Professional Documents

Culture Documents

Mark VI

Uploaded by

Ahmed EldosokyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mark VI

Uploaded by

Ahmed EldosokyCopyright:

Available Formats

GEI-100472

g

GE Industrial Systems

SPEEDTRONICTM Mark VI TMR

New Unit, Heavy Duty Gas Turbine Control

These instructions do not purport to cover all details or variations in equipment, nor to

provide every possible contingency to be met during installation, operation, and maintenance.

If further information is desired or if particular problems arise that are not covered

sufficiently for the purchaser’s purpose, the matter should be referred to GE Industrial

Systems.

This document contains proprietary information of General Electric Company, USA, and is

furnished to its customer solely to assist that customer in the installation, testing, operation,

and/or maintenance of the equipment described. This document shall not be reproduced in

whole or in part, nor shall its contents be disclosed to any third party without the written

approval of GE Industrial Systems.

Section Page

Introduction ............................................................................................................2

Redundancy ............................................................................................................3

I/O Interface............................................................................................................3

Built-in Diagnostics ................................................................................................5

System Overview ....................................................................................................5

Control Functions....................................................................................................7

Sequencing .............................................................................................................9

Protection ...............................................................................................................9

Operator Screens...................................................................................................12

Typical Turbine Instrumentation............................................................................15

Packaging .............................................................................................................17

Power Requirements .............................................................................................18

Acronyms and Abbreviations ................................................................................18

CIMPLICITY is a registered trademark of GE Fanuc Automation North America, Inc.

Ethernet is a trademark of the Xerox Corporation.

SPEEDTRONIC is a trademark of General Electric Company, USA.

Windows NT is a registered trademark of Microsoft Corporation.

Introduction

The high reliability achieved The SPEEDTRONIC Mark VI gas turbine control is a Triple Modular Redundant

by the TMR control system is (TMR), microprocessor-based control with a heritage of over 30 years of successful

due to the integration of the turbine automation. The basis of this system is the three redundant control modules

triple redundant electronics <R>, <S>, and <T>. Each controller contains its own power supply, processor,

and sensors into a robust, communications, and I/O for all of the critical control, protection and monitoring of

fault tolerant control system. the gas turbine. Some critical functions, such as emergency overspeed protection and

the phase-slip windows for backup synch check protection, are monitored by a

separate triple redundant backup protection module <P>. Most of the critical sensors

for control loops and trip protection are triple redundant. Other sensors are dual or

single element devices.

Backup Protection Module

3 Independent Sections

3 Control Modules

Mark VI Electronics

2 • SPEEDTRONIC, Mark VI TMR GEI-100472

Redundancy

An important part of the fault tolerant control architecture is the method of reliably

voting the inputs and outputs. Each control module reads its inputs and exchanges

the data with the other two control modules every time the application software is

executed at 40 ms.

In addition, a 1ms time stamp The voted value of each contact input and the median value of each analog input is

is assigned to each contact calculated within each control module, and then used as the control parameter for the

input to provide a built-in application software. Diagnostic algorithms monitor these inputs and initiate an

sequence of events (SOE) alarm if any discrepancies are found between the three sets of inputs.

monitor.

Redundant contact inputs for trip functions are connected to three separate

termination points and then individually voted. This enables the control system to

survive multiple failures of contact or analog inputs without causing an erroneous

trip command as long as the failures are not from the same circuit, such as lube oil

pressure.

An equally important part of the fault tolerance is the hardware voting of analog and

contact outputs. Three coil servos on the valve actuators are separately driven from

each control module, and the position feedback is provided with redundant linear

variable differential transformers (LVDTs). Contact outputs to the hydraulic trip

solenoids are voted with three magnetic relays on each side of the floating 125 V dc

feeder to the solenoids.

I/O Interface

The I/O is designed for direct interface to turbine and generator devices, such as

vibration sensors, flame sensors, LVDTs, magnetic speed pickups, thermocouples,

and Resistance Temperature Devices (RTDs). Direct monitoring of these sensors

eliminates the need for interposing instrumentation with its associated single point

failures, reduces long-term maintenance, and enables the Mark VI diagnostics to

directly monitor the health of the sensors on the machinery. This data is then

available to both local operator/maintenance stations and to the plant Distributed

Control System via communication links.

Contact Inputs are powered from the 125 V dc battery bus through the Mark VI

termination boards. Each contact input is optically isolated and has a 1 ms time

stamp for SOE monitoring. Contacts are open-to-alarm and open-to-trip. An

inversion mask is applied to each contact input to normalize the data values and

simplify understanding of the software. For example, 63QT is a low lube oil pressure

trip switch that will open-to-trip. The inversion mask is applied such that whenever

logic L63QT = 1 it means that there is low lube oil pressure. Conversely, if the field

contact was closed-to-trip, the inversion mask would be 0 and L63QT = 1 would still

mean that there is low lube oil pressure.

Contact Outputs are from plug-in, magnetic relays with dry, form C contact

outputs. The control provides a floating 125 V dc source and suppression for each

solenoid with a 3.2 A slow-blow fuse on each side of the 125 V dc feeder.

GEI-100472 SPEEDTRONIC, Mark VI TMR • 3

Analog inputs can monitor 4-20 mA (250 ohms), which can be configured for self-

powered, differential inputs, or as sensors that use a +24 V dc supply from the

turbine control. Selected inputs can be configured for 0-1mA inputs (5,000 ohms), or

±5, 10 V dc inputs. Analog outputs can be configured for 4-20 mA output (500

ohms max) or 0-200 mA output (50 ohms max).

Gas turbine temperatures are monitored by type K thermocouples. Critical

temperatures, such as exhaust temperature have multiple thermocouples that are

divided between the three control modules for redundancy. Non-critical

thermocouples, such as wheelspace and bearing temperatures, are connected to one

thermocouple card in one control module, but the data is transmitted to all three main

processors for monitoring and alarming. The control can interface with grounded or

ungrounded thermocouples, and software linearization is provided for types E, J, K,

or T.

