

Total sound pressure dB(A) 59 61 60 62 62 63 62

DIMENSIONS AND WEIGHTS (4)

Length mm. 3100 3100 3100 3100 3550 3550 5050

Width mm. 950 950 950 950 1300 1300 1300

Height mm. 1900 1900 1900 1900 2060 2060 2060

Weight kg. 1480 1500 1870 2030 2750 2720 3770

1 Plant (side) cooling exchanger water (in/out) 12/7 °C

Source (side) heat exchanger water (in/out) 30/35 °C

2 Source (side) heat exchanger water (in/out) 12/7 °C

Plant (side) heating exchanger water (in/out) 40/45 °C

3 Sound power on the basis of measurements made in compliance with ISO 9614 and Eurovent 8/1 for Eurovent certified units;

in compliance with ISO 3744 for non-certified units

Average sound pressure level, at 10 (m.) distance, unit in a free field on a reflective surface; non-binding value obtained

from the sound power level

4 Standard configuration

- Not available

ELCADOC - Ver. 0.9.9.11 4 TECS-HF_HC_HCH_0251_1614_200910_EN Ref.: R134a

TECS-HF

GENERAL TECHNICAL DATA

HC

SIZE 0812 0913 1053 1213 1414 1614

TECS-HF

COOLING (1)

Cooling capacity kW 811 881 1045 1213 1405 1618

Total power input (unit) kW 158 171 203 237 269 316

EER 5,14 5,15 5,15 5,12 5,23 5,13

ESEER 9,21 9,13 8,96 9,12 9,16 9,2

Heat exchanger water flow m³/h 140 152 180 209 242 279

Heat exchanger pressure drop kPa 21,6 29,5 27,5 32,3 41,5 40,3

TECS-HF/HC/H

HEATING (2)

Heating capacity kW 956 1001 1220 1430 1641 1908

Total power input (unit) kW 205 210 262 307 348 410

COP 4,67 4,78 4,65 4,66 4,71 4,66

Heat exchanger water flow m³/h 166 174 212 249 285 332

Heat exchanger pressure drop kPa 19,6 18,8 34,2 20,4 43,1 41,8

COMPRESSORS

Number N°. 2 3 3 3 4 4

Number of circuits N°. 1 1 1 1 1 1

Type of regulation STEPLESS STEPLESS STEPLESS STEPLESS STEPLESS STEPLESS

Type of refrigerant R134a R134a R134a R134a R134a R134a

Refrigerant charge kg. 440 390 530 560 620 660

NOISE LEVELS (3)

Total sound power dB(A) 96 96 96 97 97 98

Total sound pressure dB(A) 64 64 64 65 65 66

DIMENSIONS AND WEIGHTS (4)

Length mm. 5050 5050 5050 5050 6150 6150

Width mm. 1300 1300 1300 1300 1300 1300

Height mm. 2060 2060 2060 2060 2060 2060

Weight kg. 3910 4090 4860 5060 5640 6050

1 Plant (side) cooling exchanger water (in/out) 12/7 °C

Source (side) heat exchanger water (in/out) 30/35 °C

2 Source (side) heat exchanger water (in/out) 12/7 °C

Plant (side) heating exchanger water (in/out) 40/45 °C

3 Sound power on the basis of measurements made in compliance with ISO 9614 and Eurovent 8/1 for Eurovent certified units;

in compliance with ISO 3744 for non-certified units

Average sound pressure level, at 10 (m.) distance, unit in a free field on a reflective surface; non-binding value obtained

from the sound power level

4 Standard configuration

- Not available

ELCADOC - Ver. 0.9.9.11 5 TECS-HF_HC_HCH_0251_1614_200910_EN Ref.: R134a

TECS-HF

GENERAL TECHNICAL DATA

LC

SIZE 0511 0912 1012 1353 1453 1854 1954

TECS-HF

COOLING (1)

Cooling capacity kW 488 879 978 1359 1461 1809 1949

Total power input (unit) kW 93,2 172 186 258 280 344 373

EER 5,24 5,12 5,24 5,27 5,22 5,26 5,23

ESEER 9,37 9,19 9,45 9,43 9,41 9,52 9,42

Heat exchanger water flow m³/h 84,1 151 168 234 252 311 336

Heat exchanger pressure drop kPa 32,8 31,6 31,5 40,5 46,8 68,9 58,6

COMPRESSORS

Number N°. 1 2 2 3 3 4 4

Number of circuits N°. 1 1 1 1 1 1 1

Type of regulation STEPLESS STEPLESS STEPLESS STEPLESS STEPLESS STEPLESS STEPLESS

Type of refrigerant R134a R134a R134a R134a R134a R134a R134a

Refrigerant charge kg. 150 420 440 550 560 660 660

NOISE LEVELS (2)

Total sound power dB(A) 95 96 97 97 98 99 99

Total sound pressure dB(A) 63 64 65 65 66 67 67

DIMENSIONS AND WEIGHTS (3)

Length mm. 3100 5050 5050 5050 5050 6150 6150

Width mm. 950 1300 1300 1300 1300 1300 1300

Height mm. 1900 2060 2060 2060 2060 2060 2060

Weight kg. 2030 3770 3910 4920 5060 5800 6050

1 Plant (side) cooling exchanger water (in/out) 12/7 °C

Source (side) heat exchanger water (in/out) 30/35 °C

2 Sound power on the basis of measurements made in compliance with ISO 9614 and Eurovent 8/1 for Eurovent certified units;

in compliance with ISO 3744 for non-certified units

Average sound pressure level, at 10 (m.) distance, unit in a free field on a reflective surface; non-binding value obtained

from the sound power level

3 Standard configuration

- Not available

ELCADOC - Ver. 0.9.9.11 6 TECS-HF_LC_0511_1954_200910_EN Ref.: R134a

TECS-HF

COOLING CAPACITY

HC

0251

Tcd 25 30 35 40 45 50 25 30 35 40 45 50 25 30 35 40 45 50

Tev 6 7 9

Pf 230 234 233 225 211 192 233 241 241 234 219 197 237 251 256 251 235 210

Pat 32,0 39,4 46,1 52,0 57,1 61,5 31,2 39,0 46,0 52,0 57,2 61,5 29,1 37,8 45,4 51,9 57,3 61,5

Qev 39,6 40,4 40,1 38,7 36,4 33,0 40,2 41,5 41,5 40,3 37,8 34,0 40,8 43,3 44,1 43,2 40,5 36,1

Dpev 29,1 30,2 29,8 27,9 24,6 20,2 30,0 31,9 32,0 30,1 26,5 21,4 30,9 34,8 36,1 34,6 30,5 24,2

Pt 262 274 279 277 268 253 265 280 287 286 276 259 266 289 301 302 292 271

Qcd 45,0 47,0 47,8 47,5 46,0 43,4 45,4 48,0 49,2 49,1 47,5 44,4 45,6 49,6 51,7 51,9 50,2 46,6

Dpcd 21,4 23,3 24,2 23,9 22,5 20,0 21,8 24,4 25,7 25,5 23,8 20,9 22,0 26,1 28,3 28,6 26,7 23,0

Tev 12 15 18

Pf 234 261 274 273 259 230 - 263 286 293 281 253 - 258 294 309 304 278

Pat 25,0 35,0 43,8 51,1 57,0 61,6 - 31,0 41,1 49,5 56,4 61,7 - 25,8 37,3 47,2 55,4 61,9

Qev 40,3 45,0 47,2 47,1 44,6 39,7 - 45,4 49,4 50,5 48,6 43,6 - 44,5 50,7 53,4 52,5 48,0

Dpev 30,2 37,5 41,4 41,1 36,9 29,2 - 38,2 45,3 47,3 43,8 35,4 - 36,8 47,8 52,9 51,1 42,8

Pt 259 296 318 324 316 292 - 294 328 342 338 315 - 284 331 356 359 340

Qcd 44,5 50,8 54,6 55,7 54,2 50,2 - 50,5 56,3 58,8 58,1 54,2 - 48,8 57,0 61,3 61,9 58,5

Dpcd 21,0 27,3 31,5 32,9 31,2 26,7 - 27,0 33,6 36,7 35,8 31,1 - 25,2 34,4 39,8 40,5 36,3

0311

Tcd 25 30 35 40 45 50 25 30 35 40 45 50 25 30 35 40 45 50

Tev 6 7 9

Pf 278 285 284 275 258 233 281 292 293 285 268 241 283 304 311 305 287 256

Pat 39,8 49,0 57,0 63,9 69,6 74,2 38,7 48,5 57,0 64,1 69,8 74,3 36,0 47,0 56,4 64,1 70,1 74,4

Qev 47,8 49,0 48,8 47,3 44,4 40,2 48,3 50,3 50,5 49,1 46,1 41,4 48,8 52,3 53,5 52,6 49,5 44,1

Dpev 26,0 27,3 27,1 25,5 22,5 18,4 26,6 28,7 29,1 27,5 24,2 19,5 27,1 31,1 32,6 31,5 27,8 22,1

Pt 317 334 341 339 328 308 320 340 350 350 338 315 319 351 367 369 357 331

Qcd 54,4 57,2 58,4 58,1 56,2 52,8 54,8 58,4 60,1 60,0 58,0 54,0 54,8 60,1 63,0 63,4 61,3 56,8

