Professional Documents

Culture Documents

United States Patent: Mylchreest Et Al. (45) Date of Patent: Nov. 8, 2016

Uploaded by

BilalAshraf0 ratings0% found this document useful (0 votes)

19 views7 pagesCyclone Separator

Original Title

Us 9486727

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCyclone Separator

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views7 pagesUnited States Patent: Mylchreest Et Al. (45) Date of Patent: Nov. 8, 2016

Uploaded by

BilalAshrafCyclone Separator

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

US0094.

86727B2

(12) United States Patent (10) Patent No.: US 9.486,727 B2

Mylchreest et al. (45) Date of Patent: Nov. 8, 2016

(54) CYCLONE SEPARATOR USPC ................................................. 55/447, 459.1

See application file for complete search history.

(75) Inventors: George D. Mylchreest, North Granby,

CT (US); Jean-Claude Semedard, (56) References Cited

Paris (FR); Pierre Gauville, Verrieresle

Buisson (FR) U.S. PATENT DOCUMENTS

(73) Assignee: TECHNOLOGY

GENERAL ELECTRIC

GMBH, Baden (CH) 6,258,146 B1

A. 7/2001

g 1998 Semedard

Neard .................... 55/459.3

f

(Continued)

(*) Notice: Subject to any disclaimer, the term of this

patent is extended or adjusted under 35 FOREIGN PATENT DOCUMENTS

U.S.C. 154(b) by 345 days. CN 2062412 9, 1990

(21) Appl. No.: 13/824,960 CN 2434.066 6, 2001

(Continued)

(22) PCT Filed: Aug. 22, 2011

OTHER PUBLICATIONS

(86). PCT No.: PCT/US2O11?04.8598

S 371 (c)(1) European Search Report, European Searching Authority, European

(2), (4) Date: Apr. 16, 2013 Application No. 10177470, Munich, Feb. 23, 2011.

(Continued)

(87) PCT Pub. No.: WO2012/036845

PCT Pub. Date: Mar. 22, 2012 Primary Examiner — Dung H Bui

(74) Attorney, Agent, or Firm — GE Global Patent

(65) Prior Publication Data Operation; Stephen G. Midgley

US 2013/0205731 A1 Aug. 15, 2013 (57) ABSTRACT

(30) Foreign Application Priority Data A cyclone separator that collects entrained solid particles

from a gas stream, comprising a cylindrical body, an inlet

Sep. 17, 2010 (EP) ..................................... 10177470 duct connected to the body, and a gas outlet tube connected

to the body at its upper end. The ratio of the distance

(51) Int. Cl. between the parallel to a face dropped from the tip of the

BOID 45/12 (2006.01) cyclone separator and the closest point of the gas outlet tube

BOID 45/16 (2006.01) to the internal diameter of the body is at least 0.1, as

Continued measured at the lower extremity of the gas outlet tube. The

(Continued) ratio of the inlet duct area, measured at the tip of the cyclone

(52) U.S. Cl. separator and perpendicularly to the face, to the cross

CPC ............... BOID 45/16 (2013.01); B0ID 45/12 sectional area of the body, is between 0.24 and 0.32. The

(2013.01); B04C5/04 (2013.01); B04C5/081 ratio of the height of the inlet duct to the width of the inlet

(2013.01); B04C5/13 (2013.01) duct at the tip of the cyclone separator does not exceed 4.

(58) Field of Classification Search

CPC ............................... B01D 45/16: B01D 45/12 18 Claims, 1 Drawing Sheet

US 9,486,727 B2

Page 2

(51) Int. Cl. FOREIGN PATENT DOCUMENTS

B04C5/04 (2006.01)

B04C5/08

B04C 5/3

(2006.01)

(2006.01)

P 1995. A 23

(56) References Cited OTHER PUBLICATIONS

U.S. PATENT DOCUMENTS International Search Report and Written Opinion, International

Searching Authority, PCT Application No. PCT/US 11/48598,

6,322.301 B1 1 1/2001 Semedard et al. Search Completed Dec. 26, 2011, Authorized Officer Lee W. Young.

6,322.601 B1 1 1/2001 Semedard et al. Metallgesellschaft AG, German Patent Application No. 19606647

6,938,780 B2 * 9/2005 Baglione et al. ............. 209/717

8,834,800 B2 * 9/2014 Erler et al. .................... 422,147 A1 English language abstract, Sep. 19, 1996.

2005, 0126394 A1 6/2005 Reiling

2006/0226055 A1 10, 2006 Castro Soto * cited by examiner

U.S. Patent Nov. 8, 2016 US 9.486,727 B2

US 9,486,727 B2

1. 2

CYCLONE SEPARATOR The object mentioned above is accomplished by a cyclone

separator for particle collection from a gas stream containing

This is a US National Phase application claiming priority entrained solid particles, said cyclone separator comprising:

to European Application No. 10177470.1 filed having a a cylindrical-shaped body portion,

Filing Date of Sep. 17, 2010, incorporated herein in its 5 an inlet duct having an intrados face and an extrados face,

entirety by reference. and which is connected to the body portion,

TECHNICAL FIELD

a gas outlet tube connected to the body portion at its upper

end.

