Professional Documents

Culture Documents

Magnesium Extruded Products and Casting Anodes

Uploaded by

Trần Tuấn VũOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Magnesium Extruded Products and Casting Anodes

Uploaded by

Trần Tuấn VũCopyright:

Available Formats

Magnesium Extruded es Magnesium Extruded es

At the requests of clients, may produce thickness or diameter of At the requests of clients, may produce thickness or diameter of

Motor heat radiation parts

ø 1.6- ø 3.5 magnesium welding rods

Oxidized magnesium alloy tube

ø 6- ø 12 magnesium welding rods

Magnesium shrinkage tube

Magnesium Casting Anodes Magnesium Casting Anodes

Magnesium casting anodes technical requests

Chemical Composition Standard:ASTM B 843-1995、 SY/T10019-1997 、GB/ T17731—2004 7731—2004

Main application: magnesium anode suitable applies in the of anticorrosion. Such as: oil,

Alloying element Inclusion(max)

gas, water transmission in underground or fresh water, underground cable, chemical, communication, bay,

Type Other

Al Zn Mn Mg Fe Cu Nl Si watercraft and reservoir strobe.

Each Total

MGAZ63B 5.3-6.7 2.5-3.5 0.15-0.60 Balance 0.003 0.01 0.001 0.08 - 0.30

MGAZ31B 2.7-3.5 0.6-1.4 0.2-1.0 Balance 0.003 0.01 0.001 0.08 0.05 0.30

MGM1C <0.01 - 0.5-1.3 Balance 0.01 0.01 0.001 0.05 0.05 0.30

Electrochemical Performance

Open-circuit Generating current amount

Type

-V (Cu/CuSO )

4 % (Cu/CuSO )

4 (A.h)/kg (Cu/CuSO 4)

MGAZ63B 1.57-1.67 ≥55 ≥1210

MGAZ31B 1.57-1.67 ≥55 ≥1210

MGM1C 1.77-1.82 ≥50 ≥1100

Anode Dimensions

Type Diameter (mm) Weight (Kg) High Potential L (mm) AZ63 anode L (mm)

C Type

C25 75 2.56 336 325

C36 114 3.7 202 193 Standard square type anode for oil

、D

American standard S、D

D type

typeanode

anode

C41 114 4.2 230 220

C77 110 7.8 431 412

C100 110 10.2 560 536

C145 146 14.7 494 472

C227 178 22.9 520 497

C274 114 28.2 1528 1462

Type Weight (Kg)

D Type A (mm) B (mm) C (mm)

9D2 4.082 69.9 76.2 549.3

14D2 6.350 69.9 76.2 850.9

20D2 9.072 69.9 76.2 1212.9

9D3 4.082 88.9 95.3 352.4

17D3 7.711 88.9 95.3 641.4

32D5 14.515 139.7 146.1 504.8

48D5 21.772 139.7 146.1 765.2

1.5Kg 1.5 80.0 70.0 190.0

2.5Kg 2.5 80.0 70.0 300.0

Type Weight (Kg)

A (mm) B (mm) C (mm)

S Type

3S3 1.4 76.2 76.2 114.3

American standard C type anode

5S3 2.5 76.2 76.2 190.5

9S2 4.1 50.8 50.8 685.8

9S3 4.1 76.2 76.2 342.9

17S2 7.7 50.8 50.8 1295.4

Standard type squar

square

e anode

anode

anodefor

for

for

oiloil

oil

17S3 7.7 76.2 76.2 647.7

20S2 9.1 50.8 50.8 1524.0

32S3 14.5 76.2 76.2 1143.0

32S5 14.5 127.0 127.0 533.4

40S3 18.1 76.2 76.2 1524.0

48S5 21.8 127.0 127.0 787.4

60S4 27.2 101.6 127.0 1524.0

NO. Weight (Kg) Size(lengh×width×height)

