Professional Documents

Culture Documents

Cs and Low Alloy Study 1

Uploaded by

Muhammad ZariqCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cs and Low Alloy Study 1

Uploaded by

Muhammad ZariqCopyright:

Available Formats

Corrosion of carbon steel and Low-Alloy steel weldment

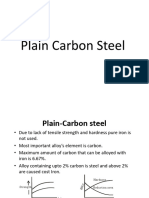

Carbon steel , steel that contain up to 2% of carbon , 1.65% Mn, 0.60%si and 0.60%Cu.

Weldability depends on carbon and manganese contents and impurity level.

Low carbon steel: contain up to approximately 0.30% and up to 1.65%Mn.

Low carbon level (less than 0.15%C), the steel are non-hardening and Weldability is excellent. Known as

aluminum-killed, continuous cast iron. The lower available oxygen in the killed sheet make it easier to

arc weld without porosity formation.

The range of 0.15% to 0.30% (sometime termed mill steel). Generally easily welded but due to

hardening is a possibility. Precautions such as preheating may require at higher manganese level, thicker

and high join restraint. Mostly used for rolled structural plate and tabular product. These are generally

killed or semi-killed. The presence of surface scale (formation of iron oxide) due high temperature rolling

process increase the likelihood of porosity formation.

Medium carbon steel: steel that contains 0.30% to 0.60% C. Can be successfully welded by all of the arc

welding processes. The higher of the carbon content of the steels, along manganese from 0.6% to 1.65%

makes the steel more hard-enable.

High carbon steel: Steel that contain 0.60% to 2.0%, has poor Weldability because of the likelihood of

formation of a hard, brittle martensitic upon weld cooling. Austenitic stainless steel electrode are

sometimes used to weld high carbon steel.

Low : up to 0.3% Medium:0.3% to 0.6% High 0.6% to 2%

LOW Alloy Steel

Exhibits mechanical property superior to plain carbon steel as result of addition of alloying elements.

Total alloy contents can range from 2.07% to up levels just below stainless steel.

Minimum of approximately 11% chromium. ( 10.5%)

High strength low alloy (HSLA) – provided for better mechanical properties, have generally have yield

strength of 290 to 550 MPa (generally carbon manganese type) , with very small addition of niobium

and Vanadium to ensure both grain refinement and precipitation of hardening.

Quenched and tempered steels- are heat treated to provide yield strength 345 to 1035 MPa

You might also like

- Resignation LetterDocument1 pageResignation LetterFerOz OthmanNo ratings yet

- Recommended Readings For NACE ExamsDocument5 pagesRecommended Readings For NACE Examsmah_abdelaal67% (3)

- Carbon Steel - Simple English Wikipedia, The Free EncyclopediaDocument11 pagesCarbon Steel - Simple English Wikipedia, The Free EncyclopediaRashid SarfrazNo ratings yet

- Welding Steel AlloysDocument2 pagesWelding Steel AlloysRathnakrajaNo ratings yet

- Metallurgy of MaterialsDocument15 pagesMetallurgy of Materialscal2_uniNo ratings yet

- What Is SteelDocument4 pagesWhat Is SteelViswatej ChoudaryNo ratings yet

- Welding Steel Alloys: Low-Carbon SteelsDocument3 pagesWelding Steel Alloys: Low-Carbon SteelsRathnakrajaNo ratings yet

- M 1.2.8 Carbon, Lowalloyed, Fine Grained, and ThermomechanicalyDocument17 pagesM 1.2.8 Carbon, Lowalloyed, Fine Grained, and Thermomechanicalydokumen qcNo ratings yet

- Carbon Steel - WikipediaDocument40 pagesCarbon Steel - WikipediaBara'ah AlnemrawiNo ratings yet

- AlloysDocument91 pagesAlloysNiccoloNo ratings yet

- Carbon Steel: Carbon Steel Is A Steel With Carbon Content From About 0.05 Up To 2.1 Percent by Weight. The Definition ofDocument7 pagesCarbon Steel: Carbon Steel Is A Steel With Carbon Content From About 0.05 Up To 2.1 Percent by Weight. The Definition ofRondeep BoraNo ratings yet

- AISI Designation: Stainless Tool Steels Killed Carbon SteelsDocument14 pagesAISI Designation: Stainless Tool Steels Killed Carbon SteelsShankar JhaNo ratings yet

- Elements of SteelDocument1 pageElements of Steelashish.mathur1No ratings yet

- Low Carbon SteelDocument2 pagesLow Carbon SteelDaniel Dowding100% (1)