The invention is related to a cyclone separator, and is According to the invention:

more particularly directed to a cyclone separator for circu 10 the ratio (d/D) of the distance (d) between the parallel to

lating fluidized bed (CFB) boilers. the extrados face dropped from the tip of the cyclone

separator and the closest point of the gas outlet tube to

BACKGROUND the internal diameter (D) of the body portion is superior

or equal to 0.1, said distance (d) being measured at the

The circulating fluidized bed boilers require the capture of 15 lower extremity of the gas outlet tube,

the particles that are entrained out of a reactor by reactor the ratio (S/S) of the inlet duct area (s), measured at the tip

gases and their separation from the gases in order to recir of the cyclone separator and perpendicularly to the

culate it into said reactor for complete reaction. extrados face, to the cross-sectional area (S) of the body

The separation is usually made by means of cyclone portion, is comprised between 0.24 and 0.32, and

separators. Cyclonic separation is a method of removing the ratio (h/w) of the height (h) of the inlet duct to the

particulates from gases, without the use of filters, through width (w) of the inlet duct at the tip of the cyclone

Vortex separation. Rotational effects and gravity are used to separator does not exceed 4, and can be for instance

separate mixtures of Solids and gases. less than 4.

The capture efficiency of the smallest particles is a key The ratio (d/D) of the distance (d) between the parallel to

issue. 25 the extrados face dropped from the tip of the cyclone

It is known that reducing the diameter of the cyclone separator and the closest point of the gas outlet tube to the

separator thus increasing the axial mean Velocity in the internal diameter (D) of the body portion is preferably

cyclone body while keeping the same similitude ratio leads comprised between 0.1 and 0.2, more preferably between

to a strong increase of the pressure drop across the cyclone 0.1 and 0.15 and even more preferably between 0.12 and

and finally to a decrease of the capture efficiency when 30 O.15.

trying to keep the pressure drop at a constant limited value

by keeping nearly constant the inlet section of the gas-solids The ratio (h/w) of the height (h) of the inlet duct to the

entrance into the cyclone. Such types of cyclones having a width (w) of the inlet duct at the tip of the cyclone separator

reduced shape ratio but a nearly constant inlet gas/solids is preferably comprised between 3 and 4, and more prefer

entrance section dimensions to get the same pressure drop as ably between 3.5 and 4.

the base cyclone operating at 6 m/s could be qualified as 35 For instance, different associations of the ratios d/D, S/S

“similar for the purpose of the comprehension. and hw that can be carried out are mentioned in Table 1.

Most of the cyclone separators that are currently used in

circulating fluidized bed boilers exhibit a good collection TABLE 1.

efficiency for body mean axial velocity of about 5 to 6 m/s.

However, the “similar cyclone separators, when used at a 40 dD SfS hw

body mean axial velocity of above 7 m/s lead to a degraded e0.1 O.24-O-32 s4

capture efficiency. Thus, it is not possible to use “similar e0.1 O.26-0.30 or O27-0.29 s4

cyclones if the cyclone collection efficiency of the cyclones 0.1-0.2 O.24-O-32 s4

operating at 8 m/s is required to be the same as the collection 0.1-0.2 O.26-0.30 or O27-0.29 s4

efficiency of the cyclones operating at 6 m/s and some 45

O. 1-0.15

O. 1-0.15

O.24-O-32

O.26-0.30 or O27-0.29

s4

s4

changes have to be invented. O.12-0.15 O.24-O-32 s4

Document U.S. Pat. No. 5,771,844 discloses a cyclone O.12-0.15 O.26-0.30 or O27-0.29 s4

separator able to operate at a body mean axial velocity of 8 e0.1 O.24-O-32 3-4

m/s with a capture efficiency which is similar to the effi e0.1 O.26-0.30 or O27-0.29 3-4

ciency of the cyclone separators that are efficient for an axial 50

0.1-0.2

0.1-0.2

O.24-O-32

O.26-0.30 or O27-0.29

3-4

3-4

mean velocity of 6 m/s. O. 1-0.15 O.24-O-32 3-4

U.S. Pat. No. 5,771,844 discloses that the ratio height/ O. 1-0.15 O.26-0.30 or O27-0.29 3-4

depth of the opening of the cyclone separator inlet is at least O.12-0.15 O.24-O-32 3-4

4f1. O.12-0.15 O.26-0.30 or O27-0.29 3-4

This cyclone separator Suffers the shortcoming that it e0.1

e0.1

O.24-O-32

O.26-0.30 or O27-0.29

3.5-4

3.5-4

makes the inlet duct more costly due to the stiffening needs 55

0.1-0.2 O.24-O-32 3.5-4

of the unusually wide vertical dimension. In addition, the 0.1-0.2 O.26-0.30 or O27-0.29 3.5-4

cyclone barrel is higher in order to locate the high vertical O. 1-0.15 O.24-O-32 3.5-4

dimension of the opening. Thus, the cyclone separator body O. 1-0.15

O.12-0.15

O.26-0.30 or O27-0.29

O.24-O-32

3.5-4

3.5-4

is more expensive than for lower ratios. Moreover, the total O.12-0.15 O.26-0.30 or O27-0.29 3.5-4

height of Such a cyclone impacts detrimentally the arrange 60

ment of the whole system.

The cyclone according to the invention avoids most of the

SUMMARY direct leak of small particles from the cyclone entrance to the

cyclone exit in the gas outlet tube, thus providing a good

An object of the present invention is to provide a cyclone 65 cyclone capture efficiency of Small particles even for high

separator in Such a manner to solve the above described mean gas axial velocity Such as 8 m/s and higher and

problems. allowing a reduction of the diameter of the body portion.