Dpcd 33,9 37,4 39,1 38,7 36,2 31,9 34,4 39,0 41,4 41,2 38,5 33,4 34,4 41,4 45,5 46,1 43,1 36,9

Tev 12 15 18

Pf 278 313 331 332 315 281 - 314 345 355 343 309 - 305 352 374 370 340

Pat 30,4 43,4 54,4 63,2 70,1 74,8 - 38,1 50,9 61,3 69,5 75,3 - 31,1 45,9 58,3 68,3 75,9

Qev 47,9 54,0 57,1 57,2 54,4 48,5 - 54,1 59,5 61,2 59,2 53,4 - 52,7 60,8 64,5 63,8 58,7

Dpev 26,1 33,2 37,1 37,3 33,6 26,8 - 33,4 40,3 42,6 39,8 32,4 - 31,6 42,1 47,4 46,4 39,2

Pt 308 357 386 395 385 356 - 352 396 416 412 385 - 336 398 432 438 416

Qcd 52,9 61,2 66,2 67,9 66,3 61,2 - 60,5 68,1 71,6 70,9 66,2 - 57,9 68,5 74,4 75,4 71,6

Dpcd 32,1 42,9 50,2 52,8 50,3 42,9 - 41,9 53,1 58,6 57,6 50,2 - 38,3 53,7 63,3 65,1 58,8

0351

Tcd 25 30 35 40 45 50 25 30 35 40 45 50 25 30 35 40 45 50

Tev 6 7 9

Pf 340 348 347 339 322 298 345 357 359 352 335 309 352 372 380 376 360 333

Pat 47,4 58,7 69,3 79,4 88,8 97,6 46,2 58,0 69,2 79,6 89,3 98,3 43,2 56,2 68,4 79,6 90,0 99,4

Qev 58,5 59,9 59,8 58,3 55,5 51,2 59,4 61,4 61,8 60,5 57,7 53,2 60,6 64,0 65,4 64,7 62,0 57,3

Dpev 22,6 23,6 23,5 22,4 20,2 17,3 23,2 24,8 25,1 24,1 21,9 18,6 24,2 27,0 28,1 27,6 25,3 21,6

Pt 388 406 417 418 411 395 391 415 428 431 424 408 395 428 448 455 450 432

Qcd 66,4 69,7 71,5 71,7 70,5 67,8 67,1 71,1 73,4 74,0 72,8 69,9 67,8 73,4 76,9 78,2 77,3 74,2

Dpcd 39,5 43,5 45,7 46,0 44,5 41,1 40,3 45,3 48,2 49,0 47,5 43,7 41,1 48,2 52,9 54,7 53,4 49,2

Tev 12 15 18

Pf 354 387 405 408 396 368 - 394 425 436 430 405 - 393 437 460 462 442

Pat 37,2 52,1 65,8 78,5 90,1 101 - 46,2 61,8 76,2 89,4 101 - 38,7 56,2 72,5 87,6 102

Qev 61,0 66,7 69,9 70,4 68,2 63,5 - 68,0 73,2 75,3 74,1 69,8 - 67,9 75,5 79,4 79,7 76,3

Dpev 24,5 29,3 32,1 32,6 30,6 26,5 - 30,5 35,3 37,3 36,2 32,1 - 30,3 37,5 41,5 41,8 38,3

Pt 391 439 471 487 486 469 - 441 486 513 519 506 - 432 493 532 549 544

Qcd 67,2 75,4 80,9 83,6 83,5 80,6 - 75,7 83,6 88,1 89,3 87,1 - 74,3 84,9 91,6 94,5 93,6

Dpcd 40,4 50,9 58,6 62,6 62,4 58,1 - 51,3 62,5 69,5 71,3 67,8 - 49,4 64,5 75,1 80,0 78,4

Tcd [°C] - Source (side) heat exchanger output water temperature

Tev [°C] - Plant (side) cooling exchanger output water temperature

Pf [kW] - Cooling capacity

Pat [kW] - Total power input

Qev [m³/h] - Plant (side) heat exchanger water flow

Dpev [kPa] - Plant (side) cooling exchanger pressure drop

Pt [kW] - Heating capacity

Qcd [m³/h] - Source (side) heating exchanger water flow

Dpcd [kPa] - Source (side) heat exchanger pressure drop

'-' Conditions outside the operating range

Waterflow and pressure drop on heat exchangers calculated with 5°C of delta T

ELCADOC - Ver. 0.9.9.11 7 TECS-HF_HC_HCH_0251_1614_200910_EN Ref.: R134a

TECS-HF

COOLING CAPACITY

HC

0411

Tcd 25 30 35 40 45 50 25 30 35 40 45 50 25 30 35 40 45 50

Tev 6 7 9

Pf 379 391 393 385 367 339 384 400 405 399 381 353 389 415 427 425 409 380

Pat 53,5 66,7 79,2 90,9 102 112 51,9 65,8 78,9 91,1 102 113 48,0 63,3 77,6 91,0 103 115

Qev 65,3 67,3 67,6 66,2 63,2 58,4 66,1 68,9 69,7 68,7 65,7 60,7 67,0 71,5 73,6 73,3 70,5 65,4

Dpev 19,8 21,0 21,2 20,3 18,5 15,8 20,3 22,0 22,6 21,9 20,0 17,1 20,8 23,7 25,1 24,9 23,1 19,8

Pt 433 458 472 476 469 451 436 466 484 490 484 466 437 479 505 516 513 494

Qcd 74,2 78,5 80,9 81,6 80,4 77,4 74,7 79,9 83,0 84,0 83,0 79,9 75,0 82,1 86,6 88,6 88,0 84,8

Dpcd 32,4 36,3 38,6 39,2 38,1 35,3 32,9 37,6 40,6 41,6 40,6 37,6 33,1 39,7 44,2 46,3 45,6 42,4

Tev 12 15 18

Pf 387 430 454 461 449 420 - 434 473 490 487 462 - 429 484 515 521 503

Pat 40,6 58,1 74,3 89,4 103 116 - 50,9 69,3 86,4 102 116 - 41,9 62,6 81,7 99,4 116

Qev 66,8 74,0 78,2 79,4 77,4 72,4 - 74,9 81,6 84,6 83,9 79,6 - 74,1 83,6 88,9 90,0 86,9

Dpev 20,7 25,4 28,4 29,2 27,8 24,4 - 26,0 30,9 33,2 32,7 29,4 - 25,5 32,4 36,6 37,6 35,0

Pt 428 488 528 550 553 536 - 485 542 577 589 578 - 471 547 596 621 619

Qcd 73,5 83,7 90,7 94,5 95,0 92,2 - 83,4 93,2 99,2 101 99,4 - 81,0 94,0 103 107 107

Dpcd 31,8 41,3 48,5 52,6 53,1 50,0 - 41,0 51,2 57,9 60,4 58,2 - 38,7 52,1 62,0 67,2 66,9

0512

Tcd 25 30 35 40 45 50 25 30 35 40 45 50 25 30 35 40 45 50

Tev 6 7 9

Pf 474 483 480 464 436 394 480 497 497 482 452 406 487 518 528 517 485 432

Pat 66,1 81,3 95,0 107 117 126 64,4 80,5 94,8 107 118 126 60,1 78,0 93,6 107 118 126

Qev 81,6 83,2 82,7 79,9 75,0 67,9 82,7 85,5 85,6 83,1 77,8 70,0 83,9 89,2 90,9 89,0 83,5 74,4

Dpev 25,9 27,0 26,6 24,9 21,9 18,0 26,7 28,5 28,6 26,9 23,6 19,1 27,4 31,0 32,2 30,9 27,2 21,6

Pt 540 565 575 571 553 520 545 577 592 590 570 532 547 596 621 624 603 558

Qcd 92,6 96,8 98,6 98,0 94,9 89,3 93,4 99,0 102 101 97,8 91,4 93,8 102 107 107 103 95,9

Dpcd 18,5 20,3 21,0 20,7 19,4 17,2 18,8 21,2 22,3 22,1 20,7 18,0 19,0 22,6 24,6 24,8 23,1 19,8

Tev 12 15 18

Pf 481 537 564 563 533 474 - 541 590 603 580 521 - 529 604 637 626 573

Pat 51,4 72,2 90,2 105 117 127 - 63,9 84,5 102 116 127 - 53,0 76,8 97,1 114 128

Qev 82,9 92,5 97,2 97,0 91,8 81,7 - 93,3 102 104 100 89,9 - 91,4 104 110 108 98,9

Dpev 26,8 33,4 36,9 36,7 32,9 26,0 - 33,9 40,4 42,2 39,0 31,5 - 32,6 42,4 47,1 45,6 38,2

Pt 532 609 654 668 650 601 - 605 674 705 696 648 - 582 681 734 740 701

Qcd 91,4 105 112 115 112 103 - 104 116 121 120 112 - 100 117 126 127 121

Dpcd 18,0 23,6 27,3 28,5 27,0 23,0 - 23,3 29,0 31,7 31,0 26,9 - 21,7 29,7 34,4 35,1 31,4

0612

Tcd 25 30 35 40 45 50 25 30 35 40 45 50 25 30 35 40 45 50

Tev 6 7 9

Pf 556 570 569 551 517 468 562 585 588 572 537 482 567 608 623 612 575 513

Pat 79,5 98,0 114 128 139 148 77,3 97,0 114 128 140 149 71,8 94,0 113 128 140 149