- Classification of Carbon and Low-Alloy Steels: AbstractDocument23 pagesClassification of Carbon and Low-Alloy Steels: AbstractharieduidNo ratings yet

- Lesson 11 Steel Steel AlloysDocument13 pagesLesson 11 Steel Steel AlloysCamille SalmasanNo ratings yet

- Classification of Carbon and Low Alloy SteelsDocument4 pagesClassification of Carbon and Low Alloy SteelsmomoitachiNo ratings yet

- PowerPoint Presentation Classification of SteelDocument6 pagesPowerPoint Presentation Classification of SteelDaniel Dowding100% (2)

- An Overview: MetalsDocument61 pagesAn Overview: MetalsjswldeepNo ratings yet

- Carbon Steel and Mild Steel DifferenceDocument8 pagesCarbon Steel and Mild Steel DifferenceSteinol SolutionsNo ratings yet

- Types of SteelDocument28 pagesTypes of SteelKathrine Kate CadiangNo ratings yet

- Steels Used in Coated Sheet Products: GalvinfonoteDocument8 pagesSteels Used in Coated Sheet Products: GalvinfonoteFabio FabregasNo ratings yet

- G1 Material ScienceDocument47 pagesG1 Material ScienceArt Lemuel LotereñaNo ratings yet

- 7steel and Heat TreatmentDocument19 pages7steel and Heat TreatmentManoj BallaNo ratings yet

- Control of PropertiesDocument65 pagesControl of PropertiesJezzrel Xandy BalmesNo ratings yet

- LTCS Vs CSDocument2 pagesLTCS Vs CSMuhammad ShahzadNo ratings yet

- Copper and Copper AlloysDocument3 pagesCopper and Copper Alloyskevin herryNo ratings yet

- Unit - Iii: Ferrous and Non Ferrous MetalsDocument101 pagesUnit - Iii: Ferrous and Non Ferrous Metalssenthilkumar tsNo ratings yet

- Chemical Composition of SteelDocument7 pagesChemical Composition of SteelArslan RaoNo ratings yet

- Products - Alloys - Carbon SteelsDocument3 pagesProducts - Alloys - Carbon SteelsSreenivasNo ratings yet

- Steel ClassificationDocument3 pagesSteel Classificationasfarjee100% (1)

- Carbon Steel - Wikipedia, The Free Encyclopedia PDFDocument6 pagesCarbon Steel - Wikipedia, The Free Encyclopedia PDFRajbirNo ratings yet

- Nickel Magnetic Brittle Hardness Carbon Heat Treatment Razor Blade SteelsDocument2 pagesNickel Magnetic Brittle Hardness Carbon Heat Treatment Razor Blade Steelssunil1879No ratings yet

- Cs PropertiesDocument2 pagesCs PropertiesMongia MoghiNo ratings yet

- Carbon SteelDocument7 pagesCarbon SteelthienmakbNo ratings yet

- SteelDocument31 pagesSteelumairNo ratings yet

- MEM MicroprojectDocument12 pagesMEM MicroprojectprathaNo ratings yet

- FC-06-Engineering Material & Metallurgy PDFDocument431 pagesFC-06-Engineering Material & Metallurgy PDFsomnath ghosh100% (1)

- Ksp-Instrument Impulse Piping & TubingDocument18 pagesKsp-Instrument Impulse Piping & TubingZulfequar R. Ali KhanNo ratings yet

- To Be EditedDocument6 pagesTo Be EditedSasaleleNo ratings yet

- Chapter 7 33Document9 pagesChapter 7 33ayushNo ratings yet

- Lecture-1, Plain Carbon SteelsDocument40 pagesLecture-1, Plain Carbon Steelssatish chinthamNo ratings yet

- BoilerDocument36 pagesBoilerrasheedshaikh2003No ratings yet

- Production of Steel and Its ClassificationDocument36 pagesProduction of Steel and Its Classificationabdullah anwar100% (1)

- What Is SteelDocument12 pagesWhat Is SteelAnonymous Y9dgyXhANo ratings yet

- Properties and Typical Applications of Low, Medium and High Carbon SteelsDocument12 pagesProperties and Typical Applications of Low, Medium and High Carbon Steelsananda narayananNo ratings yet

- Unit-4 - Carbon SteelDocument4 pagesUnit-4 - Carbon SteelItachi UchihaNo ratings yet