1 4±0.2 350×(75+85)×80

2 8±0.2 700×(75+85)×80

3 11±0.3 700×(90+100)×90

4 14±0.3 700×(100+110)×105

5 22±0.5 700×(130+150)×125

Bar-type anode for water heater Bracelet type anode ring

Magnesium Extruded Anodes Ribbon Anode

Standard:ASTM B 843-1995

843-1995 GBGB / T17731-2004 Standard:AST M B 843-1995

843-1995 SY / T0019-1997

Main application: water heater, water container, pre-polarization of steel structure in seawater, gas pipe, anticorrosion of Main Applications:Ribbon anodes are used for the cathodic protections of sleeved pipings, tanks and pipe networks and

grounding grids guarding against heavy current interference, and temporayt cathodic protection of pipings.

steel and iron structure where high resistant and electrolyte (soil and water) existed

Anode for water air conditioner

Magnesium ribbon

Flexible zinc ribbon

High effect anodes with additional resistance With screw thread bar anode (NPT-ASTM)

Chenical Cimposition

型号Type Al Zn Mn Fe Ni Cu Si Mg

Mg- <0.010 <0.010 <0.030 <0.002 <0.001 <0.001 <0.010 >99.95

Mg- <0.010 - 0.50-1.30 <0.03 <0.001 <0.02 - 余量Bal.

Chemical Composition

Product Specifications

Alloy elements Impurity elements (max) Section (A×B) (mm) 9.5×19

Designation Other Steel core diameter (mm) 3.2

Al Zn Mn Mg Fe Cu Nl Si

Each Total 重量 kg/m Weight 0.37

MGAZ63B 5.3-6.7 2.5-3.5 0.15-0.60 Balance 0.003 0.01 0.001 0.08 - 0.30 Seawater 2.4A/m

Current Output Soil(5000Ω.cm) 10mA/m

MGAZ31B 2.7-3.5 0.6-1.4 0.2-1.0 Balance 0.003 0.01 0.001 0.08 0.05 0.30

Frech Water(15000Ω.cm) 3mA/m

MGM1C <0.01 - 0.5-1.3 Balance 0.01 0.01 0.001 0.05 0.05 0.30

Electrochemistry Performance

Specification of extuded anode bar Open-circuit Close ciruit potential Generated energy Electricity efficiency

Type

(-V,Cu/CuSo 4 ) (-V,Cu/CuSo 4 ) (Ah/g) (%)

Anode Dia (mm) Core Dia (mm) Thread Unit weight (g/cm) >1.05 >1.00 780 95

>1.10 >1.05 780 90

13.97 2.0 NPT-ASTM/BSP/G/R 2.83

High purity zine >1.10 >1.05 740 90

19.05 3.4 NPT-ASTM/BSP/G/R 5.66

品 格 Product Specifications

21.34 3.4 NPT-ASTM/BSP/G/R 6.85

Dimension

Unit weight

Type

26.67 3.4 NPT-ASTM/BSP/G/R 10.42 (g/cm)

A (mm) B (mm) C (m)

33.40 3.4 NPT-ASTM/BSP/G/R 16.08 Extra Large (A) 25.4 31.75 30.5 35.72

39.65 4.8 NPT-ASTM/BSP/G/R 23.07 Large (B) 15.88 22.23 61 17.82

51.40 4.8 NPT-ASTM/BSP/G/R 37.96 Standard (C) 12.7 14.29 152.5/305/1098 8.93

Samll (D) 8.73 11.91 305 3.72

Aluminum Anode Zinc Anodes

Standard:GB/ T 4948-2002

Main application: Aluminum anodes are suitable for the cathidic protection for such metal structures as ships, machinaty,

offshore engineering, harbor facilities, and pipings and cables in an ooze corrosion envionment.

