Professional Documents

Culture Documents

Roles & Responsibilites:: Carbon Steel Pipes

Uploaded by

GR Chandra SekharOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Roles & Responsibilites:: Carbon Steel Pipes

Uploaded by

GR Chandra SekharCopyright:

Available Formats

Worked in UI Pipe Fittings Pvt Ltd As QC(Quality Control) Engineer.

Located at gandhinagar,Balanagar,Hyderabad.

Roles & Responsibilites:

Inspection of raw material visually and Spectro test (chemical composition checking) of raw materials

(pipes,).

Checking the dimensions of fittings physically by Vernier callipers, micrometer, bevel protector, angle

plate, scale, tape, etc.

Inspection of incoming fittings, in process fittings & Final stage product.

Checking hardness of different fittings.

Monitoring Heat treatment.

Coordinating with Third party Inspector.

Giving setting approval for Machining.

Notes.

Raw Materials Inspection for Pipes Cracks, Dents., etc and Chemical Inspection.which are used for

manufacturing Fittings(Elbows.Tees,Reducers) through forging.

Steel Pipes

Checking the pipe Chemically

Carbon Steel Pipes

WPB(Wrought Pipe with Grade B)– Carbon (C)%ge lessthan 0.35.

Alloy Steel pipes

WP11(Wrought Pipe with Grade 11)– having Carbon (C)%ge lessthan 0.11 - 0.15

& Chromium( Cr) - 1 – 1.6%

WP22(Wrought Pipe with Grade 22)– having Carbon (C)%ge lessthan 0.11 - 0.15

& Chromium( Cr) 2 – 2.6%

Stainless Steel Pipes

WP304(Wrought Pipe with Grade 304)– Carbon (C)%ge lessthan 0.03-0.08

Vernier calipers.

Least Count: one Main scale division/ No of vernier Scale Divisions.

0.02mm

Screw Guage

Least Count:Pitch/ Tot Divisions on Circular scale

Pitch:Distance moved by screw/No of full rotations.

0.1mm

1 Inch = 25.4mm

= 2.54cm.

Fittings are of Butt Welded.

See below Fig With Butt

Bevel Protractor is used to check the Bevel Angel 37.5 Degree for Plain Bevel See below Fig plain Bevel.

Welding is filled in V groove.

These Fittings Are used in Boiler Lines , Oil Lines etc

We manufacture fittings from ½”(half inch)- 24”(24 inch).

Inspection of in process fittings & Final stage product.

Inspecting fittings inprocess i.e during Cutting. Machining, Heat Treating etc

Checking hardness of different fittings.

1. Hardness tested through Hardness Tester Equipment.

2. Hardness interms of BHN(Brinell Hardness No).

Heat Treatment

After machining Fittings are send to Heat Treatment i.e Annealing which Increases Ductility and stresses are

relieved.

Annealing is the process heating the product at Temperature around 745-945C(Degree Centigrade) and cooled

in Air

Normalising is the process heating the product to Normalising Temperature and cooled in furnace.

Forging is done through Electrical Induction.i.e electrically heated.

Final Inspection.

Inspecting Fittings in final stage for cracks,Dents,lines and ensuring the surface finish is good.

Process flow:

Raw material – Inspecting them.

Hand over to Production Department.

Giving setting approval for Machining.

Coordinating with Third Party Inspector During Inspection.

Third Party’s SGS,TUV,INTERTEKetc.,

Standard for Pipe fittings B16.9.2007(ASME- American society for mechanical engineers)

Our customers

1. Bhel Hyderabad

2. Bhel Chennai

3. ThyssenKrupp Industries.

4. Thermax.

5. Kcp Cements

6. Thermal Systems

7. Sri cements.

8. HPCL Etc

All the Best DUDE

You might also like

- QA/QC Department ProceduresDocument63 pagesQA/QC Department ProceduresvgNo ratings yet

- ASME CODE Requirements - Heat ExchangerDocument9 pagesASME CODE Requirements - Heat ExchangerJithin FrancizNo ratings yet