US 9,486,727 B2

3 4

The distance between the projection of the body portion The inlet duct 2 is connected tangentially onto the cylin

centre on a perpendicular to the extrados face and the drical-shaped body portion or barrel portion 3 of the cyclone

projection of the gas outlet tube lower extremity centre on a separator 1.

perpendicular to the extrados face can be comprised between The gas outlet tube 4 is a vortex finder that is connected

0.04D and 0.08D, D being the internal diameter of the body 5 to the body portion 3 at its upper end.

portion. According to the invention, the ratio d/D of the distance

The ratio (a/S) of the cross-sectional area (a) of the gas d between the parallel to the extrados face 2b dropped from

outlet tube lower extremity to the cross-sectional area (S) of the tip T of the cyclone separator 1 and the closest point of

the body portion can be comprised between 0.13 and 0.20, 10

the gas outlet tube 4 to the internal diameter D of the body

and more preferably between 0.15 and 0.20. portion 3 is superior or equal to 0.1. Said distance d is

Preferably, the height of the inlet duct does not exceed the measured at the lower extremity of the gas outlet tube 4, i.e.

internal diameter (D) of the body portion. at the lower level 4a of the gas outlet tube 4. As shown in

The height of the body portion can be less than 1.2D, D FIG. 1, the second part of the intrados face 2a that ends at

being the internal diameter of the body portion. 15 the tip T of the cyclone separator 1 is parallel to the extrados

The gas outlet tube can comprise a lower conical portion face 2b. It could be also envisaged that the second part of the

and an upper cylindrical portion. The inlet orifice of the gas intrados face 2a converges towards the extrados face 2b.

outlet tube can have a lower section than the section of the Such a ratio d/Dallows a high collection efficiency of fine

upper cylindrical portion of the gas outlet tube. particles. Indeed, the direct passage of the fine particles from

The diameter (D) of the cylindrical portion and the the inlet duct 2 to the gas outlet tube 4 is avoided or remains

diameter (d) at the lower part of the conical portion can be very limited with such a ratio.

such that 0s)-di-O.3L. L being the height of the conical The ratio d/D is preferably comprised between 0.1 and

portion of the gas outlet tube. 0.15. The ratio d/D is less than 0.15 for an economical

The intrados face ending at the tip of the cyclone sepa pressure drop solution. The ratio d/D is more preferably

rator, said intrados face which connects the starting point of 25 comprised between 0.11 and 0.13.

the inlet duct to the point at the tip of the cyclone separator Then, the ratio S/S of the inlet duct areas, measured at the

can have a profile Such that it comprises at least two distinct tip T of the cyclone separator 1 and perpendicularly to the

tangents so that one intersects the extrados face at a point extrados face 2b, to the cross-sectional area S of the body

located upstream of the foot of the perpendicular to the portion 3 is comprised between 0.24 and 0.32.

extrados face taken from the tip of the cyclone separator, and 30 Such a ratio S/S makes it possible to have a gas axial mean

said intrados face can start from said point by a first part velocity in the body portion 3 that is higher than 7 m/s. The

having a rectilinear profile, followed by a second part having axial mean velocity can be defined as being the ratio of the

a curved profile with a point of inflection or else by a second gas volume flow to the cross-sectional area S of the body

rectilinear part which meets the tip of the cyclone separator, portion 3.

said point being located at the exit from the furnace. 35 The ratio S/S is higher to 0.24, in order to avoid any

The intrados face can have a first part having a rectilinear excessive pressure drop across the cyclone separator 1. The

profile followed by a second rectilinear part and in that the ratio S/S is less than 0.32, in order to allow a high velocity

rectilinear profile of the first part makes with the extrados of the particles and to facilitate the respect of the d/D ratio.

face an angle comprised between 25° and 35° so as to The ratio S/S is preferably comprised between 0.26 and

procure a good compromise between separation efficiency 40 0.30, and more preferably between 0.27 and 0.29.

(by projecting Solids on the extrados face) and pressure drop. Last, the ratio of the height h of the inlet duct 2 to the

Other features and advantages of the invention will width w of the inlet duct 2 at the tip T of the cyclone

become apparent from the following description of embodi separator 1 does not exceed 4.

ments of the invention given by way of non-limiting This ratio allows an economical inlet duct.

examples only, and with reference to the accompanying 45 The height h of the inlet duct 2 is preferably not higher

drawings, in which: than the internal diameter D of the body portion 3, which

limits the height of the cyclone body portion 3.

BRIEF DESCRIPTION OF THE DRAWINGS The height H of the body portion 3 is preferably less than

1.2D, and more preferably less than 1.1D, D being the

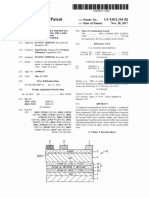

FIG. 1 is a front view of a cyclone separator according to 50 internal diameter of the body portion 3. This height is very

the invention, advantageous since it provides low cyclone separator Sur

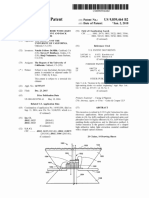

FIG. 2 is a bottom view of the cyclone separator, and face, weight and dimensions, which reduces the cost of the

FIG. 3 shows a cyclone separator according to the inven steel support structures. Moreover, the low height of the

tion with a specific inlet duct. cyclone separator 1 facilitates the arrangement of a fluidized

55 bed heat exchanger, if needed.