- Carbon Steel-Structural SteelDocument19 pagesCarbon Steel-Structural SteelMadhu BNo ratings yet

- 211 2aDocument33 pages211 2aMada ChohNo ratings yet

- SANDVIK What Is Stainless SteelDocument7 pagesSANDVIK What Is Stainless Steelpipedown456No ratings yet

- Chemical Composition SteelDocument6 pagesChemical Composition SteelSahil JhambNo ratings yet

- Classification of SteelsDocument9 pagesClassification of SteelsrajbhushanbhattNo ratings yet

- Lecture 9 - Ferrous AlloysDocument31 pagesLecture 9 - Ferrous Alloysmahmoud foudaNo ratings yet

- Weldability of Materials - Copper and Copper AlloysDocument5 pagesWeldability of Materials - Copper and Copper AlloysmanimaranNo ratings yet

- Carbon SteelDocument5 pagesCarbon SteelKun Hadipati Kusuma NegaraNo ratings yet

- Chromium:-: 21 Chemical Elements and Effects On Steel Mechanical PropertiesDocument8 pagesChromium:-: 21 Chemical Elements and Effects On Steel Mechanical Propertiesdhoni03No ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonRating: 4 out of 5 stars4/5 (1)

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Question 4 Past Year 20172018Document2 pagesQuestion 4 Past Year 20172018Muhammad ZariqNo ratings yet

- Strain GageDocument22 pagesStrain GageMuhammad ZariqNo ratings yet

- Question 4 Past Year 20172018 PDFDocument7 pagesQuestion 4 Past Year 20172018 PDFMuhammad ZariqNo ratings yet

- Test 2 SolutionsDocument8 pagesTest 2 SolutionsMuhammad ZariqNo ratings yet

- Question 4 Past Year 20172018Document7 pagesQuestion 4 Past Year 20172018Muhammad ZariqNo ratings yet

- TWI Welding TrainingDocument31 pagesTWI Welding TrainingNavneet Singh67% (3)

- Scan 21 May 2019Document1 pageScan 21 May 2019Muhammad ZariqNo ratings yet

- Performance Characteristics For Measurement and Instrumentation SystemDocument27 pagesPerformance Characteristics For Measurement and Instrumentation SystemMuhammad ZariqNo ratings yet

- Approved API Plant InspectorDocument11 pagesApproved API Plant InspectorMuhammad ZariqNo ratings yet

- Documents 04-06 115302Document1 pageDocuments 04-06 115302Muhammad ZariqNo ratings yet

- Documents 05-03 060104Document1 pageDocuments 05-03 060104Muhammad ZariqNo ratings yet

- Steel and Cast IronDocument24 pagesSteel and Cast IronMuhammad ZariqNo ratings yet

- Column Tower or EthenizerDocument1 pageColumn Tower or EthenizerMuhammad ZariqNo ratings yet

- The Study of PlantDocument1 pageThe Study of PlantMuhammad ZariqNo ratings yet

- WednesdayDocument1 pageWednesdayMuhammad ZariqNo ratings yet

- Book DietDocument9 pagesBook DietMuhammad ZariqNo ratings yet

- API 570: Piping Inspection Code (Self-Note)Document1 pageAPI 570: Piping Inspection Code (Self-Note)Muhammad ZariqNo ratings yet

- Globe Valve LWR 217: Inspection Report Defect-C0LD WorkDocument4 pagesGlobe Valve LWR 217: Inspection Report Defect-C0LD WorkMuhammad ZariqNo ratings yet

- Steel and Cast IronDocument24 pagesSteel and Cast IronMuhammad ZariqNo ratings yet

- 574Document1 page574Muhammad ZariqNo ratings yet

- Dietary Plan: Target CarbDocument3 pagesDietary Plan: Target CarbMuhammad ZariqNo ratings yet

- ChartDocument1 pageChartMuhammad ZariqNo ratings yet

- Study PlanDocument1 pageStudy PlanMuhammad ZariqNo ratings yet

- Paints Coating Failure Defects GOOD PDFDocument46 pagesPaints Coating Failure Defects GOOD PDFVasileios Iliopoulos100% (1)

- Borang Contract StaffDocument1 pageBorang Contract StaffMuhammad ZariqNo ratings yet

- CodeBlocks ManualDocument64 pagesCodeBlocks ManualIrshad Bin BasheerNo ratings yet

- Future PlanDocument1 pageFuture PlanMuhammad ZariqNo ratings yet