- Section 2 DutiesDocument3 pagesSection 2 DutiesUmaibalanNo ratings yet

- Inspection Of: Piping Systems (In-Service) 570Document36 pagesInspection Of: Piping Systems (In-Service) 570g_jeyasankar100% (2)

- 11-Quality Assurance - HariharanDocument29 pages11-Quality Assurance - Hariharanabhinay soniNo ratings yet

- YytrfDocument54 pagesYytrfpratikchothani866No ratings yet

- Heat Exchanger InspectionDocument11 pagesHeat Exchanger InspectionVivek Bhangale100% (1)

- Heat Exchanger InspectionDocument43 pagesHeat Exchanger Inspectionabdul aziz100% (6)

- Manufacturing Processes of FlangesDocument16 pagesManufacturing Processes of Flangesshaiba wahabNo ratings yet

- CERTIFICATION & TESTINGDocument2 pagesCERTIFICATION & TESTINGrouquinNo ratings yet

- Welding Inspection CourseDocument23 pagesWelding Inspection CoursepouyaNo ratings yet

- Heat Exchanger InspectionDocument6 pagesHeat Exchanger Inspectionjamaljamal20No ratings yet

- A Study On Elimination of Defects For Enhancement of Cost-Effectiveness in Wire Rod Mills in Indian ScenarioDocument8 pagesA Study On Elimination of Defects For Enhancement of Cost-Effectiveness in Wire Rod Mills in Indian ScenarioSmruti Ranjan PattanayakNo ratings yet

- Heat Exchanger InspectionDocument7 pagesHeat Exchanger InspectionHamid Albashir100% (1)

- Nanjing Daji Steel Tower Test PlanDocument9 pagesNanjing Daji Steel Tower Test PlanFernando Patiño Guevara100% (1)

- Manufacturing Process AssignmentDocument9 pagesManufacturing Process AssignmentSaad Ur Rehman0% (1)

- Siemens Internship ReportDocument17 pagesSiemens Internship ReportmirfanbilalNo ratings yet

- Industrial Inspection DivisionDocument24 pagesIndustrial Inspection Divisionjuliyanto88100% (1)

- BN-G-Y017 Welding Inspection GuideDocument5 pagesBN-G-Y017 Welding Inspection GuidePugalNo ratings yet

- Heat Exchanger InspectionDocument15 pagesHeat Exchanger InspectionroyNo ratings yet

- 00 SAIP 80 Process Equipment Insp GuideDocument90 pages00 SAIP 80 Process Equipment Insp GuideRaj BindasNo ratings yet

- Ttransition JointsDocument15 pagesTtransition JointsAdil HasanovNo ratings yet

- Work Scope - Pelotn Runner Refurbishment !Document3 pagesWork Scope - Pelotn Runner Refurbishment !manikanthNo ratings yet

- Third Party Inspection for Water Tube Boiler - ProcedureDocument5 pagesThird Party Inspection for Water Tube Boiler - ProcedureMadhan KannanNo ratings yet

- Training ReportDocument16 pagesTraining ReportJay MavaniNo ratings yet

- Welding InspectionDocument7 pagesWelding Inspectionzahid_497100% (1)

- 3 Fittings Benkan Japan PipeFittings CatalogueDocument24 pages3 Fittings Benkan Japan PipeFittings CatalogueIslam MJD100% (1)

- Heat Exchanger Inspection PDFDocument8 pagesHeat Exchanger Inspection PDFreezmanNo ratings yet

- Duties of Welding InspectorDocument3 pagesDuties of Welding InspectorSalman SyedNo ratings yet

- QA vs QC vs INSPECTION: The Key DifferencesDocument138 pagesQA vs QC vs INSPECTION: The Key DifferencesMohd SharainiNo ratings yet

- Ms-Black Steel PipeDocument4 pagesMs-Black Steel PipeYusufNo ratings yet

- Shell and Tube Heat Exchanger Inspection GuideDocument10 pagesShell and Tube Heat Exchanger Inspection GuideVarun MalhotraNo ratings yet

- Duties of A Weld InspectorDocument2 pagesDuties of A Weld Inspectorshanebowen31No ratings yet

