Professional Documents

Culture Documents

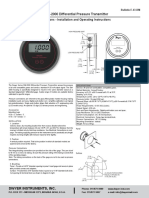

Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating Instructions

Uploaded by

Jorge Renato Chirinos QuiñonezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating Instructions

Uploaded by

Jorge Renato Chirinos QuiñonezCopyright:

Available Formats

Bulletin E-43-DM

Series DM-2000 Differential Pressure Transmitter

®

Specifications - Installation and Operating Instructions

HIGH PRESSURE PORT

1-1/4

[31.75]

LOW PRESSURE PORT

7/16

[11.11] ø4-3/4

[120.65]

17/32

[13.50]

5/32

[3.97]

1-11/16

[42.86]

The Dwyer Series DM-2000 Differential Pressure Transmitter senses the pressure SPECIFICATIONS

of air and compatible gases and sends a standard 4-20 mA output signal. The DM- Service: Air and non-combustible, compatible gases.

2000 housing is specifically designed to mount in the same diameter cutout as a Wetted Materials: Consult Factory.

standard Magnehelic® differential gage. A wide range of models are available factory Accuracy: ±1% F.S. at 70°F.

calibrated to specific ranges. Stability: ±1% F.S./yr.

Temperature Limits: 20 to 120°F (-6.67 to 48.9°C).

Pressure connections are inherent to the glass filled plastic molded housing making Pressure Limits: 10 psig (0.69 bar).

installation quick and easy. Digital push-button zero simplifies calibration over typical Thermal Effect: ±0.055% F.S./°F (0.099% F.S./°C).

turn-potentiometers. Single push button allows field selection of 5 engineering units Power Requirements: 10-35 VDC (2 wire).

(LCD models only). An optional 3.5 digit LCD shows process and engineering. Output Signal: 4 to 20 mA.

Zero and Span Adjustments: Digital push-button zero and span.

Accessories Loop Resistance: DC: 0-1250 ohms maximum.

Mounting Lugs Current Consumption: DC: 38 mA maximum.

6-20 x 2˝ Screws - 3 Electrical Connections: Screw-type terminal block.

6-19 x 1/2˝ Screws - 3 Process Connections: 1/8˝ I.D. tubing.

Mounting Orientation: Vertical.

INSTALLATION Weight: 4.8 oz (136 g).

1. Location

Select a clean, dry mounting location free from excess vibration where the Panel

temperature will remain between 20 and 120˚F (-6.7 and 48.9˚C). Distance from the

receiver is limited only by total loop resistance. See Electrical Connections on next

page. The tubing supplying pressure to the instrument can be practically any length

required, but long lengths will increase response time slightly.

2. Position

A vertical position required. That is the position in which all standard models are

spanned and zeroed at the factory.

Pressure Connections

Two integral tubing connections are provided on the side of the gage. They are sized 11/16

(17.46)

to fit 1/8˝ (3.12 mm) I.D. tubing. Be sure the pressure rating of the tubing exceeds that Surface

of the operating ranges. 65.000°

11/16

Note: The tubing connections on the back of the gage are not to be used as process (17.46)

connections.

1 65.000°

(25.40)

3. Mounting

Panel - Provide a 4-9/16˝ diameter opening in panel. Insert gage and secure in place (3) HOLES FOR #6 SCREW

1 EQUALLY SPACED ON

with provided screws and adapters. (25.40)

Surface - Provide three 3/16˝ diameter holes in panel on a 4-1/8˝ diameter bolt circle. 4-1/8 (104.78) B.C.

Cut opening for terminal block as shown in diagram to right. 1-1/2 (3) HOLES FOR #6 SCREW

(38.10) EQUALLY SPACED ON

4-1/8 (104.78) B.C.

