Professional Documents

Culture Documents

Hygienic Aspects of Electrical Installation in Food Factories

Uploaded by

maurice86Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hygienic Aspects of Electrical Installation in Food Factories

Uploaded by

maurice86Copyright:

Available Formats

Hygienic aspects of electrical

installations in food factories

By A Murray, Consulting food process engineer

Stringent standards - applied by regulators, retailers and the consumer public - are making stricter adherence to hygiene measures a necessity.

T

he purpose of the food processing industry is to produce safe of 72°C is sufficient to control the pathogens that might be present in

wholesome food from specified raw materials. Consumers are the milk. A similar pasteurisation step for beer does not constitute a

very particular about what they eat and how it is produced. This critical control point because no known pathogens are present in beer.

has always been so but it is becoming more important in a world Every food safety management system also recognises that certain

where less cooking is being done in the home and more processed prerequisite programmes must be put in place prior to identifying

foods are on offer. Consumers want tasty nutritious food - but they hazards and implementing HACCP. These include, amongst others,

also want to know that what they are eating has been hygienically pest control, recall procedures, training – as well as the hygienic

produced and is safe. design of buildings and equipment.

All the safety and quality regulations and standards that apply to Indeed, the hygienic aspects of agro-processing machinery are

other manufacturing industries apply equally to the food processing regulated in the European Union as a part of the machinery directives.

industry. In the same way that the OHS regulations and ISO 9000 [1] Although the hygienic design of food processing machinery is not

quality standards are applied to other industries, so also are they regulated in South Africa, the design of both buildings and equipment

applied the food industry. In addition to this, food safety manage- for food processing is included in South African voluntary standards

ment programmers are required in food handling facilities to ensure (SANS 10049 [3] and SANS/ISO 14159 [4]). Minimum standards for

production of safe food. food handling premises and utensils are regulated in terms of the

Most food safety management programmes today, (for instance Foodstuffs, Cosmetics and Disinfectants Act (Regulation 962 under

the ISO 20000 standards [2]) incorporate the Hazard Analysis Critical Act 54 of 1972.)

Control Point (HACCP) system. This involves a systematic seven stage Those areas of the plant which come into contact with the product

documented procedure for identifying the hazards and the points are the most important. Other areas such as the splash areas, which

in the manufacture that must be controlled in order to minimise as the name implies are areas which the food might contact due to

risk. These are the critical control points. In addition, the limits of splash or spillage, and the non contact areas, are also important

control and methods because they can become breeding grounds for micro organisms.

of monitoring and re- Although hygienic design is important in all sectors, the food

cording the results are industry also identifies high risk areas. These are areas where food

documented. In the is particularly at risk, for instance the preparation areas for frozen

production of drink- pre-cooked ready meals - such food is going to be consumed without

ing milk, the critical any further opportunity to control pathogenic organisms that might

control point is the contaminate it. The areas where the meals are assembled require

temperature of pas- special care. These areas will need measures such as defined entry

teurisation which is procedures for personnel and materials, specific air handling proce-

set at a minimum, dures and temperature control.

generally 72°C, and The distribution of electricity and the use of electrical equipment

controlled though a are particularly important in high risk areas but are also important

temperature sensor in other areas of the food factory. Because of the frequent cleaning

and a divert valve required many food production plants tend to be wet. Electrical equip-

which returns any ment in this case must be water-tight. Ingress of water would not

unpasteurised milk only be dangerous and cause damage to the electrical components,

to the balance tank. it could also carry micro-organisms with it. In the warm conditions

A chart or electronic found within electrical enclosures, breeding of such organisms is likely

recorder maintains a and will result in recontamination of the areas outside the enclosure.

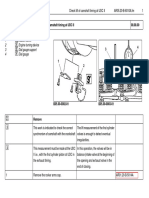

Mounting of instruments in pipeline. The

mountings are flush leaving no dead spaces. record of the opera- In certain processes such as the production of milk powders,

Photograph courtesy GEA Group tion. The temperature starch or flour milling, both dust and the risk of explosion are prevalent.