Generator temperatures are normally monitored with grounded 100 ohm platinum

RTDs. The control can interface with grounded or ungrounded RTDs. Software

linearization is provided for 10 ohm copper, 100/200 ohm platinum, or 120 ohm

nickel RTDs.

Speed Inputs include three passive, magnetic, speed sensor inputs. The median

value is used for speed control and primary overspeed protection in the control

modules. Three additional speed sensors are provided for emergency overspeed

protection. These sensors are monitored by the three sections of the backup

protection module and diagnostics are transmitted between the backup protection

module and the control modules for cross-tripping and alarm management.

The control monitors redundant Reuter Stokes type UV flame scanners and initiates

an alarm if the light intensity diminishes below an acceptable level due to carbon

buildup or other contaminants on the scanner windows.

Servo valve interface is described in the section, Control Functions.

Seismic (velocity) Vibration Transducers are monitored directly by the Mark VI

for trip protection of the turbine and generator. These devices generate a small output

current by passing a magnet through a fixed coil, thereby eliminating the need for

excitation current. All vibration sensors are continuously monitored for faults, alarm

levels, and trip levels. Protection features include:

Standard vibration protection • A start check permissive is inhibited if three or more turbine sensors or two or

in Mark VI card rack. more generator sensors are disabled or faulty.

• An automatic shutdown sequence is initiated if all turbine or all generator

sensors are disabled or faulty.

• A trip is initiated if one turbine vibration sensor indicates a trip level and any

other turbine sensor indicates an alarm level.

• A trip is initiated if one turbine vibration sensor indicates a trip level and any

adjacent pair of turbine sensors are disabled or indicates an alarm level.

• A trip is initiated if one turbine vibration sensor indicates a trip level and two or

more sensor inputs are disabled.

4 • SPEEDTRONIC, Mark VI TMR GEI-100472

An option is available for Bently Nevada Proximitors for monitoring only. The

Proximitors can be supplied as either an interface to a Bently Nevada 3300 or 3500

monitor with an additional option for a Data Manager 2000 or as a direct interface to

the turbine control. A Mark VI option is available for buffered outputs to BNC

connectors to facilitate plug-in analysis instrumentation and direct plug connection

from the Mark VI termination boards to 3500 monitors.

Note The mission of the turbine control is to provide alarm and trip protection,

whereas the mission of the Bently Nevada is to facilitate vibration analysis.

Complete synchronizing The Synchronizing Interface uses a pair of single-phase potential transformers

system: auto, manual, and (PT), which are monitored by the control modules. It matches the turbine speed to

backup synch check the line frequency and match the generator and line voltages via the Unit Data

protection.. Highway (UDH) to the generator excitation system. A command is issued to close

the breaker based on a calculated breaker closure time. Diagnostics monitor the

actual breaker closure time and self-correct each time the breaker closes. The single

phase PTs are paralleled to the triple redundant backup protection module for the

backup synch check protection. The synch check protection is used to backup the

automatic synchronizing and the manual synchronizing which is implemented from a

synchroscope screen on a Human-Machine Interface (HMI) server. Three-phase PT

inputs from the generator and line, and single-phase current transformer (CT) inputs

are normally monitored by the generator protection and the EX2000.

Built-in Diagnostics

The Mark VI control system has extensive built-in diagnostics and includes

powerup, background, and manually initiated diagnostic routines. These diagnostics

are capable of identifying both control panel, sensor, and output device faults. These

faults are identified down to the board level for the panel, and to the circuit level for

the sensors and actuators.

System Overview

The control system consists of several networks. IONET is the Ethernet-based

network for communication between the three control modules, the three sections of

the protection module, and any expansion modules. IONET uses asynchronous

drives language (ADL) to poll the modules for data instead of using the typical

collision detection techniques used in Ethernet local area networks (LAN).

Ethernet networks with peer- The UDH is an Ethernet-based network that provides peer-to-peer communications

to-peer communication between the turbine control, the generator excitation control, and the static starter.

between turbine and The network uses Ethernet Global Data (EGD), which is a message-based protocol

generator controls. with support for sharing information with multiple nodes based on the UDP/IP

standard. Data can be transmitted unicast or broadcast to peer control systems on the

network. Data (4K) can be shared between up to 10 nodes at 25 Hz.

The Mark VI is used to control megawatt output, and the EX2000 is used to control

megavar output. The generator protection panel (GPP) is used to provide primary

protection for the generator. Additional protection features are located in the

EX2000. Although the UDH is capable of communicating control data, control loops

are closed internal to the turbine or generator control.

GEI-100472 SPEEDTRONIC, Mark VI TMR • 5

In the case of var/power factor control for the generator or tie-line, the turbine

control performs the regulation of the setpoint and transmits the command to adjust

the generator field on the UDH to the excitation control. All trip commands are hard-

wired between control units, including any trip commands coming from remote

control systems such as a Distributed Control System (DCS).

An optional OSI PI- based Dual servers (CIMPLICITY/Windows NT) are available to isolate the UDH

Historian is available for from the Plant Data Highway (PDH). These servers can be used as local or remote

long term data archiving and operator and/or maintenance stations and configured in a variety of arrangements.

retrieval. Typically, one server is located in each Packaged Electrical and Electronic Control

Compartment (PEECC) that contains a turbine control, a generator protection panel,

a motor control center, and the 125 V dc batteries. The primary server can be

provided with a time synchronization interface to a Global Time Source (GTS),

which is normally implemented with IRIG-B. A backup time master can be provided

in a backup server. Network Time Protocol (NTP) is used for internal time

synchronization with ±1 ms time coherence.