1-1/2

(38.10)

DWYER INSTRUMENTS, INC. Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

ELECTRICAL CONNECTIONS USER CALIBRATION

CAUTION: Do not exceed specified supply voltage ratings. Permanent damage not The transmitter may be user calibrated with two buttons on the front. The standard

covered by warranty will result. This unit is not designed for 120 or 240 volts AC line models have buttons labeled “ZERO” and “SPAN”. LCD models have buttons labeled

operation. “ZERO” and “UNITS”. The “UNITS” button on the LCD models has 2 functions. If

pushed for less than 2 seconds and released the pressure units that are displayed on

Electrical connections are made to the terminal block located in back of the transmitter. the LCD will change when the button is released. If pushed and held for 4 - 5 seconds

Terminals are marked + and - (see Fig. B below). the “UNITS” button serves the same function as the “SPAN” button on the standard

models.

To calibrate the transmitter you will need three pieces of equipment. You will need

a calibrated pressure source capable of generating a stable pressure value for

the maximum range of the unit under test, an instrument capable of validating the

calibration pressure, and an ampmeter, capable of measuring mA, to measure the

current output from the unit under test. The transmitter is calibrated using the following

procedure.

Preparation – Connect the ampmeter and power supply, being careful to observe

polarities. The transmitter must be calibrated in a vertical position.

Performing ZERO Calibration, SPAN Calibration or Restore Factory

Figure B Calibration Coefficients:

1. Press both the ZERO and UNITS/SPAN buttons simultaneously for 6 or more

seconds. Release both buttons. The units indicator on the LCD should blink on

Wire Length and off. This indicates the gage is ready for calibration or restoration of

The maximum length of wire connecting transmitter and receiver is a function of wire coefficients. The units indicator blinks for approximately 10 minutes, then stops

size and receiver resistance. Wiring should not contribute more than 10% of the blinking.

receiver resistance to total loop resistance. For extremely long runs (over 1000 feet), 2. a) ZERO calibrate the gage by applying no pressure to the gage and

choose receivers with higher resistance to minimize size and cost of connecting leads. then pressing the ZERO button for 3 seconds.

Where wiring length is under 100 feet, hook-up wire as small as 22 AWG can be used. b) SPAN calibrate the gage by applying full-scale pressure to the gage and

then pressing the UNITS/SPAN button for 3 seconds.

2-Wire Operation c.) Restore the gage’s factory calibration coefficient by pressing both the ZERO

An external power supply delivering 10-35 VDC with minimum current capability of and UNITS/SPAN buttons simultaneously for 3 seconds.

40 mA DC (per transmitter) must be used to power the control loop. See Fig. C for

connection of the power supply, transmitter and receiver. The range of appropriate MAINTENANCE

receiver load resistance (RL) for the DC power supply voltage available is expressed Upon final installation of the Series DM2000 Differential Pressure Transmitter and

by the formula and graph in Fig. D. Shielded two wire cable is recommended for the companion receiver no routine maintenance is required. The Series DM2000

control loop wiring. If grounding is required, use the negative side of the control loop Transmitter is not field serviceable and should be returned, freight prepaid, to the

after the receiver. factory if repair is required. Please enclose a description of the problems encountered

plus any available application information.

2-Wire Connections

1

SERIES POWER

DM-2000 2

mA SUPPLY

PRESSURE 10-35 VDC

TRANSMITTER RECEIVER

Figure C

Power Supply Voltage – VDC (2-wire)

1500

1400 Maximum Value (1250 )

1300

Total Receiver Resistance ()

1200

1100

1000 Vps–10.0

900 R L Max. =

800 20mA DC

700

600

500

400

300 Operating

200 Region

100

50

0 5 10 13 15 20 25 30 35 40

Figure D

©Copyright 2017 Dwyer Instruments, Inc. Printed in U.S.A. 3/17 FR# 443402-00 Rev. 4

DWYER INSTRUMENTS, INC. Phone: 219/879-8000 dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A. Fax: 219/872-9057 e-mail: info@dwyermail.com

You might also like

- Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument2 pagesSeries DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsJuan Carlos Chara VelazcoNo ratings yet

- Transmisor Presion Diferencial dm-2007-lcdDocument2 pagesTransmisor Presion Diferencial dm-2007-lcdhanshr87No ratings yet