Qev 95,6 98,1 97,9 94,8 89,0 80,5 96,7 101 101 98,5 92,4 83,0 97,6 105 107 105 99,1 88,4

Dpev 27,0 28,4 28,3 26,5 23,4 19,1 27,6 29,9 30,3 28,6 25,2 20,3 28,1 32,3 33,9 32,8 29,0 23,0

Pt 635 668 683 679 657 616 639 682 702 700 677 631 639 702 736 740 716 662

Qcd 109 115 117 116 113 106 110 117 120 120 116 108 110 120 126 127 123 114

Dpcd 34,6 38,3 40,0 39,6 37,1 32,6 35,1 39,9 42,4 42,2 39,4 34,2 35,1 42,3 46,5 47,2 44,1 37,7

Tev 12 15 18

Pf 555 627 664 665 632 564 - 628 691 711 687 620 - 610 705 749 741 682

Pat 60,5 86,6 109 126 140 150 - 75,9 101 122 139 151 - 61,7 91,5 116 137 152

Qev 95,7 108 114 115 109 97,2 - 108 119 123 119 107 - 105 122 129 128 118

Dpev 27,0 34,4 38,6 38,8 35,0 27,9 - 34,6 41,9 44,3 41,4 33,8 - 32,7 43,7 49,2 48,2 40,9

Pt 616 714 772 792 772 714 - 704 792 833 826 771 - 672 796 865 877 834

Qcd 106 123 133 136 133 123 - 121 136 143 142 133 - 116 137 149 151 144

Dpcd 32,7 43,8 51,4 54,0 51,4 43,9 - 42,7 54,2 59,9 59,0 51,4 - 39,0 54,8 64,7 66,6 60,2

Tcd [°C] - Source (side) heat exchanger output water temperature

Tev [°C] - Plant (side) cooling exchanger output water temperature

Pf [kW] - Cooling capacity

Pat [kW] - Total power input

Qev [m³/h] - Plant (side) heat exchanger water flow

Dpev [kPa] - Plant (side) cooling exchanger pressure drop

Pt [kW] - Heating capacity

Qcd [m³/h] - Source (side) heating exchanger water flow

Dpcd [kPa] - Source (side) heat exchanger pressure drop

'-' Conditions outside the operating range

Waterflow and pressure drop on heat exchangers calculated with 5°C of delta T

ELCADOC - Ver. 0.9.9.11 8 TECS-HF_HC_HCH_0251_1614_200910_EN Ref.: R134a

TECS-HF

COOLING CAPACITY

HC

0712

Tcd 25 30 35 40 45 50 25 30 35 40 45 50 25 30 35 40 45 50

Tev 6 7 9

Pf 681 695 693 675 641 592 691 713 716 701 667 615 706 744 758 749 717 661

Pat 96,0 118 139 159 178 196 93,6 117 139 160 179 197 87,8 114 138 160 181 200

Qev 117 120 119 116 110 102 119 123 123 121 115 106 122 128 131 129 123 114

Dpev 18,9 19,7 19,6 18,6 16,8 14,3 19,5 20,8 21,0 20,1 18,2 15,5 20,4 22,6 23,5 23,0 21,0 17,9

Pt 777 813 832 835 820 788 785 830 855 861 846 812 794 857 896 909 898 861

Qcd 133 139 143 143 141 135 135 142 147 148 145 139 136 147 154 156 154 148

Dpcd 18,1 19,8 20,8 20,9 20,2 18,6 18,5 20,7 21,9 22,2 21,5 19,8 18,9 22,1 24,1 24,8 24,2 22,3

Tev 12 15 18

Pf 712 776 810 815 788 732 - 792 850 871 856 805 - 792 877 920 920 879

Pat 76,1 106 133 158 181 202 - 94,2 125 154 180 204 - 79,5 114 147 177 205

Qev 123 134 140 140 136 126 - 137 147 150 148 139 - 137 151 159 159 152

Dpev 20,8 24,7 26,9 27,2 25,5 22,0 - 25,8 29,7 31,2 30,1 26,6 - 25,8 31,6 34,8 34,8 31,8

Pt 788 882 943 973 970 934 - 886 975 1025 1036 1009 - 871 991 1066 1097 1084

Qcd 135 151 162 167 167 161 - 152 168 176 178 173 - 150 170 183 189 187

Dpcd 18,7 23,4 26,8 28,5 28,3 26,3 - 23,7 28,6 31,7 32,4 30,7 - 22,9 29,6 34,3 36,4 35,5

0812

Tcd 25 30 35 40 45 50 25 30 35 40 45 50 25 30 35 40 45 50

Tev 6 7 9

Pf 759 782 786 770 735 680 768 801 811 799 764 706 778 831 855 851 820 760

Pat 107 133 158 182 204 224 104 132 158 182 205 226 95,9 127 155 182 207 229

Qev 131 135 135 133 126 117 132 138 140 137 131 122 134 143 147 147 141 131

Dpev 18,9 20,1 20,3 19,5 17,8 15,2 19,4 21,1 21,6 21,0 19,2 16,4 19,9 22,7 24,1 23,9 22,1 19,0

Pt 866 916 945 952 938 903 872 932 969 981 969 932 874 957 1010 1033 1026 989

Qcd 148 157 162 163 161 155 149 160 166 168 166 160 150 164 173 177 176 170

Dpcd 15,6 17,5 18,6 18,9 18,4 17,0 15,9 18,1 19,6 20,1 19,6 18,2 16,0 19,2 21,3 22,3 22,0 20,5

Tev 12 15 18

Pf 775 860 909 922 900 842 - 869 946 981 974 924 - 858 968 1030 1043 1008

Pat 81,0 116 149 179 207 232 - 102 138 173 204 233 - 83,6 125 163 199 231

Qev 134 148 157 159 155 145 - 150 163 169 168 159 - 148 167 178 180 174

Dpev 19,8 24,4 27,2 28,0 26,7 23,3 - 24,9 29,6 31,8 31,3 28,2 - 24,3 31,0 35,1 36,0 33,6

Pt 856 975 1057 1101 1106 1074 - 970 1085 1154 1178 1157 - 942 1093 1193 1242 1239

Qcd 147 168 182 189 190 185 - 167 186 198 203 199 - 162 188 205 214 213

Dpcd 15,3 19,9 23,4 25,4 25,7 24,2 - 19,7 24,7 27,9 29,1 28,1 - 18,6 25,1 29,9 32,4 32,3

0913

Tcd 25 30 35 40 45 50 25 30 35 40 45 50 25 30 35 40 45 50

Tev 6 7 9

Pf 833 854 852 825 775 701 843 876 881 857 804 723 850 911 933 917 862 769

Pat 119 147 171 192 209 223 116 146 171 192 210 223 108 141 169 192 210 223

Qev 143 147 147 142 133 121 145 151 152 148 138 124 146 157 161 158 148 132

Dpev 26,3 27,7 27,5 25,8 22,8 18,6 26,9 29,1 29,5 27,9 24,5 19,8 27,5 31,5 33,1 31,9 28,2 22,4

Pt 952 1001 1023 1017 984 923 959 1022 1052 1049 1014 945 958 1052 1102 1109 1072 992

Qcd 163 172 175 174 169 158 164 175 180 180 174 162 164 180 189 190 184 170

Dpcd 16,5 18,3 19,1 18,9 17,7 15,6 16,8 19,0 20,2 20,1 18,8 16,3 16,8 20,2 22,2 22,5 21,0 18,0

Tev 12 15 18

Pf 834 940 995 997 947 845 - 942 1036 1065 1030 929 - 916 1057 1122 1110 1021

Pat 91,1 130 163 190 210 224 - 114 152 184 208 226 - 93,0 138 175 205 228

Qev 144 162 171 172 163 146 - 162 179 184 178 160 - 158 182 194 192 176

Dpev 26,4 33,6 37,6 37,8 34,1 27,2 - 33,8 40,9 43,2 40,4 32,9 - 32,0 42,6 48,0 47,0 39,8

Pt 925 1070 1158 1187 1157 1069 - 1056 1188 1249 1238 1155 - 1009 1195 1297 1315 1249

Qcd 159 184 199 204 199 184 - 181 204 215 213 199 - 173 206 223 226 215

Dpcd 15,6 20,9 24,5 25,8 24,5 21,0 - 20,4 25,9 28,6 28,1 24,5 - 18,7 26,2 30,9 31,8 28,7

Tcd [°C] - Source (side) heat exchanger output water temperature

Tev [°C] - Plant (side) cooling exchanger output water temperature

Pf [kW] - Cooling capacity

Pat [kW] - Total power input

Qev [m³/h] - Plant (side) heat exchanger water flow

Dpev [kPa] - Plant (side) cooling exchanger pressure drop

Pt [kW] - Heating capacity

Qcd [m³/h] - Source (side) heating exchanger water flow

Dpcd [kPa] - Source (side) heat exchanger pressure drop

'-' Conditions outside the operating range

Waterflow and pressure drop on heat exchangers calculated with 5°C of delta T

ELCADOC - Ver. 0.9.9.11 9 TECS-HF_HC_HCH_0251_1614_200910_EN Ref.: R134a

TECS-HF

COOLING CAPACITY

HC

1053

Tcd 25 30 35 40 45 50 25 30 35 40 45 50 25 30 35 40 45 50

Tev 6 7 9

Pf 994 1014 1011 985 936 864 1010 1041 1045 1023 974 898 1031 1086 1107 1094 1047 966