DETAILED DESCRIPTION In order to improve the cyclone separator efficiency, the

orifice of the vortex finder 4 is preferably not centred at the

As illustrated in FIG. 1 and in FIG. 2, a cyclone separator centre of the body portion 3. Thus, the distance 1 between the

1 according to the invention comprises an inlet duct 2, a projection of the body portion 3 centre on a perpendicular to

body portion 3 and a gas outlet tube 4. 60 the extrados face 2b and the projection of the gas outlet tube

The inlet duct 2, through which a mixture of particles and 4 lower extremity centre on a perpendicular to the extrados

gas enter the cyclone separator 1, may be a rectangular face 2b can be comprised between 0.04D and 0.08D, D

shaped inlet flow passageway and usually extends partially being the internal diameter of the body portion 2, as shown

into the upper portion of a fluidized bed combustion furnace. in FIG. 2.

The inlet duct 2 comprises an intrados face 2a and an 65 In order to improve the cyclone separator efficiency, the

extrados face 2b. The intrados face 2a ends at the tip T of the ratio of the cross-sectional area a of the gas outlet tube 4

cyclone separator 1. lower extremity to the cross-sectional area S of the body

US 9,486,727 B2

5 6

portion 3 can be comprised between 0.13 and 0.20, more (D) is defined as an internal diameter (D) of the body

preferably between 0.15 and 0.20. portion;

The gas outlet tube 4 can comprise a lower conical portion a ratio (S/S) is between 0.24 and 0.32,

and an upper cylindrical portion. Thus, the pressure drop in wherein (s) is defined as an inlet duct area measured

the gas outlet tube 4 is reduced compared to the pressure at the tip of the cyclone separator extending per

drop of a system having the same constant minimum section. pendicular to the extrados face, and

The gas outlet tube 4 can be designed at least partly (S) is defined as a cross-sectional area of the body

conically, the inlet orifice of the gas outlet tube 4 having the portion; and

lower section and the upper part of the gas outlet tube 4 a ratio (h/w) is less than 4.

being a cylinder with a greater section. In this case, the 10

wherein (h) is defined as a height of the inlet duct,

diameter (D) of the cylindrical portion and the diameter (d) and

at the lower part of the conical portion can be such that (w) is defined as a width of the inlet duct at the tip

D-d-0.3L. L being the height of the conical portion of the of the cyclone separator,

gas outlet tube 4.

The inlet duct 2 can be an inlet duct disclosed in EP 15 wherein the intrados face comprises:

1020229, as shown in FIG. 3. For instance, the intrados face at least two distinct tangents so that a first tangent

2a ending at the tip T of the cyclone separator 1, said intersects the extrados face at a point located

intrados face 2a which connects the starting point S of the upstream of a foot, wherein the foot is defined as a

inlet duct 2 to the point T at the tip of the cyclone separator perpendicular to the extrados face taken from the tip

1 may have a profile Such that it comprises at least two of the cyclone separator, and

distinct tangents so that one D intersects the extrados face 2b from the starting point of the inlet duct, said intrados

at a point A located upstream of the foot B of the perpen face further comprises:

dicular to the extrados 2b taken from the tip T of the cyclone a first part having a rectilinear profile, said first part

separator 1, and said intrados face 2a may start from said disposed proximate to a starting point of the inlet

point S by a first part having a rectilinear profile R, followed 25 duct,

by a second part having a curved profile V with a point of a second part having a curved profile, said second

inflection 5 or else by a second rectilinear part which meets part proximate to the tip of the cyclone separator,

the tip T of the cyclone separator 1, said point S being and

located at the exit from the furnace. a third part, said third part disposed between the

The intrados face 2a can have a first part having a 30 starting point and the tip, said third part connects

rectilinear profile that is followed by a second rectilinear together said first and second parts,

part and the rectilinear profile of the first part can make with wherein said third art comprises a profile having a point

the extrados face an angle comprised between 25° and 35°. of inflection.

as shown in FIG. 2. Thus, the pressure drop in the inlet duct 2. The cyclone separator according to claim 1, wherein a

2 is reduced. 35 distance (1) is between 0.04D and 0.08D,

The cyclone separator according to the invention accepts wherein (1) is defined as the distance between a projection

a body axial velocity of 8 to 10 m/s with same capture of a center of the body portion on a perpendicular to the

efficiency than proven current efficient cyclones operating at extrados face and a projection of a center of the gas

5 to 6 m/s while keeping acceptable pressure losses. More outlet tube lower extremity on a perpendicular to the

over, an economical design is provided since the cyclone 40 extrados face.

size is reduced. The cyclone separator is Suitable for circu 3. The cyclone separator according to claim 1, wherein a

lating fluidized bed boilers which are able to support the ratio (a/S) is between 0.13 and 0.20,

duty of separating solids that can be abrasive and which flow wherein (a) is defined as a cross-sectional area of the gas

in a high amount of entrained solids compared to the gas outlet tube lower extremity.

flow (for instance for entrained solids quantity around or 45 4. The cyclone separator according to claim 1, wherein a

above 3 kg perm gas). The cyclone separator can have a height (h) of the inlet duct does not exceed the internal

large flow capacity and may have an internal diameter of 5 diameter (D) of the body portion.

m and more. 5. The cyclone separator according to claim 1, wherein a

What is claimed is: height (H) of the body portion is less than 1.2D.