E+C SPOT ON • May 2014

BSP – British Standard Piping

HACCP – Hazard Analysis Critical Control Point

ISO – International Standards Organisation

NPT – National Pipe Taper

OHS – Occupational Health and Safety

PRP – Pre-requisite Programme

SANS – South African National Standard

Abbreviations

Control instrumentation which comes into contact with the food Electric motors

product must be hygienically designed.

Electric motors used in the food industry should be to a minimum

Some general guidelines for hygienic electrical installations are

IP55 classification. It has been common practice in the food industry

given below.

to shroud electric motors, particularly those used on pumps, with a

Materials of construction stainless steel cover. Where this is done the covers should be easily

removable to allow cleaning of the motor. This cleaning is important

Stainless steel is the material of choice for food process installations.

It is durable, smooth and cleanable. The grades used for contact parts

in most food applications are the austenitic grades 304 and 316. Other

Hygienic pipe unions used in the food industry

grades such as 3Cr12 may be used in non contact areas. may be modified to fit the instrumentation.

Other construction metals are generally less suitable in food The electrical engineer should establish

factories. Aluminium, for instance, is subject to attack by most of the from the process engineer which union pattern is

commonly used sanitisers. Galvanising and painting may provide a

standard for the plant in question.

measure of protection but coatings are subject to flaking and peeling.

because the warm area around motors provides a breeding ground

Control panels and distribution boxes

for pests.

As indicated, stainless steel is the preferred construction material, Electric motors constructed in stainless steel and suitable for wet

particularly in wet areas. Panels should be water-tight. The top surface operation are now available and may be used where budget permits.

of the panel should be sloped at 30° rather than flat to prevent, as far Where electric motors or geared drives are used, care should be

as possible, dust or moisture remaining on the surface. Unfortunately taken that condensation from the surface of the motor or oil from the

standard or off the shelf enclosures which are usually the cheaper gear drive will not contaminate the product. Drives on top-entry agita-

option are supplied with flat tops. tors in tanks and drives of belt conveyers require care in this regard.

Where enclosures are fixed to a wall they should either be

mounted flush with the area between the back or the panel and Distribution

the wall sealed with a silicon or similar material or they should be Over short runs distribution cables may be run inside the conduit.

mounted away from the wall at a sufficient distance to allow cleaning In the food industry it is common practice to use a stainless steel

in the space behind the panel. The general rule for equipment instal- tube to carry cables. The tube must be sealed at each end to prevent

lation is that either sufficient space must be left around the piece of ingress of pests.

equipment for cleaning or the area around the equipment must be Over longer distances stainless steel wire trays should be used.

completely sealed off. Cables should not be bundled - but rather mounted individually so

Where push buttons or instruments are mounted on control pan- that the area between them can be cleaned. Trays should be mounted

els these should be of a hygienic design. Anti-microbial push buttons vertically rather than horizontally to prevent accumulation of dirt. If

are available commercially. space does not allow a vertical mounting then cable trays should be

E+C SPOT ON • May 2014

mounted at an angle of 45°. Where a cable tray is mounted on a wall, used in the food industry may be modified to fit the instrumentation.

a space should be left behind the tray for cleaning. The electrical engineer should establish from the process engineer

Where practical, cable runs outside of the food processing area which union pattern is standard for the plant in question. There are

are recommended. This is particularly applicable to high risk areas several different standards currently in use in South Africa.

where the processing area is established with a ‘box’ constructed

with hygienic panels. If the cable runs are mounted on the ceiling,

Conclusion

individual power or instrument cables and pneumatic distribution Unfortunately, sound hygienic engineering can add significantly to

pipes can be introduced vertically in stainless steel conduits. Care project cost. More stringent standards being applied by regulators,

must be taken to seal such conduits to the ceiling panels to prevent retailers and the consumer public are, however, making stricter

ingress of dust into the processing room. adherence to hygiene measures a necessity. This is a brief summary

Condensation of of some of the requirements. More detail is available in the

water vapour is of bibliography and references.

concern in factories

where cooking pro- References

cesses are prevalent. [1] ISO 9000. The ISO 9000 family addresses various aspects of quality

Cable runs should management and contains some of ISO’s best known standards.

avoid areas where The standards provide guidance and tools for companies and

condensation will organisations who want to ensure that their products and services

occur. consistently meet customer’s requirements, and that quality is

consistently improved.