Pat 140 172 203 233 261 287 136 171 203 234 262 289 128 165 201 234 264 292

Qev 171 175 174 170 161 149 174 179 180 176 168 155 178 187 191 188 180 166

Dpev 24,9 25,9 25,7 24,4 22,1 18,8 25,7 27,3 27,5 26,3 23,9 20,3 26,8 29,7 30,9 30,2 27,6 23,5

Pt 1134 1186 1215 1218 1197 1151 1146 1211 1248 1256 1236 1187 1159 1251 1307 1327 1311 1258

Qcd 194 203 208 209 205 197 196 208 214 216 212 204 199 215 224 228 225 216

Dpcd 28,7 31,4 33,0 33,2 32,0 29,6 29,3 32,8 34,8 35,3 34,2 31,5 30,0 35,0 38,3 39,4 38,5 35,4

Tev 12 15 18

Pf 1040 1134 1183 1189 1151 1069 - 1157 1241 1272 1250 1175 - 1157 1281 1343 1344 1284

Pat 111 154 194 231 265 295 - 137 182 224 262 297 - 116 166 213 257 298

Qev 179 195 204 205 198 184 - 200 214 219 216 203 - 200 221 232 232 222

Dpev 27,3 32,4 35,4 35,7 33,5 28,9 - 33,9 39,0 40,9 39,5 34,9 - 33,9 41,5 45,7 45,8 41,8

Pt 1150 1287 1377 1420 1416 1365 - 1294 1423 1496 1513 1473 - 1273 1447 1556 1601 1582

Qcd 198 221 236 244 243 234 - 222 245 257 260 253 - 219 249 268 276 272

Dpcd 29,7 37,1 42,5 45,2 45,0 41,8 - 37,6 45,5 50,3 51,4 48,8 - 36,4 47,1 54,5 57,7 56,4

1213

Tcd 25 30 35 40 45 50 25 30 35 40 45 50 25 30 35 40 45 50

Tev 6 7 9

Pf 1137 1171 1176 1151 1098 1016 1151 1198 1213 1194 1141 1056 1167 1244 1280 1273 1226 1136

Pat 161 200 238 273 305 336 156 198 237 273 307 339 144 190 233 273 310 344

Qev 196 202 202 198 189 175 198 206 209 206 197 182 201 214 220 219 211 196

Dpev 28,3 30,0 30,3 29,1 26,4 22,6 29,0 31,5 32,3 31,3 28,6 24,4 29,9 34,0 35,9 35,6 33,0 28,3

Pt 1298 1371 1413 1424 1403 1351 1307 1396 1450 1467 1449 1394 1311 1434 1513 1546 1535 1480

Qcd 222 235 242 244 241 232 224 239 249 252 249 239 225 246 260 265 264 254

Dpcd 16,3 18,2 19,4 19,7 19,1 17,7 16,6 18,9 20,4 20,9 20,4 18,9 16,7 20,0 22,2 23,2 22,9 21,3

Tev 12 15 18

Pf 1163 1288 1360 1379 1345 1258 - 1303 1417 1469 1457 1382 - 1288 1451 1542 1561 1507

Pat 122 175 223 269 310 348 - 153 208 259 306 349 - 127 188 246 298 347

Qev 200 222 234 238 232 217 - 225 244 253 251 238 - 222 251 266 269 260

Dpev 29,7 36,5 40,7 41,8 39,8 34,8 - 37,4 44,2 47,5 46,7 42,0 - 36,6 46,5 52,5 53,7 50,1

Pt 1285 1463 1584 1648 1655 1606 - 1456 1626 1728 1763 1731 - 1415 1640 1788 1859 1854

Qcd 221 251 272 283 284 276 - 250 279 297 303 298 - 243 282 308 320 319

Dpcd 16,1 20,8 24,4 26,4 26,7 25,1 - 20,7 25,8 29,1 30,3 29,2 - 19,5 26,3 31,2 33,8 33,6

1414

Tcd 25 30 35 40 45 50 25 30 35 40 45 50 25 30 35 40 45 50

Tev 6 7 9

Pf 1329 1361 1360 1328 1263 1166 1348 1395 1405 1378 1313 1212 1373 1453 1486 1472 1411 1304

Pat 183 227 270 309 347 382 178 225 269 310 348 384 166 217 265 310 351 388

Qev 229 234 234 229 217 201 232 240 242 237 226 209 236 250 256 253 243 225

Dpev 37,1 38,9 38,9 37,1 33,6 28,6 38,2 40,9 41,5 39,9 36,3 30,9 39,7 44,4 46,5 45,6 41,9 35,8

Pt 1512 1588 1630 1637 1610 1548 1526 1620 1674 1688 1662 1596 1539 1670 1751 1781 1762 1692

Qcd 259 272 279 281 276 266 262 278 287 290 285 274 264 287 300 306 302 290

Dpcd 35,6 39,3 41,4 41,8 40,4 37,4 36,3 40,9 43,7 44,4 43,1 39,7 37,0 43,5 47,9 49,6 48,5 44,7

Tev 12 15 18

Pf 1379 1512 1585 1598 1551 1444 - 1538 1659 1707 1683 1587 - 1531 1706 1798 1807 1733

Pat 143 201 255 305 351 392 - 178 238 295 347 395 - 148 216 280 339 395

Qev 238 261 273 275 267 249 - 265 286 294 290 274 - 264 295 310 312 299

Dpev 40,1 48,2 53,0 53,9 50,7 44,0 - 50,0 58,1 61,5 59,8 53,2 - 49,6 61,6 68,4 69,1 63,5

Pt 1521 1713 1840 1903 1902 1836 - 1716 1897 2002 2030 1981 - 1679 1922 2078 2146 2128

Qcd 261 294 316 327 327 316 - 295 326 344 349 341 - 289 331 358 369 366

Dpcd 36,2 45,8 52,9 56,6 56,6 52,8 - 46,1 56,3 62,8 64,6 61,6 - 44,2 57,9 67,7 72,3 71,1

Tcd [°C] - Source (side) heat exchanger output water temperature

Tev [°C] - Plant (side) cooling exchanger output water temperature

Pf [kW] - Cooling capacity

Pat [kW] - Total power input

Qev [m³/h] - Plant (side) heat exchanger water flow

Dpev [kPa] - Plant (side) cooling exchanger pressure drop

Pt [kW] - Heating capacity

Qcd [m³/h] - Source (side) heating exchanger water flow

Dpcd [kPa] - Source (side) heat exchanger pressure drop

'-' Conditions outside the operating range

Waterflow and pressure drop on heat exchangers calculated with 5°C of delta T

ELCADOC - Ver. 0.9.9.11 10 TECS-HF_HC_HCH_0251_1614_200910_EN Ref.: R134a

TECS-HF

COOLING CAPACITY

HC

1614

Tcd 25 30 35 40 45 50 25 30 35 40 45 50 25 30 35 40 45 50

Tev 6 7 9

Pf 1516 1562 1568 1536 1465 1355 1535 1599 1618 1593 1523 1409 1556 1659 1707 1699 1635 1516

Pat 214 267 317 364 407 447 208 263 316 364 410 452 193 254 311 364 413 458

Qev 261 269 270 264 252 233 264 275 279 274 262 242 268 286 294 293 282 261

Dpev 35,4 37,6 37,9 36,3 33,1 28,3 36,3 39,4 40,3 39,1 35,7 30,6 37,3 42,5 44,9 44,5 41,2 35,4

Pt 1730 1829 1885 1900 1872 1803 1742 1862 1934 1957 1933 1860 1749 1913 2018 2063 2048 1974

Qcd 297 314 323 326 321 309 299 319 332 336 332 319 300 328 346 354 352 339

Dpcd 33,4 37,3 39,7 40,3 39,2 36,3 33,9 38,7 41,8 42,8 41,8 38,7 34,2 40,9 45,5 47,6 47,0 43,6

Tev 12 15 18

Pf 1550 1718 1814 1840 1795 1678 - 1737 1890 1959 1944 1843 - 1717 1936 2057 2082 2010

Pat 163 233 298 358 414 464 - 204 278 346 408 466 - 168 251 327 398 462

Qev 267 296 313 317 309 289 - 300 326 338 335 318 - 296 334 355 359 347

Dpev 37,1 45,6 50,8 52,3 49,7 43,5 - 46,7 55,3 59,4 58,4 52,6 - 45,7 58,0 65,6 67,2 62,6

Pt 1713 1950 2112 2198 2208 2143 - 1941 2168 2305 2352 2309 - 1886 2186 2385 2480 2473

Qcd 294 335 363 378 379 368 - 334 373 396 404 397 - 324 376 410 427 426

Dpcd 32,9 42,6 50,0 54,2 54,7 51,5 - 42,3 52,8 59,7 62,2 59,9 - 40,0 53,7 64,0 69,2 68,8

