Professional Documents

Culture Documents

Experiment A1: Continuous Stirred Tank Reactor: Department of Chemical Engineering

Uploaded by

ChuchayLucasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experiment A1: Continuous Stirred Tank Reactor: Department of Chemical Engineering

Uploaded by

ChuchayLucasCopyright:

Available Formats

University of Santo Tomas CHE 514L:

Faculty of Engineering Chemical Engineering Laboratory II

Department of Chemical Engineering Design of Experiment (DOE)

Name of Members:

1. Bacani, Paula Angeline A.

Date: September 5, 2018

2. Bautista, Cristian Paolo C.

3. Castro, Francis Alfred P.

Section: 5 ChE C Group No: 1 Instructor: Engr. Jhulimar C. Castro

Experiment A1: Continuous Stirred Tank Reactor

1. OBJECTIVES

a. To verify the assumed order of the reaction

b. To calculate for the reactant conversion in steady state

c. To determine the effect of flow rate on the rate constant of the reaction

d. To determine the effect of temperature on the rate constant of the reaction

2. REFERENCE/S

Schmidt, Lanny D. (1998). The Engineering of Chemical Reactions. New York: Oxford University

Press. ISBN 0-19-510588-5.

3. EQUIPMENT AND MATERIALS

Continuous Stirred Tank Reactor Apparatus

- Reactor

- Stirrer

- Feed Tanks

- Heater

Computer

Sodium Hydroxide (s)

Ethyl Acetate (aq)

Beaker

4. SAFETY

Check all the respective switch and make sure that all switches are off before powering up the

equipment. Take caution while operating the heating vessel tank, along with the hot rubber

tubings. When draining the equipment, make sure that the drainage tube is properly placed on the

waste tank.

5. PRELIMINARY

Preparation of 4.5 L (volume may be varied as needed) of each 0.2 M sodium hydroxide (NaOH)

and 0.3 M ethyl acetate (C4H8O2) were placed in the reagent vessels. Connect the vessels to the

pumps via the rubber tubings.

6. THEORY

The continuous stirred tank reactor (CSTR), also known as backmix reactor, is one of the common

types of reactors used to conduct different chemical reactions. It is normally run with continuous

flow of feed and products in steady-state. The feed maintains a uniform composition throughout

the reactor while the exit stream has the same composition as the one in the tank.

Given the general mole balance equation:

Experiment A1: Continuous Stirred Tank Reactor 2

𝑑𝑁𝑎

= 𝐹𝑎𝑜 − 𝐹𝑎 + 𝑟𝑎

𝑑𝑡

𝑑𝑁𝑎

And with the assumption of steady state, as stated above, then: 𝑑𝑡

=0

Rearranging the equation, we get

𝐹𝑎𝑜 − 𝐹𝑎

𝑉=

−𝑟𝑎

Where: V = Volume of the Reactor

Fao = Inlet stream of reactant A

Fa = Outlet stream of reactant A

-ra = Rate of reaction

7. OPERATING PROCEDURE AND CONDITIONS

7.1 Start-up

7.1.1. Clean the hot water vessel by continuously pouring distilled water while draining.

After

the vessel is free of residue, prime the vessel by filling it with distilled water

approximately

20 mm from the top.

7.1.2. Switch on the unit using the switch at the front of the unit. The main switch and

circuit breakers located at the back must also be turned on.

7.1.3. Connect the equipment to the PC using the USB lead supplied.

7.1.4. Run the Armfield CEM MkII Continuous Stirred Tank Reactor (CSTR) software. Before

operating the software, the USB virtual serial COM port must be enabled. Start the

COM

session by clicking the Start COM Session icon at the top right end of the menu bar.

7.1.5. View the Mimic Diagram by clicking the View Diagram icon from the main toolbar. Data

samples and other information can also be found from the indicated icons.

7.2 Experimental Procedure

7.2.1. Open the temperature control settings and set operation mode to automatic.

7.2.2. Input the required settings for temperature and pump speed control

7.2.3. Set the stirrer speed controller to 100

7.2.4. Start data sampling and switch on the feed pumps, agitator motor and hot water

circulator

to start the experiment. The Power On button switches the pump motor on (1) or off

(0).

The green LED marked Watchdog Enabled will blink continuously when the software

and

hardware are functioning correctly together.

7.2.5. Collection of conductivity data will be until a steady state condition is reached in

the

reactor and when 10 consecutive conductivity readings are constant. Collect the

data

DESIGN OF EXPERIMENT BACANI, BAUTISTA, CASTRO

Experiment A1: Continuous Stirred Tank Reactor 3

sampled by the program (logged in tabular form).

