Professional Documents

Culture Documents

A O Smith Meter 2 Inch Steel Model C2

Uploaded by

RomankoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A O Smith Meter 2 Inch Steel Model C2

Uploaded by

RomankoCopyright:

Available Formats

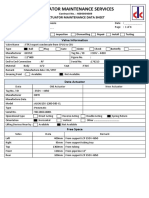

Smith Meter® Rotary Vane PD Meter

2" Steel Model C2

Specifications

Issue/Rev. 0.7 (4/10) Bulletin SS01010

The Smith Meter® Model C2 Meter is a 2", double-case,

straight-through (S1 through S7), rotary vane, positive

displacement meter. Applications include: blending,

batching, dispensing, inventory control, and custody

transfer of oils, solvents, chemicals, paints, fats, and

fertilizers.

Features

Superior Accuracy – The Smith Meter® Rotary Vane

Meter principle, combined with the meter’s uniquely

designed (offset) inlet and outlet nozzles, minimizes

pressure drop across the measuring chamber, which

reduces flow through the meter clearances to maxi-

mize accuracy.

Low Pressure Drop – Streamlined flow path provides

low pressure drop.

Positive and Accurate Registration – High torque

drive calibrator with adjustment in 0.05% increments

ensures accurate registration.

Model C2-S1 with Large Numeral Counter and Ticket

Long Service Life – Low friction ball bearings, fixed Printer

cam-type timing, and rugged construction give sus-

tained accuracy and long service life.

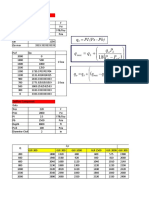

Minimum Flow Rate – Typical Performance

Options Viscosity (Centipoise - mPa•s)

Linearity Units 0.5 1

2

5 20 100 400

High Viscosity Meter Clearances – To extend opera- USGPM 25 15 6 1.5 0.30 0.08

tion at maximum flow rate from 400 mPa•s to 2,000 ±0.15%

l/min 95 57 23 6.0 1.00 0.30

mPa•s.

USGPM 17 10 4 1.0 0.20 0.05

High Temperature Clearances – To extend operating ±0.25%

temperatures from 150°F to 200°F (65°C to 93°C). l/min 65 38 15 4.0 0.75 0.20

All Iron Trim – For operating temperatures above USGPM 13 8 3 0.8 0.16 0.04

±0.50%

200°F (93°C). l/min 50 30 11 3.0 0.60 0.15

LPG Trim – For low lubricity liquids such as LPG.

NACE Construction – Special components available Repeatability

to meet requirements of NACE Standard MR-01-75. ±0.02%

Viscosity

Operating Specifications

Standard: 400 mPa•s3 (2,000 SSU) maximum.

Maximum Flow Rate Optional: 2 Pa•s (10,000 SSU) maximum – specify “High

Viscosity Meter Clearances.”

USGPM L/min

Over 2 Pa•s: Specify “High Viscosity Meter Clearances”

Continuous Rating 125 475

and derate maximum flow rate in direct proportion to

Intermittent Rating1 150 570 viscosity over 2 Pa•s (e.g., at 4 Pa•s, derate Maximum

Continuous/Intermittent Rating - Flow Rate to 50% of normal continuous rating - 63

All Iron, and LPG Construction 100 375 USGPM).

1 Intermittent rating applies to service on clean, refined products where continuous operation is not required (e.g., truck loading, rail loading,

and other batching applications).

2 Linearity based on a maximum flow rate of 125 USGPM (475 L/min)

3 1,000 mPa·s = 1,000 cP = 1 Pa·s.