- Differential Pressure Transmitter: Same Size As Standard Magnehelic Differential Pressure GageDocument1 pageDifferential Pressure Transmitter: Same Size As Standard Magnehelic Differential Pressure GageJose Antonio Yupa MedinaNo ratings yet

- P - 616KD Manual TransmiterDocument2 pagesP - 616KD Manual TransmiterFR PERANo ratings yet

- Sensor de Presion Serie DM-2000Document1 pageSensor de Presion Serie DM-2000Giancarlo Reategui GuerraNo ratings yet

- Dwyer-1910-1-Product OverviewDocument1 pageDwyer-1910-1-Product OverviewRusty AllenNo ratings yet

- Purafil Side Access BulletinDocument5 pagesPurafil Side Access BulletinPablo TorresNo ratings yet

- Magnehelic-Gage Series 2000Document2 pagesMagnehelic-Gage Series 2000Jonathan GanNo ratings yet

- Series 1630 Differential Pressure Switch: Specifications - Installation and Operating InstructionsDocument2 pagesSeries 1630 Differential Pressure Switch: Specifications - Installation and Operating InstructionseeeNo ratings yet

- Series 629C Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument4 pagesSeries 629C Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsjguerrerosperuNo ratings yet

- Dwyer 2300 250pa Pressure Gauge DatasheetDocument2 pagesDwyer 2300 250pa Pressure Gauge DatasheetGorch Marroko100% (1)

- DM 2000 IxxxxxxDocument1 pageDM 2000 IxxxxxxJose MeraNo ratings yet

- MAGNEHELICDocument2 pagesMAGNEHELICCésar Arturo TorresNo ratings yet

- 616&616C CatDocument1 page616&616C CatDaniel GomesNo ratings yet

- Series 673 Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument1 pageSeries 673 Pressure Transmitter: Specifications - Installation and Operating InstructionsallaadeenNo ratings yet

- 3-In-1 Differential Pressure ControllerDocument1 page3-In-1 Differential Pressure ControllerHector J. VegaNo ratings yet

- Electronic Pressure Controller: 2 Switches, Indicating Gauge, and Transmitter in One PackageDocument1 pageElectronic Pressure Controller: 2 Switches, Indicating Gauge, and Transmitter in One Packageluat1983No ratings yet

- 616 Pressure Transmitter DwyerDocument2 pages616 Pressure Transmitter Dwyerbrodystun66No ratings yet

- 616wl 14 Manual PDFDocument2 pages616wl 14 Manual PDFcoolguy19895No ratings yet

- Installsheet - 77 - 629c 01 CH p1 E1 s1Document4 pagesInstallsheet - 77 - 629c 01 CH p1 E1 s1Mc EswaranNo ratings yet

- DOWYER Transmisor Temperatura-HumedadDocument4 pagesDOWYER Transmisor Temperatura-Humedadian_gushepiNo ratings yet

- Compact Low Differential Pressure Switches: Set Points From 0.07 To 20 in W.C. Repetitive Accuracy Within 3%Document1 pageCompact Low Differential Pressure Switches: Set Points From 0.07 To 20 in W.C. Repetitive Accuracy Within 3%ANGEL FLORESNo ratings yet

- CDT Duct Mount ManualDocument4 pagesCDT Duct Mount ManualHùng ĐỗNo ratings yet

- Series 647 Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDocument2 pagesSeries 647 Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating Instructionsindra_onevisionNo ratings yet

- Wet/Wet Differential Pressure Transmitter: Series 629CDocument2 pagesWet/Wet Differential Pressure Transmitter: Series 629CElmer Ramón Murillo MejiaNo ratings yet

- Series 2-5000 Minihelic II Differential Pressure Gage: Bulletin A-36-ADocument2 pagesSeries 2-5000 Minihelic II Differential Pressure Gage: Bulletin A-36-ATrie IrsadNo ratings yet