7.2.6. Repeat all steps but do the other settings given to you, whether it is another flow rate

or

a different temperature.

7.3 Shutdown

7.3.1. Stop the COM session.

7.3.2. Disconnect the USB cable from the equipment and proceed shutdown of the software

and PC.

7.3.3. Switch off the front switch and the main switch at the back of the equipment.

7.3.4. Drain the tank reactor and hot water vessel.

7.3.5. Clean the hot water vessel by continuously pouring distilled water while draining (step

1

in preliminary procedure).

8. TREATMENT OF RESULTS

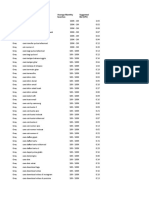

The flowrates and temperatures are variables to determine the rate constant, and the relation of

temperature and flowrate to the rate constant. Each group will have different sets of temperatures

and flowrates to determine different results from other groups. From the data gathered,

conductivity curve is formed.

9. ANALYSIS AND INTERPRETATION OF DATA

The relationship of temperature & flowrate and conductance will be used to determine the rate

constant.

10. PRACTICAL QUESTIONS

1. How does flow rate affect the rate law of the system?

2. What other factors can be controlled in order to achieve a desired order?

3. What is the relationship between conductance in comparison to flowrate and temperature?

DESIGN OF EXPERIMENT BACANI, BAUTISTA, CASTRO

Experiment A1: Continuous Stirred Tank Reactor 4

4. Describe the trend of the graph.

DESIGN OF EXPERIMENT BACANI, BAUTISTA, CASTRO

You might also like

- Fixed-Bed Reactor Design and Diagnostics: Gas-Phase ReactionsFrom EverandFixed-Bed Reactor Design and Diagnostics: Gas-Phase ReactionsRating: 4 out of 5 stars4/5 (5)

- 2 Reactor Power CalibrationDocument7 pages2 Reactor Power CalibrationBerlianiNo ratings yet

- Chemical Reaction Engineering LAB MANUALDocument67 pagesChemical Reaction Engineering LAB MANUALkaviyas.21chemNo ratings yet

- Martinez HEAT EXCHANGERDocument26 pagesMartinez HEAT EXCHANGERVernix FoNo ratings yet

- Lab PlanningDocument2 pagesLab PlanningYong ShengNo ratings yet

- Martinez STEAM INJECTORDocument26 pagesMartinez STEAM INJECTORVernix FoNo ratings yet

- LabDocument7 pagesLabshriraam asokumarNo ratings yet

- Boiling and CondensingDocument2 pagesBoiling and CondensingZia Ul NoorNo ratings yet

- Experiment 2 (2023) - 1Document7 pagesExperiment 2 (2023) - 1Hussein SaeedNo ratings yet

- CSTRDocument15 pagesCSTRbilisfreak100% (3)

- Lab ViewDocument13 pagesLab ViewKhadir MohammedNo ratings yet

- PFR 1Document4 pagesPFR 1Jihad AlboureeniNo ratings yet

- Exp 1Document9 pagesExp 1zackwanNo ratings yet

- Batch ReactorDocument12 pagesBatch ReactorShashi RaajNo ratings yet

- Draft Standard Operating Procedure - Tubular Reactor and CSTRDocument5 pagesDraft Standard Operating Procedure - Tubular Reactor and CSTRshivaNo ratings yet

- Determination of Rate of EvaporationDocument4 pagesDetermination of Rate of EvaporationRalph EvidenteNo ratings yet

- Lab Report CSTR 40LDocument26 pagesLab Report CSTR 40LAnonymous NyvKBW33% (3)

- CSTR Experiment ManualDocument5 pagesCSTR Experiment ManualEvan DulayNo ratings yet

- On Controlling An Autothermal Fixed-Bed Reactor at An Unstable State-IvDocument15 pagesOn Controlling An Autothermal Fixed-Bed Reactor at An Unstable State-IvNIKHIL SHINDENo ratings yet

- Manuscript For (CSTR - Batch Mode) - Group 1 - Ceeh2205iDocument8 pagesManuscript For (CSTR - Batch Mode) - Group 1 - Ceeh2205iNURSYAHIRAH MOHD NAZIRNo ratings yet

- Saponificación 1Document51 pagesSaponificación 1gilmcmxNo ratings yet

- CPE5005-B Reaction Engineering: Tubular Reactor Lab ExperimentDocument22 pagesCPE5005-B Reaction Engineering: Tubular Reactor Lab ExperimentJuan CalderonNo ratings yet