Plant DCS Network

Ethernet TCP-IP GSM

Ethernet TCP-IP Modbus

RS232/485 Modbus

IRIG-B

Time Synch

Local Local

Engineer's

Operator Operator

Station

Station Station

Gas Turbine #1 Gas Turbine #2 Steam Turbine

Unit Data Highway - Ethernet Network Time Protocol NTP

Gas Turbine Generator Gas Turbine Generator Static Starter Steam Turbine Generator

Control Excitation Control Excitation Control Excitation

Mark VI EX2000 Mark VI EX2000 Mark VI EX2000

Typical 207FA Control Network

The Plant Data Highway is used to communicate data to the plant distributed control

system or other third party platforms. A variety of protocols are supported for

communication with a plant DCS including RS-232C and RS-485 Modbus remote

terminal unit (RTU) master/slave, Ethernet TCP-IP Modbus slave, and Ethernet

TCP-IP with GEDS Standard Messages (GSM). The GSM protocol provides the

following messages:

• Administration

• Spontaneous Event Driven (with local time tags)

• Periodic Group Data (at rates to 1 second)

• Common Request

6 • SPEEDTRONIC, Mark VI TMR GEI-100472

Control Functions

Startup Control is an open loop system that increases the fuel stroke reference

(FSR) as the turbine startup sequence progresses to preassigned plateaus.

Acceleration Control adjusts the FSR according to the rate of change of the turbine

speed to reduce the thermal shock to the hot gas path parts of the turbine.

Speed Control uses the median speed from three speed sensors for droop and

isochronous speed control with an automatic transfer to isochronous upon loss of the

tie-line breaker.

The FSR is determined by the Load Control compares the load setpoint with the MW feedback from a single-

control parameter calling for phase transducer and adjusts the speed setpoint to regulate the load. Selection of fast

the least fuel. load start or pre-selected load will raise the setpoint to the pre-selected load limit.

Selection of base or peak will raise the setpoint to the maximum limit.

Exhaust Temperature Control thermocouples are divided between the three

control modules for redundancy. All of the temperature data is transmitted to all of

the control modules that sort the data from the highest to the lowest temperature,

automatically reject bad thermocouple data, average the remaining data values, and

then execute the control algorithm. Three redundant transducers are supplied for

monitoring the compressor discharge pressure and biasing the temperature control to

correct for ambient temperature and the corresponding variations in mass flow.

Inlet Guide Vane Control modulates the position of the compressor stator vanes to

provide optimum compressor and unit operation. During startup, the guide vanes

open as the turbine speed increases. When the unit is online, the guide vanes

modulate to control turbine airflow temperature to optimize combustion system and

combine cycle performance.

Fuel Control consists of a reference from the governor and feedback of the fuel

control valves. The FSR is determined by the turbine parameter (speed, temperature,

and so on.) calling for the least fuel. Calculation of the FSR is performed in the main

processor and transmitted to the servo valve cards on the backplane of the control

modules. High speed regulation of the servo loop with LVDT position feedback is

performed on each servo card to obtain the maximum performance.

In liquid fuel control systems, FSR establishes the called for stroke of the bypass

valve. Fuel flow is proportional to the speed (fuel flow = speed X FSR). In gas fuel

systems with only a gas control valve, the fuel flow is a function of pressure (fuel

flow = pressure X FSR); therefore, a stop/speed ratio valve is added, which is

programmed by speed. Pressure is now a function of speed and the liquid fuel control

system and the gas fuel control system have the same characteristic (refer to the

following diagram).

GEI-100472 SPEEDTRONIC, Mark VI TMR • 7

Control Module Gas Fuel

Termination Stop/Speed

Main Processor VCMI VSVO Card

Board Ratio Valve

Card

Constants

FPRG

Software Servo

Logic D/A

Regulator 90SR

TSVO

TNH (Speed) +

A/D LVDT

-

96SR

Gas Fuel

Pressure

VAIC Card TBAI

D/A 96FG

Gas Control

VSVO Card

Valve

Logic

FSROUT

Software Servo

D/A

Regulator 65GC

TSVO

A/D LVDT

96GC

FSR2

Combustion

Logic Chamber

Fuel

FSR Splitter

Stop/Speed

Ratio Valve

FSR1 Pulse Flow

A/D

77FD Divider

VSVO Card TSVO

FSROUT

TNH (Speed)

Logic Software Servo

D/A

Regulator 65FP

Liquid Fuel

Duel Fuel Control System

Generator Excitation Setpoints for volts (voltage matching during

synchronization) and var/power factor control for the generator and tie-line are in the

turbine control. References come from operator commands, and feedback comes

from a single-phase var transducer. Power factor is calculated from watts and vars.

Setpoints are transmitted from the turbine control to the generator excitation control

on the UDH.

Synchronizing is described in the section, I/O Interface.

Emissions Control is available with diluent (water or steam) injection through a

multi-nozzle quiet combustor to quench flame temperature and reduce thermal NOX

formation. Lean-burning, pre-mixed flame combustors are available for lower NOX

levels without the need for water or steam injection (dry low nox).

8 • SPEEDTRONIC, Mark VI TMR GEI-100472

Sequencing

This automation enables The turbine control includes a completely automated startup and shutdown sequence,

operation of the gas turbine including interface to all of the auxiliary systems in the motor control center and

from a remote (off-site) generator protection system. Operators can choose to have the turbine automatically

location with the assurance sequence to intermediate hold points by selecting Crank or Fire without enabling

that the turbine is fully automatic synchronization. All ramp rates and hold times are pre-programmed for

protected and diagnostics will optimum performance, and counters record the number of starts, shutdowns, trips

capture and record any and running time under various conditions in non-volatile memory. Counters and

abnormal conditions that may timers for a 7FA, gas fuel, and dry low Nox (DLN) turbine are as follows:

occur.