- Din Rail Differential Pressure Transmitter: Mounts On 35 MM DIN Rail, 0.25% Full-Scale AccuracyDocument1 pageDin Rail Differential Pressure Transmitter: Mounts On 35 MM DIN Rail, 0.25% Full-Scale AccuracyMike Alex Herrera DominguezNo ratings yet

- Explosion-Proof Differential Pressure SwitchDocument1 pageExplosion-Proof Differential Pressure SwitchTadau EnergyNo ratings yet

- Industrial Pressure Transmitter: 0.13% FS Accuracy, External Adjustments, 4 To 20 Ma OutputDocument3 pagesIndustrial Pressure Transmitter: 0.13% FS Accuracy, External Adjustments, 4 To 20 Ma OutputAsif BhatiNo ratings yet

- Din Rail Differential Pressure Transmitter: Mounts On 35 MM DIN Rail, 0.25% Full Scale AccuracyDocument1 pageDin Rail Differential Pressure Transmitter: Mounts On 35 MM DIN Rail, 0.25% Full Scale AccuracyNic DziemianNo ratings yet

- Aq CDT CDTRDocument4 pagesAq CDT CDTRDon Roseller DumayaNo ratings yet

- Digital Indicating Transmitter: 0.25% Full Scale Accuracy, Optional Switch OutputsDocument1 pageDigital Indicating Transmitter: 0.25% Full Scale Accuracy, Optional Switch Outputsluat1983No ratings yet

- Series 616W Differential Pressure Transmitter Specifications - Installation and Operating InstructionsDocument4 pagesSeries 616W Differential Pressure Transmitter Specifications - Installation and Operating InstructionsErwin Gonzalez MedinaNo ratings yet

- Inverter R 410a Cooling Only Type 201709142324162961Document4 pagesInverter R 410a Cooling Only Type 201709142324162961Minh Nhut LuuNo ratings yet

- Magnehelic Series 2000 - CatDocument2 pagesMagnehelic Series 2000 - CatFerdian AriestaNo ratings yet

- Series 616Kd - : Differential Pressure Transmitter 0.25, 1 or 2% AccuracyDocument2 pagesSeries 616Kd - : Differential Pressure Transmitter 0.25, 1 or 2% AccuracyOperacao RDBrasilandiaNo ratings yet

- Series DA/DS-7000 Bourdon Tube Pressure Switches: Specifications - Installation and Operating InstructionsDocument4 pagesSeries DA/DS-7000 Bourdon Tube Pressure Switches: Specifications - Installation and Operating InstructionsargaNo ratings yet

- Photo Helic Ps PDFDocument4 pagesPhoto Helic Ps PDFSoumen PaulNo ratings yet

- Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 2%Document2 pagesMagnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 2%SlametKhoerudinNo ratings yet

- Dwyer Instruments Magnehelic Pressure Gauge Mounting DimensionsDocument1 pageDwyer Instruments Magnehelic Pressure Gauge Mounting DimensionsCésar Arturo TorresNo ratings yet

- Digihelic 3 Differential Pressure Controllers: Digihelic Controller in Photohelic Gage, Square Root Output For FlowDocument1 pageDigihelic 3 Differential Pressure Controllers: Digihelic Controller in Photohelic Gage, Square Root Output For FlowAdriana Zarahi Velez HernandezNo ratings yet

- Diaphragm Seal For DA Series Pressure Switch: PVC and FEP Construction For Corrosive ApplicationsDocument1 pageDiaphragm Seal For DA Series Pressure Switch: PVC and FEP Construction For Corrosive Applicationsluat1983No ratings yet

- Series 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsDocument4 pagesSeries 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsAlberto Angel Mora ZavalaNo ratings yet

- Ficha Tecnica Mod 2-5002Document2 pagesFicha Tecnica Mod 2-5002Nestor Augusto Duran SanchezNo ratings yet

- DWYER_1630-PRESOSTATO SWITCHDocument2 pagesDWYER_1630-PRESOSTATO SWITCHomorales.cyvsaNo ratings yet

- Manual Dwyer MS-111 Pressure TransmitterDocument4 pagesManual Dwyer MS-111 Pressure TransmitterSunko MachineryNo ratings yet