- Lab Report CSTR 40LDocument26 pagesLab Report CSTR 40LHazieqahNo ratings yet

- LTH Msc2007Document7 pagesLTH Msc2007Dianta RaNo ratings yet

- CSTR Done 22Document12 pagesCSTR Done 22Dyala KlaibNo ratings yet

- Vernier Act9 Evaporation of AlcoholsDocument8 pagesVernier Act9 Evaporation of AlcoholsBerra SirmaliNo ratings yet

- Lab 1 - Stoichiometric ReactorsDocument9 pagesLab 1 - Stoichiometric ReactorschinyuanNo ratings yet

- Group 1A - Lab Report Combine PDFDocument87 pagesGroup 1A - Lab Report Combine PDFHanifatur AffiqNo ratings yet

- Lab Name: Steam Power Plant Overview and It's Different Components (Rankine Cycle)Document19 pagesLab Name: Steam Power Plant Overview and It's Different Components (Rankine Cycle)Farhan EdwinNo ratings yet

- LabSheet1 - Familiarization of Lab MaterialsDocument6 pagesLabSheet1 - Familiarization of Lab MaterialsJenifer PetrolaNo ratings yet

- Circular Cylinder APPM 4350Document7 pagesCircular Cylinder APPM 4350Atenea SilverioNo ratings yet

- Lab BMI 1Document4 pagesLab BMI 1pareesabuxshoroNo ratings yet

- Adiabatic Production of Acetic AnhydrideDocument7 pagesAdiabatic Production of Acetic AnhydrideSunilParjapatiNo ratings yet

- Enzyme Action: Testing Catalase Activity: ExperimentDocument12 pagesEnzyme Action: Testing Catalase Activity: ExperimentsannsannNo ratings yet

- The Millikan Oil-Drop Experiment: Two Weights Recommended ReadingsDocument5 pagesThe Millikan Oil-Drop Experiment: Two Weights Recommended ReadingsJoaquimNo ratings yet

- PFR CSTR - Systems Overview and Protocols FinalDocument20 pagesPFR CSTR - Systems Overview and Protocols Finalfmachour9316No ratings yet

- Galicia Luna2000Document7 pagesGalicia Luna2000Moltimer Folchart CrawNo ratings yet

- Benedict-Webb-Rubin Equation of State For An AlterDocument8 pagesBenedict-Webb-Rubin Equation of State For An AlterSantiago AguirreNo ratings yet

- L2 Plug Flow Reactor Cover PageDocument23 pagesL2 Plug Flow Reactor Cover PageShahrizatSmailKassim100% (1)

- 5 - (CSTR Bp143)Document12 pages5 - (CSTR Bp143)Aisyah Addia AzizanNo ratings yet

- RTD For CistrDocument5 pagesRTD For CistrGebrehanaNo ratings yet

- Lab2 ENT143 171110107-5Document8 pagesLab2 ENT143 171110107-5Ahmed Ali MuflehNo ratings yet

- Tank Level Control ExperimentDocument3 pagesTank Level Control ExperimentLi Xue0% (1)

- Sgsa ProceduresDocument5 pagesSgsa ProceduresemiljuchiacNo ratings yet

- Isothermal CSTR PDFDocument9 pagesIsothermal CSTR PDFprashant_cool_4_uNo ratings yet

- EKC 291 - 14 - Solar Power Cycle UnitDocument4 pagesEKC 291 - 14 - Solar Power Cycle Uniteven leeNo ratings yet

- Lab 1 - CSTRDocument22 pagesLab 1 - CSTRnur athilahNo ratings yet

- TH3 Saturation Pressure Experiment GuideDocument12 pagesTH3 Saturation Pressure Experiment GuideChelseaNo ratings yet

- Isothermal Batch ReacterDocument1 pageIsothermal Batch ReacterVirender RanaNo ratings yet

- 203 Lab04 Circuits Sum08 PDFDocument6 pages203 Lab04 Circuits Sum08 PDFJun MendozaNo ratings yet

- Experiment No: 3: ObjectivesDocument14 pagesExperiment No: 3: ObjectivesAlimah Azeli100% (1)

- ME-495 Laboratory Exercise Number 3 ME Dept, SDSU - KassegneDocument6 pagesME-495 Laboratory Exercise Number 3 ME Dept, SDSU - KassegneJasmine_lai00No ratings yet

- Heat Transfer Lab ManualDocument59 pagesHeat Transfer Lab ManualMarNo ratings yet

- Advanced Electrical Engineering Lab Manual PDFDocument32 pagesAdvanced Electrical Engineering Lab Manual PDFrijilpoothadiNo ratings yet