1. A cyclone separator for particle collection from a gas 50 6. The cyclone separator according to claim 1, wherein the

stream containing entrained solid particles, said cyclone intrados face comprises

separator comprising: a first part having a rectilinear profile followed by a

a cylindrical-shaped body portion, second rectilinear part,

an inlet duct having an intrados face and an extrados face, wherein the rectilinear profile of the first part forms an

said inlet duct in fluid communication to the body 55 angle with the extrados face between 25° and 35°.

portion, 7. The cyclone separator according to claim 1, wherein the

a gas outlet tube in fluid communication with the body ratio (h/w) is between 3 and 4.

portion, the gas outlet tube disposed at an upper end of 8. The cyclone separator according to claim 1, wherein the

the body portion, ratio (h/w) is between 3.5 and 4.

wherein: 60 9. The cyclone separator according to claim 1, wherein a

a ratio (d/D) is greater than or equal to 0.1. center of the gas outlet tube is offset from a center of the

wherein (d) is defined as a distance between a cylindrical-shaped body portion.

parallel to the extrados face extending from a tip 10. The cyclone separator according to claim 1, wherein

of the cyclone separator and the closest point of the gas outlet tube comprises a lower conical portion and an

the gas outlet tube, said distance (d) being mea 65 upper cylindrical portion.

sured at a lower extremity of the gas outlet tube, 11. The cyclone separator according to claim 10, wherein

and a diameter (D) of the cylindrical portion and a diameter (d)

US 9,486,727 B2

7 8

at the lower part of the conical portion are such that upstream of a foot, wherein the foot is defined as a

0<D-d-0.3L. L being the height of the conical portion of perpendicular to the extrados face taken from the tip

the gas outlet tube. of the cyclone separator, and

12. A cyclone separator for particle collection from a gas from the starting point of the inlet duct, said intrados

stream containing entrained solid particles, said cyclone 5 face further comprises:

separator comprising: a first part having a rectilinear profile, said first part

a cylindrical-shaped body portion, disposed proximate to a starting point of the inlet

an inlet duct having an intrados face and an extrados face, duct,

said inlet duct in fluid communication to the body a second part having a curved profile, said second

portion, 10 part proximate to the tip of the cyclone separator,

and

a gas outlet tube in fluid communication with the body a third part, said third part disposed between the

rtion, th tlet tube di d at d of

E. y E" el lube d1sposed at an upper end o starting point and the tip, said- - third

- -

part connects

wherein: together said first and second parts,

a ratio (d/D) is between 0.1 and 0.2 15 wherein said third art comprises a profile having a point

s of inflection.

wherein (d) is defined as a distance between a 13. The cyclone separator according to claim 12, wherein

parallel to the extrados face extending from a tip

of the cyclone separator and the closest point of the14.ratio (d/D) is between 0.1-0.15.

The cyclone separator according to claim 12, wherein

the gas outlet tube, said distance (d) being mea a distance

sured at a lower extremity of the gas outlet tube, 20 defined as (1) is between 0.04D and 0.08D, wherein (1) is

the distance between a projection of a center of

and he body porti dicular to the extrados face and

(D)portion;

is defined as an internal diameter (D) of the body the body portion on a perpendicular to the extrados face an

a projection of a center of the gas outlet tube lower extremity

tio (s/S)

a ratio (S/S) isis between

between 0.24 and

al 0.32, on15.

a perpendicular to the extrados

The cyclone separator face.to claim 12, wherein

according

wherein (s) is defined as an inlet duct area measured 25 a ration (a/S) is between 0.13 and 0.20, wherein (a) is

at the tip of the cyclone separator extending per

pendicular to the extrados face, and defined as a cross-sectional area of the gas outlet tube lower

S) is defined -sectional f the bod extremity.

( still a cross-secuonal area of the body 16. The cyclone separator according to claim 12, wherein

a ratio (h/w) is less than 4 30 a height (h) of the inlet duct does not exceed the internal

h defined height of the inlet duct diameter (D) of the body portion.

W en (h) is defined as a height of the inlet duct, 17. The cyclone separator according to claim 12, wherein

(w) is defined

cyclone as a width of the inlet duct at the tip of the alight

separator; 18. The(H)cyclone

of theseparator

body portion is lesstothan

according claim12P.

12, wherein

wherein the intrados face comprises: 35 the gas outlet tube comprises a lower conical portion and an

at least two distinct tangents so that a first tangent upper cylindrical portion.

intersects the extrados face at a point located ck k < k cic

You might also like

- 2500 Busbar CalculationDocument4 pages2500 Busbar CalculationPramod B.Wankhade100% (1)

- AudiV6TDI MechanicsDocument15 pagesAudiV6TDI Mechanicsmarc4266No ratings yet

- Terrence Howard US9168465Document17 pagesTerrence Howard US9168465kleephNo ratings yet

- Sleeperwall 1Document6 pagesSleeperwall 1John SmithNo ratings yet

- BS EN 10228-12016 Non-Destructive Testing of Steel Forgings Part 1 Magnetic Particle InspectionDocument20 pagesBS EN 10228-12016 Non-Destructive Testing of Steel Forgings Part 1 Magnetic Particle InspectionudomNo ratings yet

- Demand Controlled VentilationDocument58 pagesDemand Controlled VentilationthenshanNo ratings yet

- CH3080 Cyclone Separator Format ErrorDocument19 pagesCH3080 Cyclone Separator Format ErrorMerlando Dany SNo ratings yet