- 629 - Cat-Chenh AP NuocDocument1 page629 - Cat-Chenh AP NuocMinh Nhut LuuNo ratings yet

- Dwyer B - 30Document20 pagesDwyer B - 30Alex MeadowsNo ratings yet

- Ocv Series 129FC METRICDocument2 pagesOcv Series 129FC METRICmuthuvelaa100% (1)

- WWDPDocument1 pageWWDPJose ItzmoyotlNo ratings yet

- Magnehelic Gauge CalibrationDocument7 pagesMagnehelic Gauge CalibrationgrajukankayyaNo ratings yet

- Dwyer Tte ManualDocument4 pagesDwyer Tte ManualFatih Al BaridNo ratings yet

- Affordable, Accurate Differential Pressure Transmitters for HVAC and Industrial ApplicationsDocument3 pagesAffordable, Accurate Differential Pressure Transmitters for HVAC and Industrial Applicationsugui81No ratings yet

- DP Sensor Tech Sheet (Dwyer Series 629)Document2 pagesDP Sensor Tech Sheet (Dwyer Series 629)jed_poliNo ratings yet

- Mercoid pblt2 ManualDocument1 pageMercoid pblt2 ManualRudy HerreraNo ratings yet

- DS 616KDRev.2Document2 pagesDS 616KDRev.2Carlos TorresNo ratings yet

- Dwyer MagnehelicmanualDocument2 pagesDwyer MagnehelicmanualAndres GonzalesNo ratings yet

- Differential Pressure Transmitter: NEMA 4X Enclosure, 0.25% FS AccuracyDocument1 pageDifferential Pressure Transmitter: NEMA 4X Enclosure, 0.25% FS AccuracyDanielle YepezNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- Declaracio JuaradaDocument3 pagesDeclaracio JuaradaJorge Renato Chirinos QuiñonezNo ratings yet

- Le 4Document17 pagesLe 4Jorge Renato Chirinos QuiñonezNo ratings yet

- Recursive dynamics solver (ReDySim) efficiently simulates multibody systemsDocument6 pagesRecursive dynamics solver (ReDySim) efficiently simulates multibody systemsJorge Renato Chirinos QuiñonezNo ratings yet

- Submittal VRF Samsung BCP (Sede Chorrillos) 2022-12-29Document22 pagesSubmittal VRF Samsung BCP (Sede Chorrillos) 2022-12-29Jorge Renato Chirinos QuiñonezNo ratings yet

- Le 3Document9 pagesLe 3Jorge Renato Chirinos QuiñonezNo ratings yet

- Duct S specifications for AC018 and AC024 modelsDocument3 pagesDuct S specifications for AC018 and AC024 modelsJorge Renato Chirinos QuiñonezNo ratings yet

- Research and Simulation of SVPWM Algorithm Based On BP NeuralDocument7 pagesResearch and Simulation of SVPWM Algorithm Based On BP NeuralJorge Renato Chirinos QuiñonezNo ratings yet

- 4007ES Fire Control PanelsDocument8 pages4007ES Fire Control PanelsJorge Renato Chirinos QuiñonezNo ratings yet

- System Identification of NN-based Model Reference Control of RUAV During HoverDocument27 pagesSystem Identification of NN-based Model Reference Control of RUAV During HoverJorge Renato Chirinos QuiñonezNo ratings yet

- 1995 AdaptativeNeurocontrolDocument19 pages1995 AdaptativeNeurocontrolJorge Renato Chirinos QuiñonezNo ratings yet

- MAGOOSH TOEFL Practice Questions PDFDocument76 pagesMAGOOSH TOEFL Practice Questions PDFPolivio J. Rosario100% (1)

- Algorithms For Adaptive Control of Two-Arm Flexible Manipulators Under Uncertainty PDFDocument9 pagesAlgorithms For Adaptive Control of Two-Arm Flexible Manipulators Under Uncertainty PDFJorge Renato Chirinos QuiñonezNo ratings yet