Tcd [°C] - Source (side) heat exchanger output water temperature

Tev [°C] - Plant (side) cooling exchanger output water temperature

Pf [kW] - Cooling capacity

Pat [kW] - Total power input

Qev [m³/h] - Plant (side) heat exchanger water flow

Dpev [kPa] - Plant (side) cooling exchanger pressure drop

Pt [kW] - Heating capacity

Qcd [m³/h] - Source (side) heating exchanger water flow

Dpcd [kPa] - Source (side) heat exchanger pressure drop

'-' Conditions outside the operating range

Waterflow and pressure drop on heat exchangers calculated with 5°C of delta T

ELCADOC - Ver. 0.9.9.11 11 TECS-HF_HC_HCH_0251_1614_200910_EN Ref.: R134a

TECS-HF

COOLING CAPACITY

LC

0511

Tcd 25 30 32 35 38 40 25 30 32 35 38 40 25 30 32 35 38 40

Tev 6 7 9

Pf 493 494 488 472 448 427 502 508 503 488 465 444 517 532 530 519 499 480

Pat 72,1 85,1 88,9 93,2 95,7 96,4 70,7 84,4 88,5 93,2 96,2 97,3 67,1 82,3 87,0 92,9 97,1 99,0

Qev 84,8 85,0 84,0 81,2 77,1 73,5 86,5 87,4 86,6 84,1 80,0 76,5 89,0 91,6 91,3 89,5 85,9 82,6

Dpev 33,4 33,5 32,7 30,6 27,6 25,1 34,7 35,4 34,8 32,8 29,7 27,2 36,8 38,9 38,7 37,1 34,2 31,7

Pt 565 579 577 565 544 524 573 592 591 582 561 542 584 614 617 612 596 579

Qcd 96,8 99,2 98,9 96,9 93,2 89,8 98,2 102 101 99,8 96,3 93,0 100 105 106 105 102 99,3

Dpcd 55,2 58,0 57,6 55,3 51,2 47,5 56,8 60,7 60,6 58,6 54,6 50,9 59,1 65,4 66,1 65,0 61,6 58,1

Tev 12 15 18

Pf 527 559 564 562 549 534 523 576 589 599 598 591 - 583 606 631 646 651

Pat 59,6 77,4 83,4 91,3 97,8 101 49,5 70,4 77,9 88,4 97,8 103 - 61,4 70,7 84,2 97,1 105

Qev 90,8 96,4 97,2 96,8 94,6 92,1 90,3 99,4 102 103 103 102 - 101 105 109 112 112

Dpev 38,3 43,1 43,8 43,5 41,5 39,3 37,8 45,9 47,9 49,5 49,4 48,3 - 47,0 50,8 55,1 57,8 58,5

Pt 587 637 647 653 647 636 573 647 667 688 696 695 - 644 677 716 744 756

Qcd 101 109 111 112 111 109 98,4 111 115 118 120 119 - 111 116 123 128 130

Dpcd 59,7 70,4 72,8 74,1 72,7 70,2 57,0 72,8 77,4 82,2 84,3 84,0 - 72,3 79,7 89,2 96,3 99,6

0912

Tcd 25 30 32 35 38 40 25 30 32 35 38 40 25 30 32 35 38 40

Tev 6 7 9

Pf 910 898 883 848 800 761 932 926 912 879 831 791 968 976 966 938 894 855

Pat 137 158 164 171 176 178 136 157 164 172 177 179 131 155 163 172 179 182

Qev 157 155 152 146 138 131 160 159 157 151 143 136 167 168 166 162 154 147

Dpev 33,9 33,0 31,9 29,4 26,2 23,6 35,5 35,1 34,0 31,6 28,3 25,6 38,4 39,0 38,2 36,0 32,7 29,9

Pt 1048 1056 1047 1019 976 938 1068 1083 1076 1051 1008 970 1100 1131 1129 1110 1072 1037

Qcd 180 181 179 175 167 161 183 186 184 180 173 166 189 194 194 190 184 178

Dpcd 32,9 33,4 32,8 31,2 28,6 26,4 34,2 35,2 34,7 33,1 30,5 28,3 36,3 38,4 38,3 37,0 34,6 32,3

Tev 12 15 18

Pf 1004 1037 1037 1021 988 956 1016 1083 1095 1098 1083 1062 - 1112 1140 1168 1178 1175

Pat 121 149 158 171 181 187 106 139 151 168 183 192 - 126 141 163 184 198

Qev 173 179 179 176 170 165 175 187 189 189 187 183 - 192 197 202 203 203

Dpev 41,3 44,1 44,1 42,8 40,0 37,4 42,4 48,1 49,2 49,5 48,1 46,3 - 50,8 53,4 56,1 57,1 56,8

Pt 1124 1186 1195 1192 1169 1142 1122 1222 1246 1266 1266 1254 - 1238 1281 1331 1362 1373

Qcd 193 204 205 205 201 196 193 210 214 218 218 216 - 213 220 229 234 236

Dpcd 38,0 42,3 43,0 42,7 41,1 39,3 37,9 44,9 46,7 48,3 48,3 47,4 - 46,2 49,5 53,4 56,0 56,9

1012

Tcd 25 30 32 35 38 40 25 30 32 35 38 40 25 30 32 35 38 40

Tev 6 7 9

Pf 986 989 977 945 897 855 1005 1016 1007 978 931 890 1034 1065 1061 1040 999 960

Pat 144 170 178 186 191 193 141 169 177 186 193 195 134 164 174 186 194 198

Qev 170 170 168 163 154 147 173 175 173 168 160 153 178 183 183 179 172 165

Dpev 32,0 32,1 31,4 29,4 26,4 24,1 33,3 34,0 33,4 31,5 28,5 26,1 35,2 37,3 37,1 35,6 32,9 30,4

Pt 1131 1159 1155 1132 1088 1048 1147 1185 1184 1164 1124 1085 1168 1229 1235 1226 1193 1158

Qcd 194 199 198 194 187 180 197 203 203 200 193 186 200 211 212 210 205 199

Dpcd 26,7 28,0 27,8 26,7 24,7 23,0 27,4 29,3 29,3 28,3 26,4 24,6 28,5 31,6 31,9 31,4 29,8 28,1

Tev 12 15 18

Pf 1054 1119 1129 1125 1099 1070 1046 1153 1179 1199 1198 1184 - 1166 1212 1264 1294 1303

Pat 119 155 167 182 196 203 98,6 141 156 177 196 207 - 122 141 168 194 211

Qev 182 193 195 194 189 184 180 199 203 207 207 204 - 201 209 218 223 225

Dpev 36,6 41,3 42,0 41,7 39,8 37,7 36,2 43,9 45,9 47,5 47,4 46,3 - 45,0 48,6 52,8 55,4 56,1

Pt 1173 1274 1295 1307 1295 1273 1145 1294 1335 1376 1393 1391 - 1289 1354 1432 1488 1514

Qcd 201 219 222 225 222 219 197 222 229 236 239 239 - 222 233 246 256 260

Dpcd 28,8 34,0 35,1 35,8 35,1 33,9 27,5 35,1 37,4 39,7 40,7 40,6 - 34,9 38,5 43,1 46,5 48,1

Tcd [°C] - Source (side) heat exchanger output water temperature

Tev [°C] - Plant (side) cooling exchanger output water temperature

Pf [kW] - Cooling capacity

Pat [kW] - Total power input

Qev [m³/h] - Plant (side) heat exchanger water flow

Dpev [kPa] - Plant (side) cooling exchanger pressure drop

Pt [kW] - Heating capacity

Qcd [m³/h] - Source (side) heating exchanger water flow

Dpcd [kPa] - Source (side) heat exchanger pressure drop

'-' Conditions outside the operating range

Waterflow and pressure drop on heat exchangers calculated with 5°C of delta T

ELCADOC - Ver. 0.9.9.11 12 TECS-HF_LC_0511_1954_200910_EN Ref.: R134a

TECS-HF

COOLING CAPACITY

LC

1353

Tcd 25 30 32 35 38 40 25 30 32 35 38 40 25 30 32 35 38 40

Tev 6 7 9

Pf 1396 1385 1364 1313 1240 1179 1426 1426 1407 1359 1287 1226 1474 1498 1487 1448 1383 1324

Pat 204 236 246 258 265 268 201 235 245 258 267 270 193 231 243 258 269 274

Qev 240 238 235 226 213 203 245 245 242 234 222 211 254 258 256 249 238 228

Dpev 42,7 42,1 40,8 37,8 33,7 30,5 44,6 44,6 43,4 40,5 36,4 33,0 47,7 49,2 48,5 46,0 42,0 38,5

Pt 1600 1622 1610 1571 1506 1448 1627 1661 1652 1617 1554 1497 1667 1728 1729 1706 1651 1599

Qcd 274 278 276 269 258 248 279 285 283 277 267 257 286 297 297 293 284 274

Dpcd 57,1 58,7 57,9 55,2 50,7 46,9 59,1 61,6 61,0 58,5 54,0 50,1 62,1 66,8 66,9 65,1 61,1 57,3

Tev 12 15 18

Pf 1517 1585 1590 1573 1527 1481 1523 1647 1673 1688 1674 1649 - 1683 1737 1794 1824 1828