Lighting [2] ISO/IEC 20000-1:2011. Information technology: Service manage-

The importance of ment. Part 1: Service management system requirements.

An enclosure with a sloping top.

Photograph courtesy Delvalle. good lighting design [3] SANS 10049. 2011. Food safety management - Requirements for

common to all indus- pre0-requisite programmes (PRPs).

tries is also applicable to the food industry. The areas where visual [4] SANS 14159. 2006. Safety of machinery - Hygiene requirements

inspection of the food product takes place are particularly important. for the design of machinery.

For general operations, 220 lux is recommended and for places where

the examination of the food products takes place, 550 lux is recom- Bibliography

mended. It is important that illumination does not significantly alter Moerman F. (2011). Hygienic supply of electricity in food factories.

the colour of food products being examined. In Hygienic design of food factories, ed Holah J and Lelieveld HLM.

Experts in the food industry are divided on the use of natural Woodhead Publishing

light in food industry operations. On the one hand the use of glass for Schmitt H and Koch H-R, (nd) Hygienic design of enclosure boxes in

windows introduces the risk of breakage and product contamination relation to high pressure cleaning? EHEDG publication.

with glass fragments. All food factories should have a glass inspection

routine. The absence of glass windows eases the burden of inspection.

On the other hand it is felt that the glass can be suitably protected

and that the use of natural light provides energy saving. Many food

factories rely on artificial light.

Armatures must be provided with protective plastic covers to

prevent product contamination in case of breakage.

Positioning of light fittings should take cognisance of the fact that

cleaning and maintenance will be required. The positioning of equip-

ment in food processing lines can make it difficult to access armatures.

Instrumentation Andrew Murray is a consulting food process engineer. He

Controls in the food contact area and in the splash area must be hy- specialises in feasibility studies and design of plant for

dairy, fruit processing, canning and other sectors of the

gienically designed. This applies to devices such as pressure gauges

food and beverage industries. He is particularly involved

or temperature gauges in pipelines as well and level measuring instru-

in energy analysis and auditing of the hygienic design of

ments installed in the domes of tanks. Tees in pipelines make for dead

equipment and premises. For ten years he was a part time

spaces that are difficult to clean particularly if they are deep. The best lecturer in the Department of Food Science at the University

instrument connections are those where the instrument pocket or tee of Pretoria; he has conducted more than twenty-five short courses in various

is flush with the pipeline. For food contact areas and for splash areas aspects of food engineering and sanitary design.

threaded connections of the BSP or NPT patterns or flanges should be Enquiries: Tel. 028 312 3064 or email andrew.murray@mweb.co.za.

avoided. It is not possible to keep these clean. Hygienic pipe unions

E+C SPOT ON • May 2014

You might also like

- Product Data Sheet: Evlink Charging Cable 10M 32A 3-Phase T2-T2 Iec Ev AccessoryDocument2 pagesProduct Data Sheet: Evlink Charging Cable 10M 32A 3-Phase T2-T2 Iec Ev Accessorymaurice86No ratings yet

- איוורור חדרי שנאים PDFDocument24 pagesאיוורור חדרי שנאים PDFשוהם בן טוביםNo ratings yet

- 3M Scotchlok 314Document2 pages3M Scotchlok 314maurice86No ratings yet

- SKMM MCMC Technical Code - Basic Civil Works Part 1Document49 pagesSKMM MCMC Technical Code - Basic Civil Works Part 1maurice86No ratings yet

- Learning Objectives: Evan ChaffeyDocument16 pagesLearning Objectives: Evan Chaffeymaurice86No ratings yet

- BEAMA Technical Bulletin - Part P & Part M - Multirow Consumer Unit Installation Height - Updated 2015Document1 pageBEAMA Technical Bulletin - Part P & Part M - Multirow Consumer Unit Installation Height - Updated 2015maurice86No ratings yet