- General Specs - SBK S 07 - Section 1A - GS - Main - PIDSDocument340 pagesGeneral Specs - SBK S 07 - Section 1A - GS - Main - PIDSkyawoo.sg0% (1)

- BS 10 Flange PDFDocument6 pagesBS 10 Flange PDFmozammilNo ratings yet

- 1.2.3 Internet Principles of OperationDocument7 pages1.2.3 Internet Principles of OperationDragonflyNo ratings yet

- 06 100 HR Management PlanDocument12 pages06 100 HR Management PlanBrian Shanny100% (1)

- Repeater Installation and CommissioningDocument34 pagesRepeater Installation and CommissioningTuan TocdaiNo ratings yet

- CCNPv6 ROUTE Lab4-3 Administrative Distance StudentDocument16 pagesCCNPv6 ROUTE Lab4-3 Administrative Distance StudentWilliam WhitakerNo ratings yet

- BS EN 12568 Foot and Leg Protector RequirementsDocument19 pagesBS EN 12568 Foot and Leg Protector RequirementsArif Hasnat JonyNo ratings yet

- Catalog-Ekarat Solar 200 W Module-MonoDocument2 pagesCatalog-Ekarat Solar 200 W Module-MonoFalcon EgyNo ratings yet

- Hade KanDocument137 pagesHade KanasepramboNo ratings yet

- ODU-MAC Blue-Line Open Modular Connector System PDFDocument77 pagesODU-MAC Blue-Line Open Modular Connector System PDFConstantin-Iulian TraiciuNo ratings yet

- Currie Palletizer Product Line PDFDocument4 pagesCurrie Palletizer Product Line PDFtintucinbNo ratings yet

- Seat Back PetitionDocument24 pagesSeat Back PetitionCBS Austin WebteamNo ratings yet

- Substations PDFDocument16 pagesSubstations PDFsorry2qaz100% (1)

- Crankcase Removal (4JK1) TIEMPOSDocument67 pagesCrankcase Removal (4JK1) TIEMPOSTALLER DE MECATRONICA100% (2)

- Owner's Manual Manuel D'utilisation BedienungsanleitungDocument35 pagesOwner's Manual Manuel D'utilisation Bedienungsanleitungcostelo63No ratings yet

- 15 Au50es ManualDocument9 pages15 Au50es ManualluisNo ratings yet

- Interzone 954: Modified EpoxyDocument4 pagesInterzone 954: Modified Epoxyparthiv_mechmind1987No ratings yet

- MDS SD Series: Setup GuideDocument4 pagesMDS SD Series: Setup GuideCarlos David Ordaz JuárezNo ratings yet

- Struts (Printable)Document63 pagesStruts (Printable)sakthimurugan_pNo ratings yet

- FfmpegDocument44 pagesFfmpegKrishnadevsinh GohilNo ratings yet

- Chapter 6 - TQMDocument4 pagesChapter 6 - TQManki23100% (1)

- Safety Instruction Sheets For Plant Piping and Cross-Country PipelinesDocument35 pagesSafety Instruction Sheets For Plant Piping and Cross-Country PipelinesRaj Bindas50% (2)

- Metric and Inch (Sae) Fasteners: All ModelsDocument22 pagesMetric and Inch (Sae) Fasteners: All ModelsLenin100% (1)

- Cable Fault DetectorDocument25 pagesCable Fault DetectorHarshalNo ratings yet

- Access Integrated Project 2Document7 pagesAccess Integrated Project 2Mohini SharmaNo ratings yet

- Point Naming Standards: by James F. Butler, Member ASHRAE and Robert Veelenturf, P.EDocument6 pagesPoint Naming Standards: by James F. Butler, Member ASHRAE and Robert Veelenturf, P.Estatic245No ratings yet

- Diaphragm Valves: A Class of Their OwnDocument9 pagesDiaphragm Valves: A Class of Their OwnROMNANo ratings yet

- Ieee C57.12.90Document82 pagesIeee C57.12.90Cae Fue100% (8)