Chenical Cimposition

Impurities Less than

Element Al Cd

Fe Cu Pb Si Zn

Comtent % 0.3-0.6 0.05-0.12 0.005 0.005 0.006 0.125 Balance

Electrochemical Performanc

Open-circuit Working potential Theoretical Current Capacity Practical Capacity Current efficiency

Item

V (SCE) V (SCE) A·h/kg A·h/kg %

Performance -1.05∼-1.09 -1.00 ∼-1.05 820 >780 >95

Chenical Cimposition

Type of Alloy Zn In Cd Sn Mg Si Fe Cu Al

Standard:GB/ T 4950-2002

Al-Zn-In-Cd 2.5-4.5 0.018-0.050 0.005-0.020 - - ≤0.10 ≤0.15 ≤0.15 Balance Main application: Zinc anodes are suitable for the cathadic protetion for ships machinary, offshore engineering and harbor

Al-Zn-In-Sn 2.2-5.2 0.020-0.045 - 0.018-0.035 - ≤0.10 ≤0.15 ≤0.15 Balance facilities in seawater and fresh seawater and for pipes and cables embeded in soil with Cower resistivity.

Al-Zn-In-Si 5.5-7.0 0.025-0.035 - - - 0.10-0.15 ≤0.15 ≤0.15 Balance

Al-Zn-In-Sn-Mg 2.5-4.0 0.020-0.05 - 0.025-0.075 0.50-1.00 ≤0.10 ≤0.15 ≤0.15 Balance

Electrochemical Performanc

Open-circuit Working potential Practical Current Capacity Current efficiency

Item

V (SCE) V (SCE) A.h/kg \%

Performance -1.18∼-1.10 -1.12 ∼-1.05 ≥2400 ≥85

High Silicon Cast Iron Anode Complete Sets Of Anticorrosion Products

Standard:SYJ36-89

Main Applications:It is widely applied to the impressed current cathodic protection of oil drilling platform at sea.buried

pipings and cables under ground.

Testing patch with cable

Long effective electrode Cu/ CuSO4

Zinc grounding batteries

Chenical Cimposition

Type Si Cr Mn C Fe P S

Magnesium grounding batteries

High silicon cast iron 14-16 - 0.6-0.8 0.8-0.15 Balance ≤0.25 ≤0.1

Cr-containing silicon iron 14-16 4.0-4.5 0.6-0.8 0.8-0.15 Balance ≤0.25 ≤0.1

Electrochemical performance

Working current density Consumption

Material Environment

(A/m 2) (kg/A·a)

Seawater 50 0.3-1.0

High silicon cast iron

Fresh water, soil 10 0.05-0.2

Specifiection

Cable atteched to anode

Type Size (mm) Weight (Kg)

Section (mm 2 ) Length (mm)

YGT- Φ50×1500 22 25 1000

YGT- Φ75×1200 40 25 1000

YGT- Φ75×1500 50 25 1000 High potential anode filled with fillings

Testing peg

YGT- Φ100×1500 90 25 1000

Other Products

Lead and antimony alloy tube Magnesium welded frame parts Aluminum alloys casting

Magnesium alloy castings

You might also like

- Material Data Sheet: Manganese Bronze (High Strength Yellow Brass)Document1 pageMaterial Data Sheet: Manganese Bronze (High Strength Yellow Brass)Fred Duarte CaldeiraNo ratings yet

- Welding ConsumablesDocument79 pagesWelding Consumablesazam RazzaqNo ratings yet

- Aluminio 6063 T5 (Perfiles)Document5 pagesAluminio 6063 T5 (Perfiles)Carlos Andres Garcia MuñozNo ratings yet

- Magnesium Anodes 2020 Rev 2 DraftDocument7 pagesMagnesium Anodes 2020 Rev 2 DraftDiego Fernando HenaoNo ratings yet

- GS 22mo4 DatasheetDocument3 pagesGS 22mo4 Datasheetpateta50No ratings yet

- Inox 316 L: (Stainless Steel, Austenitic, AISI 316L, Annealed)Document3 pagesInox 316 L: (Stainless Steel, Austenitic, AISI 316L, Annealed)Hamid AZZOUZINo ratings yet