- Globally Project Conception and Literature ReviewDocument11 pagesGlobally Project Conception and Literature ReviewBilalAshrafNo ratings yet

- PIEAS Sample Test Paper For MS Engineers and ScientistsDocument9 pagesPIEAS Sample Test Paper For MS Engineers and ScientistsEngr Saleem Chandio100% (2)

- Us9726002 PDFDocument10 pagesUs9726002 PDFAgung Achmad SubadiNo ratings yet

- Airbus Compound HelicopterDocument15 pagesAirbus Compound Helicopterjorge paezNo ratings yet

- Air Lubrication System and Vessel PDFDocument13 pagesAir Lubrication System and Vessel PDFOUSSAMA AIT BOULAALAMNo ratings yet

- United States Patent: (10) Patent No .: US 10, 023, 524 B2 (45) Date of Patent: Jul - 17, 2018Document18 pagesUnited States Patent: (10) Patent No .: US 10, 023, 524 B2 (45) Date of Patent: Jul - 17, 2018Akhwat MujahidahNo ratings yet

- United States Patent: (10) Patent No.: US 9,512,052 B2Document20 pagesUnited States Patent: (10) Patent No.: US 9,512,052 B2M FNo ratings yet

- Us 9455054Document11 pagesUs 9455054FadimeNo ratings yet

- Saturation Process For Making Lubricant Base OilsDocument27 pagesSaturation Process For Making Lubricant Base OilsBreak LimsNo ratings yet

- United States Patent: (10) Patent No.: US 9,518,006 B2Document17 pagesUnited States Patent: (10) Patent No.: US 9,518,006 B2Kevin 070898No ratings yet

- Us9976567 (B2)Document10 pagesUs9976567 (B2)Gabriel PhilippiNo ratings yet

- WWWWWWWWWWWWWWWWWWWWWWWWWWW: (12) United States PatentDocument13 pagesWWWWWWWWWWWWWWWWWWWWWWWWWWW: (12) United States PatentMasquito JFcNo ratings yet

- Patente EGDocument19 pagesPatente EGRodrigo Thomaz TaralloNo ratings yet

- United States Patent (10) Patent No.: US 9,115,565 B1Document20 pagesUnited States Patent (10) Patent No.: US 9,115,565 B1VladislavNo ratings yet

- US9831310Document19 pagesUS9831310profuntressNo ratings yet

- US9520619 Inerting PatentDocument18 pagesUS9520619 Inerting PatentNursena SEVİNÇNo ratings yet

- Aparatos y Metodos para Mantener La Circulación Constante Durante La Perforación.Document9 pagesAparatos y Metodos para Mantener La Circulación Constante Durante La Perforación.Raul BlancoNo ratings yet

- Ule Iiiibiibiitiibii: (12) United States PatentDocument19 pagesUle Iiiibiibiitiibii: (12) United States PatentTangtang GuoNo ratings yet

- United States Patent (10) Patent No.: US 9.255,006 B2Document8 pagesUnited States Patent (10) Patent No.: US 9.255,006 B2Radit Setia KumalaNo ratings yet

- Sandra: (12) United States PatentDocument16 pagesSandra: (12) United States PatentAnonymous 4OgzTeINo ratings yet

- United States Patent (10) Patent No.: US 9,002,621 B2Document12 pagesUnited States Patent (10) Patent No.: US 9,002,621 B2Lowela AbogadieNo ratings yet

- United States Patent: (10) Patent No .: US 9, 809, 402 B2Document30 pagesUnited States Patent: (10) Patent No .: US 9, 809, 402 B2OTO TAKNo ratings yet

- US11530031Document21 pagesUS11530031engine wangNo ratings yet

- US10018353Document12 pagesUS10018353nguyenhuutan91No ratings yet

- Us9999224 PDFDocument20 pagesUs9999224 PDFjackie huNo ratings yet

- United States Patent: Cheng Et Al. (10) Patent No.: US 9,078,547 B2Document10 pagesUnited States Patent: Cheng Et Al. (10) Patent No.: US 9,078,547 B2Alex BrcNo ratings yet

- US7109268Document8 pagesUS7109268Kamilo ArciniegazNo ratings yet

- United States Patent: (45) Date of Patent: Mar - 19, 2019Document17 pagesUnited States Patent: (45) Date of Patent: Mar - 19, 2019Kristína100% (1)

- United States Patent: (10) Patent No.: (45) Date of PatentDocument12 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentM FNo ratings yet

- Geared Turbofan Gas Turbine Engine ArchitectureDocument26 pagesGeared Turbofan Gas Turbine Engine ArchitectureFouad0% (1)

- Us7390970 PDFDocument9 pagesUs7390970 PDFabiliovieiraNo ratings yet

- Apple 17Document20 pagesApple 17Choo Wei shengNo ratings yet

- US9200371Document16 pagesUS9200371vianaufgNo ratings yet

- US10689086Document17 pagesUS10689086keyupequauce-2083No ratings yet

- US10370602 (Tabla I - ASTM D1160)Document10 pagesUS10370602 (Tabla I - ASTM D1160)Facundo MendezNo ratings yet

- Clara, CA Francisco ,: (12) United States PatentDocument15 pagesClara, CA Francisco ,: (12) United States PatentSanjay SharmaNo ratings yet