The Most Trusted Name In Measurement

Temperature Pressure Drop (∆P)

Standard Meter Clearances With:

Buna N/EPR/PTFE7: -20°F to 150°F (-29°C to 65°C). Flow - Litres per Minute

Viton: 10°F to 150°F (-12°C to 65°C). 0 100 200 300 400 500 600

20.0

2.8

High Temperature Meter Clearances With: Data based on 0.82 sp. gr.,

Buna N/EPR/PTFE7: -20°F to 200°F (-29°C to 93°C). 2.4 2 mPa•s product. 16.0

Viton: 10°F to 200°F (-12°C to 93°C). 2.0

All Iron Trim With: 12.0

∆P

1.6 ∆P

Buna N: -20°F to 225°F (-29°C to 108°C). kPa

psi 1.2

EPR: -20°F to 300°F (-29°C to 149°C). 8.0

PTFE7 -20°F to 400°F (-29°C to 205°C). 0.8

Viton: 10°F to 400°F (-12°C to 205°C). 4.0

0.4

0 0

Meter Gearing 0 20 40 60 80 100 120 140 160

Flow - U.S. Gallons per Minute

Five U.S. gallons or 1 dekalitre per revolution of meter

calibrator output shaft (standard).

Maximum Working Pressure Materials of Construction

Model Flange

PSI kPa Trim Housing Internals Seals

C2-S1 150 150 1,034 Standard Iron, Steel, Stainless

C2-S3 150 2854 1,9654 Steel, Aluminum

C2-S5 300 300 2,068

C2-S6 300 7404 5,1024 Steel Buna N6, PTFE7,

LPG Add Rulon and Nylon or Viton5, EPR

C2-S7 600 1,4804 10,2044

Flange Class per ANSI B16.5 Raised Face Flange.

All Iron Delete Aluminum

Installation

It is recommended that the meter be protected with a

suitable mesh strainer.

4 Maximum W.P. at 100°F (38° C).

5 All S3 through S7 meters with Viton adder will have Polytetrafluoroethylene (PTFE) packing gland seals.

6 Standard.

7 Polytetrafluoroethylene (PTFE).

Page 2 • SS01010 Issue/Rev. 0.7 (4/10)

Dimensions

Inches (mm)

Drain

Meter

Anchor Bolt Holes

3 - 0.6" (15) Bolt Holes

G on a "F" Diameter Bolt Circle.

E

Top View

D

3.5"

(89)

A 30°

2.9" (74) required

to open Printer Top 11.2"

(284)

4.6"

(117)

9.4"

(239)

6"*

(152)

Drain 1/2" NPT

0.9"

(23)

Note: Dimensions – inches to the nearest tenth (millimetres to the nearest whole mm), each independently dimensioned from respective

engineering drawings.

Model A B C D E F G Weight - lb (kg)

C2-S1 14.0" (356) 5.6" (142) 15.8" (400) 7.4" (188) 13.4" (340) 8.5" (216) 3.8" (97) 95 (43)

C2-S3 14.0" (356) 5.6" (142) 18.6" (472) 7.4" (188) 13.4" (340) 8.5" (216) 3.8" (97) 110 (50)

C2-S5 14.6" (371) 5.6" (142) 18.6" (472) 7.4" (188) 13.4" (340) 8.5" (216) 3.8" (97) 115 (52)

C2-S6 18.0" (457) 5.8" (147) 21.0" (533) 7.8" (198) 14.8" (375) 9.1" (232) 4.3" (109) 170 (77)

C2-S7 18.8" (476) 6.4" (162) 21.6" (548) 7.8" (198) 15.1" (385) 9.1" (232) 4.3" (109) 255 (116)

Issue/Rev. 0.7 (4/10) SS01010 • Page 3

Ordering Information Printer

Application Batching, Loading, Blending, Inventory, Seven-digit accumulative.

Process Control, etc. Optional six-digit zero start.

Operating Liquid — Name and sp. gr.or API Gravity,

Flow Range8, Temp. Range8, Viscosity Preset Counter

Range8, Maximum Working Pressure, C of E. 300C Series – four-digit (five-digit optional) mechanical

Seals Buna N9, Viton, PTFE7 or EPR. pushbutton preset with valve linkage. Microswitch pack-

Units of age for hydraulic valve, pump control, or other interlock

Registration Gallons, Litres, Pounds, Kilograms optional.