- Pipe Fittings InspectionDocument7 pagesPipe Fittings InspectionRamalingam PrabhakaranNo ratings yet

- BoilerDocument36 pagesBoilerGanesh MuruganNo ratings yet

- Introduction To Piping FabricationDocument5 pagesIntroduction To Piping FabricationSyed IbrahimNo ratings yet

- Safe Remaining Lifetime Assesment of Power Plant Steam BoilersDocument9 pagesSafe Remaining Lifetime Assesment of Power Plant Steam Boilersmuh4iminNo ratings yet

- Quality Management System SystemDocument4 pagesQuality Management System SystemMario YañezNo ratings yet

- 3.post Weld Heat TreatmentDocument50 pages3.post Weld Heat TreatmentvgNo ratings yet

- Steel Pipe Welding Inspection Method StatementDocument1 pageSteel Pipe Welding Inspection Method StatementAhmed SherifNo ratings yet

- How To View The Material Certificate? - Part 1: EN10204 HISTORYDocument11 pagesHow To View The Material Certificate? - Part 1: EN10204 HISTORYQaisir MehmoodNo ratings yet

- CarCarbon and Stainless Steel Pipes For The Transport of Liquids and Gasesbon and Stainless Steel Pipes For The Transport of Liquids and GasesDocument27 pagesCarCarbon and Stainless Steel Pipes For The Transport of Liquids and Gasesbon and Stainless Steel Pipes For The Transport of Liquids and Gaseskhaledaj1977No ratings yet

- Raja MottuDocument25 pagesRaja MottuNaveen PipperaNo ratings yet

- EGE00B20Document17 pagesEGE00B20Jhonny Rafael Blanco Caura100% (1)

- Basic Training Material For QADocument10 pagesBasic Training Material For QANilesh GhodekarNo ratings yet

- PV PIPE - CONNECTING OIL AND GASDocument2 pagesPV PIPE - CONNECTING OIL AND GASKyNo ratings yet

- Inspection of Subsea and Surface Wellhead & Christmas Tree EquipmentDocument14 pagesInspection of Subsea and Surface Wellhead & Christmas Tree Equipmentshifa100% (1)

- Importance of Welding: QA/QC DepartmentDocument55 pagesImportance of Welding: QA/QC Departmentimran jamil0% (1)

- Piping Work Method For Fuel Oil Pipe Fabrication Installation and TestingDocument7 pagesPiping Work Method For Fuel Oil Pipe Fabrication Installation and Testingsamsul maarif100% (1)

- CSWIP Question AnswersDocument11 pagesCSWIP Question AnswersMuhammed Sulfeek100% (1)

- Pulley Manufacturing ProceduresDocument4 pagesPulley Manufacturing ProceduresVijayakumar SamyNo ratings yet

- Charpy Test Explained - Impact Strength MeasurementDocument7 pagesCharpy Test Explained - Impact Strength MeasurementKa Chian100% (1)

- Plumbing and Piping Systems Inspection Notes: Up to CodeFrom EverandPlumbing and Piping Systems Inspection Notes: Up to CodeRating: 3 out of 5 stars3/5 (2)

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- Total Quality Process Control for Injection MoldingFrom EverandTotal Quality Process Control for Injection MoldingRating: 5 out of 5 stars5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Cellar Proposed Layout 26Document1 pageCellar Proposed Layout 26GR Chandra SekharNo ratings yet

- Master Bed Northwall Elevation-Model PDFDocument1 pageMaster Bed Northwall Elevation-Model PDFGR Chandra SekharNo ratings yet

- TV Door Door: TV Unit Internal LayoutDocument1 pageTV Door Door: TV Unit Internal LayoutGR Chandra SekharNo ratings yet

- Cellar Proposed Layout 26Document1 pageCellar Proposed Layout 26GR Chandra SekharNo ratings yet

- Media Elevation ModelDocument1 pageMedia Elevation ModelGR Chandra SekharNo ratings yet

- Meebhoomi Land Records Map ViewDocument10 pagesMeebhoomi Land Records Map ViewGR Chandra SekharNo ratings yet