- Thrust Foil Bearing PatentDocument17 pagesThrust Foil Bearing PatentOye OdemadighiNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument20 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentzhenyupanNo ratings yet

- Modular Scalable Coolant Distribution UnitDocument22 pagesModular Scalable Coolant Distribution UnitviniciusschwabNo ratings yet

- CO2 Absorption1Document8 pagesCO2 Absorption1arun manchekarNo ratings yet

- US9321711Document18 pagesUS9321711Phenol GroupNo ratings yet

- United States Patent: Chang Et Al. (10) Patent No.: US 9,071,100 B2Document28 pagesUnited States Patent: Chang Et Al. (10) Patent No.: US 9,071,100 B2Sanjay SharmaNo ratings yet

- United States Patent: Slater Et AlDocument34 pagesUnited States Patent: Slater Et AlFran Sanchez MirallesNo ratings yet

- II0 00I 0I: United States PatentDocument12 pagesII0 00I 0I: United States PatentDaniel BurwellNo ratings yet

- US7721978 - B2 LVMeditedDocument10 pagesUS7721978 - B2 LVMeditedsakthivel ArumugamNo ratings yet

- Plastic Bottle PDFDocument21 pagesPlastic Bottle PDFnasyahrahNo ratings yet

- US9212603Separate-type Rotary EngineDocument12 pagesUS9212603Separate-type Rotary Engine임학진No ratings yet

- Quick Connector With A Sensor HousingDocument11 pagesQuick Connector With A Sensor HousingTUNCAY GUMUSNo ratings yet

- 4US8911515Document30 pages4US8911515M FNo ratings yet

- 2017 Merging Unit and Method of Operating A Merging UnitDocument12 pages2017 Merging Unit and Method of Operating A Merging UnitAndrés ZúñigaNo ratings yet

- United States Patent: Fiigel US 6,840,540 B2Document12 pagesUnited States Patent: Fiigel US 6,840,540 B2jemanuelvNo ratings yet

- US8809787Document30 pagesUS8809787Carlos OrtegaNo ratings yet

- United States Patent: (10) Patent No .: US 9, 859, 464 B2 (45) Date of Patent: Jan - 2, 2018Document21 pagesUnited States Patent: (10) Patent No .: US 9, 859, 464 B2 (45) Date of Patent: Jan - 2, 2018pmurphNo ratings yet

- United States Patent (10) Patent No.: US 9,096,564 B2Document6 pagesUnited States Patent (10) Patent No.: US 9,096,564 B2Ahmad InterestaNo ratings yet

- SinghDocument20 pagesSinghAlfikriNo ratings yet

- US9522835Document7 pagesUS9522835Majid MJNo ratings yet

- United States Patent (10) Patent No.: US 9,000,000 B2Document12 pagesUnited States Patent (10) Patent No.: US 9,000,000 B2johnmaxin1114No ratings yet

- US7963479Document10 pagesUS7963479雷黎明No ratings yet

- Us9714199 EtnDocument34 pagesUs9714199 EtnTeleson MarquesNo ratings yet

- United States Patent: Hayward Et Al. Mar. 28, 2017Document17 pagesUnited States Patent: Hayward Et Al. Mar. 28, 2017Sabiya KabeerNo ratings yet

- How to Find Out About Patents: The Commonwealth and International Library: Libraries and Technical Information DivisionFrom EverandHow to Find Out About Patents: The Commonwealth and International Library: Libraries and Technical Information DivisionNo ratings yet

- Experimental Study On Co2 Absorption Into Aqueous Ammonia Based AbsorbentsDocument18 pagesExperimental Study On Co2 Absorption Into Aqueous Ammonia Based AbsorbentsBilalAshrafNo ratings yet

- Experimental Study On Co2 Absorption Into Aqueous Ammonia Based AbsorbentsDocument18 pagesExperimental Study On Co2 Absorption Into Aqueous Ammonia Based AbsorbentsBilalAshrafNo ratings yet

- Effects of The Gas Outlet Duct Length On The Performance of Cyclone SeparatorDocument4 pagesEffects of The Gas Outlet Duct Length On The Performance of Cyclone SeparatorBilalAshrafNo ratings yet

- 2) Haseeb PresentationDocument27 pages2) Haseeb PresentationBilalAshrafNo ratings yet

- Design of Cyclone and Study of Its Performance Parameters: Research PaperDocument6 pagesDesign of Cyclone and Study of Its Performance Parameters: Research PaperManish VankudreNo ratings yet

- Ethics Programs and Their Dimensions : &even N. BrennerDocument9 pagesEthics Programs and Their Dimensions : &even N. BrennerBilalAshrafNo ratings yet

- Separation and Purification Technology: Bingtao ZhaoDocument7 pagesSeparation and Purification Technology: Bingtao ZhaoBilalAshrafNo ratings yet

- PresentationDocument24 pagesPresentationBilalAshrafNo ratings yet

- PFD On WORDDocument1 pagePFD On WORDBilalAshrafNo ratings yet

- Tkis Star ProcessDocument24 pagesTkis Star ProcessBilalAshrafNo ratings yet

- Pinch Analysis and Process Integration 2edDocument1 pagePinch Analysis and Process Integration 2edBilalAshrafNo ratings yet

- Block Flow Diagram: Reactors Preheater Feed StorageDocument1 pageBlock Flow Diagram: Reactors Preheater Feed StorageBilalAshrafNo ratings yet