Direction Left to right flow (as viewed above) is standard

of Flow10 and will be supplied unless right to left Pulse Transmitters

flow is specified. Type E – SPDT Mercury Wetted Switch.

Options and LNC Pulse Transmitter (adapts to 600 Series Counters).

Accessories As required.

Low-Resolution - 1 or 10 pulses11.

High-Resolution (HR) - 50 or 100 pulses11.

Accessories UPT – Quad-channel, infrared, security pulse transmitter

in an explosion-proof housing (up to 1,000 pulses/rev.).

Strainer

Flow Rate Indicator

2" steel, R.F. flanged, 4 mesh or finer screen.

Direct Mount Mechanical.

Mechanical Preset Valves Remote Electronic.

2" offset or straight through type, steel, flanged, 150 psi Remote Registration

and 300 psi (300 psi straight through only) maximum

Electro-Mechanical Counters.

working pressure respectively.

Electronic Totalizers.

Hydraulic Valves

Automatic Temperature Compensation

2" globe type, steel, R.F. flanged, 300 psi maximum

Model ATC – Factory-set for a given product.

working pressure.

Model ATG – Field-adjustable for different products.

Air Eliminator

2" steel, R.F. flanged.

Counters

200 Series – Accumulative, nine-digit, non-reset type.

600 Series – Five large digit reset, eight small digit

non-reset.

7 Polytetrafluoroethylene (PTFE).

8 Specify: minimum/normal/maximum.

9 Standard seals supplied unless optional material specified.

10 For right-to-left flow on C2-S1 meters, add reversing gear kit.

11 Per revolution of LNC right hand wheel.

Revisions included in SS01010 Issue/Rev. 0.7 (4/10):

Page 2: C2-S6 and C2-S7 – PSI and kPa revised.

Editorial Change: 11/13: Seals - material reference changed to PTFE.

Headquarters: Operations: The specifications contained herein are subject to change without notice and any user of said

500 North Sam Houston Parkway West, Measurement Products and Equipment: specifications should verify from the manufacturer that the specifications are currently in effect.

Suite 100, Houston, TX 77067 USA Ellerbek, Germany +49 (4101) 3040 Otherwise, the manufacturer assumes no responsibility for the use of specifications which

Phone: +1 (281) 260 2190 Erie, PA USA +1 (814) 898 5000 may have been changed and are no longer in effect.

Fax: +1 (281) 260 2191

Contact information is subject to change. For the most current contact information, visit our

Integrated Measurement Systems:

website at www.fmctechnologies.com/measurementsolutions and click on the “Contact Us”

Corpus Christi, TX USA +1 (361) 289 3400 link in the left-hand column.

Kongsberg, Norway +47 (32) 286700

www.fmctechnologies.com/measurementsolutions

Printed in U.S.A. © 4/10 FMC Technologies Measurement Solutions, Inc. All rights reserved. SS01010 Issue/Rev. 0.7 (4/10)

You might also like

- 4" Steel Model F4: Smith Meter PD Rotary Vane MeterDocument4 pages4" Steel Model F4: Smith Meter PD Rotary Vane MeterVictor FreireNo ratings yet

- 12" Steel Model K12: Smith Meter CT Series PD Meter For Crude TransportationDocument4 pages12" Steel Model K12: Smith Meter CT Series PD Meter For Crude Transportationjuan carlosNo ratings yet

- Smith Meter Prime 4Document2 pagesSmith Meter Prime 4gerosuca800No ratings yet

- Smith Meter UPTDocument6 pagesSmith Meter UPTvalimironescuNo ratings yet

- Smith Meter Flow ComputerDocument10 pagesSmith Meter Flow Computeriky7750% (2)

- Design, Operation and Maintenance of Lact UnitsDocument3 pagesDesign, Operation and Maintenance of Lact UnitsJose gonzalezNo ratings yet