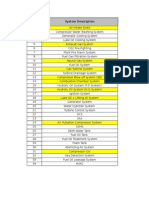

Timers Counters

Total Fired Time Manually Initiated Starts

DLN Primary Mode Total Starts

DLN Lean-lean Mode Fast Load Starts

DLN Premix Mode Fired Starts

DLN Extended Lean-Lean Mode Emergency Trips

Protection

The turbine control system monitors all control and protection parameters and

initiates an alarm if an abnormal condition is detected. If the condition exceeds a

predefined trip level, the turbine control will drive the gas/liquid control valves to a

zero flow position and de-energize the hydraulic trip solenoids. Since this action is

vital to protecting the turbine, the electronics are triple redundant.

All of the control, protection, and monitoring algorithms are contained in the control

modules for efficiency in sharing the common data used in these calculations.

Backup protection for emergency overspeed and synch check protection is

performed in the protection module.

GEI-100472 SPEEDTRONIC, Mark VI TMR • 9

Primary

Overspeed

Combustion

Monitor

<R> Fuel To

Loss Of Flame

Module Turbine

<S> Fuel Control Fuel

Rotor Vibration Control

Module System Valve

Fuel

Compressor <T> Hydraulic Trip Stop

Ratio

Surge Module System Valve

TMR Applications

Fire Protection

System

<P> Protection Module

High Lube Oil <X> Steam Turbine

Header Temp. Section Stop Valves

For Single Shaft STAG

Generator <Y>

Synchronization Section

Steam Cycle

Trip System

Emergency <Z>

Overspeed Section

For Turbines With No

Exhaust Mech. Overspeed Bolt

Overtemperature

Generator Synch

Check Protection

Manual Low Hydraulic

Customer Protect. Low Lube Oil Manual

Emergency Supply / Trip

Shutdown Pressure Hydraulic Trip

Trip Pressure

Typical Protection System

Each trip solenoid is powered from the 125 V dc floating battery bus with contacts

from the control module in series with the negative side of the bus and contacts from

the backup protection module in series with the positive side of the bus. Since there

are three control modules and three sections of the backup protection module, each

trip solenoid has three relays from the control module voting on one side and three

relays from the backup protection module voting on the other side.

10 • SPEEDTRONIC, Mark VI TMR GEI-100472

Diagnostics monitor a contact from each relay and also monitor the voltage directly

across the trip solenoid. For added insurance, diagnostic and trip data are

communicated between the control modules and the backup protection modules on

the triple redundant IONets for cross-tripping.

Overspeed protection consists of a primary overspeed monitoring system in the three

control modules and an emergency overspeed monitoring system in the backup

protection module, which replaces the mechanical overspeed bolt used on older

turbines. Each control module and each section of the backup protection module

monitors a separate passive magnetic speed sensor (6 total) from 2 rpm on a 60 tooth

wheel. Diagnostics monitor the speed and acceleration and exchange the data

between the control modules and the backup protection module on startup to verify

that all sensors are active.

The following is a list of typical trips supplied on a 7FA, gas fuel, DLN turbine.

Pre-ignition Trips Post-ignition Trips General Trips

Auxiliary Check (Servos) Loss of Flame Starting Device Trouble

Seal Oil DC Motor Undervoltage High Exhaust Temperature Inlet Guide Vane Trouble

DC Lube Oil Pump Exhaust Thermocouples Open Manual Trip

Undervoltage

Failure to Ignite on Gas Fuel Compressor Bleed Valve Position Control Speed Signal Lost - HP

Trouble

Load Tunnel Temperature High Protective Speed Signal Trouble

Red. Sensor Gas Fuel Hydraulic Control Speed Signal Trouble

Pressure Low

Turbine Lube Oil Header Gas CV Not Following Reference

Temperature

Turbine Electronic Overspeed Secondary CV Not Following Ref.

Dry Low Nox System Trip PM3 CV Not Following Reference

Compressor Operating Limit Error Quaternary CV Not Following Ref.

Control System Fault

Low Lube Oil Pressure

Fire Indication

Generator Differential Trip

Lockout

Transf. Differential Trip Lockout

Exhaust Pressure High

Breaker Failure Trip Lockout

Vibration Trip

Startup Fuel Flow Excessive

Loss of Protection HP Speed

Inputs

Customer Trip

GEI-100472 SPEEDTRONIC, Mark VI TMR • 11

Operator Screens

The operator/maintenance interface is commonly referred to as the Human Machine

Interface (HMI). It is a PC with a GE CIMPLICITY graphics screen system, a

Microsoft Windows NT operating system, a Control System Toolbox with editors for

the application software and unit specific screens. This interface can be applied as:

• primary operator interface for one or multiple units

• backup operator interface to the plant DCS operator interface

• gateway for communication links to other control systems

• permanent or temporary maintenance station

• engineer’s workstation

All control and protection is resident in the turbine control, which allows the HMI to

be a non-essential component of the control system. It can be reinitialized or

replaced with the turbine running with no impact on the control system. The HMI

communicates with the processor card in the turbine control via the Ethernet-based

UDH.

Operator Interface Graphics

12 • SPEEDTRONIC, Mark VI TMR GEI-100472

Gas turbine control screens show a diagram of the turbine with the primary control

parameters. The diagram is repeated on most of the screens to enable operators to

maintain a visual picture of the turbine’s performance while changing screens. Some

screens such as the exhaust temperature monitor and the static starter screen have

unique graphics. All screens have a menu on the right-hand side of the display,

which has a hierarchy of an Overview screen (for a multiple unit site), Unit selection

(such as GT1 or GT2), Control/Monitor/Auxiliaries/Tests screen category selection,

and a sub-menu of specific screens for each category.