- Survey Report 1 PDFDocument1 pageSurvey Report 1 PDFGR Chandra SekharNo ratings yet

- Cellar With Out DimensionsDocument1 pageCellar With Out DimensionsGR Chandra SekharNo ratings yet

- Cellar With Parking Area PDocument1 pageCellar With Parking Area PGR Chandra SekharNo ratings yet

- 15082a400 - Reflected Ceiling PlanDocument1 page15082a400 - Reflected Ceiling PlanGR Chandra SekharNo ratings yet

- Rejoice 89jhDocument1 pageRejoice 89jhGR Chandra SekharNo ratings yet

- Crockery Unit ElevationDocument1 pageCrockery Unit ElevationGR Chandra SekharNo ratings yet

- Floor Plan 678Document1 pageFloor Plan 678GR Chandra SekharNo ratings yet

- 10 CoverageDocument12 pages10 CoverageGR Chandra SekharNo ratings yet

- SCC Mall Fit-Out GuidelineDocument68 pagesSCC Mall Fit-Out GuidelineGR Chandra SekharNo ratings yet

- Master Bedroom West Wall ElevationDocument1 pageMaster Bedroom West Wall ElevationGR Chandra SekharNo ratings yet

- Facility ManagementDocument1 pageFacility ManagementGR Chandra SekharNo ratings yet

- Master Bed RoomDocument1 pageMaster Bed RoomGR Chandra SekharNo ratings yet

- Angry Bird GGDocument1 pageAngry Bird GGGR Chandra SekharNo ratings yet

- Osho Coatings PVT - LTD Name: G. Chandra Sekhar: Balance: 106 0Document1 pageOsho Coatings PVT - LTD Name: G. Chandra Sekhar: Balance: 106 0GR Chandra SekharNo ratings yet

- Guest Bed Room ElevationDocument1 pageGuest Bed Room ElevationGR Chandra SekharNo ratings yet

- Expenditure: S.No Date Items Nagendra Chandu Sharma Kiran Nfrancis SrikanthDocument8 pagesExpenditure: S.No Date Items Nagendra Chandu Sharma Kiran Nfrancis SrikanthGR Chandra SekharNo ratings yet

- S.Anil Kumar: S.No Name of The Course Name of The Board/University Year of Passing Percentage of MarksDocument2 pagesS.Anil Kumar: S.No Name of The Course Name of The Board/University Year of Passing Percentage of MarksGR Chandra SekharNo ratings yet

- InternalDocument15 pagesInternalChandra Vinoth SenthilnathanNo ratings yet

- Osho Coatings PVT - LTD Name: G. Chandra Sekhar: BalanceDocument1 pageOsho Coatings PVT - LTD Name: G. Chandra Sekhar: BalanceGR Chandra SekharNo ratings yet

- Osho Coatings Travel Expense ReportDocument1 pageOsho Coatings Travel Expense ReportGR Chandra SekharNo ratings yet

- Osho Coatings PVT - LTD Name: G. Chandra Sekhar: Balance: 106 0Document1 pageOsho Coatings PVT - LTD Name: G. Chandra Sekhar: Balance: 106 0GR Chandra SekharNo ratings yet

- MathsDocument1 pageMathsGR Chandra SekharNo ratings yet

- J GHVHGCGDocument1 pageJ GHVHGCGGR Chandra SekharNo ratings yet

- Kinds of ObligationDocument50 pagesKinds of ObligationKIM GABRIEL PAMITTANNo ratings yet

- HR PlanningDocument47 pagesHR PlanningPriyanka Joshi0% (1)

- Approvals Management Responsibilities and Setups in AME.BDocument20 pagesApprovals Management Responsibilities and Setups in AME.BAli LoganNo ratings yet

- Dues+&+Bylaws+Committee+Packet ICPI John@bestadmix Com Tholyfield@Document52 pagesDues+&+Bylaws+Committee+Packet ICPI John@bestadmix Com Tholyfield@Greefield JasonNo ratings yet