- LectureDocument9 pagesLecturePrince Jonas Bautista CanlasNo ratings yet

- Vortex TrainingDocument17 pagesVortex TrainingRexCrazyMindNo ratings yet

- (TP0A002) Pipeline Meter SelectionDocument3 pages(TP0A002) Pipeline Meter SelectionRoberto Carlos TeixeiraNo ratings yet

- Close Interval Potential Survey: Orrosion Echnology ErvicesDocument4 pagesClose Interval Potential Survey: Orrosion Echnology ErvicesAndika ChemEng100% (1)

- Net Positive Suction HeadDocument7 pagesNet Positive Suction HeadNenad MutavdzicNo ratings yet

- Flow Measurement and ControlDocument43 pagesFlow Measurement and ControlCao AnhNo ratings yet

- Pipeline Cleaning Case StudyDocument5 pagesPipeline Cleaning Case StudyJason MooreNo ratings yet

- Smith Meter VDR Vertical Deaerator SpecificationsDocument8 pagesSmith Meter VDR Vertical Deaerator SpecificationsClarkFedele27No ratings yet

- Desalting and DehydrationDocument10 pagesDesalting and DehydrationRizwan umerNo ratings yet

- Actuator Maintenance ServicesDocument7 pagesActuator Maintenance ServicesKevin MuhalingNo ratings yet

- GT Tray Tower1 PDFDocument12 pagesGT Tray Tower1 PDFJose Christian Viladegut GuzmanNo ratings yet

- Introduction to Metering & Allocation ProcessesDocument22 pagesIntroduction to Metering & Allocation ProcessesSameer AhmadNo ratings yet

- NMi Productflyer EuroLoopDocument2 pagesNMi Productflyer EuroLoopSarah ClarkNo ratings yet

- Project ReportDocument36 pagesProject Reportvishi89No ratings yet

- Cleaning of Pipes by Gas Discharge Back PuffingDocument1 pageCleaning of Pipes by Gas Discharge Back PuffingVamsi MahantiNo ratings yet

- Tosilon TUR 200DDocument24 pagesTosilon TUR 200DDave NakpodiaNo ratings yet

- Well StimulationDocument58 pagesWell StimulationRizwan FaridNo ratings yet

- Coriolis Well Performance Measurement With Net Oil ComputersDocument18 pagesCoriolis Well Performance Measurement With Net Oil ComputersJoelAlbertoMugnoCampoNo ratings yet

- Leve LDocument42 pagesLeve LSubodh SawantNo ratings yet

- Actuator Maintenance ServicesDocument7 pagesActuator Maintenance ServicesKevin MuhalingNo ratings yet

- Multi-Cyclone Scrubber Centrifugal Separator BrochureDocument4 pagesMulti-Cyclone Scrubber Centrifugal Separator BrochureadrianioantomaNo ratings yet

- Electromagnetic FlowmeterDocument5 pagesElectromagnetic FlowmeterEllen ShengNo ratings yet

- INSTRUDocument130 pagesINSTRUJustine-Denisse OngNo ratings yet

- Domestic Gas MetersDocument3 pagesDomestic Gas MetersSrinivas VenkatramanNo ratings yet

- Gas LiftDocument9 pagesGas LiftRiska IndahNo ratings yet

- DTA - Dynamic Torque Anchor Technical DatasheetDocument5 pagesDTA - Dynamic Torque Anchor Technical DatasheetEvolution Oil ToolsNo ratings yet

- 20200605-P117 Portable Ultrasonic FlowmeterDocument8 pages20200605-P117 Portable Ultrasonic FlowmeterRoger Cueva ZutaNo ratings yet

- Acumulador 1Document30 pagesAcumulador 1Carolina GalavisNo ratings yet

- En-FAB Metering & Measurement 2016 BrochureDocument58 pagesEn-FAB Metering & Measurement 2016 Brochurecarmel BarrettNo ratings yet

- 650 01 GB 0111 01Document12 pages650 01 GB 0111 01Phan HaiNo ratings yet

- 8155 PPI Chapter Explains Programmable Peripheral InterfaceDocument12 pages8155 PPI Chapter Explains Programmable Peripheral InterfacebelihuNo ratings yet