Typical Gas Turbine Screens

Control Screens Monitor Screens Auxiliaries Tests

Startup Bearing Temperature Flame Overspeed Tests

Dry Low Nox Exhaust Temperature Generator Capability

FSR Control Generator RTDs Start Check

Generator/Exciter Hydrogen Static Starter

IGV Control Seismic Vibration Timers

Motors Wheelspace Temperature Trip Diagram

Synchronizing Water Wash

The primary screen in the system is the Startup screen. Since the gas turbine control

provides fully automatic startup including all interface to auxiliary systems, an

operator can initiate all of the basic commands and observe all of the primary control

parameters and status conditions from this single screen.

All operator commands can be given through momentary pushbutton commands on

the screen. The command is sent to the Mark VI control where the application

software initiates the requested action assuming that the appropriate permissives are

satisfied. A response to the command can be observed within one second, if it does

not involve subsequent system time delays like purging.

As an example, if Ready to Start is displayed in the Startup Status field, a Start

command can be given. A small pop-up window displays above the Start button for

the operator to verify the start of the turbine. Upon verification, the application

software checks the startup permissives and initiates a startup sequence, which

displays Starting and Sequence in Progress messages on the left side of the screen.

The purpose of the alarm If the unit was not ready to start, then the message Not Ready to Start displays and

queue is to identify any an alarm message displays in the bottom left-hand corner of the screen identifying

abnormal condition including the reason. In addition, there is a Start Check screen (under Auxiliaries), which

any reason to inhibit a start provides a graphical representation and status of the Start Check / Ready to Start

sequence. permissives. This graphic also relates to the functional organization of the

application software for the Start Check/Ready to Start Permissives. Similarly, all

trips displayed in the alarm field and in the Trip Diagram under Auxiliaries. If a

latched trip is the reason for not being ready to start, then the operator must select

the Master Reset button on the Startup screen. This references another screen to

remind the operator to investigate the latched trip prior to issuing a Master Reset.

GEI-100472 SPEEDTRONIC, Mark VI TMR • 13

In some cases, it is more convenient for the operator to change a setpoint, such as

MW, by typing in a numerical value for the setpoint rather than issuing raise/lower

commands. This capability is provided, and the application software in the Mark VI

automatically compares the requested setpoint with acceptable limits and determines

a suitable rate to ramp the setpoint to the new target.

A Startup Trend can be selected with pre-assigned parameters for the mean exhaust

temperature, speed, maximum vibration, compressor discharge pressure, inlet guide

vane position, and the fuel stroke reference. More detailed information and trending

are provided on supporting screens, and customized trends can be created too.

14 • SPEEDTRONIC, Mark VI TMR GEI-100472

Typical Turbine Instrumentation

Redundant and Multiple Sensors

Device Parameter Function Device Type Quantity Redundant

26QA/T Lube oil temp high A/P Temp switch 3 S

28FD Flame detector A/P UV scanner 4/8 S

33FL Liquid fuel stop valve M Limit switch 2 S

39VX Vibration sensor A/P Velocity pu 2 S

45FX Fire detector A/P Temp switch 2* S

63HG Gas fuel trip oil pressure A/P Press switch 3 D

63HL Liquid fuel trip oil pressure A/P Press switch 3 D

63QA/T Lube oil hydraulic pressure A/P Press switch 3 S

63TF Inlet filter pressure C/P Press switch 3 D

65FP Liquid fuel pump servo C 3 coil servo 1 D

65GC Gas control valve servo C 3 coil servo 1 D

77FD Liquid fuel flow C/P Magnetic pu 3 D

77NH Speed magnetic pickup C Magnetic pu 3 D

77NT Speed magnetic pickup A/P Magnetic pu 3 D

77WN Water flow magnetic pu C Magnetic pu 4 S

90SR Gas ratio valve servo C 3 coil servo 1 D

90TV Inlet guide vane servo C 3 coil servo 1 D

96FG-2 Gas fuel control pressure C Transducer 3 D

96GC Gas control valve C LVDT 2 S

96SR Gas ratio valve C LVDT 2 S

96TV Inlet guide vane C LVDT 2 S

CTDA Compressor discharge M TC 2 S

temperature

CTIF Compressor inlet temperature M TC 2 S

FTGI-x Fuel gas supply temperature C TC 3 D

ST-SJ-x Steam supply pressure C TC 3 D

TTWS-x GT wheelspace temperature A/P TC 2/w S

TTXD-x GT exhaust temperature C/P TC 18* D/S

* All channels/locations except one are redundant by means of two sensors per location. The non-redundant

location has one sensor.

The number of exhaust thermocouples (TCs) varies with the gas turbine (GT) model from 13 to 27. TCs are

divided between the control modules for redundancy.

Legend: S = Shared D = Dedicated A = Alarm M = Monitor P = Protection C = Control

GEI-100472 SPEEDTRONIC, Mark VI TMR • 15

Non-Redundant Sensors (Partial Listing)

Device Parameter Function Device Type Quantity

12HA Mechanical overspeed bolt sensor A/P Limit switch 1

20FG Gas fuel trip oil C Solenoid valve 1

20FL Liquid fuel trip oil C Solenoid valve 1

26FD Liquid fuel temperature C Temp switch 1

26QL/M Lube oil temperature low / moderate C Temp switch 1 each

26QN Lube oil temperature normal P Temp switch 1

33CS Starting clutch M Limit switch 1

33HR Ratchet position C/A Limit switch 1

39FC Cooler fan vibration A Vibration switch 1/fan

63AD Atomizing air differential pressure A Pressure switch 1

63FD Liquid fuel pressure A* Pressure switch 1

63FG Gas fuel pressure A* Pressure switch 1

63LF1 Liquid fuel filter pressure A Pressure switch 1

63LF2 Liquid fuel forwarding filter pressure A Pressure switch 1

63QA Lube oil pressure P Pressure switch 1

63QL Lube oil pressure P Pressure switch 1

63TK Exhaust frame cooling pressure A/P Pressure switch 1/fan

63WC Cooling water pressure low A Pressure switch 1

71QH Lube tank high level A Level switch 1

71QL Lube tank low level A Level switch 1

71WL Water tank low level A Level switch 1

96FF-1 Gas fuel flow pressure C Transducer 1

96FG1 Gas fuel supply pressure C Transducer 1

*Can be used to initiate a transfer from primary to backup fuel.