Pat 174 219 235 255 272 281 149 203 222 250 274 290 - 181 205 241 276 299

Qev 261 273 274 271 263 255 263 284 289 291 289 284 - 290 300 310 315 316

Dpev 50,6 55,2 55,6 54,4 51,3 48,2 51,1 59,7 61,6 62,8 61,7 59,8 - 62,4 66,5 71,0 73,3 73,7

Pt 1691 1804 1824 1828 1799 1762 1672 1849 1895 1938 1949 1938 - 1863 1942 2036 2100 2127

Qcd 290 310 313 314 309 303 287 318 326 333 335 333 - 320 334 350 361 366

Dpcd 64,0 72,9 74,6 74,9 72,6 69,7 62,7 76,7 80,6 84,3 85,3 84,4 - 78,0 84,7 93,1 99,2 102

1453

Tcd 25 30 32 35 38 40 25 30 32 35 38 40 25 30 32 35 38 40

Tev 6 7 9

Pf 1476 1478 1460 1412 1339 1277 1505 1520 1505 1461 1391 1329 1549 1592 1587 1554 1492 1434

Pat 217 255 267 280 287 289 213 253 266 280 289 292 202 247 261 279 291 297

Qev 254 254 251 243 231 220 259 262 259 252 239 229 267 274 273 268 257 247

Dpev 47,8 47,9 46,7 43,7 39,3 35,8 49,7 50,6 49,7 46,8 42,4 38,7 52,7 55,7 55,3 53,0 48,9 45,2

Pt 1692 1733 1726 1691 1626 1567 1717 1773 1771 1741 1679 1621 1751 1840 1848 1833 1783 1731

Qcd 290 297 296 290 279 269 294 304 304 299 288 278 300 316 317 315 306 297

Dpcd 27,8 29,1 28,9 27,8 25,7 23,8 28,6 30,5 30,4 29,4 27,4 25,5 29,8 32,9 33,2 32,7 30,9 29,2

Tev 12 15 18

Pf 1580 1676 1689 1682 1642 1598 1571 1728 1765 1794 1790 1769 - 1749 1816 1891 1934 1946

Pat 180 233 251 274 293 304 149 212 234 266 293 310 - 185 213 253 292 316

Qev 272 289 291 290 283 275 271 298 304 309 309 305 - 302 313 326 334 336

Dpev 54,9 61,7 62,7 62,2 59,3 56,1 54,3 65,7 68,6 70,8 70,5 68,9 - 67,4 72,7 78,8 82,5 83,5

Pt 1760 1908 1939 1956 1936 1902 1720 1940 2000 2059 2083 2079 - 1934 2029 2144 2226 2262

Qcd 302 328 333 336 333 327 296 333 344 354 358 357 - 333 349 369 383 389

Dpcd 30,1 35,4 36,6 37,2 36,5 35,2 28,8 36,7 39,0 41,3 42,3 42,2 - 36,5 40,2 44,9 48,4 50,0

1854

Tcd 25 30 32 35 38 40 25 30 32 35 38 40 25 30 32 35 38 40

Tev 6 7 9

Pf 1838 1833 1808 1747 1656 1579 1877 1887 1866 1809 1720 1644 1937 1982 1972 1928 1848 1775

Pat 266 312 327 343 355 359 261 311 326 344 356 362 250 304 322 343 359 367

Qev 316 316 311 301 285 272 323 325 321 311 296 283 334 341 340 332 318 306

Dpev 71,1 70,7 68,8 64,2 57,7 52,4 74,1 74,9 73,3 68,9 62,3 56,8 79,1 82,7 81,9 78,3 71,9 66,4

Pt 2103 2145 2135 2090 2010 1938 2138 2198 2192 2153 2077 2005 2187 2286 2294 2271 2208 2142

Qcd 361 368 366 358 345 332 367 377 376 369 356 344 375 392 394 390 379 368

Dpcd 49,4 51,4 50,9 48,8 45,2 42,0 51,1 54,0 53,7 51,8 48,3 45,0 53,5 58,5 58,9 57,7 54,6 51,4

Tev 12 15 18

Pf 1986 2092 2104 2089 2036 1978 1985 2164 2204 2231 2219 2188 - 2197 2273 2354 2397 2404

Pat 225 289 310 339 362 374 190 265 292 329 362 381 - 234 267 314 359 387

Qev 342 361 363 360 351 341 342 373 380 385 383 377 - 379 392 406 414 415

Dpev 83,2 92,3 93,4 92,1 87,4 82,5 83,2 98,9 103 105 104 101 - 102 109 117 122 122

Pt 2211 2381 2415 2428 2397 2353 2175 2429 2496 2560 2580 2569 - 2431 2540 2668 2755 2790

Qcd 380 409 415 417 412 404 374 417 429 440 444 442 - 418 437 459 474 480

Dpcd 54,7 63,5 65,3 66,1 64,5 62,1 53,1 66,2 69,9 73,6 74,8 74,1 - 66,4 72,5 80,0 85,4 87,6

Tcd [°C] - Source (side) heat exchanger output water temperature

Tev [°C] - Plant (side) cooling exchanger output water temperature

Pf [kW] - Cooling capacity

Pat [kW] - Total power input

Qev [m³/h] - Plant (side) heat exchanger water flow

Dpev [kPa] - Plant (side) cooling exchanger pressure drop

Pt [kW] - Heating capacity

Qcd [m³/h] - Source (side) heating exchanger water flow

Dpcd [kPa] - Source (side) heat exchanger pressure drop

'-' Conditions outside the operating range

Waterflow and pressure drop on heat exchangers calculated with 5°C of delta T

ELCADOC - Ver. 0.9.9.11 13 TECS-HF_LC_0511_1954_200910_EN Ref.: R134a

TECS-HF

COOLING CAPACITY

LC

1954

Tcd 25 30 32 35 38 40 25 30 32 35 38 40 25 30 32 35 38 40

Tev 6 7 9

Pf 1969 1972 1948 1884 1787 1705 2007 2027 2008 1949 1856 1773 2066 2124 2117 2074 1991 1914

Pat 289 340 356 373 383 386 283 338 354 373 385 389 269 329 348 372 388 396

Qev 339 339 335 324 308 293 346 349 346 336 319 305 356 366 365 357 343 330

Dpev 59,7 59,9 58,4 54,7 49,2 44,8 62,1 63,3 62,1 58,6 53,1 48,5 65,8 69,6 69,1 66,3 61,1 56,5

Pt 2257 2312 2303 2257 2170 2090 2290 2365 2362 2322 2240 2162 2335 2454 2466 2445 2379 2310

Qcd 387 396 395 387 372 359 393 405 405 398 384 371 400 421 423 420 408 397

Dpcd 56,9 59,7 59,3 56,9 52,6 48,9 58,6 62,5 62,3 60,3 56,2 52,3 60,9 67,3 68,0 66,9 63,4 59,8

Tev 12 15 18

Pf 2107 2235 2253 2243 2191 2132 2094 2304 2354 2393 2388 2360 - 2332 2422 2522 2580 2596

Pat 239 310 334 365 391 405 199 282 312 354 391 414 - 246 284 337 389 422

Qev 363 385 388 387 378 368 361 397 406 413 412 407 - 402 418 435 445 448

Dpev 68,6 77,2 78,4 77,7 74,2 70,2 67,8 82,1 85,7 88,6 88,2 86,1 - 84,2 90,9 98,5 103 104

Pt 2346 2545 2587 2609 2582 2538 2293 2587 2667 2747 2779 2774 - 2578 2706 2860 2969 3018

Qcd 403 437 444 448 444 436 394 444 458 472 478 477 - 443 465 492 511 519

Dpcd 61,6 72,6 75,0 76,3 74,8 72,2 59,0 75,1 79,8 84,7 86,7 86,4 - 74,7 82,2 91,9 99,1 102

Tcd [°C] - Source (side) heat exchanger output water temperature

Tev [°C] - Plant (side) cooling exchanger output water temperature

Pf [kW] - Cooling capacity

Pat [kW] - Total power input

Qev [m³/h] - Plant (side) heat exchanger water flow

Dpev [kPa] - Plant (side) cooling exchanger pressure drop

Pt [kW] - Heating capacity

Qcd [m³/h] - Source (side) heating exchanger water flow

Dpcd [kPa] - Source (side) heat exchanger pressure drop

'-' Conditions outside the operating range

Waterflow and pressure drop on heat exchangers calculated with 5°C of delta T

ELCADOC - Ver. 0.9.9.11 14 TECS-HF_LC_0511_1954_200910_EN Ref.: R134a

TECS-HF

HEAT PUMP CAPACITY

HC/H

0251

Tev 6 7 8 9 10 11 6 7 8 9 10 11 6 7 8 9 10 11

Tcd 32 35 40

Pt 274 281 287 293 297 301 276 284 292 299 305 310 274 283 291 299 307 314

Qcd 47,4 48,7 49,7 50,7 51,5 52,1 47,8 49,2 50,5 51,7 52,8 53,7 47,5 49,1 50,5 51,9 53,3 54,5

Pcd 23,8 25,1 26,2 27,2 28,1 28,8 24,2 25,7 27,0 28,3 29,5 30,6 23,9 25,5 27,0 28,6 30,0 31,5

Pat 42,2 41,9 41,5 41,0 40,4 39,6 46,1 46,0 45,7 45,4 45,0 44,4 52,0 52,0 52,0 51,9 51,7 51,4