- Intro Process Xmitters (Suresh)Document33 pagesIntro Process Xmitters (Suresh)sreeyukthaNo ratings yet

- PSV SizingDocument18 pagesPSV SizingGo IELTSNo ratings yet

- Turbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Document8 pagesTurbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Alexander KlmNo ratings yet

- An Week4Document24 pagesAn Week4Tania NoorNo ratings yet

- Piping: Wing Union ConnectionsDocument8 pagesPiping: Wing Union ConnectionsMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Compact ProverDocument14 pagesCompact ProverEka Pramudia SantosoNo ratings yet

- SeparatorDocument8 pagesSeparatorIra Purnama SariNo ratings yet

- Gas Metering PT-4Document30 pagesGas Metering PT-4brianNo ratings yet

- Gas Metering TrainingDocument276 pagesGas Metering Trainingsushant shirsatNo ratings yet

- MI199 Training Flow MeasurementDocument9 pagesMI199 Training Flow MeasurementT S VirdiNo ratings yet

- Oil & Gas Upstream Production Facilities OverviewDocument49 pagesOil & Gas Upstream Production Facilities OverviewabdulzahraNo ratings yet

- TechnicalDocument3 pagesTechnicalbmanojkumar16No ratings yet

- Flow Metering Tutorial Part 4 Ultrasonic Flow MetersDocument4 pagesFlow Metering Tutorial Part 4 Ultrasonic Flow MetersSenthil KumarNo ratings yet

- Pressure-Operated Valves Series 290-390-298-398Document8 pagesPressure-Operated Valves Series 290-390-298-398Nelson AlvarezNo ratings yet

- Pillard - Packlight Buk 117 CDocument2 pagesPillard - Packlight Buk 117 CAlfonso Blanco100% (1)

- Determination of Net Oil For Well Performance by R Dutton 33Document4 pagesDetermination of Net Oil For Well Performance by R Dutton 33moralesmjyNo ratings yet

- 67Document10 pages67johnnylim456No ratings yet

- Separator Sizing - PPTDocument21 pagesSeparator Sizing - PPTD K SNo ratings yet

- Vortex Pilot Gas Heater Over Temperature ProtectionDocument17 pagesVortex Pilot Gas Heater Over Temperature ProtectionDon BettonNo ratings yet

- Energy Equation & Its ApplicationsDocument47 pagesEnergy Equation & Its ApplicationsRopah ChihuriNo ratings yet

- 16" Steel Model M16: Smith Meter CT Series PD Meter For Crude Transportation SpecificationsDocument4 pages16" Steel Model M16: Smith Meter CT Series PD Meter For Crude Transportation SpecificationsAnnisa RahmadayantiNo ratings yet

- 16 Steel Model M16Document4 pages16 Steel Model M16JAIME CIFUENTESNo ratings yet

- How To Select A Pump-By Majid HamedyniaDocument72 pagesHow To Select A Pump-By Majid Hamedyniamajid100% (2)

- DSE7310 MKII DSE7320 MKII Installation Instructions PDFDocument2 pagesDSE7310 MKII DSE7320 MKII Installation Instructions PDFDaniel StanNo ratings yet

- Product data sheet for discontinued 8501KPD12V51 relayDocument2 pagesProduct data sheet for discontinued 8501KPD12V51 relayRomankoNo ratings yet

- Pressure Leak Testing GuideDocument20 pagesPressure Leak Testing Guidefezzeh kabiri kenari100% (1)

- 400w Electric Power Steering Kit Installation GuideDocument2 pages400w Electric Power Steering Kit Installation GuideRomankoNo ratings yet

- Flexzorber PDFDocument4 pagesFlexzorber PDFRomankoNo ratings yet

- How To Resolve A Connection Problem: G E N E R A L D E S C R I P T I O NDocument5 pagesHow To Resolve A Connection Problem: G E N E R A L D E S C R I P T I O NRomankoNo ratings yet