- Zamak-3 XometryDocument1 pageZamak-3 XometryFrancisco BocanegraNo ratings yet

- CeramicoDocument3 pagesCeramicoLivio EscuderoNo ratings yet

- Data Table For Grades Tool Die Steels SKD-11Document3 pagesData Table For Grades Tool Die Steels SKD-11Adhi candra irawanNo ratings yet

- Stainless Steel 1.4404Document1 pageStainless Steel 1.4404Alexandra PetreNo ratings yet

- C2700Document6 pagesC2700Andrew TanNo ratings yet

- CLC 18-12-4LN: A 3%mo Austenitic Stainless Steel With Nitrogen Addition (317LN Grade)Document4 pagesCLC 18-12-4LN: A 3%mo Austenitic Stainless Steel With Nitrogen Addition (317LN Grade)PeterWayNo ratings yet

- Material Data Sheet: Manganese Bronze (High Strength Yellow Brass)Document1 pageMaterial Data Sheet: Manganese Bronze (High Strength Yellow Brass)Fred Duarte CaldeiraNo ratings yet

- X12CrNiMoV12 3Document3 pagesX12CrNiMoV12 3manjunath k sNo ratings yet

- InTech-Welding and Joining of Magnesium Alloys PDFDocument23 pagesInTech-Welding and Joining of Magnesium Alloys PDFTrương Ngọc SơnNo ratings yet

- Welding and Joining of Magnesium Alloys: Frank CzerwinskiDocument24 pagesWelding and Joining of Magnesium Alloys: Frank Czerwinskivenkat mechNo ratings yet

- Acero S2Document5 pagesAcero S2Marta GarciaNo ratings yet

- Kaiser Aluminum 7075 Rod and BarDocument2 pagesKaiser Aluminum 7075 Rod and BarH VNo ratings yet

- Bronze C86300 SpecificationsDocument2 pagesBronze C86300 SpecificationsDoss MartinNo ratings yet

- Steel-1 0570Document1 pageSteel-1 0570Klemen KavčičNo ratings yet

- Alcoa Specialty Alloys:: Evercast™Document2 pagesAlcoa Specialty Alloys:: Evercast™ShivNo ratings yet

- Diamondspark Ni1 RC: Seamless Cored WireDocument2 pagesDiamondspark Ni1 RC: Seamless Cored Wiresanul mulyNo ratings yet

- Sheet Coil & Plate Alloy 6061Document2 pagesSheet Coil & Plate Alloy 6061Sarat SrinivasNo ratings yet

- Alloy 6061 Technical Data SheetDocument2 pagesAlloy 6061 Technical Data SheetSarat SrinivasNo ratings yet

- CLC 17-13-5LN - High corrosion resistant austenitic stainless steelDocument4 pagesCLC 17-13-5LN - High corrosion resistant austenitic stainless steelPeterWayNo ratings yet

- Stainless SteelDocument1 pageStainless SteelSadashiva sahoo100% (1)

- Silicon Bronze PDFDocument1 pageSilicon Bronze PDFFabian Andres Pinilla CarballoNo ratings yet

- Merit S-6: Lincoln Electric China Gmaw Solid WireDocument2 pagesMerit S-6: Lincoln Electric China Gmaw Solid Wirelovaldes62No ratings yet

- Union MV Mo and RV 71 Flux Cored WiresDocument1 pageUnion MV Mo and RV 71 Flux Cored WiresAnghelache RazvanNo ratings yet

- Bohler-Welding-Germany 207Document1 pageBohler-Welding-Germany 207Anghelache RazvanNo ratings yet

- OK Tigrod 12.64Document1 pageOK Tigrod 12.64ilkinNo ratings yet

- DIE CASTING GUIDELINESDocument12 pagesDIE CASTING GUIDELINESstalinb618No ratings yet