Legend: S = Shared D = Dedicated A = Alarm M = Monitor P = Protection C = Control

16 • SPEEDTRONIC, Mark VI TMR GEI-100472

Packaging

Cabinet access: Front door access only

Card Backplane: VME type (VERSA Module Eurocard)

Cabinet: NEMA 1 convection cooled, similar to IP-20

Cable Entrance: Top and/or bottom

Finish: E-coat primed, pebble gray – RAL 7032 Door, rear wall, roof: powder

painted

Locks: Lockable door

Material: Sheet steel

Terminal Blocks: (24) point, barrier type terminal blocks that can be unplugged for

maintenance. Each screw can terminate (2) #12 AWG (3.0mm2), 300 V insulated

wires.

Weight: 3,500 lbs. (1,587 kg.)

Type Width Depth Height

3 cabinet lineup with 1 Control Cabinet & 2 Termination Cabinets 4,200 mm 602mm 2,324mm

(Typical for 7FA) 165.4 inches 23.7 inches 91.5 inches

2 cabinet lineup with 1 Control Cabinet & 1 Termination Cabinet 2,600 mm 602mm 2,324mm

(Typical for 7EA) 102.4 inches 23.7 inches 91.5 inches

GEI-100472 SPEEDTRONIC, Mark VI TMR • 17

Power Requirements

The control cabinet is powered from the 125 V dc battery bus and short circuit

protected in the motor control center. Both sides of the floating 125 V dc bus are

continuously monitored with respect to ground. The 125 V dc is fuse isolated in the

Mark VI power distribution module and fed to the internal power supplies for the

control modules, the termination boards for the field contact inputs, and to the

termination boards for the turbine solenoids. Additional 3.2 A fuse protection is

provided on the termination board for each solenoid. Separate 120 V ac feeds are

provided from the motor control center for the ignition transformers. Auxiliary

120/240 V ac sources can be provided for cabinet power if required. A separate UPS

is required for power to the HMI and network equipment.

Control Cabinet Power

Steady-State Voltage Frequency Load Comments

125 V dc (100 to 145Vdc) 10 A dc Ripple <= 5% Add 0.5 A dc continuous for each dc

solenoid

120 V ac (105 to 132 V ac) 47 - 63Hz 15 A rms Harmonic distortion < 7% Add 6.0 A rms for a continuously

powered ignition transformer

240 V ac (210 to 264 V ac) 47 - 63 Hz 7.5 A rms Harmonic distortion < 7 % Add 3.5 A rms for a continuously

powered ignition transformer

Acronyms and Abbreviations

TMR Triple Modular Redundant PDH Plant Data Highway

SOE Sequence of Events PEECC Packaged Electrical and Electronic Control Compartment

LVDT Linear Variable Differential GTS Global Time Source

Transformers

RTD Resistance Temperature Device IRIG-B Inter-Range Instrumentation Group

UDH Unit Data Highway NTP Network Time Protocol

HMI Human-Machine Interface RTU Remote Terminal Unit

CT Current Transformer GSM GEDS Standard Messages

ADL Asynchronous Drives Language FSR Fuel Stroke Reference

EGD Ethernet Global Data DLN Dry Low Nox

GPP Generator Protection Panel GT Gas Turbine

TC Thermocouple PT Potential Transformer

DCS Distribution Control System

g

GE Industrial Systems

Issue date: 2000-07-05 General Electric Company

2000 by General Electric Company, USA.

All rights reserved. 1501 Roanoke Blvd.

Salem, VA 24153-6492 USA

You might also like

- Mark VI For Gas Turbine Control Retrofits Application OverviewDocument22 pagesMark VI For Gas Turbine Control Retrofits Application Overviewcrsswa100% (1)

- GE SpeedTronics MarkVI Turbine ControlDocument22 pagesGE SpeedTronics MarkVI Turbine ControlBijayananda Nayak100% (3)

- Ge Mark VieDocument43 pagesGe Mark VieKevin Ngo100% (1)

- GE Gas Turbine IGV AngleDocument8 pagesGE Gas Turbine IGV Angleramkrishna100% (1)

- 03 ToolboxST BasicsDocument24 pages03 ToolboxST Basicssmart_eng2009100% (2)

- GEI-100667 Mark VIe Serial CommunicationsDocument4 pagesGEI-100667 Mark VIe Serial CommunicationsjosseNo ratings yet

- GHT-200003 How To Download A Mark VIe Controller and IP AddressDocument8 pagesGHT-200003 How To Download A Mark VIe Controller and IP AddressjosseNo ratings yet

- Mark VieDocument4 pagesMark VieWalid Bahi100% (1)

- Mark VIe ClassDocument40 pagesMark VIe ClassRam Krishna100% (10)

- GEH 6700bDocument478 pagesGEH 6700baurel_c12-1100% (3)

- 5 Trenders - 5Document41 pages5 Trenders - 5smart_eng2009100% (1)

- Troubleshooting Failure To Reach I/O Status A7: GE Power Systems Training and DevelopmentDocument15 pagesTroubleshooting Failure To Reach I/O Status A7: GE Power Systems Training and DevelopmentIsmail Djeghoubbi100% (1)

- Mark VI Manual Vol 1Document164 pagesMark VI Manual Vol 1Mitrofan Mihai100% (1)

- Gei 100516Document82 pagesGei 100516Karim BenNo ratings yet

- GT Trip ProtectionsDocument2 pagesGT Trip Protectionsakeel_haq100% (7)

- Learn Gas Turbine by SimulationDocument41 pagesLearn Gas Turbine by SimulationAnonymous 8RRc42G100% (1)