- How the Crisis in Ukraine Explains Future Great Power ConflictDocument73 pagesHow the Crisis in Ukraine Explains Future Great Power ConflictRomankoNo ratings yet

- Trunk Limb Scalp PsoriasisDocument1 pageTrunk Limb Scalp PsoriasisRomankoNo ratings yet

- Coupler-Couplings TodoDocument8 pagesCoupler-Couplings TodoRomankoNo ratings yet

- FILTON Swivel Joints PDFDocument12 pagesFILTON Swivel Joints PDFRomankoNo ratings yet

- Brochure Offshore Hoses PDFDocument16 pagesBrochure Offshore Hoses PDFRomankoNo ratings yet

- DIXON Cam & Groove Type Line Drawings PDFDocument2 pagesDIXON Cam & Groove Type Line Drawings PDFRomankoNo ratings yet

- AMEREX Owners-Service-Manual-12386s22Document4 pagesAMEREX Owners-Service-Manual-12386s22RomankoNo ratings yet

- FILTON Swivel JointsDocument12 pagesFILTON Swivel JointsRomankoNo ratings yet

- Flexzorber PDFDocument4 pagesFlexzorber PDFRomankoNo ratings yet

- Coupler-Couplings TodoDocument8 pagesCoupler-Couplings TodoRomankoNo ratings yet

- Iacs Class What Why HowDocument16 pagesIacs Class What Why HowJuniorJavier Olivo Farrera100% (1)

- DIXON Cam & Groove Type Line Drawings PDFDocument2 pagesDIXON Cam & Groove Type Line Drawings PDFRomankoNo ratings yet

- CATERPILLAR C13-C15-And-C18-Engines-Acceleration-Is-Poor-Or-Throttle-Res PDFDocument4 pagesCATERPILLAR C13-C15-And-C18-Engines-Acceleration-Is-Poor-Or-Throttle-Res PDFRomankoNo ratings yet

- OM 010 QD InstallationDocument3 pagesOM 010 QD InstallationRomankoNo ratings yet

- MSN 1668Document15 pagesMSN 1668J FixNo ratings yet

- Hydradine o RingDocument1 pageHydradine o RingRomankoNo ratings yet

- Tech GuidesDocument52 pagesTech GuidesAHMED MAHMOUD100% (1)

- Outdoor 2018 We Lowres 2Document84 pagesOutdoor 2018 We Lowres 2RomankoNo ratings yet

- Catalogo RacorDocument179 pagesCatalogo RacorEdwin Maldonado Castro100% (1)

- POCKET BOOK EN Standard PDFDocument35 pagesPOCKET BOOK EN Standard PDFAshok Kumar YalamanchiliNo ratings yet

- POCKET BOOK EN Standard PDFDocument35 pagesPOCKET BOOK EN Standard PDFAshok Kumar YalamanchiliNo ratings yet

- Understanding ISO CodesDocument4 pagesUnderstanding ISO CodesBRAULIO MALCHICNo ratings yet

- FRANKLIN ELECTRIC Convertible - Jet - Manual - 06-16-FinalDocument32 pagesFRANKLIN ELECTRIC Convertible - Jet - Manual - 06-16-FinalRomankoNo ratings yet

- Fuel Oil AnalysisDocument6 pagesFuel Oil AnalysisPawan BeniwalNo ratings yet

- O Level Chemistry 5070 Polymer Chemistry Worksheet 1Document10 pagesO Level Chemistry 5070 Polymer Chemistry Worksheet 1Choolwe CheeloNo ratings yet

- Production Technology Course OutDocument5 pagesProduction Technology Course Outmurjass85No ratings yet

- PiezoDocument17 pagesPiezonileshsawNo ratings yet

- FTJ Series Product Guide PDFDocument12 pagesFTJ Series Product Guide PDFJhon SendokNo ratings yet

- Catalogo Herramientas CaterpillarDocument112 pagesCatalogo Herramientas CaterpillarJorge Perez100% (2)