- SBS Academy Overview V2Document1 pageSBS Academy Overview V2maurice86No ratings yet

- Vitamin D Paper in JISSN.: Home: CorrespondenceDocument19 pagesVitamin D Paper in JISSN.: Home: Correspondencemaurice86No ratings yet

- GE Water-Cooled Package Circuit Breaker Size Recommendation (Consultant Reference) 090120 With Indivual CalculationDocument1 pageGE Water-Cooled Package Circuit Breaker Size Recommendation (Consultant Reference) 090120 With Indivual Calculationmaurice86No ratings yet

- Lower Body Progressions and PregressionsDocument25 pagesLower Body Progressions and Pregressionsmaurice86No ratings yet

- Iclp2004 8 Surtees PDFDocument7 pagesIclp2004 8 Surtees PDFSyed Salman AliNo ratings yet

- Freebies Kitchen Section (DB Demarcation) 1Document3 pagesFreebies Kitchen Section (DB Demarcation) 1maurice86No ratings yet

- Workshop Presentation Group 6 r2 161205170945Document73 pagesWorkshop Presentation Group 6 r2 161205170945maurice86No ratings yet

- Recommendations On Storage Systems For BIPV Systems: Cea, Tecnalia March 2017Document44 pagesRecommendations On Storage Systems For BIPV Systems: Cea, Tecnalia March 2017maurice86No ratings yet

- Civil Law Act 1956Document38 pagesCivil Law Act 1956Ho Shun MingNo ratings yet

- Circular On CPD 002Document10 pagesCircular On CPD 002Hisham WanNo ratings yet

- GbiDocument14 pagesGbimaurice86No ratings yet

- Guidelines On OSH For Lighting at Workplace - PDF Versi BiDocument71 pagesGuidelines On OSH For Lighting at Workplace - PDF Versi BidannywdcgmailNo ratings yet

- Contractor measurements note for furniture layout planDocument8 pagesContractor measurements note for furniture layout planmaurice86No ratings yet

- 30-TNB Surat Akujanji & Tanggungrugi Dan Arahan Mula Kerja HDD TemplateDocument8 pages30-TNB Surat Akujanji & Tanggungrugi Dan Arahan Mula Kerja HDD Templatemaurice86No ratings yet

- 2 x 150mm Class C GI Pipe Road CrossingDocument1 page2 x 150mm Class C GI Pipe Road Crossingmaurice86No ratings yet

- Approval of Electrical Equipment - 2016 EditionDocument67 pagesApproval of Electrical Equipment - 2016 EditionMuhd NajeliNo ratings yet

- Cap Bank LegrandDocument62 pagesCap Bank LegrandNimahl Harikrishnan100% (1)

- Esah 3.1Document34 pagesEsah 3.1maurice86100% (1)

- Candelas Lumens and Lux Chapter SamplesDocument24 pagesCandelas Lumens and Lux Chapter Samplesish1394No ratings yet

- Menara TCM Infra Coordination PlanDocument1 pageMenara TCM Infra Coordination Planmaurice86No ratings yet

- Addendum On ESAH V3Document18 pagesAddendum On ESAH V3Hong Leong KuNo ratings yet

- DP10 Cat HlightDocument2 pagesDP10 Cat Hlightmaurice86No ratings yet

- Chapter 13 EX Wiring MethodsDocument51 pagesChapter 13 EX Wiring Methodsmaurice86No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- REPORT On Power Line Carrier CommunicationDocument28 pagesREPORT On Power Line Carrier CommunicationAshish Jain100% (4)

- AR05.20-B-6010A.fm Check Lift of Camshaft Timing at UDC II 08.08.00Document4 pagesAR05.20-B-6010A.fm Check Lift of Camshaft Timing at UDC II 08.08.00LUKASNo ratings yet

- Power and Eff WorksheetDocument6 pagesPower and Eff WorksheetYu ErinNo ratings yet

- Highway Engineering Rural Roads and Pavements (1921)Document391 pagesHighway Engineering Rural Roads and Pavements (1921)teslionNo ratings yet