- Cuzn37 Industrial RolledDocument6 pagesCuzn37 Industrial RolledcvgfgNo ratings yet

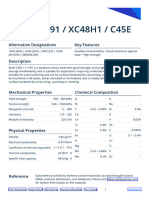

- Steel 1.1191 XC48H1 C45EDocument1 pageSteel 1.1191 XC48H1 C45EAmirhossein Shahidi NejadNo ratings yet

- 26MoCr11 Datasheet PDFDocument3 pages26MoCr11 Datasheet PDFEugen PosticaNo ratings yet

- 1.7734-DatasheetDocument4 pages1.7734-DatasheetMax PrzybyllaNo ratings yet

- Aisi H10Document6 pagesAisi H10Diego ParedesNo ratings yet

- Enamelled Copper Wire: ApplicationsDocument2 pagesEnamelled Copper Wire: ApplicationsDiana Elena CojocariuNo ratings yet

- Glaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiDocument2 pagesGlaistytieji Elektrodai (Smaw) Žemos Vandenilio Jonų Koncentracijos ElektrodaiKiranNo ratings yet

- 4-Mg Alloys (05.05.2015)Document39 pages4-Mg Alloys (05.05.2015)zzirapovNo ratings yet

- NiCu-7 solid wire for welding nickel-copper alloysDocument1 pageNiCu-7 solid wire for welding nickel-copper alloyssatnamNo ratings yet

- Sheet Coil & Plate Alloy 6061: Technical DataDocument2 pagesSheet Coil & Plate Alloy 6061: Technical DataSarat SrinivasNo ratings yet

- PPTDocument18 pagesPPTKaushik SenguptaNo ratings yet

- IS2002 Steel SpecDocument2 pagesIS2002 Steel Speceraman_meNo ratings yet

- Datasheet For Steel Grades High Alloy Aquamet 22Document3 pagesDatasheet For Steel Grades High Alloy Aquamet 22MarioNo ratings yet

- muh-1009-6 (2)Document8 pagesmuh-1009-6 (2)Chris BothaNo ratings yet

- LM6 Aluminum Casting Alloy Chemical Composition Properties ApplicationsDocument3 pagesLM6 Aluminum Casting Alloy Chemical Composition Properties ApplicationsSohail ShaikhNo ratings yet

- Low Alloy13Document5 pagesLow Alloy13Branko FerenčakNo ratings yet

- 903 Datasheet 17Document1 page903 Datasheet 17Fred Duarte CaldeiraNo ratings yet

- G25CrMo4 DatasheetDocument3 pagesG25CrMo4 DatasheetErika GyengésiNo ratings yet

- Extrusion Basic MetallurgyDocument28 pagesExtrusion Basic MetallurgyAry OctavianiNo ratings yet

- 2 - Basic Bricks - Dec 2017 Incl RED2Document62 pages2 - Basic Bricks - Dec 2017 Incl RED2quỳnh lêNo ratings yet

- Product Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument3 pagesProduct Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLNo ratings yet

- 1.3532 16NiCrMo16-5Document3 pages1.3532 16NiCrMo16-5RedNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocument1 pageCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNo ratings yet

- Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument2 pagesCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodesdarmawan listyonoNo ratings yet

- Ra-253-Ma DB Us en PDFDocument12 pagesRa-253-Ma DB Us en PDFbadesharamkNo ratings yet

- E16 8 2Document4 pagesE16 8 2Branko FerenčakNo ratings yet

- Mẫu số 8Document1 pageMẫu số 8Trần Tuấn VũNo ratings yet

- Mẫu số 8Document1 pageMẫu số 8Trần Tuấn VũNo ratings yet

- RP O501 PDFDocument43 pagesRP O501 PDFTrần Tuấn VũNo ratings yet

- pH Control Problems in Wastewater TreatmentDocument9 pagespH Control Problems in Wastewater TreatmentTrần Tuấn VũNo ratings yet