- DeneyDocument13 pagesDeneyTuğbaNo ratings yet

- Lab 2 Enthalpy and EntropyDocument9 pagesLab 2 Enthalpy and EntropyAmanda Marie GundrumNo ratings yet

- Lab AssignmentDocument8 pagesLab AssignmentRaihanNo ratings yet

- Refrigeration Laboratory UnitDocument8 pagesRefrigeration Laboratory Unitkhalijahjamal50% (2)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- For Immediate ReleaseDocument3 pagesFor Immediate ReleaseLiberty Building Forensics GroupNo ratings yet

- Chapter 5 - Launch Vehicle Guidance Present Scenario and Future TrendsDocument20 pagesChapter 5 - Launch Vehicle Guidance Present Scenario and Future TrendsAdrian ToaderNo ratings yet

- E-Hrm PracticesDocument211 pagesE-Hrm PracticesMukta Pahlajani50% (2)

- 3dconfig Setting Di AutocadDocument4 pages3dconfig Setting Di Autocadvr_talleiNo ratings yet

- PFI ES-27-1994 - Visual Examination - The Purpose, Meaning and Limitation of The TermDocument4 pagesPFI ES-27-1994 - Visual Examination - The Purpose, Meaning and Limitation of The TermThao NguyenNo ratings yet

- Exercise-6 1 1 2-6 1 1 5Document7 pagesExercise-6 1 1 2-6 1 1 5Ramgie Danielle NamolNo ratings yet

- Globalization and MediaDocument24 pagesGlobalization and MediaCyka Blyat0% (2)

- Usa PDFDocument1 pageUsa PDFRemy CaperochoNo ratings yet

- Technical Note - Measurement MicrophonesDocument4 pagesTechnical Note - Measurement MicrophonesWillFonsecaNo ratings yet

- Theatre at HierapolisDocument7 pagesTheatre at HierapolisrabolaNo ratings yet

- RRL ResearchDocument4 pagesRRL ResearchRamel PaglanganNo ratings yet

- MM 321 Field ReportDocument15 pagesMM 321 Field ReportSiddhant Vishal Chand0% (1)

- Basic Vibration Analysis in AnsysDocument30 pagesBasic Vibration Analysis in AnsysmanjunathbagaliNo ratings yet

- HealthSafety Booklet PDFDocument29 pagesHealthSafety Booklet PDFAnonymous VQaagfrQINo ratings yet

- Instruction Manual (BFP A5992 N)Document482 pagesInstruction Manual (BFP A5992 N)Odeny JúniorNo ratings yet

- B2+ UNIT 10 Test Answer Key HigherDocument2 pagesB2+ UNIT 10 Test Answer Key HigherMOSQUITO beats100% (1)

- Property 261Document4 pagesProperty 261lynNo ratings yet

- Anxiety in Practicing English Language As A Means of Communication in Esl ClassroomDocument40 pagesAnxiety in Practicing English Language As A Means of Communication in Esl Classroomkirovdust100% (1)

- Data Mining Chapter3 0Document32 pagesData Mining Chapter3 0silwalprabinNo ratings yet

- More More SymcliDocument10 pagesMore More SymcliSrinivas Gollanapalli100% (1)

- Light SensorDocument27 pagesLight SensorDevilal Dewanda90% (10)

- Research PaperDocument154 pagesResearch Paperleo lokeshNo ratings yet

- Sensor Modbus-Register: 22DTH-..5.. 22UTH-..50X 22DTM-..5 22ADP-..5.Document9 pagesSensor Modbus-Register: 22DTH-..5.. 22UTH-..50X 22DTM-..5 22ADP-..5.manzoor ansariNo ratings yet

- KW CaraDocument100 pagesKW CaraDTC TrainzNo ratings yet

- Seminar FormatDocument6 pagesSeminar Formatupasana joliaNo ratings yet

- 2-General Physics 1-Uncertainties in MeasurementDocument22 pages2-General Physics 1-Uncertainties in MeasurementLiza Macalinao MangalimanNo ratings yet

- OCOM FTA ReviewerDocument5 pagesOCOM FTA ReviewerJulluis DagoNo ratings yet

- Sorting - Problem Solving With Algorithms and Data StructuresDocument30 pagesSorting - Problem Solving With Algorithms and Data Structuressatya1401No ratings yet

- 7 HabitsDocument8 pages7 HabitssaliimjNo ratings yet

- Decision TreeDocument3 pagesDecision Tree64-Shashank SagarNo ratings yet