Pf 241 241 241 241 241 241 241 241 241 241 241 241 241 241 241 241 241 241

Qev 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5

Dpev 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0

Tev 6 7 8 9 10 11 6 7 8 9 10 11 6 7 8 9 10 11

Tcd 42 45 48

Pt 271 280 288 297 304 312 265 273 281 289 297 305 256 263 270 277 285 292

Qcd 47,1 48,6 50,1 51,5 52,8 54,2 46,0 47,5 48,8 50,2 51,6 52,9 44,6 45,8 47,0 48,3 49,5 50,8

Pcd 23,5 25,0 26,5 28,1 29,6 31,1 22,5 23,8 25,3 26,7 28,2 29,7 21,1 22,2 23,4 24,7 26,0 27,3

Pat 54,1 54,2 54,2 54,2 54,1 53,9 57,1 57,2 57,2 57,3 57,2 57,2 59,8 59,9 59,9 60,0 60,0 60,0

Pf 241 241 241 241 241 241 241 241 241 241 241 241 241 241 241 241 241 241

Qev 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5 41,5

Dpev 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0 32,0

0311

Tev 6 7 8 9 10 11 6 7 8 9 10 11 6 7 8 9 10 11

Tcd 32 35 40

Pt 334 343 350 356 361 365 337 347 356 364 371 377 335 346 356 366 375 383

Qcd 57,9 59,3 60,5 61,6 62,5 63,1 58,4 60,1 61,6 63,0 64,3 65,3 58,1 60,0 61,7 63,4 65,0 66,5

Pcd 38,3 40,3 42,0 43,4 44,7 45,7 39,1 41,4 43,5 45,5 47,3 48,9 38,7 41,2 43,7 46,1 48,4 50,7

Pat 52,4 52,1 51,6 51,0 50,2 49,2 57,0 57,0 56,8 56,4 55,9 55,2 63,9 64,1 64,2 64,1 63,9 63,6

Pf 293 293 293 293 293 293 293 293 293 293 293 293 293 293 293 293 293 293

Qev 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5

Dpev 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1

Tev 6 7 8 9 10 11 6 7 8 9 10 11 6 7 8 9 10 11

Tcd 42 45 48

Pt 331 342 352 362 372 381 324 334 343 353 363 372 312 321 330 339 348 357

Qcd 57,5 59,4 61,2 62,9 64,6 66,1 56,2 58,0 59,7 61,3 63,0 64,6 54,3 55,8 57,4 58,9 60,5 62,0

Pcd 37,9 40,4 42,9 45,3 47,7 50,1 36,2 38,5 40,8 43,1 45,5 47,8 33,8 35,7 37,7 39,7 41,9 44,1

Pat 66,3 66,6 66,7 66,7 66,6 66,5 69,6 69,8 70,0 70,1 70,2 70,1 72,5 72,7 72,8 72,9 73,0 73,1

Pf 293 293 293 293 293 293 293 293 293 293 293 293 293 293 293 293 293 293

Qev 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5 50,5

Dpev 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1 29,1

0351

Tev 6 7 8 9 10 11 6 7 8 9 10 11 6 7 8 9 10 11

Tcd 32 35 40

Pt 408 418 426 434 440 446 413 424 434 444 453 460 413 426 439 451 462 472

Qcd 70,6 72,2 73,7 75,1 76,2 77,2 71,5 73,4 75,2 76,9 78,4 79,7 71,7 74,0 76,1 78,2 80,1 81,9

Pcd 44,6 46,7 48,7 50,4 52,0 53,3 45,7 48,2 50,7 52,9 55,0 56,9 46,0 49,0 51,9 54,7 57,4 60,1

Pat 63,0 62,6 62,0 61,2 60,2 59,0 69,3 69,2 68,8 68,4 67,7 66,9 79,4 79,6 79,7 79,6 79,4 79,0

Pf 359 359 359 359 359 359 359 359 359 359 359 359 359 359 359 359 359 359

Qev 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8

Dpev 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1

Tev 6 7 8 9 10 11 6 7 8 9 10 11 6 7 8 9 10 11

Tcd 42 45 48

Pt 411 425 438 450 462 473 406 419 432 445 457 469 397 410 422 435 447 460

Qcd 71,4 73,7 75,9 78,1 80,1 82,1 70,5 72,8 75,1 77,3 79,4 81,5 69,1 71,3 73,5 75,7 77,8 80,0

Pcd 45,7 48,7 51,6 54,6 57,5 60,3 44,5 47,5 50,4 53,4 56,4 59,5 42,7 45,5 48,3 51,3 54,2 57,3

Pat 83,2 83,6 83,8 83,9 83,8 83,6 88,8 89,3 89,7 90,0 90,1 90,2 94,2 94,8 95,3 95,8 96,1 96,4

Pf 359 359 359 359 359 359 359 359 359 359 359 359 359 359 359 359 359 359

Qev 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8 61,8

Dpev 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1 25,1

Tev [°C] - Source (side) heat exchanger output water temperature

Tcd (°C) - Plant (side) heating exchanger output water temperature

Pt (kW) - Heating capacity

Qcd (m³/h) - Plant (side) heating exchanger water flow

Dpcd (kPa) - Plant (side) heating exchanger pressure drop

Pat (kW) - Total power input

Pf (kW) - Cooling capacity

Qev (m³/h) - Source (side) heat exchanger water flow

Dpev (kPa) - Source (side) cooling exchanger pressure drop

'-' - Conditions outside the operating range

Waterflow and pressure drop on heat exchangers calculated with 5°C of delta T

ELCADOC - Ver. 0.9.9.11 15 TECS-HF_HC_HCH_0251_1614_200910_EN Ref.: R134a

TECS-HF

HEAT PUMP CAPACITY

HC/H

0411

Tev 6 7 8 9 10 11 6 7 8 9 10 11 6 7 8 9 10 11

Tcd 32 35 40

Pt 460 470 479 487 493 498 467 479 490 500 509 517 470 484 498 511 523 534

Qcd 79,7 81,4 82,9 84,2 85,3 86,2 80,9 83,0 84,9 86,6 88,2 89,6 81,6 84,0 86,4 88,6 90,7 92,7

Pcd 37,4 39,0 40,5 41,8 42,9 43,8 38,6 40,6 42,5 44,2 45,8 47,2 39,2 41,6 44,0 46,3 48,5 50,6

Pat 71,8 71,1 70,3 69,2 67,9 66,4 79,2 78,9 78,4 77,6 76,7 75,6 90,9 91,1 91,1 91,0 90,6 90,1

Pf 405 405 405 405 405 405 405 405 405 405 405 405 405 405 405 405 405 405

Qev 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7

Dpev 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6

Tev 6 7 8 9 10 11 6 7 8 9 10 11 6 7 8 9 10 11

Tcd 42 45 48

Pt 468 483 497 511 524 536 463 478 492 507 520 534 453 468 482 497 511 525

Qcd 81,3 83,9 86,3 88,7 90,9 93,1 80,4 83,0 85,6 88,0 90,4 92,7 78,8 81,4 83,9 86,4 88,9 91,3

Pcd 38,9 41,4 43,9 46,3 48,7 51,0 38,1 40,6 43,1 45,6 48,2 50,6 36,6 39,0 41,5 44,0 46,5 49,1

Pat 95,4 95,7 96,0 96,0 95,9 95,6 102 102 103 103 103 103 108 109 110 110 111 111

Pf 405 405 405 405 405 405 405 405 405 405 405 405 405 405 405 405 405 405

Qev 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7 69,7

Dpev 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6 22,6

0512

Tev 6 7 8 9 10 11 6 7 8 9 10 11 6 7 8 9 10 11

Tcd 32 35 40

Pt 565 580 593 604 613 620 569 586 602 616 628 639 565 583 601 617 633 648

Qcd 97,8 100 103 104 106 107 98,6 102 104 107 109 111 98,0 101 104 107 110 112

Pcd 20,7 21,8 22,7 23,6 24,3 24,9 21,0 22,3 23,5 24,6 25,6 26,5 20,7 22,1 23,4 24,8 26,0 27,3

Pat 87,0 86,5 85,6 84,6 83,2 81,6 95,0 94,8 94,3 93,6 92,7 91,6 107 107 107 107 107 106

Pf 497 497 497 497 497 497 497 497 497 497 497 497 497 497 497 497 497 497

Qev 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6

Dpev 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6

Tev 6 7 8 9 10 11 6 7 8 9 10 11 6 7 8 9 10 11

Tcd 42 45 48

Pt 559 577 594 611 627 643 546 563 579 595 612 627 528 542 557 571 586 602

Qcd 97,0 100 103 106 109 112 94,9 97,8 101 103 106 109 91,8 94,3 96,8 99,4 102 105

Pcd 20,3 21,7 23,0 24,3 25,6 26,9 19,4 20,7 21,9 23,1 24,4 25,7 18,2 19,2 20,3 21,3 22,5 23,7