- 01-1022-000-SPC-FU-0007-IFC (02) - Spec FuelDocument64 pages01-1022-000-SPC-FU-0007-IFC (02) - Spec FuelTrần Tuấn VũNo ratings yet

- NMS Magazine Anodes PDFDocument44 pagesNMS Magazine Anodes PDFTrần Tuấn VũNo ratings yet

- STN 004124 C6 0001 - Caisson Cathodic Protection - GDocument20 pagesSTN 004124 C6 0001 - Caisson Cathodic Protection - GTrần Tuấn VũNo ratings yet

- FlowDocument22 pagesFlowWG GZNo ratings yet

- 01 - Fluid FlowDocument76 pages01 - Fluid FlowMubarak AhmadNo ratings yet

- Two Phaseflowgas Flowlinesizing 170303054950Document24 pagesTwo Phaseflowgas Flowlinesizing 170303054950Trần Tuấn VũNo ratings yet

- RP O501 - 2011 01Document43 pagesRP O501 - 2011 01widjai10No ratings yet

- pH Control Problems in Wastewater TreatmentDocument9 pagespH Control Problems in Wastewater TreatmentTrần Tuấn VũNo ratings yet

- Brochure CP Feb16 High Res Blue PDFDocument44 pagesBrochure CP Feb16 High Res Blue PDFTrần Tuấn VũNo ratings yet

- Presentation Sacrificial Anodes Incl MGN 2016-02Document45 pagesPresentation Sacrificial Anodes Incl MGN 2016-02Trần Tuấn VũNo ratings yet

- Class Notes Example ProblemDocument4 pagesClass Notes Example ProblemTrần Tuấn VũNo ratings yet

- Pump and Line Calculation SheetDocument7 pagesPump and Line Calculation SheetNghiaNo ratings yet

- Heating CoilsDocument26 pagesHeating CoilsTrần Tuấn VũNo ratings yet

- Galvanic Anode Selection and Design ConsiderationsDocument58 pagesGalvanic Anode Selection and Design ConsiderationsJuan Camaney XngonNo ratings yet

- Rev 00Document9 pagesRev 00Trần Tuấn VũNo ratings yet

- 1081ch6 13 PDFDocument14 pages1081ch6 13 PDFTrần Tuấn VũNo ratings yet

- ORC Power PlantDocument22 pagesORC Power PlantMudabbir Shan AhmedNo ratings yet

- Book 1Document2 pagesBook 1Trần Tuấn VũNo ratings yet

- 11-4080 HYSYS Relief Valve Sizing Demo Guide FinalDocument18 pages11-4080 HYSYS Relief Valve Sizing Demo Guide FinalNoman Abu-FarhaNo ratings yet

- Energies 09 00432Document20 pagesEnergies 09 00432Nikola TrnavacNo ratings yet

- Energies 09 00432Document20 pagesEnergies 09 00432Nikola TrnavacNo ratings yet

- InTech-Fouling of Heat Transfer Surfaces PDFDocument40 pagesInTech-Fouling of Heat Transfer Surfaces PDFTrần Tuấn VũNo ratings yet

- RP O501 - 2011 01Document43 pagesRP O501 - 2011 01widjai10No ratings yet

- PIPE SUPPORTS 2012 EDITION GUIDEDocument174 pagesPIPE SUPPORTS 2012 EDITION GUIDEharoub_nasNo ratings yet

- Section 10Document6 pagesSection 10Trần Tuấn VũNo ratings yet

- Fortnightly Sub Test-1A (C-9) Phase-I - Science (14-05-2021)Document4 pagesFortnightly Sub Test-1A (C-9) Phase-I - Science (14-05-2021)I AM KIM TAEHYUNG50% (2)

- About Soda Ash - ANSACDocument2 pagesAbout Soda Ash - ANSAChabib1234No ratings yet