- IGV AssamblyDocument31 pagesIGV AssamblyPhong le100% (1)

- GEH-6721 Vol IDocument202 pagesGEH-6721 Vol Ivishnu ramkaran100% (1)

- GEA-S1212 Mark VIe IO Modules IndexDocument4 pagesGEA-S1212 Mark VIe IO Modules IndexjosseNo ratings yet

- Speedtronic Mark Vie Training Course Section 8Document31 pagesSpeedtronic Mark Vie Training Course Section 8cucumelero barrios100% (1)

- Basics in Intrumentation in Mark-VDocument11 pagesBasics in Intrumentation in Mark-VGnanaseharan ArunachalamNo ratings yet

- Calibrate Servo and LVDT Feedback in Mark VI Control SystemDocument6 pagesCalibrate Servo and LVDT Feedback in Mark VI Control SystemlagoskadunaNo ratings yet

- Presentation Slides - Mark VIEDocument33 pagesPresentation Slides - Mark VIEolegprikhodko2809No ratings yet

- GE - Mark V Turbine ControlDocument1 pageGE - Mark V Turbine ControlAdil Butt0% (1)

- Network Blackout and Mark Vi/Vie Vulnerabilities: Presented by Omran M. Al-Majid Lead Control EngineerDocument21 pagesNetwork Blackout and Mark Vi/Vie Vulnerabilities: Presented by Omran M. Al-Majid Lead Control Engineerkatibra100% (1)

- GT LogicsDocument1,232 pagesGT Logicssrinivas100% (3)

- GE Oil & Gas Control Systems GuideDocument110 pagesGE Oil & Gas Control Systems Guideمحمد أبو لؤي100% (1)

- Mark V HardwareDocument27 pagesMark V HardwareAnonymous IErc0FJ100% (1)

- SpeedTronic™ Mark V Configuration FilesDocument2 pagesSpeedTronic™ Mark V Configuration FilesMagoroku D. YudhoNo ratings yet

- 2b - GEH-6353B MK 5 LM Panel ManualDocument248 pages2b - GEH-6353B MK 5 LM Panel ManualBouazza100% (1)

- مارك 6Document96 pagesمارك 6Mohamed Sheba92% (13)

- CD Final 138039958 Mark VI Control Platform Upgrade - 1 of 2Document255 pagesCD Final 138039958 Mark VI Control Platform Upgrade - 1 of 2Anis HamdaneNo ratings yet

- 7FA AA SystemDocument50 pages7FA AA Systemsmart_eng2009100% (2)

- HMI Configuration Setup r1Document13 pagesHMI Configuration Setup r1Mohamed AmineNo ratings yet

- Gei 100517Document76 pagesGei 100517Karim BenNo ratings yet

- Geh-6421 Vol I Mkvi Vol2Document350 pagesGeh-6421 Vol I Mkvi Vol2Bouazza100% (4)

- Mark VIDocument18 pagesMark VIshafqat2008100% (6)

- On Mark Vi ControlDocument27 pagesOn Mark Vi Controlatreya_baruaa94% (32)

- lIQUID FUEL SYSTEM PDFDocument23 pageslIQUID FUEL SYSTEM PDFJJNo ratings yet

- 6421C Vol II System Manual For Mark VIDocument228 pages6421C Vol II System Manual For Mark VIQuynh Trang100% (1)

- GEI-100535 Direct Modbus For Mark VI and EX2100 PDFDocument34 pagesGEI-100535 Direct Modbus For Mark VI and EX2100 PDFmeirangong100% (1)

- 000start CDDocument1,170 pages000start CDEd Conrreales Arriojas100% (6)

- EX2100 Excitation SystemDocument26 pagesEX2100 Excitation SystemJeziel Juárez100% (2)

- Mark V ICS System - GE Control-Turbine PDFDocument25 pagesMark V ICS System - GE Control-Turbine PDFRashid100% (1)

- GE Speedtronic Mark VDocument14 pagesGE Speedtronic Mark VRyan Anthony Umali50% (4)

- GSM Based Distribution Transformer Monitoring and Controlling System Ijariie1748Document3 pagesGSM Based Distribution Transformer Monitoring and Controlling System Ijariie1748Velu SamyNo ratings yet

- Ge Mark ViDocument22 pagesGe Mark Vichudyace100% (1)

- Speedtronic™ Mark Vi TMR: GE Industrial SystemsDocument19 pagesSpeedtronic™ Mark Vi TMR: GE Industrial Systemsnboulegroune100% (1)

- Motor Protection ManualDocument20 pagesMotor Protection ManualNirmal mehtaNo ratings yet

- Speedtronic Mark VI Control Configuration and Operation Part 1 - Power Industry NewsDocument7 pagesSpeedtronic Mark VI Control Configuration and Operation Part 1 - Power Industry NewsShumraiz M100% (1)

- GE Industrial SystemsDocument20 pagesGE Industrial Systemsfishzee100% (2)

- Planar Safety ManualDocument60 pagesPlanar Safety Manualsoroush_bme100% (1)

- Manual MPPT 100A Solar Charge ControllerDocument36 pagesManual MPPT 100A Solar Charge ControllerVolin RabahNo ratings yet

- TA2100 Toxic SIL2 01-2640 Arsine 0.00-1.00ppm PDFDocument41 pagesTA2100 Toxic SIL2 01-2640 Arsine 0.00-1.00ppm PDFGilman Robert Montalvo100% (1)

- Manual XTRA6415AN V2.2.ENDocument36 pagesManual XTRA6415AN V2.2.ENAmer AlmansoryNo ratings yet

- MM 2Document8 pagesMM 2John Arllan DiestroNo ratings yet

- Motor and Generator Terminals REM 543/545Document2 pagesMotor and Generator Terminals REM 543/545Rahul SinganiaNo ratings yet

- Iot Based Transformer Monitoring System.Document82 pagesIot Based Transformer Monitoring System.ra patNo ratings yet