- Infineon ICE3BXX65J DS v02 - 09 en PDFDocument28 pagesInfineon ICE3BXX65J DS v02 - 09 en PDFcadizmabNo ratings yet

- Solved Problems: EEE 241 Computer ProgrammingDocument11 pagesSolved Problems: EEE 241 Computer ProgrammingŞemsettin karakuşNo ratings yet

- Progress ReportDocument5 pagesProgress Reportapi-394364619No ratings yet

- Private Car Package Policy - Zone B Motor Insurance Certificate Cum Policy ScheduleDocument3 pagesPrivate Car Package Policy - Zone B Motor Insurance Certificate Cum Policy ScheduleijustyadavNo ratings yet

- Dse Placement Report PDFDocument78 pagesDse Placement Report PDFAbhijithKríshñàNo ratings yet

- An-7004 IGBT Driver Calculation Rev00Document8 pagesAn-7004 IGBT Driver Calculation Rev00Raghuram YaramatiNo ratings yet

- How To Generate Your First 20,000 Followers On InstagramDocument44 pagesHow To Generate Your First 20,000 Followers On InstagramAdrian Pratama100% (1)

- Eileen MarcelDocument3 pagesEileen Marcelapi-3825833No ratings yet

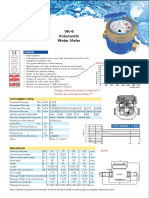

- Baylan: VK-6 Volumetric Water MeterDocument1 pageBaylan: VK-6 Volumetric Water MeterSanjeewa ChathurangaNo ratings yet

- Ab Initio Interview Questions - HTML PDFDocument131 pagesAb Initio Interview Questions - HTML PDFdigvijay singhNo ratings yet

- COA (Odoo Egypt)Document8 pagesCOA (Odoo Egypt)menams2010No ratings yet

- JEdwards PaperDocument94 pagesJEdwards PaperHassan Hitch Adamu LafiaNo ratings yet

- Earth Planet - Google SearchDocument1 pageEarth Planet - Google SearchDaivik Lakkol Eswara PrasadNo ratings yet

- Ibad Rehman CV NewDocument4 pagesIbad Rehman CV NewAnonymous ECcVsLNo ratings yet

- S650 Service - 6987168 enUS SMDocument1,311 pagesS650 Service - 6987168 enUS SMcarlos andres salazar sanchez75% (4)

- A400 PDFDocument4 pagesA400 PDFsnarmeNo ratings yet

- THE MEDIUM SHAPES THE MESSAGEDocument56 pagesTHE MEDIUM SHAPES THE MESSAGELudovica MatildeNo ratings yet

- SWOT Analysis of Fruit Juice BusinessDocument16 pagesSWOT Analysis of Fruit Juice BusinessMultiple UzersNo ratings yet

- HOS Dials in The Driver App - Samsara SupportDocument3 pagesHOS Dials in The Driver App - Samsara SupportMaryNo ratings yet

- MBA Stats Essentials: Measures, Prob, Hypothesis TestsDocument4 pagesMBA Stats Essentials: Measures, Prob, Hypothesis TestsIbrahim JawedNo ratings yet

- Private Copy of Vishwajit Mishra (Vishwajit - Mishra@hec - Edu) Copy and Sharing ProhibitedDocument8 pagesPrivate Copy of Vishwajit Mishra (Vishwajit - Mishra@hec - Edu) Copy and Sharing ProhibitedVISHWAJIT MISHRANo ratings yet

- My Con Pds Sikafloor 161 HCDocument5 pagesMy Con Pds Sikafloor 161 HClaurenjiaNo ratings yet

- Jurisdiction of The Supreme CourtDocument1 pageJurisdiction of The Supreme CourtAnshul Yadav100% (1)

- SMG Wireless Gateway ManualV2.2.0Document95 pagesSMG Wireless Gateway ManualV2.2.0shahedctgNo ratings yet

- March 29, 2013 Strathmore TimesDocument31 pagesMarch 29, 2013 Strathmore TimesStrathmore TimesNo ratings yet

- SQL DBA Mod 1 IntroDocument27 pagesSQL DBA Mod 1 IntroDivyaNo ratings yet