- POWER JACK Report 35 PagesDocument35 pagesPOWER JACK Report 35 Pagesankush belkarNo ratings yet

- ZAPOSH CONSULTANCY MAKES WORKPLACES SAFERDocument40 pagesZAPOSH CONSULTANCY MAKES WORKPLACES SAFERJohn Paul Marin ManzanoNo ratings yet

- Evinrude E-TEC G2 Operator's Manual - ManualsLibDocument3 pagesEvinrude E-TEC G2 Operator's Manual - ManualsLibzizanNo ratings yet

- Entropy Problems AnswersDocument6 pagesEntropy Problems AnswersTots HolaresNo ratings yet

- Hydraulic Cartridge Logic Valves - Hydraulic ValveDocument2 pagesHydraulic Cartridge Logic Valves - Hydraulic Valveasif bashaNo ratings yet

- Manual Moto Rev 125Document33 pagesManual Moto Rev 125Mario Recio LoríaNo ratings yet

- Spring BarDocument3 pagesSpring BarAkinoJohnkennedy100% (1)

- CFMPresentation PowerPointDocument159 pagesCFMPresentation PowerPointClaudio Alves100% (1)

- Online Loan Application and Verification System AbstractDocument7 pagesOnline Loan Application and Verification System AbstractEdison Gregory100% (2)

- Canon Irc3200 Parts CatalogDocument313 pagesCanon Irc3200 Parts CatalogStratis SiderisNo ratings yet

- (WRC-SouthAfrica-2001-R. McKenzei) PRESMAC User GuideDocument80 pages(WRC-SouthAfrica-2001-R. McKenzei) PRESMAC User GuideStephenson Xavier Molina ArceNo ratings yet

- 5 Sol To s2 Phy PressureDocument7 pages5 Sol To s2 Phy PressureShreyan KhetaniNo ratings yet

- Sr. No. Description Material Grade Length (MM) Weight (KG)Document4 pagesSr. No. Description Material Grade Length (MM) Weight (KG)Shriniwas NaikNo ratings yet

- Inspection Test Plan For: Project TitleDocument1 pageInspection Test Plan For: Project TitleKarthi Keyan100% (2)

- Resume - Afiif Prima YunantoDocument3 pagesResume - Afiif Prima YunantoAfiif Prima YunantoNo ratings yet

- Canning 160513032223Document28 pagesCanning 160513032223Nitin SinghalNo ratings yet

- Chapter-XI-BOQ and Percentage Weightages-2279Document29 pagesChapter-XI-BOQ and Percentage Weightages-2279Prince AnejaNo ratings yet

- Marathon Special Products-601RJ 03-DatasheetDocument146 pagesMarathon Special Products-601RJ 03-DatasheetJoão Victor SarmieroNo ratings yet

- Instruction Manual of Gravity Destoner: Zhengzhou Chinatown Grain Machinery Co., LTDDocument9 pagesInstruction Manual of Gravity Destoner: Zhengzhou Chinatown Grain Machinery Co., LTD(Doc - Bto) Renato Alejandro Andara EscalonaNo ratings yet

- Buried PipeDocument11 pagesBuried PipeAKKI KUMARNo ratings yet

- Solar Wiring EbookDocument11 pagesSolar Wiring EbookLucian LazarutNo ratings yet

- Rhino MocksDocument3 pagesRhino MocksVenkateswararao KonjetiNo ratings yet

- Managing SAP BW Projects Part-2Document54 pagesManaging SAP BW Projects Part-2tupacshakrNo ratings yet

- WIND LOADING ANALYSIS - Wall Components and Cladding: Input DataDocument15 pagesWIND LOADING ANALYSIS - Wall Components and Cladding: Input DataMartin VenichNo ratings yet

- Iso+9000 3 1997Document38 pagesIso+9000 3 1997api-19846338No ratings yet

- Basics Configuration of PBX Nortel Meridain 81cDocument26 pagesBasics Configuration of PBX Nortel Meridain 81cGil HaleNo ratings yet