- Actuadores Eléctrico EmersonDocument44 pagesActuadores Eléctrico EmersonmaparejaaNo ratings yet

- 239 ManDocument158 pages239 Mancristian gonzalezNo ratings yet

- Auma ManualDocument17 pagesAuma ManualAhmed EldosokyNo ratings yet

- Sl. No. Activity Observation SignatureDocument2 pagesSl. No. Activity Observation SignatureAhmed EldosokyNo ratings yet

- Instrument Calibration Report for BASE-MODULE & PIPING SKIDDocument2 pagesInstrument Calibration Report for BASE-MODULE & PIPING SKIDAhmed EldosokyNo ratings yet

- Catalytic CombustionlDocument2 pagesCatalytic CombustionlAhmed EldosokyNo ratings yet

- 1.5 - IT Cabinet Layout Rev2Document1 page1.5 - IT Cabinet Layout Rev2Ahmed EldosokyNo ratings yet

- Fire & Gas Detection Philosophy Part 1 - Fire Detection - Instrumentation and Process ControlDocument6 pagesFire & Gas Detection Philosophy Part 1 - Fire Detection - Instrumentation and Process ControlAhmed EldosokyNo ratings yet

- GT SystemsDocument54 pagesGT SystemsAhmed EldosokyNo ratings yet

- Cascade LoopDocument6 pagesCascade LoopAhmed EldosokyNo ratings yet

- Desalination Plants Start Up ProcedureDocument5 pagesDesalination Plants Start Up ProcedureAhmed EldosokyNo ratings yet

- BurnerDocument33 pagesBurnertoficNo ratings yet

- International System'S Units: Jebel Ali Power PlantDocument14 pagesInternational System'S Units: Jebel Ali Power PlantAhmed EldosokyNo ratings yet

- Fluke 741B 743B Documenting Process Calibrator User ManualDocument134 pagesFluke 741B 743B Documenting Process Calibrator User Manualmirco1No ratings yet

- Effectiveness-NTU Correlation For Low Temperature PCM Encapsulated in SpheresDocument7 pagesEffectiveness-NTU Correlation For Low Temperature PCM Encapsulated in SpheresJoão JúniorNo ratings yet

- Ds Te3204 en CoDocument18 pagesDs Te3204 en CoHamed YadegariNo ratings yet

- Apple Juice Making ProcessDocument33 pagesApple Juice Making ProcessCt Hajar69% (13)

- Two-Wire Transmitters For PH, Orp, Conductivity, Oxygen, Ozone, and ChlorineDocument16 pagesTwo-Wire Transmitters For PH, Orp, Conductivity, Oxygen, Ozone, and ChlorineKleiber OrtegaNo ratings yet

- Thermosensitive Sensors Part - 1Document15 pagesThermosensitive Sensors Part - 1jayNo ratings yet

- Temp TXRDocument64 pagesTemp TXRmanipsNo ratings yet

- WLC WLS V1Document40 pagesWLC WLS V1RISHI FOOD TESTING LABNo ratings yet

- Euromet Calibration of Indicators-SimulatorsDocument22 pagesEuromet Calibration of Indicators-Simulatorsliam15111981No ratings yet

- ST100 Series Complete Manual 06EN003400fDocument106 pagesST100 Series Complete Manual 06EN003400fKarthik balaNo ratings yet

- Instrumentation Q&A GuideDocument46 pagesInstrumentation Q&A Guidemushahid980No ratings yet

- Condenser Performance Monitoring GuideDocument70 pagesCondenser Performance Monitoring Guidesri_bala100% (2)

- DFFFFDocument29 pagesDFFFFAman RatheeNo ratings yet

- Acez Sensing Green Mark Sensor Catalogue TE25Document5 pagesAcez Sensing Green Mark Sensor Catalogue TE25v6656100% (1)

- Manual TMD-SeriesDocument1 pageManual TMD-SeriesAlex VargasNo ratings yet

- Yta310 & Yta320 YokogawaDocument8 pagesYta310 & Yta320 Yokogawahenryhariyadi100% (1)

- EI 6704 Biomedical Instrumentation Unit IDocument69 pagesEI 6704 Biomedical Instrumentation Unit IInfant Raj100% (2)

- Namur 43Document28 pagesNamur 43Subrangshu100% (1)

- Alphasense User Manual A4 Analogue Front End (AFE) Circuit Board FamilyDocument9 pagesAlphasense User Manual A4 Analogue Front End (AFE) Circuit Board FamilyRafael Asorey Cacheda100% (1)

- Interfacing Temperature Sensors with Galil ProductsDocument3 pagesInterfacing Temperature Sensors with Galil Productsshadi22No ratings yet

- PDC ReportDocument17 pagesPDC ReportRooth AdajetNo ratings yet

- Transducers and Data Acquisition SystemsDocument176 pagesTransducers and Data Acquisition SystemsBenson Mansingh P MNo ratings yet

- Experiment 8 Temperature MeasurementDocument25 pagesExperiment 8 Temperature MeasurementEvan ChinNo ratings yet

- Mechanical Measurements and Metrology Lab ManualDocument111 pagesMechanical Measurements and Metrology Lab ManualSnigdhaNo ratings yet

- XTR 105Document22 pagesXTR 105Omar AlmonteNo ratings yet

- Instrumentation Notes by Alamgir RahimDocument66 pagesInstrumentation Notes by Alamgir RahimmersiumNo ratings yet

- Instrumentation For Process ControlDocument153 pagesInstrumentation For Process ControlAudrey Patrick KallaNo ratings yet

- Industrial Automation Guide: Costs, Benefits & ApplicationsDocument153 pagesIndustrial Automation Guide: Costs, Benefits & ApplicationsTanvir KhanNo ratings yet

- Operating and ControlDocument378 pagesOperating and Controlباسم باسمNo ratings yet