Pat 111 112 112 112 111 111 117 118 118 118 118 118 123 123 123 123 123 123

Pf 497 497 497 497 497 497 497 497 497 497 497 497 497 497 497 497 497 497

Qev 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6 85,6

Dpev 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6 28,6

0612

Tev 6 7 8 9 10 11 6 7 8 9 10 11 6 7 8 9 10 11

Tcd 32 35 40

Pt 670 686 701 713 723 730 676 695 713 729 743 755 671 693 713 733 751 768

Qcd 116 119 121 123 125 126 117 120 123 126 129 131 116 120 124 127 130 133

Pcd 39,2 41,2 42,9 44,4 45,7 46,6 40,0 42,4 44,5 46,5 48,3 50,0 39,6 42,2 44,7 47,2 49,5 51,8

Pat 105 104 103 102 100 98,2 114 114 114 113 112 110 128 128 128 128 128 127

Pf 588 588 588 588 588 588 588 588 588 588 588 588 588 588 588 588 588 588

Qev 101 101 101 101 101 101 101 101 101 101 101 101 101 101 101 101 101 101

Dpev 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3

Tev 6 7 8 9 10 11 6 7 8 9 10 11 6 7 8 9 10 11

Tcd 42 45 48

Pt 664 686 706 726 745 763 648 668 688 707 726 745 626 643 660 678 696 714

Qcd 115 119 123 126 129 132 113 116 120 123 126 130 109 112 115 118 121 124

Pcd 38,8 41,4 43,9 46,4 48,8 51,3 37,1 39,4 41,7 44,1 46,5 49,0 34,6 36,5 38,5 40,6 42,8 45,1

Pat 133 133 133 133 133 133 139 140 140 140 140 140 145 145 146 146 146 146

Pf 588 588 588 588 588 588 588 588 588 588 588 588 588 588 588 588 588 588

Qev 101 101 101 101 101 101 101 101 101 101 101 101 101 101 101 101 101 101

Dpev 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3 30,3

Tev [°C] - Source (side) heat exchanger output water temperature

Tcd (°C) - Plant (side) heating exchanger output water temperature

Pt (kW) - Heating capacity

Qcd (m³/h) - Plant (side) heating exchanger water flow

Dpcd (kPa) - Plant (side) heating exchanger pressure drop

Pat (kW) - Total power input

Pf (kW) - Cooling capacity

Qev (m³/h) - Source (side) heat exchanger water flow

Dpev (kPa) - Source (side) cooling exchanger pressure drop

'-' - Conditions outside the operating range

Waterflow and pressure drop on heat exchangers calculated with 5°C of delta T

ELCADOC - Ver. 0.9.9.11 16 TECS-HF_HC_HCH_0251_1614_200910_EN Ref.: R134a

TECS-HF

HEAT PUMP CAPACITY

HC/H

0712

Tev 6 7 8 9 10 11 6 7 8 9 10 11 6 7 8 9 10 11

Tcd 32 35 40

Pt 815 835 853 868 882 894 824 847 868 888 905 921 825 851 876 900 922 943

Qcd 141 144 148 150 153 155 143 147 150 154 157 160 143 148 152 156 160 164

Pcd 20,3 21,3 22,2 23,0 23,8 24,4 20,8 21,9 23,1 24,1 25,1 26,0 20,9 22,2 23,6 24,8 26,1 27,3

Pat 127 126 125 124 122 119 139 139 139 138 137 135 159 160 160 160 160 159

Pf 716 716 716 716 716 716 716 716 716 716 716 716 716 716 716 716 716 716

Qev 123 123 123 123 123 123 123 123 123 123 123 123 123 123 123 123 123 123

Dpev 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0

Tev 6 7 8 9 10 11 6 7 8 9 10 11 6 7 8 9 10 11

Tcd 42 45 48

Pt 821 847 873 897 921 944 809 835 861 887 911 935 791 817 842 867 892 916

Qcd 142 147 152 156 160 164 141 145 150 154 158 163 138 142 146 151 155 159

Pcd 20,7 22,1 23,4 24,8 26,1 27,4 20,2 21,5 22,9 24,2 25,6 27,0 19,3 20,6 21,9 23,2 24,5 25,9

Pat 167 168 168 169 169 168 178 179 180 181 181 181 189 190 191 192 193 194

Pf 716 716 716 716 716 716 716 716 716 716 716 716 716 716 716 716 716 716

Qev 123 123 123 123 123 123 123 123 123 123 123 123 123 123 123 123 123 123

Dpev 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0 21,0

0812

Tev 6 7 8 9 10 11 6 7 8 9 10 11 6 7 8 9 10 11

Tcd 32 35 40

Pt 921 941 959 974 987 997 935 959 981 1001 1019 1035 941 970 997 1022 1047 1069

Qcd 159 163 166 169 171 173 162 166 170 173 176 179 163 168 173 177 182 185

Pcd 18,0 18,8 19,5 20,2 20,7 21,1 18,6 19,6 20,5 21,3 22,1 22,8 18,9 20,1 21,2 22,3 23,4 24,4

Pat 144 142 140 138 136 133 158 158 157 155 153 151 182 182 182 182 181 180

Pf 811 811 811 811 811 811 811 811 811 811 811 811 811 811 811 811 811 811

Qev 140 140 140 140 140 140 140 140 140 140 140 140 140 140 140 140 140 140

Dpev 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6

Tev 6 7 8 9 10 11 6 7 8 9 10 11 6 7 8 9 10 11

Tcd 42 45 48

Pt 938 967 996 1023 1048 1073 926 956 986 1014 1041 1068 907 937 966 994 1023 1051

Qcd 163 168 173 178 182 186 161 166 171 176 181 186 158 163 168 173 178 183

Pcd 18,8 20,0 21,2 22,4 23,5 24,6 18,4 19,6 20,8 22,0 23,3 24,5 17,7 18,8 20,0 21,2 22,5 23,7

Pat 191 191 192 192 192 191 204 205 206 207 207 207 216 218 219 220 221 222

Pf 811 811 811 811 811 811 811 811 811 811 811 811 811 811 811 811 811 811

Qev 140 140 140 140 140 140 140 140 140 140 140 140 140 140 140 140 140 140

Dpev 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6 21,6

0913

Tev 6 7 8 9 10 11 6 7 8 9 10 11 6 7 8 9 10 11

Tcd 32 35 40

Pt 1004 1029 1050 1068 1083 1095 1013 1042 1068 1092 1114 1132 1006 1038 1069 1098 1125 1151

Qcd 174 178 182 185 187 189 175 180 185 189 193 196 174 180 185 190 195 200

Pcd 18,7 19,6 20,5 21,2 21,8 22,3 19,1 20,2 21,2 22,2 23,1 23,8 18,9 20,1 21,3 22,5 23,6 24,7

Pat 157 156 155 153 150 148 171 171 170 169 168 166 192 192 192 192 192 191

Pf 881 881 881 881 881 881 881 881 881 881 881 881 881 881 881 881 881 881

Qev 152 152 152 152 152 152 152 152 152 152 152 152 152 152 152 152 152 152

Dpev 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5

Tev 6 7 8 9 10 11 6 7 8 9 10 11 6 7 8 9 10 11

Tcd 42 45 48

Pt 995 1027 1058 1088 1116 1144 971 1001 1031 1060 1089 1117 938 964 990 1016 1043 1071

Qcd 173 178 184 189 194 199 169 174 179 184 189 194 163 168 172 177 182 186

Pcd 18,5 19,7 20,9 22,1 23,3 24,4 17,7 18,8 19,9 21,0 22,2 23,4 16,5 17,4 18,4 19,4 20,4 21,5

Pat 199 200 200 200 200 199 209 210 210 210 210 210 218 218 218 219 219 219

Pf 881 881 881 881 881 881 881 881 881 881 881 881 881 881 881 881 881 881

Qev 152 152 152 152 152 152 152 152 152 152 152 152 152 152 152 152 152 152

Dpev 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5 29,5

Tev [°C] - Source (side) heat exchanger output water temperature

Tcd (°C) - Plant (side) heating exchanger output water temperature

Pt (kW) - Heating capacity

Qcd (m³/h) - Plant (side) heating exchanger water flow

Dpcd (kPa) - Plant (side) heating exchanger pressure drop

Pat (kW) - Total power input

Pf (kW) - Cooling capacity

Qev (m³/h) - Source (side) heat exchanger water flow

Dpev (kPa) - Source (side) cooling exchanger pressure drop

'-' - Conditions outside the operating range

Waterflow and pressure drop on heat exchangers calculated with 5°C of delta T

ELCADOC - Ver. 0.9.9.11 17 TECS-HF_HC_HCH_0251_1614_200910_EN Ref.: R134a

TECS-HF

HEAT PUMP CAPACITY

HC/H

1053

Tev 6 7 8 9 10 11 6 7 8 9 10 11 6 7 8 9 10 11

Tcd 32 35 40

Pt 1190 1218 1244 1267 1287 1304 1202 1236 1267 1295 1321 1345 1204 1242 1279 1313 1346 1377

Qcd 206 211 215 219 223 226 208 214 219 224 229 233 209 216 222 228 233 239

Pcd 32,2 33,8 35,2 36,5 37,7 38,7 33,0 34,8 36,6 38,3 39,8 41,2 33,2 35,3 37,4 39,4 41,4 43,4

Pat 185 184 182 180 177 174 203 203 202 201 199 197 233 234 234 234 233 232

Pf 1045 1045 1045 1045 1045 1045 1045 1045 1045 1045 1045 1045 1045 1045 1045 1045 1045 1045