- Steel QuizDocument2 pagesSteel Quizjakeer7No ratings yet

- Jurnal Analisis Stabilitas Lidokain HCLDocument11 pagesJurnal Analisis Stabilitas Lidokain HCLMusfira Dewy SuardiNo ratings yet

- ASAT Class 7Document16 pagesASAT Class 7kamalsharma2014100% (1)

- Fundamentals of Natural Gas Liquid MeasurementsDocument9 pagesFundamentals of Natural Gas Liquid Measurementsmakasad26No ratings yet

- 2.1.1 Temperature Programmed Reduction/Oxidation/Desorption (TPR/O/D)Document4 pages2.1.1 Temperature Programmed Reduction/Oxidation/Desorption (TPR/O/D)AnnafiNo ratings yet

- ISC Class 12 Chemistry Practical SyllabusDocument3 pagesISC Class 12 Chemistry Practical SyllabusmaniksinghmehraNo ratings yet

- Fluid Mechanics: Properties, Viscosity and ApplicationsDocument77 pagesFluid Mechanics: Properties, Viscosity and ApplicationsvijaynieNo ratings yet

- Pva 2019Document7 pagesPva 2019kashyap8291100% (1)

- Water Steam Chemistry OptimizationDocument4 pagesWater Steam Chemistry OptimizationAshish ParasharNo ratings yet

- Cyliani's Hermes UnveiledDocument31 pagesCyliani's Hermes UnveiledAndre Bambu100% (2)

- Scotch Tape Method: Producing Graphene FlakesDocument3 pagesScotch Tape Method: Producing Graphene Flakestaniya balochNo ratings yet

- Tool Makers MicroscopeDocument13 pagesTool Makers MicroscopeLokesh LokiNo ratings yet

- Qian, Hrnjak - Void Fraction Measurement and Flow Regimes Visualization of R134a in Horizontal and Vertical ID 7 MM Circular Tubes PDFDocument41 pagesQian, Hrnjak - Void Fraction Measurement and Flow Regimes Visualization of R134a in Horizontal and Vertical ID 7 MM Circular Tubes PDFHanim BasarudinNo ratings yet

- The Effect of Open Area On Sieve Tray Performance: T. YanagiDocument24 pagesThe Effect of Open Area On Sieve Tray Performance: T. Yanagifumanchu@fastmail.fmNo ratings yet

- Glass Ionomer Cement Properties and ApplicationsDocument67 pagesGlass Ionomer Cement Properties and ApplicationsJayalakshmi Preetha100% (1)

- MNL 67-2009 PDFDocument128 pagesMNL 67-2009 PDFlolo100% (2)

- Group 2 CationsDocument15 pagesGroup 2 Cationsember_memories50% (2)

- ELITE™ AT 6900: The Dow Chemical Company - Enhanced Polyethylene ResinDocument2 pagesELITE™ AT 6900: The Dow Chemical Company - Enhanced Polyethylene ResinLeductoan LeNo ratings yet

- Aerospace Standard: (R) Fittings, Straight Threaded Boss or Flanged, Fluid ConnectionDocument16 pagesAerospace Standard: (R) Fittings, Straight Threaded Boss or Flanged, Fluid ConnectionAlberto De La CruzNo ratings yet

- Notice: Applications, Hearings, Determinations, Etc.: Lin Zhi International Inc.Document1 pageNotice: Applications, Hearings, Determinations, Etc.: Lin Zhi International Inc.Justia.comNo ratings yet

- QSonic Brochure 209Document12 pagesQSonic Brochure 209Anish DonaldNo ratings yet

- Glassware Cleaning ProcedureDocument3 pagesGlassware Cleaning ProcedureMukta TalukderNo ratings yet

- ADMIX CATALOG 2015 16 WEB Links PDFDocument248 pagesADMIX CATALOG 2015 16 WEB Links PDFdan0427No ratings yet

- Effect of Concentration in Rate of ReactionDocument3 pagesEffect of Concentration in Rate of ReactionblablaNo ratings yet