- Scribed DownloadedDocument1 pageScribed DownloadedBilalAshrafNo ratings yet

- Block Flow Diagram: Reactors Preheater Feed StorageDocument1 pageBlock Flow Diagram: Reactors Preheater Feed StorageBilalAshrafNo ratings yet

- Assignment No 1: Safety DR - Syed Amjad AhmadDocument6 pagesAssignment No 1: Safety DR - Syed Amjad AhmadBilalAshrafNo ratings yet

- Scribed DownloadedDocument1 pageScribed DownloadedBilalAshrafNo ratings yet

- BooooDocument1 pageBooooBilalAshrafNo ratings yet

- Scribed DownloadedDocument1 pageScribed DownloadedBilalAshrafNo ratings yet

- Permanent WayDocument7 pagesPermanent Wayaishwarya mundraNo ratings yet

- 2011121503-3-Wannate 8221enDocument2 pages2011121503-3-Wannate 8221en8612106535No ratings yet

- Phy P1Document105 pagesPhy P1Godfrey Muchai100% (1)

- Low Stress Mechanical Properties of Woven Silk Fabrics (Part-1)Document6 pagesLow Stress Mechanical Properties of Woven Silk Fabrics (Part-1)Mohammed Atiqul Hoque ChowdhuryNo ratings yet

- Penerapan Metode Sonikasi Terhadap Adsorpsi FeIIIDocument6 pagesPenerapan Metode Sonikasi Terhadap Adsorpsi FeIIIappsNo ratings yet

- Document: Syllabus Course Code: Memael20 Copies Issued To: Date of Effectivity / Revision: Course Title: Machine Elements - LectureDocument7 pagesDocument: Syllabus Course Code: Memael20 Copies Issued To: Date of Effectivity / Revision: Course Title: Machine Elements - LectureArvin VillanuevaNo ratings yet

- Room Air Conditioner System Modeling: Acrc Tr-60 July 1994Document97 pagesRoom Air Conditioner System Modeling: Acrc Tr-60 July 1994eyob feshaNo ratings yet

- Elasticity - HeatDocument13 pagesElasticity - HeatHarsh GuptaNo ratings yet

- Exploring The Lalitha Sahasranamam: (Where Spirituality Guides Science)Document9 pagesExploring The Lalitha Sahasranamam: (Where Spirituality Guides Science)ShraddhamritaChaitanyaNo ratings yet

- 6 - Pressuremeter PDFDocument71 pages6 - Pressuremeter PDFjenvarmatNo ratings yet

- 03 - ICSE9th - Physics BookLet 27 May 21Document99 pages03 - ICSE9th - Physics BookLet 27 May 21Vivaan GandhiNo ratings yet

- Capability Guidance Sheet - Three Point EstimatesDocument1 pageCapability Guidance Sheet - Three Point EstimatesSaleha ShakoorNo ratings yet

- 7th Balkan Mining Congress - Proceedings Book 2Document312 pages7th Balkan Mining Congress - Proceedings Book 2Mikan Radenko MikanovićNo ratings yet

- Timoshenko Beam ElementDocument11 pagesTimoshenko Beam ElementMahmoud M.S. DwaikatNo ratings yet

- Chemical Physics: Manish Chopra, Niharendu ChoudhuryDocument11 pagesChemical Physics: Manish Chopra, Niharendu ChoudhuryasdikaNo ratings yet

- Fluid Mechanics Lecture Week 6 Chapter 2 PPT With NotesDocument40 pagesFluid Mechanics Lecture Week 6 Chapter 2 PPT With NotesJake CanlasNo ratings yet

- 2SK2847Document6 pages2SK2847jsalinas78No ratings yet

- Adaptive Dpca Radar ConceptDocument4 pagesAdaptive Dpca Radar ConceptRaviKiranNo ratings yet

- Cows and ChickensDocument9 pagesCows and Chickensapi-298565250No ratings yet

- CHAPTER 2 - Data & SignalDocument65 pagesCHAPTER 2 - Data & SignalIzzati RahimNo ratings yet

- 2004-CHIN-YOU HSU-Wear Resistance and High-Temperature Compression Strength of FCC CuCoNiCrAl0.5Fe Alloy With Boron AdditionDocument5 pages2004-CHIN-YOU HSU-Wear Resistance and High-Temperature Compression Strength of FCC CuCoNiCrAl0.5Fe Alloy With Boron Additionsaurav kumarNo ratings yet

- CH 10 Lecture 3 Angular Overlap: I. Ligand Field Theory and Square Planar ComplexesDocument16 pagesCH 10 Lecture 3 Angular Overlap: I. Ligand Field Theory and Square Planar ComplexesIsrael PobleteNo ratings yet

- Corresponds To The Correct Answer. Write You Answers On The Space Before Each NumberDocument2 pagesCorresponds To The Correct Answer. Write You Answers On The Space Before Each NumberJESSA SUMAYANGNo ratings yet

- Instructions HMG 47-48Document2 pagesInstructions HMG 47-48arindamdhar2004No ratings yet

- 0.the Water Vapour Permeability Mechanical Properties and Solubility of Fish Gelatin Chitosan Films Modified With Transglutaminase or 1 Ethyl 3 3 DimethDocument6 pages0.the Water Vapour Permeability Mechanical Properties and Solubility of Fish Gelatin Chitosan Films Modified With Transglutaminase or 1 Ethyl 3 3 DimethValentina RoznovNo ratings yet