- Analysis of ToothpasteDocument29 pagesAnalysis of Toothpasteanushka chadha100% (1)

- Lab Report MayonnaiseDocument5 pagesLab Report Mayonnaiseapi-295870217No ratings yet

- Climate Change EQsDocument49 pagesClimate Change EQsValenciaNo ratings yet

- Determination of Reducing SugarsDocument5 pagesDetermination of Reducing SugarsrheamaeNo ratings yet

- FCE345 Highway MaterialsDocument43 pagesFCE345 Highway Materialsjava nameNo ratings yet

- Class NotesDocument20 pagesClass Notesrockybhaighost97No ratings yet

- B Som and FM Lab ManualDocument101 pagesB Som and FM Lab ManualGANESH GOMATHINo ratings yet

- Ni ComplexDocument11 pagesNi ComplexJ Luis MlsNo ratings yet

- Discover The Difference Between Glycolysis and Krebs CycleDocument5 pagesDiscover The Difference Between Glycolysis and Krebs Cyclepond_1993No ratings yet

- Corrosion On BoilersDocument105 pagesCorrosion On BoilersPlínio Silveira100% (1)

- IS 401.2001 - Preservation of Timber PDFDocument30 pagesIS 401.2001 - Preservation of Timber PDFMehul BansalNo ratings yet

- Yemigeba DocumentDocument78 pagesYemigeba DocumentDemelashNo ratings yet

- Sixto Giménez, Juan Bisquert (Eds.) - Photoelectrochemical Solar Fuel Production - From Basic Principles To Advanced Devices-Springer (2016)Document574 pagesSixto Giménez, Juan Bisquert (Eds.) - Photoelectrochemical Solar Fuel Production - From Basic Principles To Advanced Devices-Springer (2016)firox2005No ratings yet

- Data XRF ST14Document78 pagesData XRF ST14Achmad Nabil ZulfaqarNo ratings yet

- AP Physics 1 Free ResponseDocument2 pagesAP Physics 1 Free ResponseafhNo ratings yet

- Nox Abatement TechnologiesDocument16 pagesNox Abatement TechnologiesMohita JaiswalNo ratings yet

- Stauff Englisch BT 6 2023Document4 pagesStauff Englisch BT 6 2023PeterNo ratings yet

- Solutions - AIATS Medical-2021 (XI Studying) - Test-01 - (Code-C & D) - 06!10!2019Document28 pagesSolutions - AIATS Medical-2021 (XI Studying) - Test-01 - (Code-C & D) - 06!10!2019GauriNo ratings yet

- TUTORIAL SHEET 2019 On Hydrostatic PressureDocument5 pagesTUTORIAL SHEET 2019 On Hydrostatic PressureAndrew ChikuselaNo ratings yet

- Heat Loss PDFDocument2 pagesHeat Loss PDFJessica ZagitaNo ratings yet

- Set 1Document18 pagesSet 1RON MARK EDWARD ANDALUZNo ratings yet

- Week - 2 - Proyect - 2 - Bgu - Activity 5.telescopesDocument8 pagesWeek - 2 - Proyect - 2 - Bgu - Activity 5.telescopesEunisse Macas Palma100% (1)

- T-308 Admixture - Edition 2015Document2 pagesT-308 Admixture - Edition 2015John Kurong100% (1)

- Electronegativity ChartDocument2 pagesElectronegativity ChartDana FransenNo ratings yet

- Geology For Civil EngineersDocument4 pagesGeology For Civil EngineersMr. DummyNo ratings yet

- Test Specification Table Type of Test: MCQ No of Items: 40 QuestionsDocument5 pagesTest Specification Table Type of Test: MCQ No of Items: 40 QuestionsAhmad ZaidiNo ratings yet

- Chapter 6 Explosives and ExplosionsDocument9 pagesChapter 6 Explosives and ExplosionsCHRISTIAN PAHAYAHAY D.No ratings yet